<"

" ""

"

Table&of&Contents&

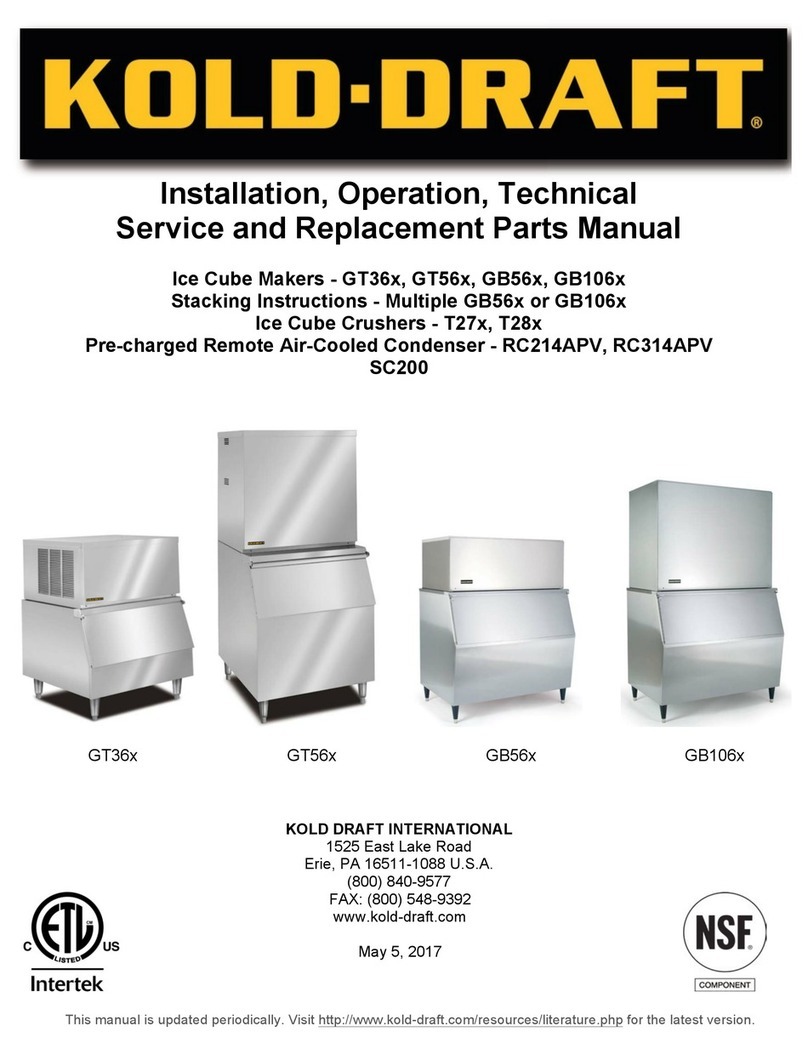

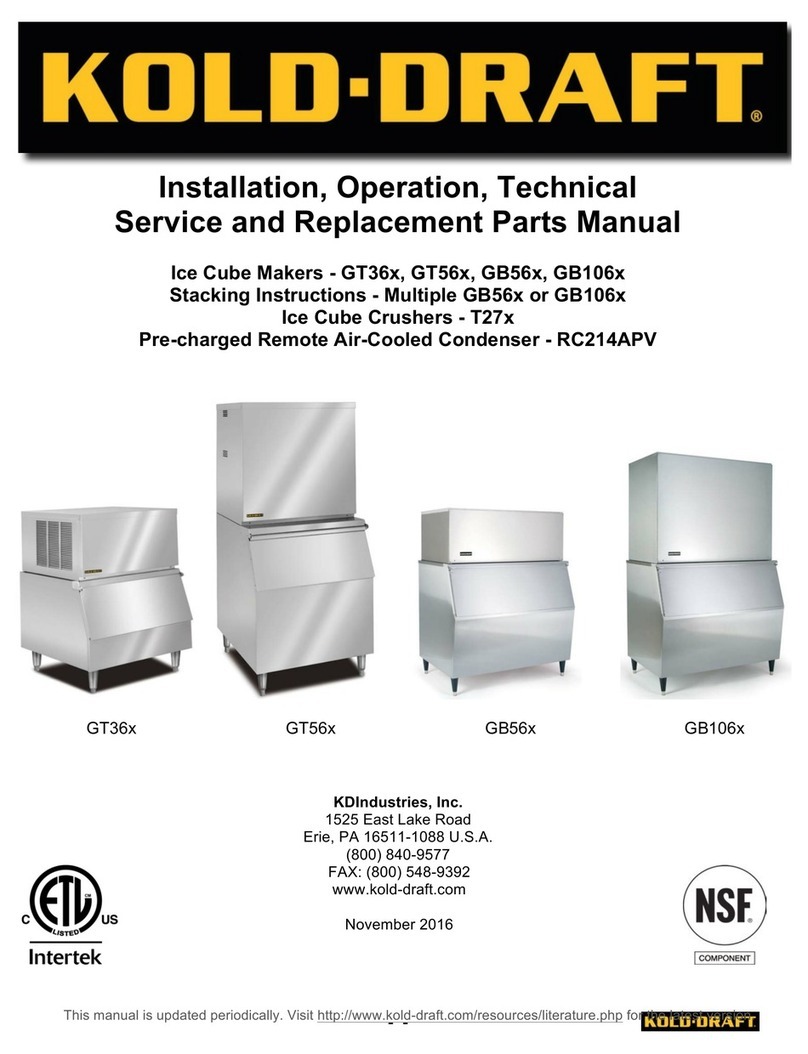

KOLD-DRAFT GT & GB MODELS"9999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"#"

EQUIPMENT CLEARANCE REQUIREMENTS"99999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"#"

DRAINS"999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"#"

COOLING TOWER APPLICATION"99999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"#"

POTABLE WATER SUPPLY"9999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"4"

BRANCH CIRCUIT PROTECTION"99999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"4"

VOLTAGE TOLERANCE"9999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"="

ASSEMBLY"999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"="

START-UP"9999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"7"

GT/GB SCHEMATICS"9999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"F"

GT360 AIR & LIQUID WIRING DIAGRAM"99999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"F"

GB/GB560 AIR & LIQUID WIRING DIAGRAM"99999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"!6"

GT/GB560 REMOTE WIRING DIAGRAM"9999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"!!"

GB1064 AIR & LIQUID WIRING DIAGRAM"999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"!$"

GB1064 REMOTE WIRING DIAGRAM"99999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"!<"

KOLD-DRAFT REMOTE CONDENSERS"99999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"!;"

INSTALLATION"999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"!;"

AMPACITY"99999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"!#"

BRANCH CIRCUIT PROTECTION"999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"!#"

REMOTE PRE-CHARGED AIR COOLED CONDENSERS"9999999999999999999999999999999999999999999999999999999999999999999999999"!4"

ELECTRICAL INFORMATION"99999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"!7"

REMOVING FROM SERVICE"99999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"!7"

KOLD-DRAFT AKD ICE DISPENSER"99999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"!F"

INSTALLATION"999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"$6"

INSTALLATION SPECIFICATIONS"99999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"$<"

DISPENSER MAINTENANCE"99999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"$<"

CLEANING"99999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"$<"

WIRING DIAGRAM"999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"$;"

KOLD-DRAFT CRUSHER"9999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"$#"

CRUSHER INSTALLATION INSTRUCTIONS"999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999999"$#"