Table of Contents

SAFETY INFORMATION ................................................................................................................. 4

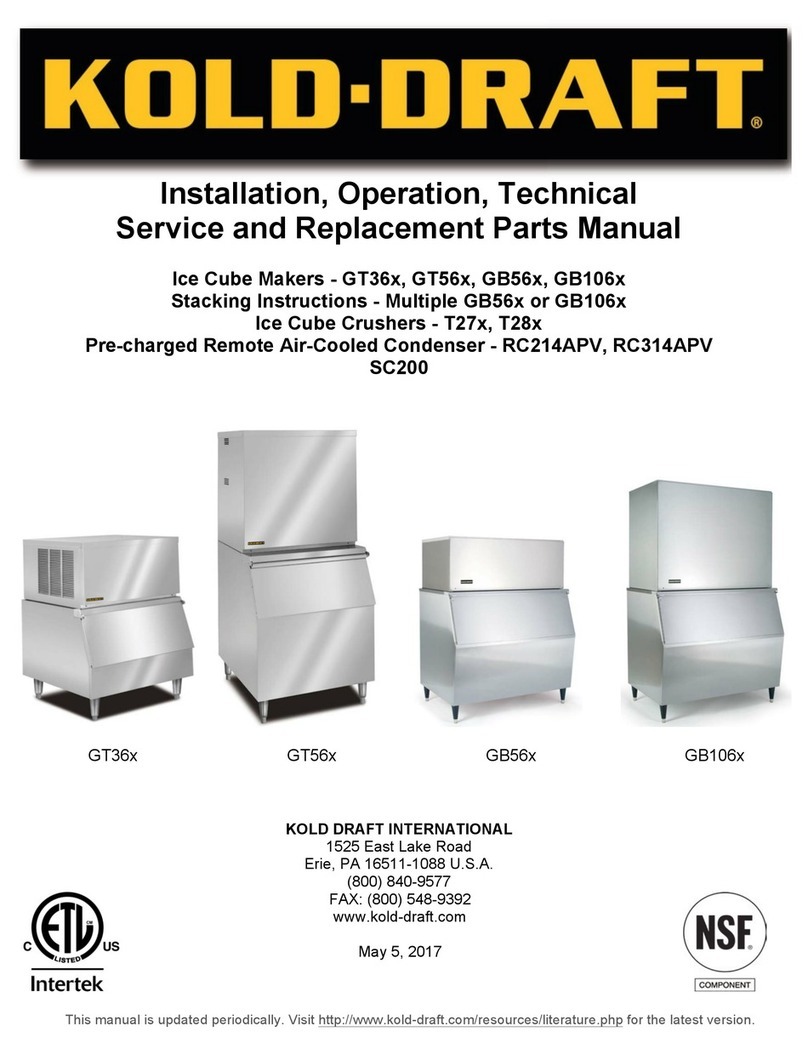

ICE MAKER IDENTIFICATION ........................................................................................................ 2

Serial Number Plate Location ....................................................................................................... 2

Date Code Key ............................................................................................................................. 2

Model Number Key ....................................................................................................................... 3

ICE CUBER Installation .................................................................................................................... 4

What’s in the box .......................................................................................................................... 4

Required Tools ............................................................................................................................. 4

Pre-Install Checklist ...................................................................................................................... 5

Additional Pre-install Information for Cooling Tower Applications (L models) .............................. 7

ASSEMBLY ...................................................................................................................................... 8

Unpacking ..................................................................................................................................... 8

Assembly Procedure ..................................................................................................................... 8

INITIAL START PROCEDURE ....................................................................................................... 10

ICE MACHINE CLEANING PROCEDURE ..................................................................................... 11

SPECIFICATIONS .......................................................................................................................... 12

Machine Capacities .................................................................................................................... 12

Electrical Use and Machine Dimensions/Weight ........................................................................ 13

Water Fill Levels, Cycle Times and Harvest Weights ................................................................. 14

Cube Information ........................................................................................................................ 14

Typical Refrigerant Operating Pressures .................................................................................... 14

COMPONENTS .............................................................................................................................. 15

Mechanical Components ............................................................................................................ 15

GB106x Series Unique Components .......................................................................................... 18

Controller .................................................................................................................................... 19

ERROR-CODE TROUBLESHOOTING .......................................................................................... 22

SEQUENCE OF OPERATION ....................................................................................................... 26

Ice Making Sequence ................................................................................................................. 26

Ice Bin Full/Cleaning Mode ......................................................................................................... 27

Description of Each Process ....................................................................................................... 27

Fill ............................................................................................................................................ 27

Freeze ..................................................................................................................................... 27

Lower ...................................................................................................................................... 28

Harvest .................................................................................................................................... 28

Raise ....................................................................................................................................... 28

Ice Bin Full .............................................................................................................................. 28

Cleaning Mode ........................................................................................................................ 28

Water Plate Closure Problems ................................................................................................ 28

Shutdown-High Pressure ........................................................................................................ 28

START METHODS ......................................................................................................................... 29

Ice Making Mode Start Up .......................................................................................................... 29

Cleaning Mode Start Up ............................................................................................................. 29

GT36X, GT56X, GB56X WIRING DIAGRAM ................................................................................. 30

GB1064 A & L WIRING DIAGRAM ................................................................................................ 31

GB106XR WIRING DIAGRAM ....................................................................................................... 32