Komfovent DOMEKT ReGO 400VE-B Manual

DOMEKT REGO 400VE(W)-B

Series Air Handling Units

Installation and Maintenance Service Manual

EN

2

Content

Safety Requirements ..................................................................................3

Transportation ..................................................................................3

Brief Description of the Unit ..................................................................................5

Installation ..................................................................................6

Maintenance ................................................................................11

Technical Information ................................... ............................................13

Ordering Key ................................................................................15

This symbol indicates that this product is not to be disposed of with your household waste, according to the WEEE Directive (2002/96/EC)

and your national law. This product should be handed over to a designated collection point, or to an authorised collection site for recycling

waste electrical and electronic equipment (EEE). Improper handling of this type of waste could have a possible negative impact on the

environment and human health due to potentially hazardous substances that are generally associated with EEE. At the same time, your

cooperation in the correct disposal of this product will contribute to the effective usage of natural resources. For more information about

where you can drop off your waste equipment for recycling, please contact your local city ofce, waste authority, approved WEEE scheme

or your household waste disposal service.

3

Installation and Maintenance Service Manual

We reserve the right to make changes without prior notice.

1 Picture

Safety Requirements

• To avoid accidents and/or unit damage, only a trained technician must carry

out the connection.

• The appropriate Personal Protective Equipment (PPE) attire is worn relative to

the operation being carried out.

• Electrical equipment is rated, connected and earthed in accordance with CE

regulations.

The air handling unit must be plugged in to an electrical outlet (with earth), which is in good order and

corresponds with all requirements of electric safety.

Before starting any operations inside the unit, make sure that the unit is switched off, and the power

cable is unplugged.

• Earth must be installed according EN61557, BS 7671.

• The unit should be installed according to Installation and Maintenance Manual.

• Before starting the unit, check correct position of air lters.

• Service maintenance should be carried out only in conformity with the

instructions specied herein below.

• If main cable is damaged, only manufacturer, service team or trained technician

must change it in order to avoid accidents.

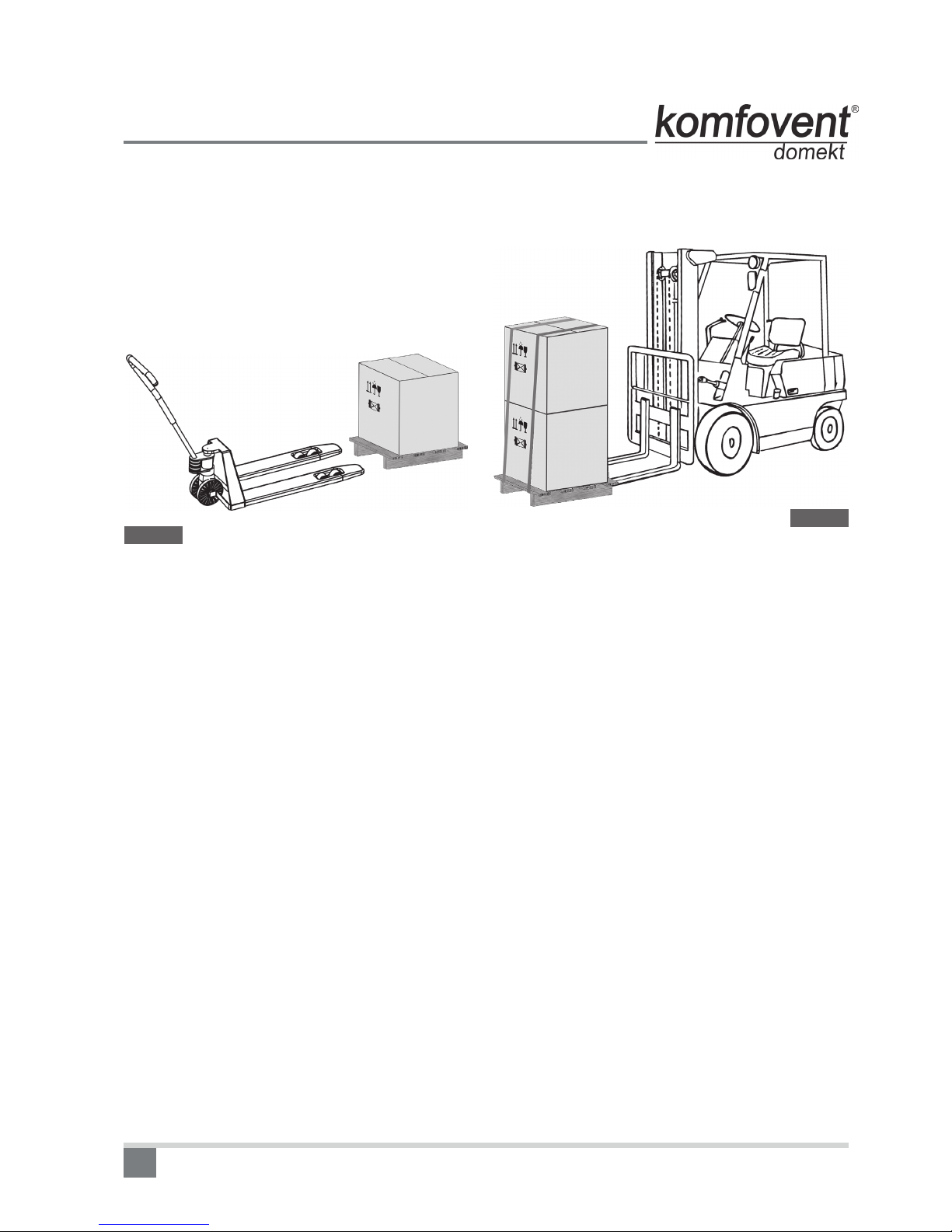

Transportation

The air handling units are ready for transit and storage (1 Picture). The unit is packed to prevent damage of the

external and internal parts of the unit, dust and moisture penetration.

The unit is packed to box after that corners of the air handling units are protected against the damage –

protective corners are used. The entire unit is wrapped up in protective lm. For transit or storage, units are mount-

ed on timber pallets. The unit is fastened to the pallet with polypropylene packing tape over protective corners.

Air handling unit ready for transit and storage

4

Installation and Maintenance Service Manual

We reserve the right to make changes without prior notice.

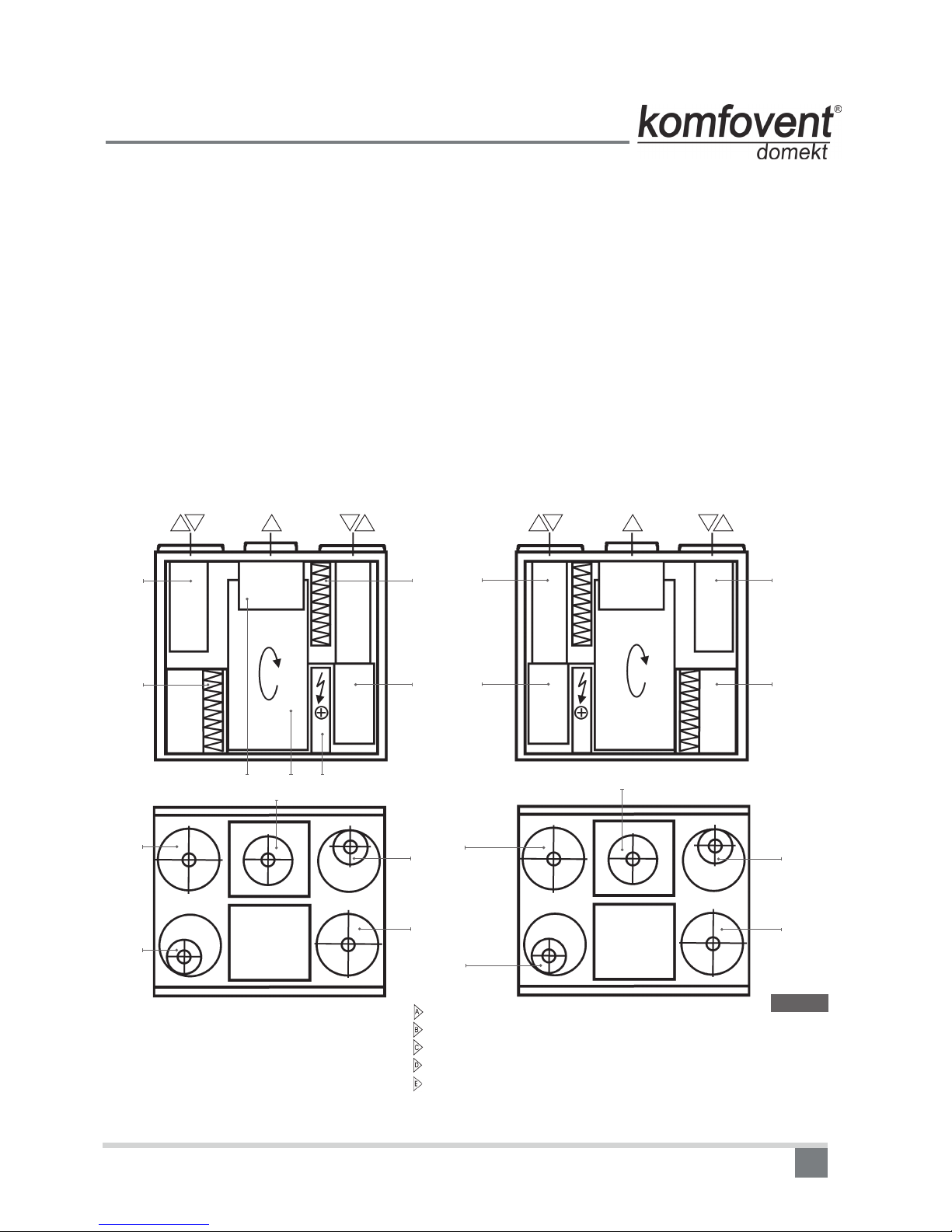

2 a Picture

Forklift truck or hand pallet truck can transport air handling unit as it is shown ( 2 a, b Pictures).

Air handling unit transportation by forklift truck or hand pallet truck

2 a Unit is transported by hand pallet truck on a wooden pallet;

2 b Unit is transported by forklift truck on a wooden pallet.

The unit should be examined upon receipt, to ensure that no visible damage has occurred during transit,

and the advice note checked to ensure that all items have been received. If damage or delivery shortages are

discovered, the carrier should be immediately informed. AMALVA should be notied within three days of receipt,

with a written conrmation sent within seven days. AMALVA can accept no responsibility for damage by unloading

from carrier or for subsequent damage on site.

If the unit is not to be installed immediately, it should be stored in a clean, dry area. If stored externally, it should

be adequately protected from the weather.

2 b Picture

5

Installation and Maintenance Service Manual

A. Outdoor intake

B. Supply air

C. Extract indoor

D. Exhaust air

E. Kitchen hood connection (by-pass – extraction without heat recovery)

3 Picture

Brief Description of the Unit

• The air handling units are intended for ventilation of small and medium-sized spaces (eg. single family houses,

ofces, etc.), having operating ambient temperature and relative humidity. The unit is intended to be in-

stalled in the kitchen or other domestic premises. Mineral wool is used for thermal insulation and sound

attenuation. Units cover panels are 25 mm thick. As standard, the unit is designed for indoor placement. The

operating temperature range for the unit is -300C ... 400C, outdoor air temperature.

The air handling unit is not to be used to transport solid particles, even not in areas where there is a risk of

explosive gases.

• DOMEKT REGO 400VE(W) (3 Picture) series units are equipped with a rotary heat exchanger, air lters, an

electric air heater, fans and automation control system, to ensure safe and efcient operation of the unit.

• Before you open the door, the unit must be switched off and the fans must have been given time to stop (up to

3 minutes).

• The unit contains heating elements that must not be touched when they are hot.

• To maintain a good indoor climate, comply with regulations and, to avoid condensation damage, the unit must

never be stopped apart from during service/maintenance or in connection with an accident.

• If the unit is placed in spaces with high humidity, condensation might occur on the surface of the unit when

outdoor temperatures are very low.

DOMEKT REGO 400VE(W)-B Air Handling Unit Scheme

1. Rotary heat exchanger

2. Supply air lter

3. Exhaust air lter

4. Supply fan

5. Exhaust fan

6. Electric air heater *

7. Automation control system * AHU REGO-400VW-B is suitable for use with water duct air heater.

Note: to reduce the noise level to the premises, it is recommended to install sound attenuators in the ducts.

ECB

5

E

B

D

A

C

2

3

4

71 6

C

B

E

D

A

DABCEAD

3

4

5

2

We reserve the right to make changes without prior notice.

6

Installation and Maintenance Service Manual

We reserve the right to make changes without prior notice.

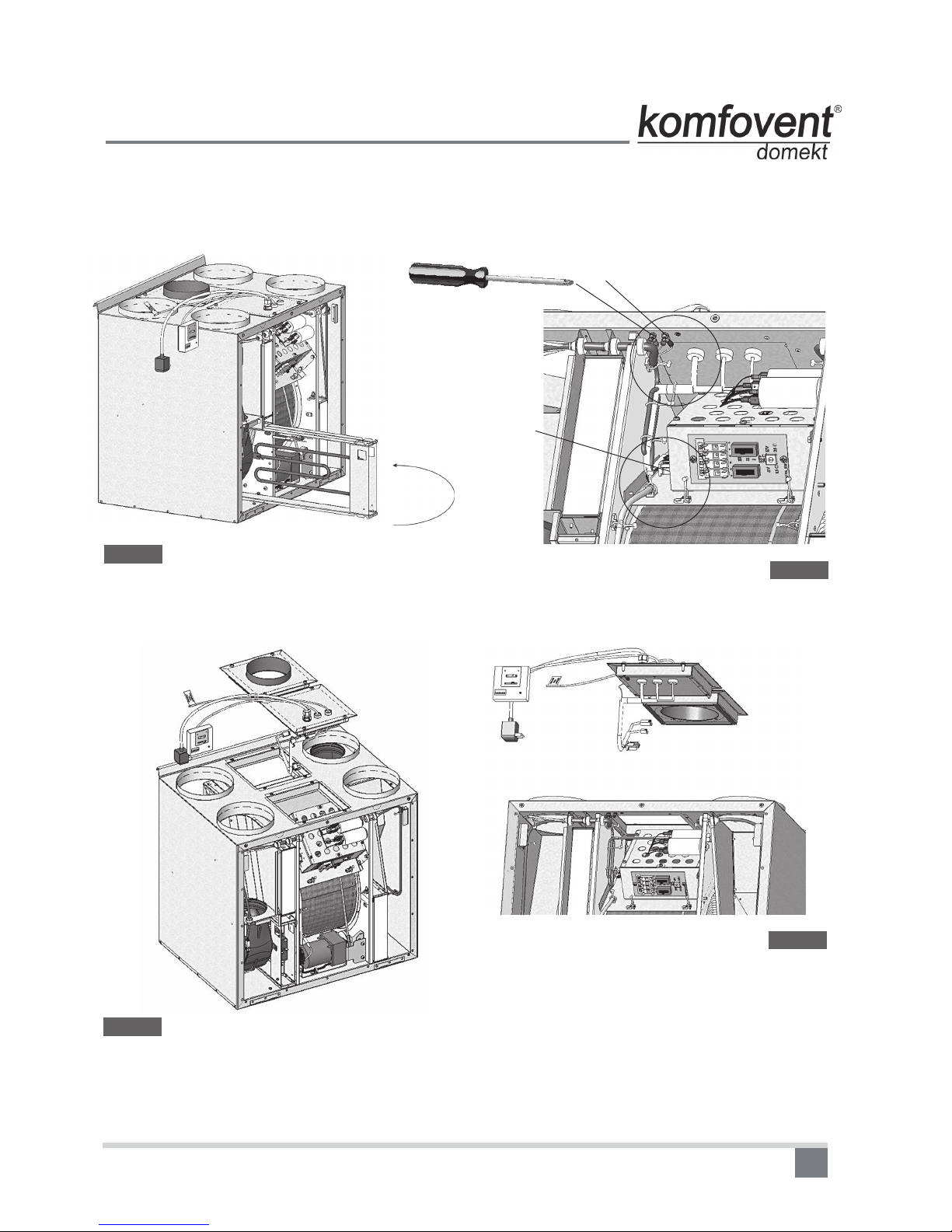

5 Picture

Installation

Unit Inspection

Before installing the unit, inspection must be carried out. Unit has removable panels from its both sides (4 Picture).

All internal unit components can be extracted from inspection side.After choosing desired inspection side, it is ne-

cessary to check if rotary heat exchanger, electric heater and automatics box are positioned correctly. Rotary heat

exchanger and automatics box are maintained from inspection side. Picture 4 shows unit with left-hand inspec-

tion side. To get unit with right-hand inspection side, internal unit elements must be turned round. Remove both

unit’s panels, which afterwards must be counterchanged to have possibility of other side inspection. Start with

electric heater (5 Picture). After removing the cover of the electric heater, electrical connection with the rotor must

be disconnected.

unplug

plug

Taking off the switch from the unit it is needed to take it apart from each other and check if the contacts are

fouled.

4 Picture

7

Installation and Maintenance Service Manual

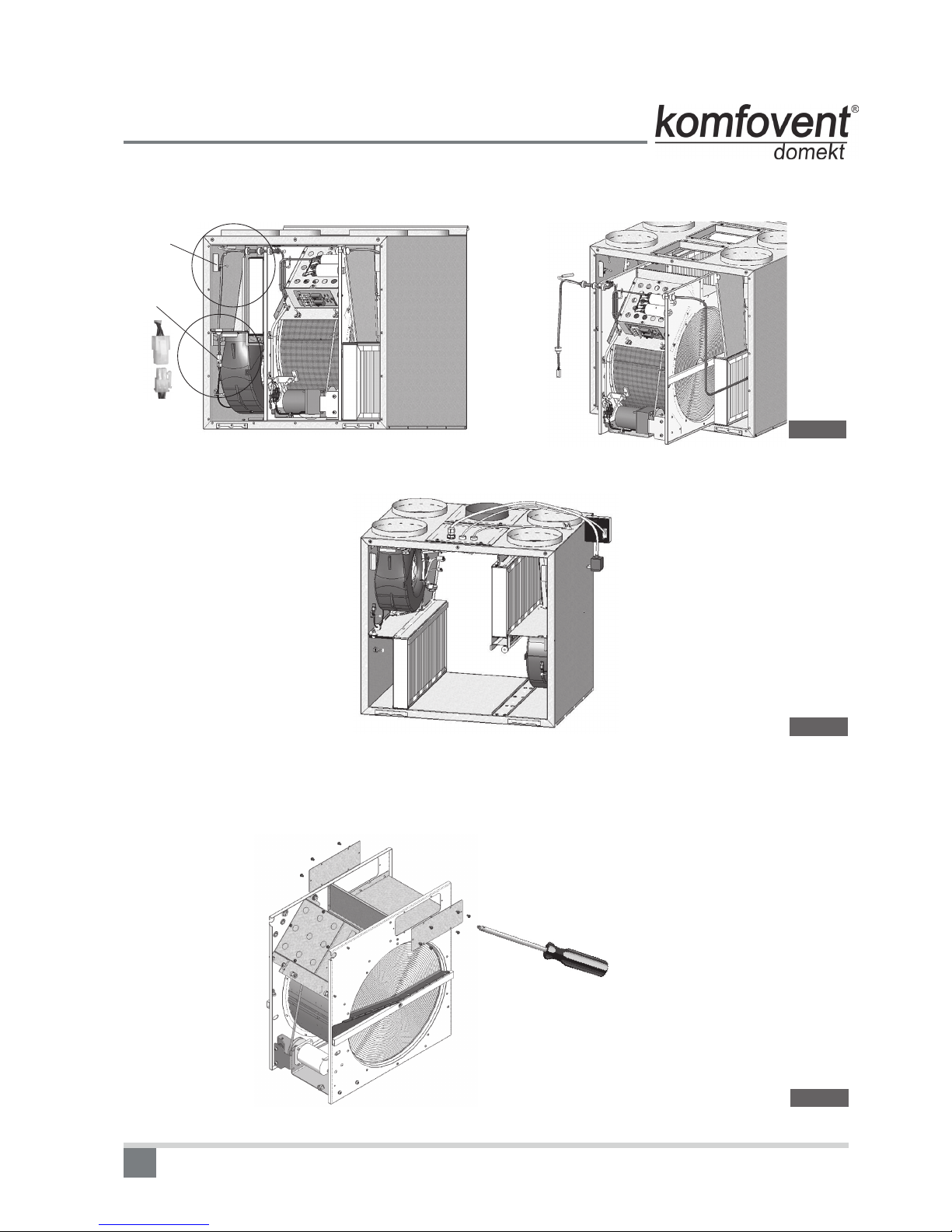

8b Picture

7 Picture

unscrew

disconnect

Afterwards electric heater may be extracted, turned round and put in by its other side (6 Picture). Then rotary

heat exchanger and automatics box must be turned round being already disconnected from all connections and

with unscrewed grounding wires (7 Picture).

pull and screw

Screw off and remove top covers of automatics and by-pass. Afterwards they must be counterchanged and

screwed again (8 a, b Pictures).

6 Picture

8a Picture

We reserve the right to make changes without prior notice.

8

Installation and Maintenance Service Manual

We reserve the right to make changes without prior notice.

9 Picture

10 Picture

Disconnect fans’ connections; pull out air temperature sensor together with a rubber plug. Loosen all wires

xed in the partitions with rubber gaskets and extract rotary heat exchanger (9 Picture).

disconnect

pull

While unit casing is disassembled, all protective gaskets from the unit back side must be removed on its front

one (10 Picture). Then assemble in inverse way to get the unit of opposite inspection side.

Before inserting rotary heat exchanger, one by-pass cover which is located in it must be removed. Cover is

unscrewed with six screws. This is done to have correct by-pass air ow direction. Opened vent must always be

near exhaust ow fan (11 Picture).

Note: There are two by-pass covers by default. When connecting the by-pass, one cover must be removed.

11 Picture

9

Installation and Maintenance Service Manual

12 Picture

13 Picture

14 Picture

Insert rotor by its correct side; put on protective gaskets to their places (12 Picture).

When changing inspection sides, be sure fans’ connecting plugs are not counter-

changed. Fans are connected by the same connections. In case if unit is right-hand

side, fans wires are crossed over in rotary heat exchanger’s electronics place. Also

by crossing the wires, correct air temperature sensor position will be achieved.

Then electric heater is connected (13 Picture), cables must be carefully connected and xed to appropriate

places. Do not forget to screw on grounding wires and make connections in indicated places.

Picture 14 shows unit from right-hand inspection side.

Do not forget to put on elements for hanging before screwing on back panel.

Use the same instruction of changing the inspection side of AHU, but without the notes of electric heater.

We reserve the right to make changes without prior notice.

10

8

2

7

1

Installation and Maintenance Service Manual

We reserve the right to make changes without prior notice.

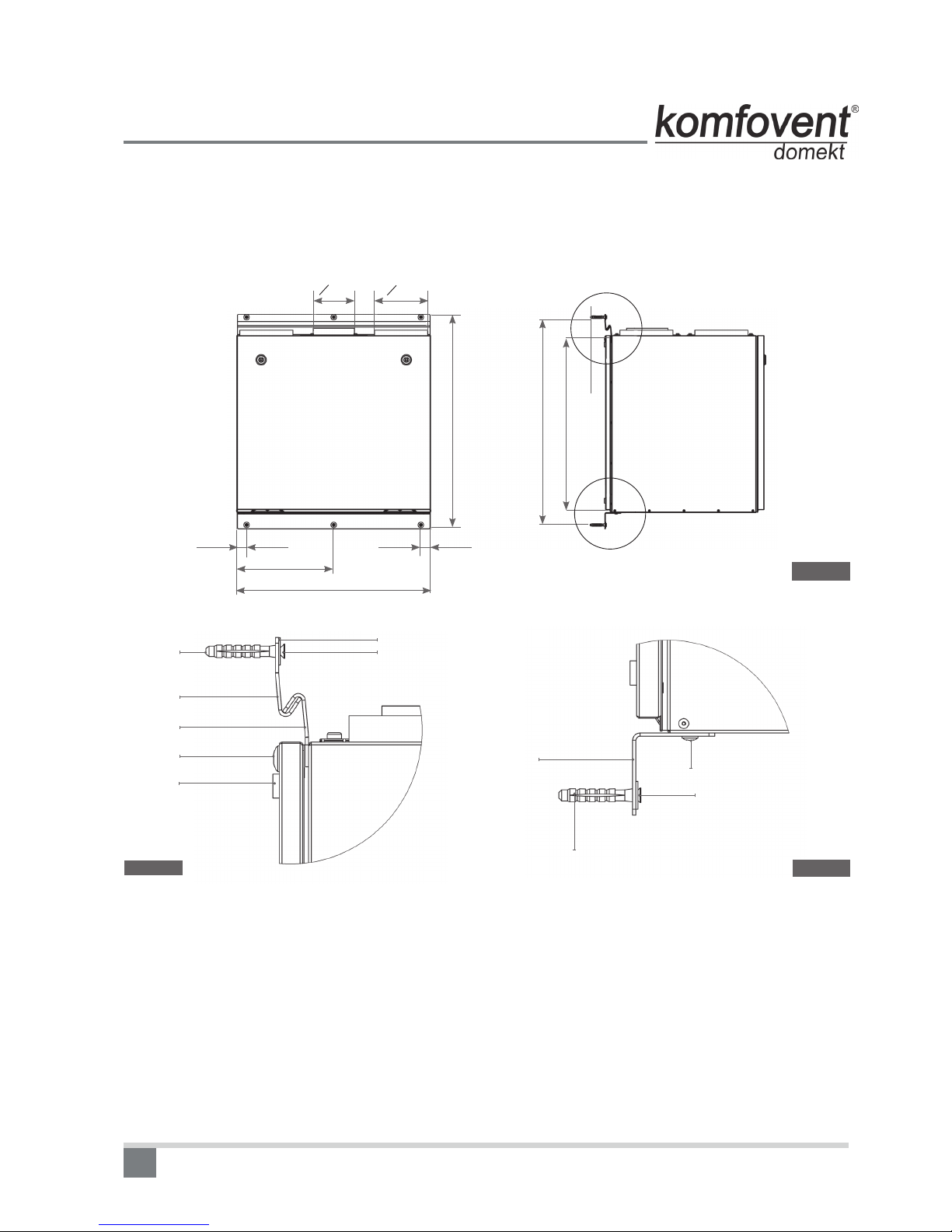

15 Picture

16a Picture

The place for the unit should be selected with allowance for minimum access to the unit for maintenance and

service inspection. The minimum free space in front of the inspection panel should be not less than 600 mm. It

is recommended to install the air handling unit in a separate room (15 Picture).

Unit brackets’ positions

B

A

641

604

57

662

30

300

600

30

O125 O160

Pictures 16 a and 16 b show unit’s upper and bottom xing element.

1. Screw 4. Hanging bracket 2 7. Self tapping screw

2. Wall plug 5. Bolt M5 8. L-shape bracket

3. Hanging bracket 1 6. Gasket 9. Washer M5 DIN9021

Final Inspection

After installation of the unit, a thorough inspection should be carried out. This should include inspecting the

inside of the unit and removing debris and tools, which may have been left behind by on site contractors. Replace

any panels, which may have been removed and close all access doors, ensuring that the door sealing gaskets

have not been damaged.

16b Picture

3

21

4

5

6

9

11

Installation and Maintenance Service Manual

17 Picture

Heating coil connection* and the pipe work should be done in order to ensure the space for maintenance and

service work. When carrying out the installation of heater pipes, make sure that hot water supply is completely

disconnected. Before start-up of the air handling unit, the heater system should be lled in with water. Glycol is

used in the air handling units with coil heat exchanger. Never pour glycol down a drain; collect it in a receptacle

and leave it at a recycling centre or the like. Glycol is highly dangerous to consume and can cause fatal poisoning

or damage the kidneys. Contact a doctor! Avoid breathing glycol vapour in conned spaces. If you get glycol in

your eyes, fush them thoroughly with water (for about 5 minutes).

*If water heater build in.

When operating air handling unit in the temperatures lower than 0°C, it is

necessary to use glycol additionally or assure the reversible heating agent

temperature more than 25°C.

It is important to maintain air heaters and coolers cleanliness; that is to change

lters installed in the air handling unit on time. If the air heater or cooler gets dirty,

to perform periodical cleaning.

Maintenance

It is recommended to carry out routine maintenance of the air handling unit KOMFOVENT DOMEKT

REGO 400VE(W) 3 – 4 times per year. Extracting unit elements (see 17 Picture). Cables must be disconnected

when extracting electric heater and rotary heat exchanger.

During inspection, the following operations should be performed:

1. Rotary heat exchanger check. Inspection of the rotary heat exchanger is performed once per year. Free

rotation of the rotary heat exchanger, continuity of the rotating belt, absence of damages of the rotor drums

and the seal gasket are checked. It is necessary to check the stretch of belt. Free belt will slide and the ef-

ciency of rotary heat exchanger will fall down. To reach maximal efciency, rotor must turn at least 6 times

per minute. Polluted heat exchanger will decrease efciency. Cleaning can be performed by compressed

air or soapsuds. Check out water falling on the rotor’s electric motor.

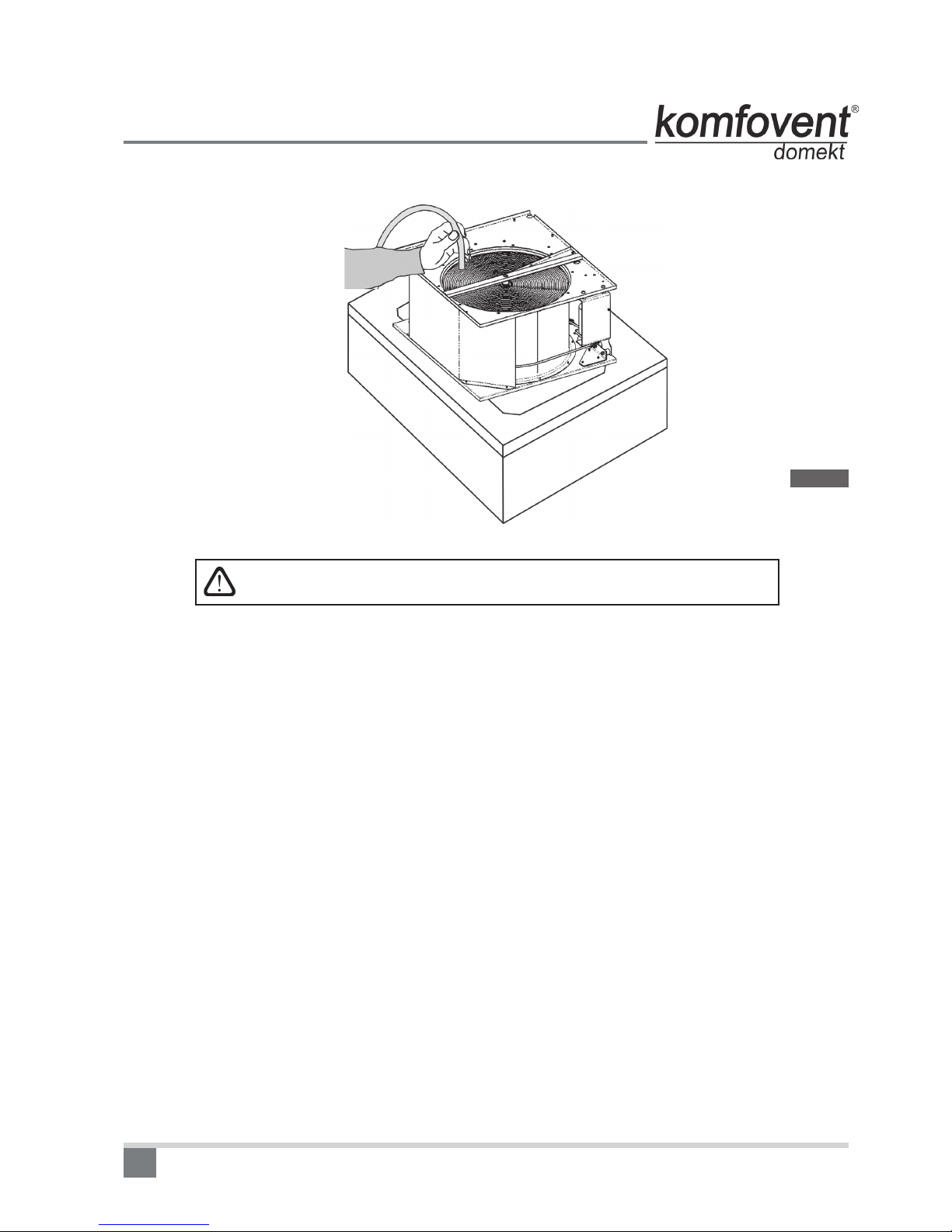

Rotor cleaning. If rotor cleaning by compressed air is not effective, it can be washed with soapsuds

(18 Picture), or if needed – use degreasing soak for metal (aluminum) cleaning. Check out water falling

on the rotor’s electric motor and other automatics’ elements. In case if water got into details, they must be

urgently dry up. Leave rotor to dry in a warm place. Rotor can be connected only when it is absolutely dry.

We reserve the right to make changes without prior notice.

12

Installation and Maintenance Service Manual

We reserve the right to make changes without prior notice.

Rotor cleaning

2. Fans check (once per year). Polluted fans decrease efciency.

Before performing any inspection work, check whether the unit is switched off

from the electric power supply.

Fans should be carefully cleaned with textile or soft brush. Do not use water. Do not break balance. Check

if fan freely rotates and is not mechanically damaged, if impeller does not touch suction nozzles, fan does

not spread noise and mounting bolts are screwed.

3. Air heater check. Check if electric air heater is properly xed, wires connections are not damaged and heat-

ing elements are not bent. Check the plates of water air heater. The air heater is cleaned with hoover from

supply air side or with air blast from exhaust air side. If it is very dirty, wash with tepid water, which will

not make corrosion of aluminium. Check if position of return water temperature sensor is right. They can

be damaged or bent due to uneven heat or uneven and turbulent air direction. Check if electric air heater is

clear of unnecessary things and heating elements are not clogged, because this can cause unpleasant smell

or in the worst case – dust can start burning. Air ow through the air heater should be greater than 1,5 m/s.

Heating elements can be cleaned with hoover or wet textile.

4. Airltercloggingcheck. Change air lters when air lter clogging is indicated. We recommend to change

lters at least twice per year: before and after heating season, or more*. Filters are one time used. We do

not recommend cleaning them. Stop the air handling unit before changing lters.

*Clogged lters unbalance ventilation system, air handling unit uses more power.

18 Picture

13

Technical Information

Specications

REGO 400VE(W) Dimensions AC VE/VW EC VE/VW

Nominal air ow m3/h 300 300

Unit weight kg 40 41

Heater capacity kW 1,0 / 1,2 1,0 / 1,2

Fans input power W 2x137 2x70

Supply voltage V / Hz ~230 / 50 /1 phase ~230 / 50 /1 phase

Maximal operating current A 5,75 / 1,41 5,15 / 0,76

Ducts connection mm 160 160

Thermal efciency of rotary heat exchanger up to % 82 82

Energy recovery of rotary heat exchanger up to kW 3,5 3,5

Filters

Supply air Exhaust air Dimensions

Filter class F5 / F7 F5 / F7

Filter type Panel Panel

Filters dimensions bxhxl 450x210x46 450x210x46 mm

Acoustic data of REGO 400VE(W)-B-AC

63 125 250 500 1000 2000 4000 8000 dB(A)

Supply air ow

(into air ducts)

Intake 56 54 53 53 51 49 45 39 56,2

Supply 60 62 63 61 60 58 54 50 65,0*

Exhaust air ow

(into air ducts)

Extract 56 54 53 53 51 50 45 40 56,4

Exhaust 60 62 63 61 60 58 54 50 65,0

Kitchen hood connection 59 59 59 59 58 58 56 48 62,7

Surrounding (3 m distance) 52 53 51 44 37 32 27 23 46,5

* For AHU REGO 400VW-B, sound power less up to 2 dB(A).

Acoustic data of REGO 400VE(W)-B-EC

63 125 250 500 1000 2000 4000 8000 dB(A)

Supply air ow

(into air ducts)

Intake 49 47 43 43 45 41 38 36 48.8

Supply 55 56 54 54 54 52 50 48 59.0*

Exhaust air ow

(into air ducts)

Extract 49 47 43 43 45 41 38 36 48.8

Exhaust 55 56 54 54 54 52 50 48 59.0

Kitchen hood connection 53 51 47 48 50 49 47 45 55.2

Surrounding (3 m distance) 47 47 44 38 32 29 25 22 40.3

* For AHU REGO 400VW-B, sound power less up to 1,5 dB(A).

We reserve the right to make changes without prior notice.

14

Installation and Maintenance Service Manual

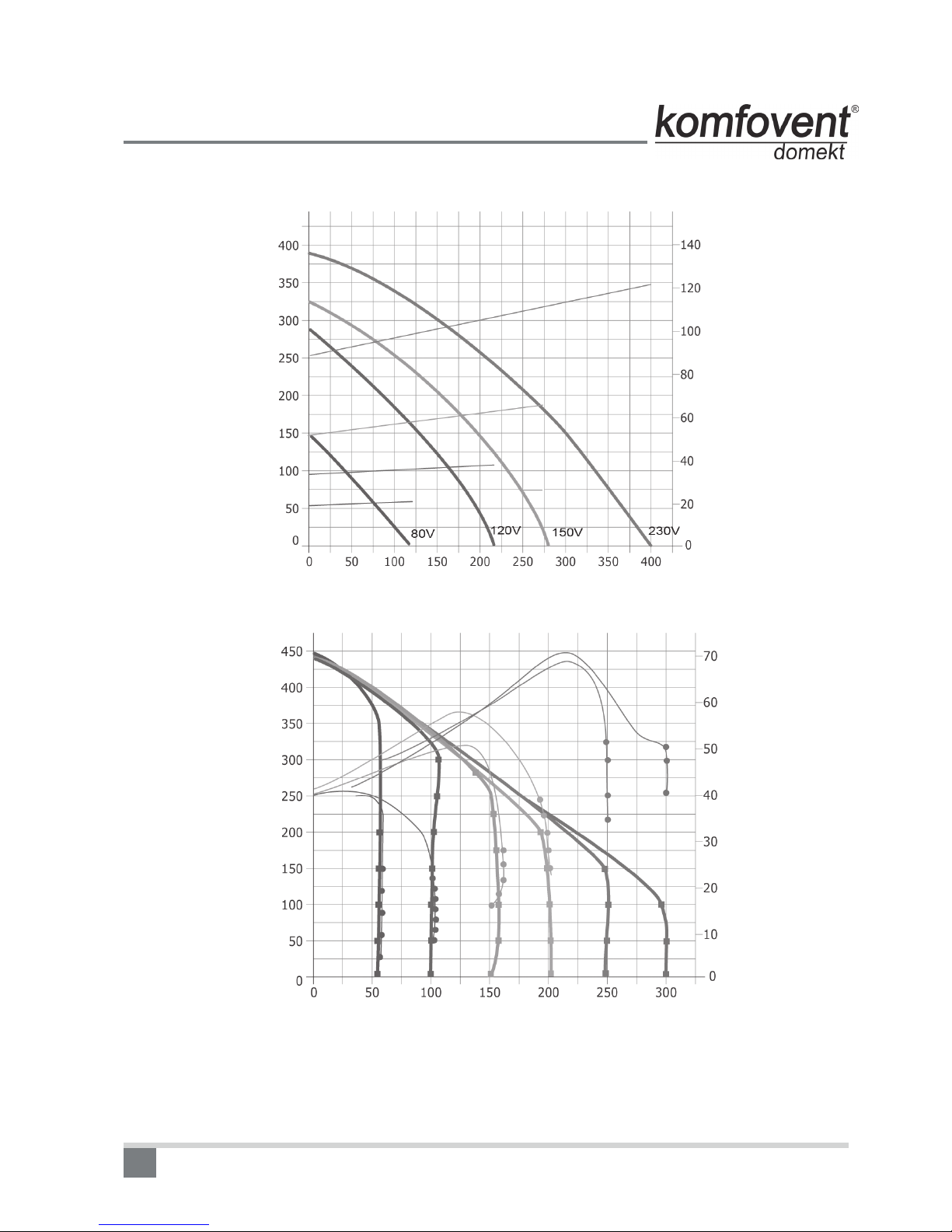

REGO 400VE(W*)-B-AC Performance

REGO 400VE(W*)-B-EC Performance

* Correction factor for REGO 400VW - 15Pa

We reserve the right to make changes without prior notice.

Power consumption, W

Static pressure, Pa

Air volume, m3/h

Power consumption, W

Static pressure, Pa

Air volume, m3/h

15

Installation and Maintenance Service Manual

Scheme

600

547

563

500

418 91

232

133

300

160(4x)

125

Ordering Key

REGO – 400 – V E(W) – B AC / EC – C4 – F

Filter class (F5 or F7)

Controller type: C4

Motor type: AC – alternating current,

EC – electronically commutated

By - pass

Air heater: W-water, E-electric

Version: vertical

Unit size (shows nominal air ow)

AHU type:

REGO – with rotary heat exchanger

We reserve the right to make changes without prior notice.

UAB AMALVA

Ozo str. 10,

LT–08200 VILNIUS, LITHUANIA

e-mail [email protected]

www.amalva.com

www.komfovent.com 2012

This manual suits for next models

1

Table of contents

Other Komfovent Air Conditioner manuals

Popular Air Conditioner manuals by other brands

Fujitsu

Fujitsu ASYG 09 LLCA installation manual

York

York HVHC 07-12DS Installation & owner's manual

Carrier

Carrier Fan Coil 42B Installation, operation and maintenance manual

intensity

intensity IDUFCI60KC-3 installation manual

Frigidaire

Frigidaire FAC064K7A2 Factory parts catalog

Sanyo

Sanyo KS2432 instruction manual

Mitsubishi Electric

Mitsubishi Electric PUHZ-RP50VHA4 Service manual

Panasonic

Panasonic CS-S18HKQ Service manual

Panasonic

Panasonic CS-E15NKE3 operating instructions

Gree

Gree GWH18TC-K3DNA1B/I Service manual

Friedrich

Friedrich ZoneAire Compact P08SA owner's manual

Daikin

Daikin R32 Split Series installation manual