Komfovent MOU-24HN1-Q User manual

Installation manual

AIR CONDITIONER

OUTDOOR UNITS

2

Content

Safety considerations .......................... 3

Installation information .......................... 3

Installation place .......................... 4

Outdoor unit installation .......................... 5

Install the connecting pipe .......................... 6

Wiring ......................... 11

Piping diagrams ......................... 13

Outdoor unit connection to KOMPAKT and VERSO units ........................ 14

Test operation ......................... 17

Self - diagnosis and troubleshooting ......................... 17

Indoor Temp. and Pipe Temp. Sensor Resistance Value ......................... 20

Outdoor Units

3

Safety considerations

Installation and servicing of air conditioning equipment can be hazardous due to system pressure

andelectric components. Only trained and qualied service personnel should install, repair or service air

conditioning equipment.

Before performing service or maintenance operations on system, turn off main

power switch of the unit. Electrical shock could cause personal injury.

This unit shall be installed in accordance with national wiring regulations.

If the supply cord is damaged, it must be replaced by the manufacturer or

its service agent or similarly qualied person in order to avoid a hazard.

The means for disconnection from the supply having a contact separation

of at least 3 mm in all poles.

Caution

1. Wire the outdoor unit, then wire the indoor unit. You are not allow to connect the air conditioner

with the power source until wiring and piping the air conditioner is done.

2. For installation of the indoor unit, outdoor unit, and connection piping in between, follow the

instructions given in this manual as strictly as possible.

3. Installation in the following places may cause trouble. If it is unavoidable using in such places,

please consult with the dealer.

a) A place full of machine oil.

b) A saline place such as coast.

c) Hot-spring resort.

d) A place full of sulde gas.

e) A place where there are high frequency machines such as wireless installation, welding

machine, medical facilities.

f) A place of special environmental conditions.

4. Don’t install this unit in the laundry.

üNote

Remark per EMC Directive 89/336/EEC or to prevent icker impressions during the start of the

compressor (technical process) ,following installation conditions do apply.

1. The power connection for the air conditioner has to be done at the main power distribution. The distribution

has to be of a low impedance, normally the required impedance reaches at a 32 A fusing point.

2. No other equipment has to be connected with this power line.

3. For detailed installation acceptance please refer to your contract with the power supplier, if restrictions do

apply for products like washing machines, air conditioners or electrical ovens.

4. For power details of the air conditioner refer to the rating plate of the product.

5. For any question contact your local dealer.

Installation information

• To install properly, please read this “installation manual” at rst.

• The air conditioner must be installed by qualied persons.

• When installing the indoor unit or its tubing, please follow this manual as strictly as possible.

• When all the installation work is nished, please turn on the power only after a thorough check.

• Regret for no further announcement if there is any change of this manual caused by product improvement.

Outdoor Units

4

Installation order

1. Select the location;

2. Install the indoor unit;

3. Install the outdoor unit;

4. Install the connecting pipe;

5. Connect the drain pipe;

6. Wiring;

7. Test operation.

Outdoor Units

Installation place

Cautions

Location in the following places may cause malfunction of the machine.(If unavoidable, please

consult your local dealer)

a. There is petrolatum existing.

b. There is salty air surrounding (near the coast).

c. There is caustic gas (the sulde, for example) existing in the air (near a hot spring).

d. The Volt vibrates violently (in the factories).

e. In buses or cabinets.

f. In kitchen where it is full of oil gas.

g. There is strong electromagnetic wave existing.

h. There are inammable materials or gas.

i. There is acid or alkaline liquid evaporating.

j. Other special conditions.

Notices before installation

1. Select the correct carry-in path.

2. Move this unit as originally packaged as possible.

3. If the air conditioner is installed on a metal part of the building, it must be electrically insulated according

to the relevant standards to electrical appliances.

1. The outdoor unit

• There is enough room for installation and maintenance.

• The air outlet and the air inlet are not impeded, and can not be reached by strong wind.

• It must be a dry and well ventilating place.

• The support is at and horizontal and can stand the weight of the outdoor unit. And will no additional

noise or vibration.

• Your neighborhood will not feel uncomfortable with the noise or expelled air. There is no leakage of

combustible air.

• It is easy to install the connecting pipe or cables.

• Determine the air outlet direction where the discharged air is not blocked.

• A place free of a leakage of combustible gases. In the case that the installation place is exposed to

a strong wind such as a seaside or high position, secure the normal fan operation by putting the unit

lengthwise along the wall or using a duct or shield plates.

• If possible, do not install the unit where it is exposed to direct sunlight.

• If necessary, install a blind that does not interfere with the air ow.

• During the heating mode, the water drained off the outdoor unit ,The condensate should be well

drained away by the drain hole to an appropriate place, so as not to interfere other people or public.

• Select the position where it will not be subject to snow drifts, accumulation of leaves or other seasonal

debris. It is important that the air ow for the outdoor unit is not impeded as this will result in reduction

in heating or cooling performance.

5

Outdoor Units

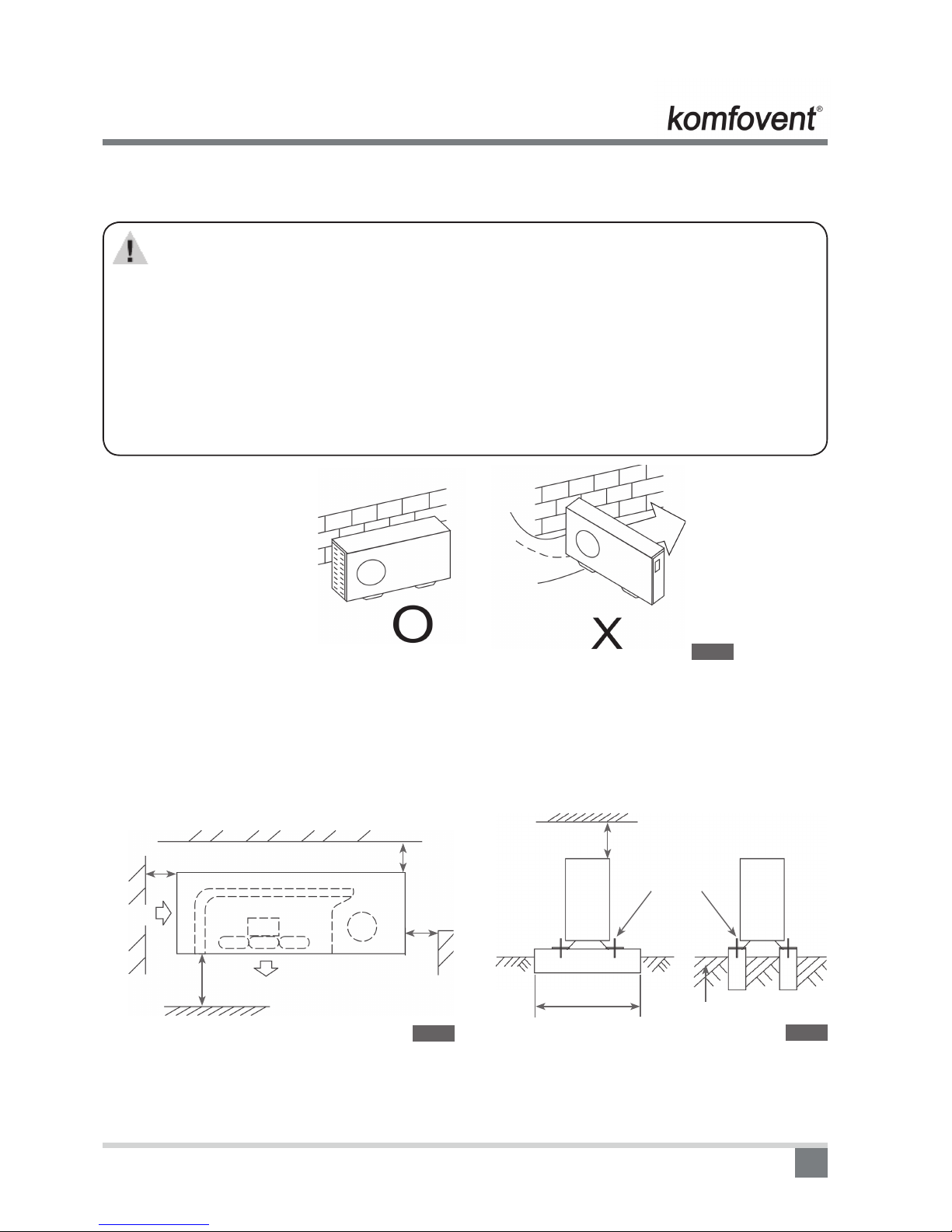

Outdoor unit installation

Cautions

• Keep this unit away from direct radiation of the sun or other heaters.

• If unavoidable, please cover it with a shelter.

• In places near coast or with a high attitude where the wind is violent, please install the out-

door unit against the wall to ensure normal performance.

Use a bafe when necessary.

• In the case of extremely strong wind, please prevent the air from owing backwards into the

outdoor unit. ( Refer to chart 16)

• Locate the outdoor unit as close to the indoor unit as possible.

• The minimum distance between the outdoor unit and obstacles described in the installation

chart does not mean that the same is applicable to the situation of an airtight. Leave open

two of three directions A,B,C.

Necessary room for installation and maintenance

(Refer to chart 2, chart 3)

If possible, please remove the obstacles nearby to prevent the performance from being impeded by too little

of air circulation.

The minimum distance between the outdoor unit and obstacles described in the installation chart does not

mean that the same is applicable to the situation of an airtight room. Leave open two of the three directions

(A,B,C).

Chart 1

Strong wind

Wall or obstacle

Air inlet

Air inlet

>30 cm

>60 cm

C

Air outlet

>200 cm

A

>30 cm

Chart 2

Maintain channel

Chart 3

>60 cm

Necessary width

Fix with bolt

Deep foundation

6

Outdoor Units

600mm is necessary between 2 indoor units.

Chart 4

Moving and intalling

• Since the gravity center of this unit is not at its physical center, so please be careful when lifting it with a

sling.

• Never hold the air-in of the outdoor unit to prevent it from deforming.

Do not touch the fan with hands or other objects.

• Do not lean it more than 450, and do not lay it sidelong.

• Please fasten the feet of this unit with bolts rmly to prevent it from collapsing in case of earthquake

• or strong wind.

• Make concrete foundation of the size of 590*328.(Refer to chart 3)

Install the connecting pipe

Cautions

Check whether the height drop between the indoor unit and outdoor unit, the length of

refrigerant pipe, and the number of the bends meet the following requirements:

The max height drop 8, 15, 20, 25 m

If the height drop is more than 10m, you had better put the outdoor unit over above the

indoor unit.

The length of refrigerant pipe 15, 25, 30, 50 m

The number of bends less than15

* Look at specication (page 12.).

Cautions

• Do not let air, dust, or other impurities fall in the pipe system during the time of installation.

• The connecting pipe should not be installed until the indoor and outdoor units have been xed

already.

• Keep the connecting pipe dry, and do not let moisture in during installation.

Refrigerant pipe installation

Measure the necessary length of the connecting pipe, and make it by the following way.

1) Connect the indoor unit at rst, then the outdoor unit.

• Bend the tubing in proper way. Do not harm to them.

7

Chart 5

Use frozen oil

Chart 6

Bend the pipe with thumb

Min-radius - 100 mm

Chart 7

Make the

end straight

Cautions

• Daub the surfaces of the are pipe and the joint nuts with frozen oil, and wrench it for 3~4

rounds with hands before fasten the are nuts.(Refer to chart 5)

• Be sure to use two wrenches simultaneously when you connect or disconnect the pipes.

2) The stop value of the outdoor unit should be closed absolutely (as original state). Every time you connect

it, rst loosen the nuts at the part of stop value , then connect the are pipe immediately (in 5 minutes).

If the nuts have been loosened for a long time, dusts and other impurities may enter the pipe system

and may cause malfunction later. So please expel the air out of the pipe with refrigerant (R410a) before

connection.

3) Expel the air (refer to the “Expel The Air”) after connecting the refrigerant pipe with the indoor unit. Then

fasten the nuts at the repair-points.

üNotices For Bendable Pipe

• The bending angle should not exceed 900.

• Bending position is preferably in the middle of the bendable pipe. The larger the bending radius the better

it is.

• Do not bend the pipe more than three times.

Bend the connecting pipe of small wall thickness (9,5 mm)

• Cut out a desired concave at the bending part of the insulating pipe.

• Then expose the pipe (cover it with tapes after bending).

• To prevent collapsing or deforming, please bend the pipe at its biggest radius.

• Use bender to get a small radius pipes.

Use the market brass pipe

• Be sure to use the same insulating materials when you buy the brass pipe (more than 9mm thick).

Locate The Pipe

• Drill a hole in the wall (suitable just for the size of the wall conduit), then set on the ttings such as the wall conduit

and its cover.

• Bind the connecting pipe and the cables together tightly with binding tapes. Do not let air in, which will

cause water leakage by condensation.

• Pass the bound connecting pipe through the wall conduit from outside. Be careful of the pipe allocation to

do no damage to the tubing.

1. Connect the pipes.

2. So please expel the air out of the pipe with refrigerant (R410a) before connection.

3. Then, open the stem of stop values of the outdoor unit to make the refrigerant pipe connecting the indoor

unit with the outdoor unit in uent ow.

4. Be sure of no leakage by checking it with leak detector or soap water.

5. Cover the joint of the connecting pipe to the indoor unit with the soundproof / insulating heath (ttings), and

bind it well with the tapes to prevent leakage.

Outdoor Units

8

Outdoor Units

Fasten the nuts

• Put the connecting tubing at the proper position, wrench the nuts with hands, then fasten it with a wrench.

( Refer to Chart 10)

1. Cut a pipe with a pipe cutter.

2. Insert a are nut into a pipe and are the pipe.

Outside-diameter

(mm)

A (mm)

Min Max

6.4 8.3 8.7

9.5 12.0 12.4

12.7 15.4 15.8

15.9 18.6 19.1

19.1 22.9 23.3

Cautions

Too large torque will harm the bellmouthing and too small will cause leakage. Please

determine the torque according to Table.

Tubing Size Torque

6.4 15~16 Nm (153~163 kgf-cm)

9.5 25~26 Nm (255~265 kgf-cm)

12.7 35~36 Nm (357~367 kgf-cm)

15.9 45~47 Nm (459~480 kgf-cm)

19.1 65~67 Nm (663~684 kgf-cm)

450 + 20

900 + 40

900lean crude burr

Chart 8

Chart 10

Chart 9

A

450 + 20

900 + 40

9

Necessary Refrigerant Stow Capacity

Length (L) Capacity 18000-24000Btu/h 30000-48000Btu/h

Less than 8m (one-way) —— ——

Added Refrigerant When Over 8m(one-way) 65 x (L-8) m

• Please record and reserve well the refrigerant stow capacity of your air conditioner for later maintenance.

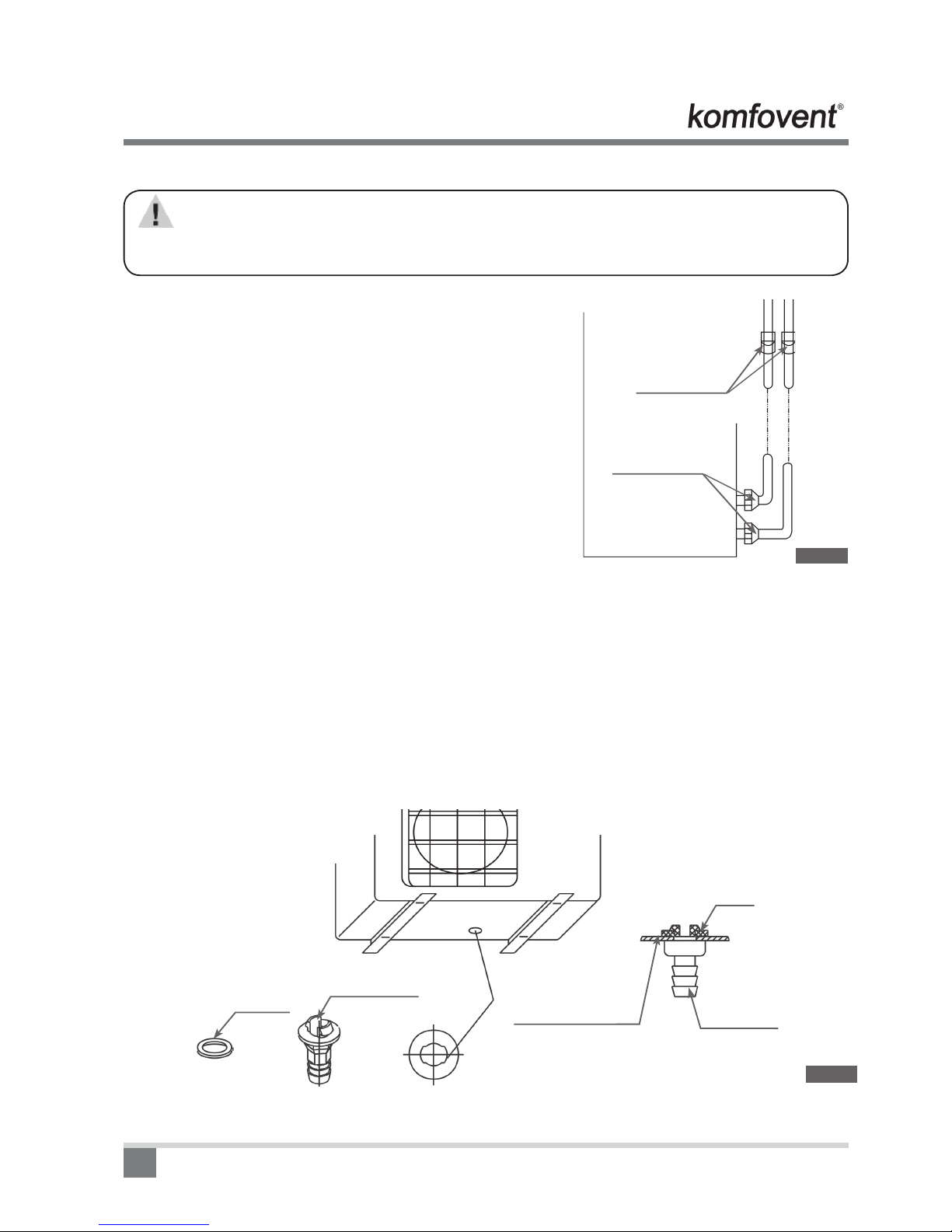

Expel the air with a vacuum pump

(please refer to its manual for the way of using manifold value)

Vacuum Dry: use vacuum pump to change the moisture (liquid) into steam (gas) in the pipe and discharge it out

of the pipe to make the pipe dry. Under one atmospheric pressure, the boiling point of water(steam temperature)

is 1000C. Use vacuum pump to make the pressure in the pipe near vacuum state, the boiling point of water falls

relatively. When it falls under outdoor temperature, the moisture in the pipe will be vaporized.

1. Loosen and remove the maintenance nuts of stop values A and B, and connect the charge hose of the

manifold value with the maintenance terminator of stop value A. (Be sure that stop values A and B are both

closed).

2. Connect the joint of the charge hose with the vacuum pump.

3. Open the Lo-lever (Lo) of the manifold value completely.

4. Turn on the vacuum pump. At the beginning of pumping, loosen the maintenance terminator nut of stop

value B a little to check whether the air comes in (the sound of the pump changes, and the indicator of

compound meter turns below zero). Then fasten the nut.

5. When the pumping has nished, close the Lo-lever of the manifold value completely and turn off the

vacuum pump.

• When you have pumped for over 15 minutes, please conrm that the indicator of multi-meter is on

1.0x10-5 Pa (-76cmHg).

6. Loosen and remove the quadrangle cover of stop values A and B to open stop value A and B completely,

then fasten them.

7. Disassemble the charge hose from the repair-mouth of stop value A, and fasten the nut.

If the pump can’t achieve below -755mmHg after pumping 2 hours, moisture or leakage point will still exist in

the pipe. At this time, it should be pumped 1 hour more.

Outdoor Units

Chart 11

Manifold valve

Multi-meter Pressure meter

-76 cmHg

Lo - lever Hi- lever

Charge hose

Charge hose

Vacuum pump

Lo- lever

Flare nut

Cap

Stopper

Valve body

Valve stern

Chart 12

10

Cautions

All the stop values should be opened before test operation. Each air conditioner has two stop

values of different sizes on the side of the outdoor unit which operate as Lo-stop value and

Hi-stop value, respectively. (Refer to Chart 12)

Check the leakage CHECK THE LEAKAGE

Check all the joints with the leak detector or soap water.

(refer to Chart 13)

NOTE: in the chart 13:

A.......... Lostop value

B .......... Histop value

C, D ..... Joints of the connecting pipe to the indoor unit.

In order to ensure a perfect unit work on the back of low-pressure pipe should be tted with water lter!

Insulation

• Be sure to with insulating materials cover all the exposed parts of the are pipe joints and refrigerant pipe

on the liquid-side and the gas-side. Ensure that there is no gap between them.

• Incomplete insulation may cause water condensation.

Drain Elbow Installation

Fit the seal into the drain elbow, then insert the drain elbow into the base pan hole of outdoor, rotate 900to

securely assemble them. Connect the drain elbow with an extension drain hose (Locally purchased), in case of

the condensate draining off the outdoor unit during the heating mode.

Chart 13

Check-point of

outdoor unit

Check-point of

indoor unit

Outdoor Units

A

B

C

D

Seal

Drain elbow The base pan hole of

outdoor unit Drain elbow

Seal

Chart 14

11

Wiring

Caution!

1. The air conditioner should use separate power supply with rated voltage.

2. The external power supply to the air conditioner should have ground wiring, which is linked to

the ground wiring of the indoor and outdoor unit.

3. The wiring work should be done by qualied persons according to circuit drawing.

4. A disconnection device having an air gap contact separation in all active conductors should

incorporated in the xed wiring according to the National wiring regulation.

5. Be sure to locate the power wiring and the signal wring well to avoid cross-disturbance and

their contact with connecting pipe or stop value body.

6. The wiring attached to this air conditioner is 6m long. Be sure to prolong it with wiring of the

same type and proper length if necessary. Generally, do not twist two wiring together unless

the joint is soldered well and covered with insulator tape.

7. Do not turn on the power until you have checked carefully after wiring.

1. Nominal cooling capacities are based on the following conditions:

Indoor temp: 27°C, relative humidity 50%. Outdoor temp: 35°C; Equivalent ref. Piping: 8m(horizontal)

2. Nominal heating capacities are based on the following conditions:

Indoor temp: 20°C; Outdoor temp: 7°C, relative humidity 90%; Equivalent ref. Piping: 8m(horizontal)

3. Actual noise level may differ, depending on the room structure, etc, since these noise values are from an

anechoic room.

Remove the protection board

Disassemble the bolts from the maintenance board, and pull it in the direction of the arrow to remove

the protection board.

Notice: Do not scratch the surface during operation.

ATTENTION: Chart 15 is based on the standard model, which may look a little different from your

own outdoor unit.

Outdoor Units

Terminator

Protection board

Chart 15

12

Model MOU-12HN1 MOU-18HN1-Q MOU-24HN1-Q MOU-36HN1-R MOU-48HN1-R MOUA-60HN1-R

Power supply V-ph-Hz 230-1-50 230-1-50 230-1-50 400-3-50 400-3-50 400-3-50

Max. input consumption W 1500 2950 3450 4950 6300 7500

Max. input current A 7 15 18 10,0 10,5 12,8

Cooling / Heating capacity W 3520/3810 5280/5860 7030/7620 10550/11720 14100/15240 17600/19100

Compressor

Type ROTARY ROTARY ROTARY Scroll SCROLL SCROLL

Brand MIDEA-TOSHIBA MIDEA-TOSHIBA MIDEA-TOSHIBA SANYO SANYO SANYO

Capacity Btu/h 11567 18697 24498 33438 48109 55956,8

Oil ml ESTEL OIL

VG74, 480

ESTER OIL

VG74, 750

ESTER OIL

VG74/950 FV68S/1700 FV68S 1700 FV68S, 1700

Outdoor unit

Outdoor air ow m3/h 2100 2439 3200 5000 6800 6850

Outdoor noise level

(sound pressure) dB(A) 43 54 55 57 59 59,3

Dimension(W×H×D) mm 780×547×250 762×593×282 845×695×335 990×966×354 900×1167×340 900×1167×340

Packing (W×H×D) mm 910×575×335 887x645x355 965×755×395 1120×1100×435 1032×1307×443 1032×1307×443

Net/Gross weight kg 34/37 39/42 53/57 92/96 110/115 93/99

Refrigerant type R410A R410A R410A R410A R410A R410A

Refrigerant charged

volume g 1120 1400 1900 2900 3250 3200

Design pressure MPa 4.2/1.5 4.2/1.5 4.2/1.5 4.2/1.5 4.2/1.5 4.2/1.5

Refrigerant piping

Liquid side/ Gas side mm φ6.4/φ12.7 φ6.4/φ12.7 φ9.5/φ15.9 φ12.7/φ19 φ12.7/φ19 φ12.7/φ19

Liquid side - Gas side inch 1/4 - 1/2 1/4 - 1/2 3/8 - 5/8 1/2 - 3/4 1/2 - 3/4 1/2 - 3/4

Max. pipe length m 15 25 25 30 50 30

Max. difference in level m 8 15 15 20 25 20

Ambient temp. C cooling: 18~43;

heating: -7~24

Outdoor Units

1. Specication

13

Indoor unit Outdoor unit

Liquid side

3-way valve

Gas side

3-way valve

Heat exchange

(evaporator)

Check valve

(Heating Model only)

Capillary tube

Heat exchange

(Condenser)

Reversing valve

(Heating Model Only)

Cooling

Heating

Accumulator

Compressor

Chart 16

1. For MOU-18HN1 and MOU-24N1, accumulator is not included.

2. Check valve and auxiliary capillary is only for MOU-18HN1.

Outdoor Units

Piping Diagrams

14

Outdoor Units

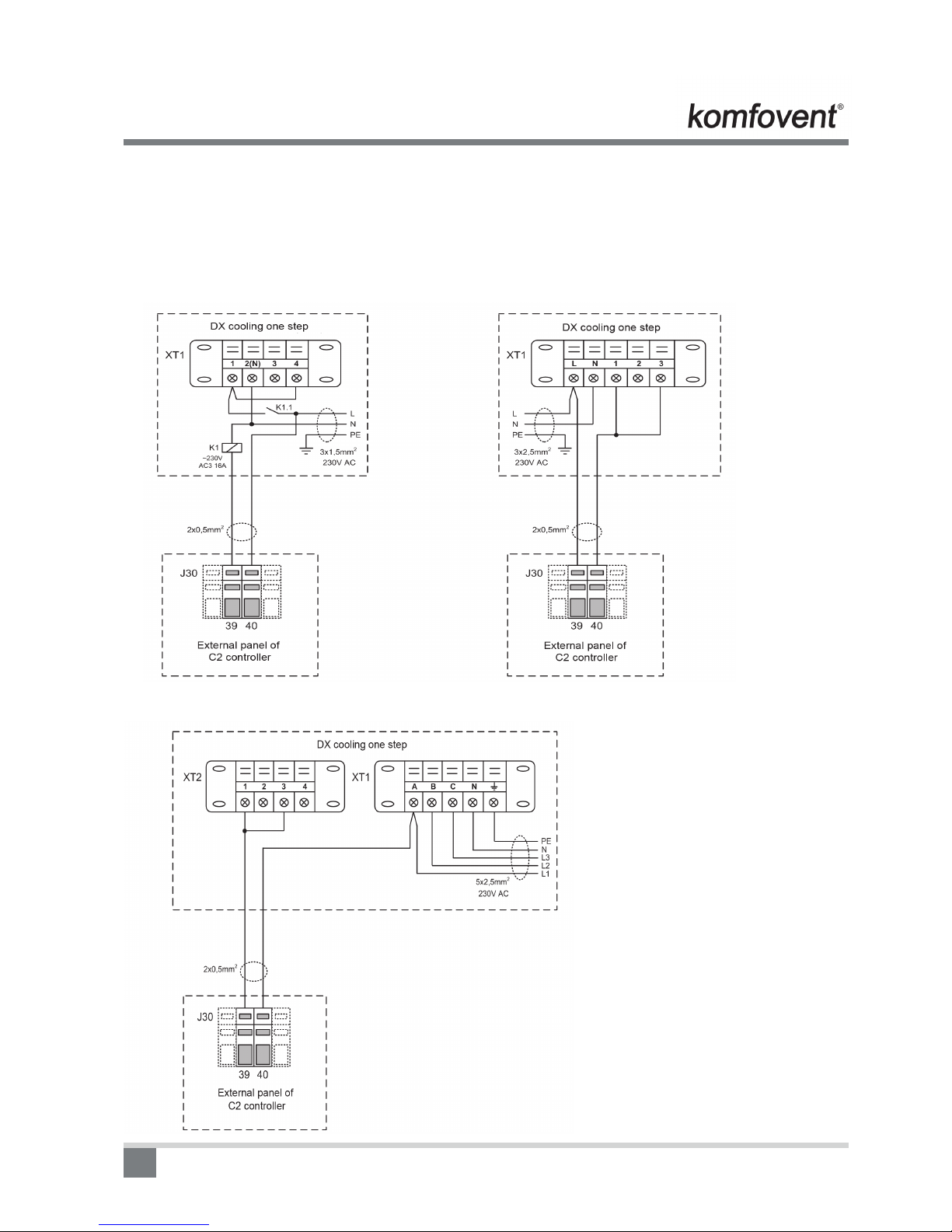

Outdoor unit connection to KOMPAKT and VERSO units

Outdoor unit connection to AHU with C2 controller.

MOU-12HN1 and MOU-18HN1-Q (1 phase) MOU-24HN1(1 phase)

MOU-36HN1, MOU-48HN1 and MOU-60HN1 (3 phases)

15

Outdoor Units

Outdoor unit connection to AHU with C3 controller with external panel C3-P1.

MOU-12HN1 and MOU-18HN1-Q (1 phase) MOU-24HN1(1 phase)

MOU-36HN1, MOU-48HN1 and MOU-60HN1 (3 phases)

16

Outdoor Units

Outdoor unit connection to AHU with C3 controller with external panel P3.

MOU-12HN1 and MOU-18HN1-Q (1 phase) MOU-24HN1(1 phase)

MOU-36HN1, MOU-48HN1 and MOU-60HN1 (3 phases)

17

Outdoor Units

Test operation

1. The test operation must be carried out after the entire installation has been completed.

2. Please conrm the following points before the test operation:

• The indoor unit and outdoor unit are installed properly.

• Tubing and wiring are correctly completed.

• The refrigerant pipe system is leakage-checked.

• The drainage is unimpeded.

• The heating insulation works well.

• The ground wiring is connected correctly.

• The length of the tubing and the added stow capacity of the refrigerant have been recorded.

• The power voltage ts the rated voltage of the air conditioner.

• There is no obstacle at the outlet and inlet of the outdoor and indoor units.

• The gas-side and liquid-side stop values are both opened.

• The air conditioner is pre-heated by turning on the power.

1) The outdoor unit

a. Whether there is vibration or abnormal noise during operation.

b. Whether the generated wind, noise, or condensed of by the air conditioner have inuenced your

neighborhood.

c. Whether any of the refrigerant is leaked.

Caution

A protection feature prevents the air conditioner from being activated for approximately 3

minutes when it is restarted immediately after shut off.

Self-diagnosis and troubleshooting

LEDs’ for the indication of outdoor trouble(3 phase type, 4~7HP)

Type Contents LED1 LED2 LED3

Trouble Phase sequence Flash Off Off

Trouble Lack of phase Flash Off Off

Trouble Protection of pressure Flash Flash Off

Trouble Overload of current Off Off Flash

Trouble Open-circuit and short-circuit trouble of T3 Off Flash Flash

Trouble Open-circuit and short-circuit trouble of T4 Off Flash Off

Trouble High temperature protection of condenser Flash Flash Flash

18

Lack of phase

Lack of phase

ä

Check the power supply, is it 3 phases, 400V?

ä

Check the connection between power supply

and terminal, is the voltage in outdoor

terminal 3 phases, 400V?

ä

Outdoor PCB is defective

Outdoor Units

Phase sequence error:

Change the order of two of the wires to power supply.

ä

Switch on the unit again.

ä

If the problem can not be solved, the outdoor

PCB is defective

Overload of current:

Overload of current

ä

Check the current, normally

The max. current for MOU-36HN1 is 10 A

The max. current for MOU-48HN1 is 10.5A

The max. current for MOU-60HN1 is 12.8A

Is the current in rated range?

ä

The outdoor PCB is defective Possible reason

1. Outdoor fan is defective

2. The compressor is defective

3. Refrigerant is over charged

4. Air entered the refrigerant system

5. Heat exchanger is too dirty

ä NO

YES

19

YES

Protection of pressure or temperature:

Protection of pressure or temperature

ä

Is it K1 or K2 open?

ä

Is temp. protection switch K1 open

ä

Possible reason

1. The wires is loose to K1

2. Air or other gas in the refrigerant.

3. Heat exchanger is dirty

4. Outdoor fan or fan blade is defective

5. Outdoor unit is bad ventilation

6. Refrigerant leaked

7. K1 switch is defective

YES

YES

ä

Is pressure protective switch K2 open?

ä

Possible reason

1. The wires is loose to K2

2. Air or other gas in the refrigerant.

3. Heat exchanger is dirty

4. Outdoor fan or fan blade is defective

5. Outdoor unit is bad ventilation

6. Refrigerant is excessive

7. K2 switch is defective

NO

YES

Outdoor Units

Open-circuit and short-circuit trouble of T3 or T4

Is connection to connector of temp. sensor good?

ä

Check the resistance of the temp. sensor

according to Annex 1

ä

Is it the resistance is normal?

ä

Indoor PCB is defective.

YES

YES

YES

ä

Repair connector

NO

ä

Replace the sensor

NO

20

Outdoor Units

High temperature protection of condenser:

High temperature protection of condenser

ä

Check the resistance of the temp. sensor

according to Annex 1, is it normal?

ä

Possible reason

• Air or other gas in the refrigerant.

• Heat exchanger is dirty

• Outdoor fan or fan blade is defective

• Outdoor unit is bad ventilation

• Refrigerant leaked

• Outdoor PCB is defective

ä

Replace the sensor

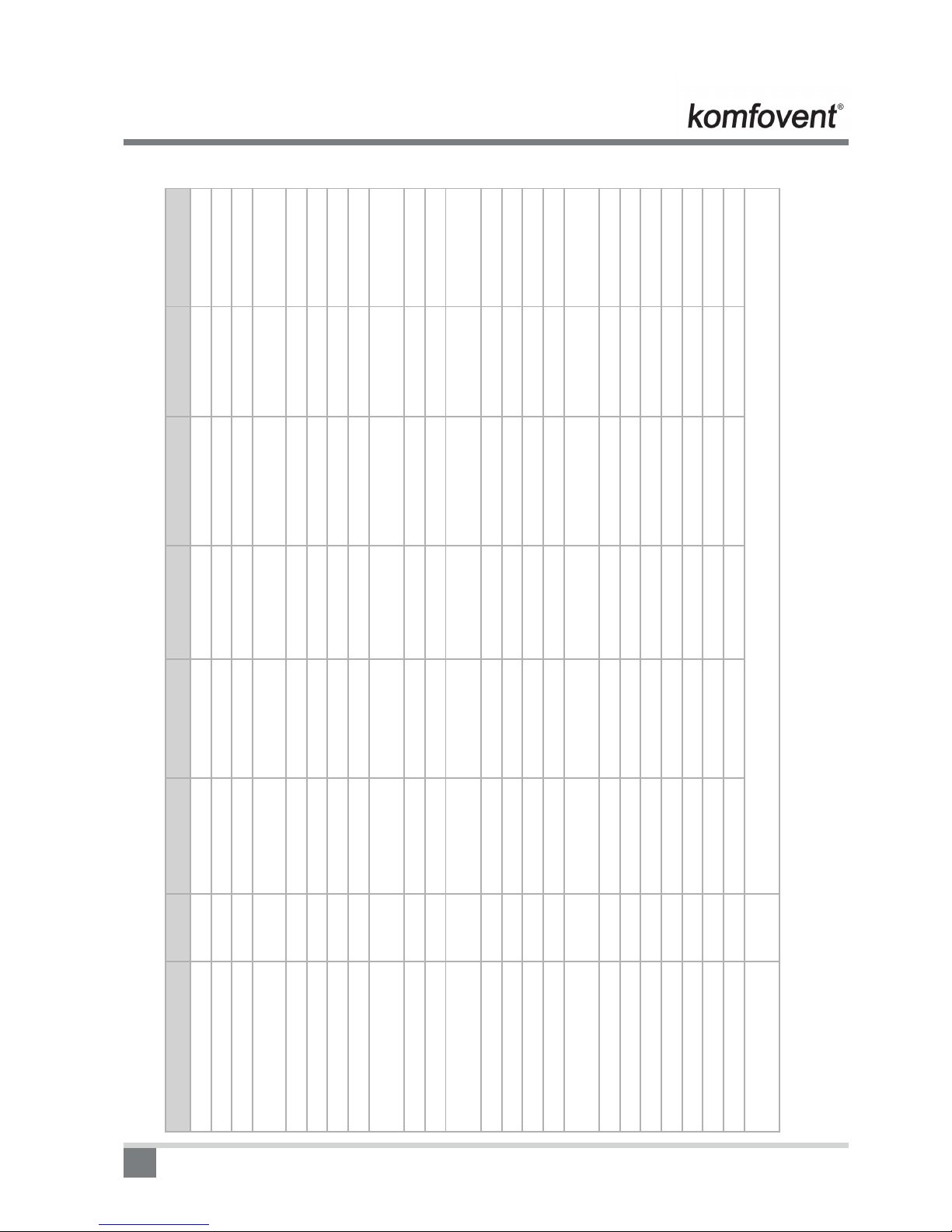

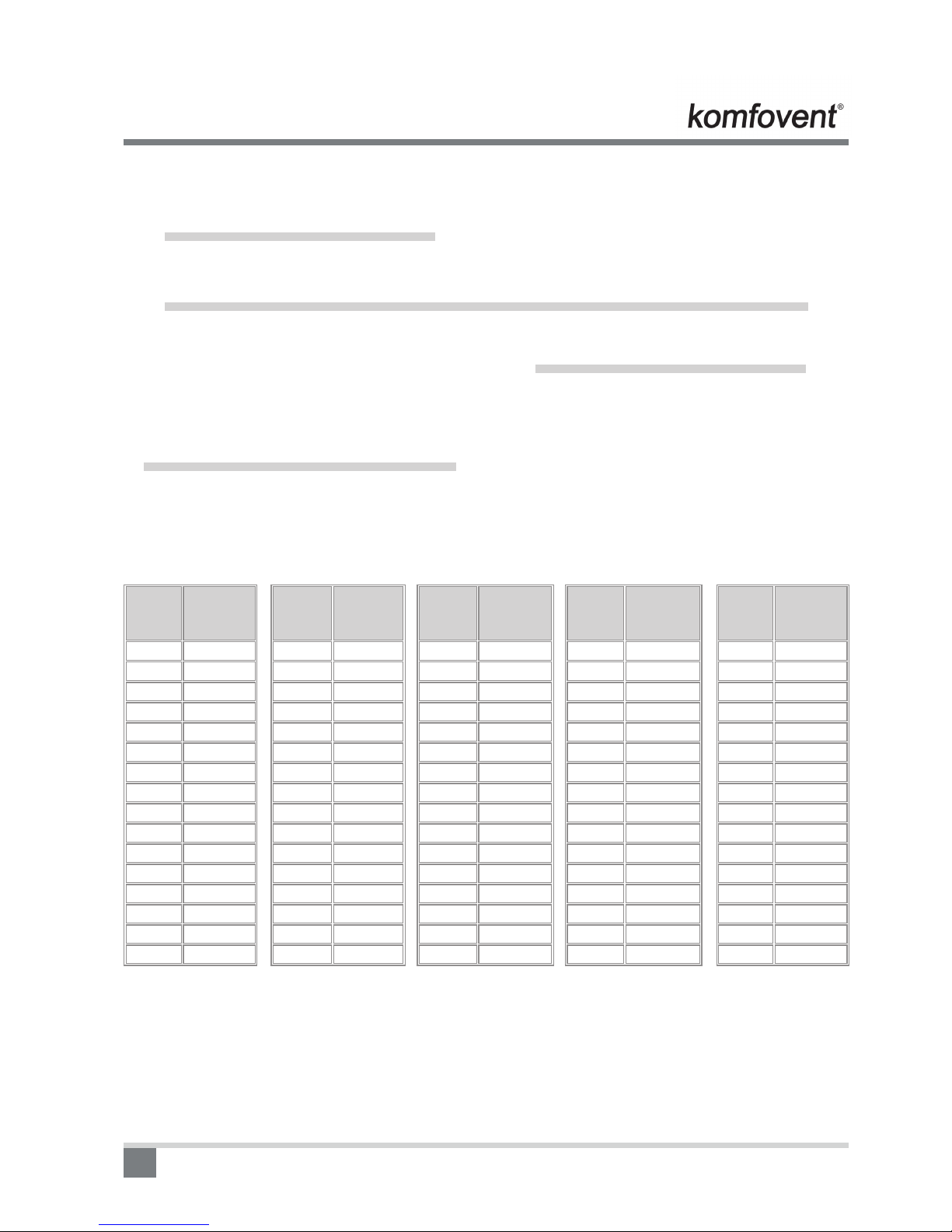

Indoor Temp. and Pipe Temp. Sensor Resistance Value

Appendix 1

Outdoor

Temp.

0C

Sensor

Resistance

kΩ

-20 115.266

-19 108.146

-18 101.517

-17 96.3423

-16 89.5865

-15 84.2190

-14 79.3110

-13 74.5360

-12 70.1698

-11 66.0898

-10 62.2756

-9 58.7079

-8 56.3694

-7 52.2438

-6 49.3161

-5 46.5725

Outdoor

Temp.

0C

Sensor

Resistance

kΩ

-4 44.0000

-3 41.5878

-2 39.8239

-1 37.1988

0 35.2024

1 33.3269

2 31.5635

3 29.9058

4 28.3459

5 26.8778

6 25.4954

7 24.1932

8 22.5662

9 21.8094

10 20.7184

11 19.6891

Outdoor

Temp.

0C

Sensor

Resistance

kΩ

12 18.7177

13 17.8005

14 16.9341

15 16.1156

16 15.3418

17 14.6181

18 13.9180

19 13.2631

20 12.6431

21 12.0561

22 11.5000

23 10.9731

24 10.4736

25 10.0000

26 9.55074

27 9.12445

Outdoor

Temp.

0C

Sensor

Resistance

kΩ

28 8.71983

29 8.33566

30 7.97078

31 7.62411

32 7.29464

33 6.98142

34 6.68355

35 6.40021

36 6.13059

37 5.87359

38 5.62961

39 5.39689

40 5.17519

41 4.96392

42 4.76253

43 4.57050

Outdoor

Temp.

0C

Sensor

Resistance

kΩ

44 4.38736

45 4.21263

46 4.04589

47 3.88673

48 3.73476

49 3.58962

50 3.45097

51 3.31847

52 3.19183

53 3.07075

54 2.95896

55 2.84421

56 2.73823

57 2.63682

58 2.53973

59 2.44677

This manual suits for next models

5

Table of contents

Other Komfovent Air Conditioner manuals

Popular Air Conditioner manuals by other brands

Fujitsu

Fujitsu ASYG 09 LLCA installation manual

York

York HVHC 07-12DS Installation & owner's manual

Carrier

Carrier Fan Coil 42B Installation, operation and maintenance manual

intensity

intensity IDUFCI60KC-3 installation manual

Frigidaire

Frigidaire FAC064K7A2 Factory parts catalog

Sanyo

Sanyo KS2432 instruction manual

Mitsubishi Electric

Mitsubishi Electric PUHZ-RP50VHA4 Service manual

Panasonic

Panasonic CS-S18HKQ Service manual

Panasonic

Panasonic CS-E15NKE3 operating instructions

Gree

Gree GWH18TC-K3DNA1B/I Service manual

Friedrich

Friedrich ZoneAire Compact P08SA owner's manual

Daikin

Daikin R32 Split Series installation manual