H215 AE Rev.: 10 kortho Hot Quick Coder-D vii

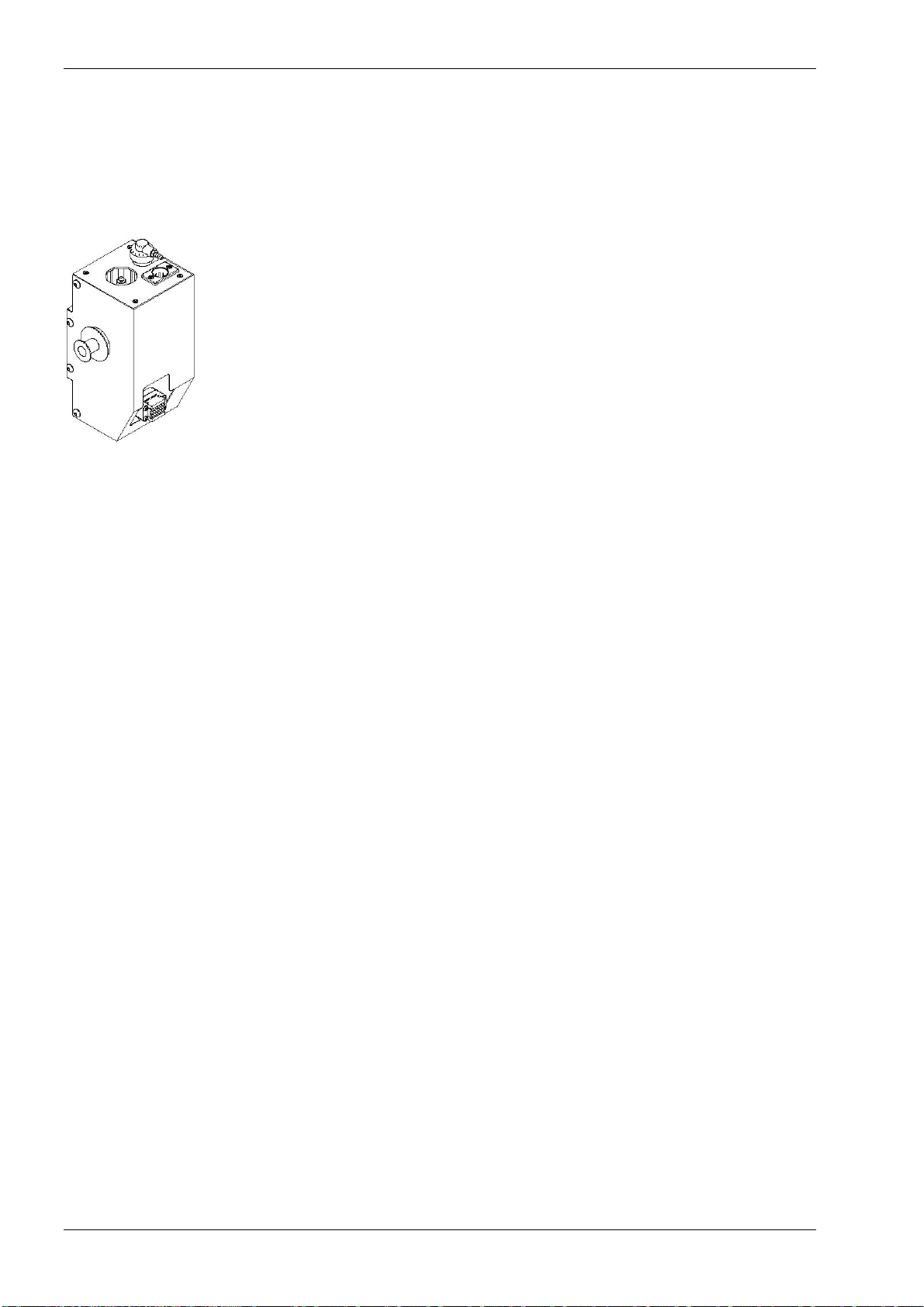

5.4 Mounting the control box ................................................................................................... 5-3

5.5 Initial setup......................................................................................................................... 5-3

5.5.1 Prepare the text holder..................................................................................... 5-3

5.5.2 Placing a text holder......................................................................................... 5-3

5.5.3 Placing a hotroll................................................................................................ 5-4

6OPERATION

6.1 Powering up....................................................................................................................... 6-1

6.2 Printer mode ...................................................................................................................... 6-2

6.2.1 Stop mode........................................................................................................ 6-2

6.2.2 Run mode......................................................................................................... 6-3

6.3 Parameter / message screens........................................................................................... 6-3

6.3.1 Preset list.......................................................................................................... 6-3

6.3.2 Set delay .......................................................................................................... 6-4

6.3.3 Set temp........................................................................................................... 6-4

6.3.4 Set time ............................................................................................................ 6-5

6.3.5 Firmware message........................................................................................... 6-5

6.3.6 Set LCD contrast.............................................................................................. 6-5

6.3.7 Set alarm.......................................................................................................... 6-6

6.3.8 Extended busy (optional).................................................................................. 6-6

6.3.9 Ready temperature........................................................................................... 6-6

6.3.10 Power on.......................................................................................................... 6-7

6.4 User settings...................................................................................................................... 6-8

7TROUBLESHOOTING

7.1 Error 001............................................................................................................................ 7-1

7.2 Error 002............................................................................................................................ 7-1

7.2.1 -20°C................................................................................................................ 7-1

7.2.2 300°C ............................................................................................................... 7-1

7.3 Error 003............................................................................................................................ 7-2

7.3.1 -20°C................................................................................................................ 7-2

7.3.2 300°C ............................................................................................................... 7-2

7.4 Error 004............................................................................................................................ 7-2

7.5 Error 016............................................................................................................................ 7-3

7.6 LCD screen is not lit...........................................................................................................7-3

8MAINTENANCE

8.1 Quick and regular checks.................................................................................................. 8-1

8.2 Monthly maintenance......................................................................................................... 8-1

8.3 Yearly maintenance........................................................................................................... 8-1

9DISMANTLING & DISPOSAL

9.1 Dismantling........................................................................................................................ 9-1

9.2 Disposal............................................................................................................................. 9-1

9.2.1 Disposal method............................................................................................... 9-1

9.2.2 Waste separation ............................................................................................. 9-1