8/14

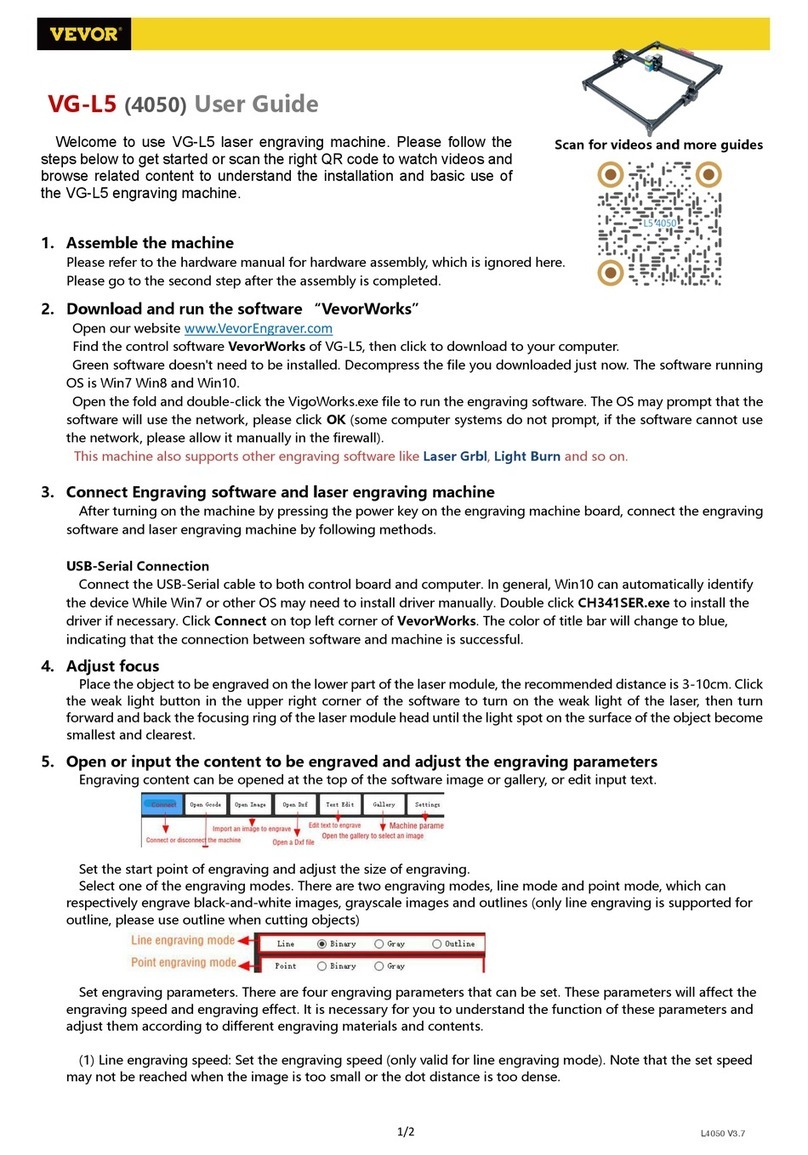

Supported functions:

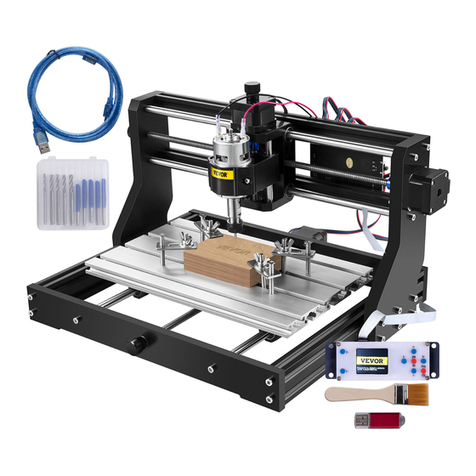

(1) Controlling GRBL-based CNC-machine via console commands, buttons on form, numpad.

(2) Monitoring CNC-machine state.

(3) Load, edit, save and send G-code files to CNC-machine.

(4) Visualizing G-code files.

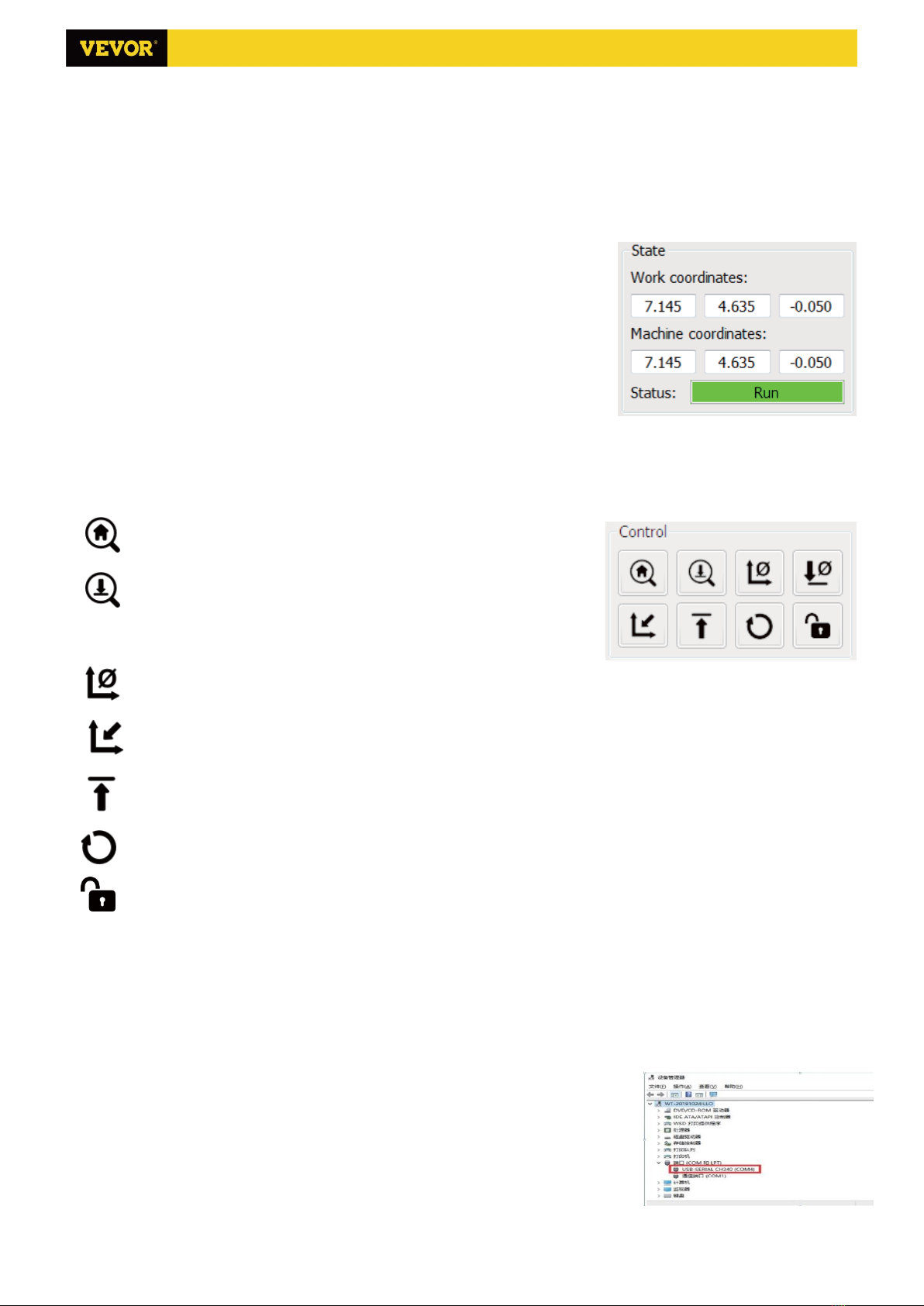

4.1 States

Work coordinates:

Represents current X, Y & Z local coordinates of the CNC.

Machine coordinates:

Represents current X, Y & Z absolute machine coordinates.

One of following CNC status:

Idle - waiting for a G-code command Running - running a G-code command

Home - homing cycle is executing

Check - G-code command check mode is turned on

Hold - paused by a "!" command, need to be restarted by a "~" command

Alarm - CNC doesn't know where it is and blocks all G-code commands

Door - door sensor has triggered

4.2 Control

Home button

Starts the homing cycle procedure with "$H" command

Z-probe

Starts the zero Z-axis search procedure using the command specified in the

settings ("Z-probe commands" box). Example command: G91G21;

G38.2Z-30F100; G0Z1; G38.2Z-1F10

Zero XY

Zeroes the "X" and "Y" coordinates in the local coordinate system. Also retains an local system offset ("G92") for later use.

Restore XYZ

Restores local system coordinates with "G92" command.

Safe Z

Moves tool by "Z"-axis to safe position. Position coordinate can be specified in the "Safe Z" setting. Position must be

specified in machine coordinates.

Reset

Resets CNC with "CTRL+X" command

Unlock Unlocks CNC with "$X" command.

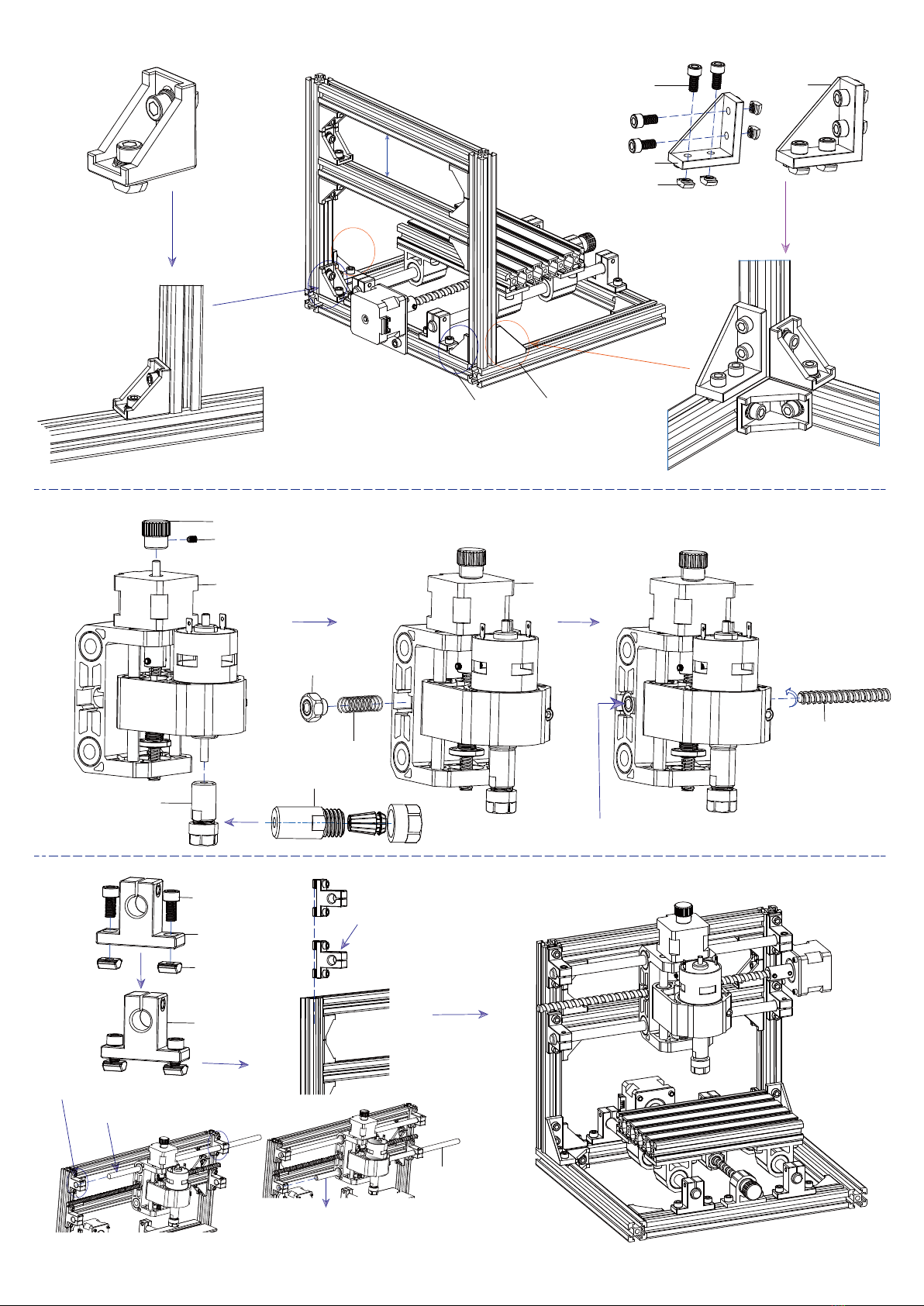

4.3 Software using steps

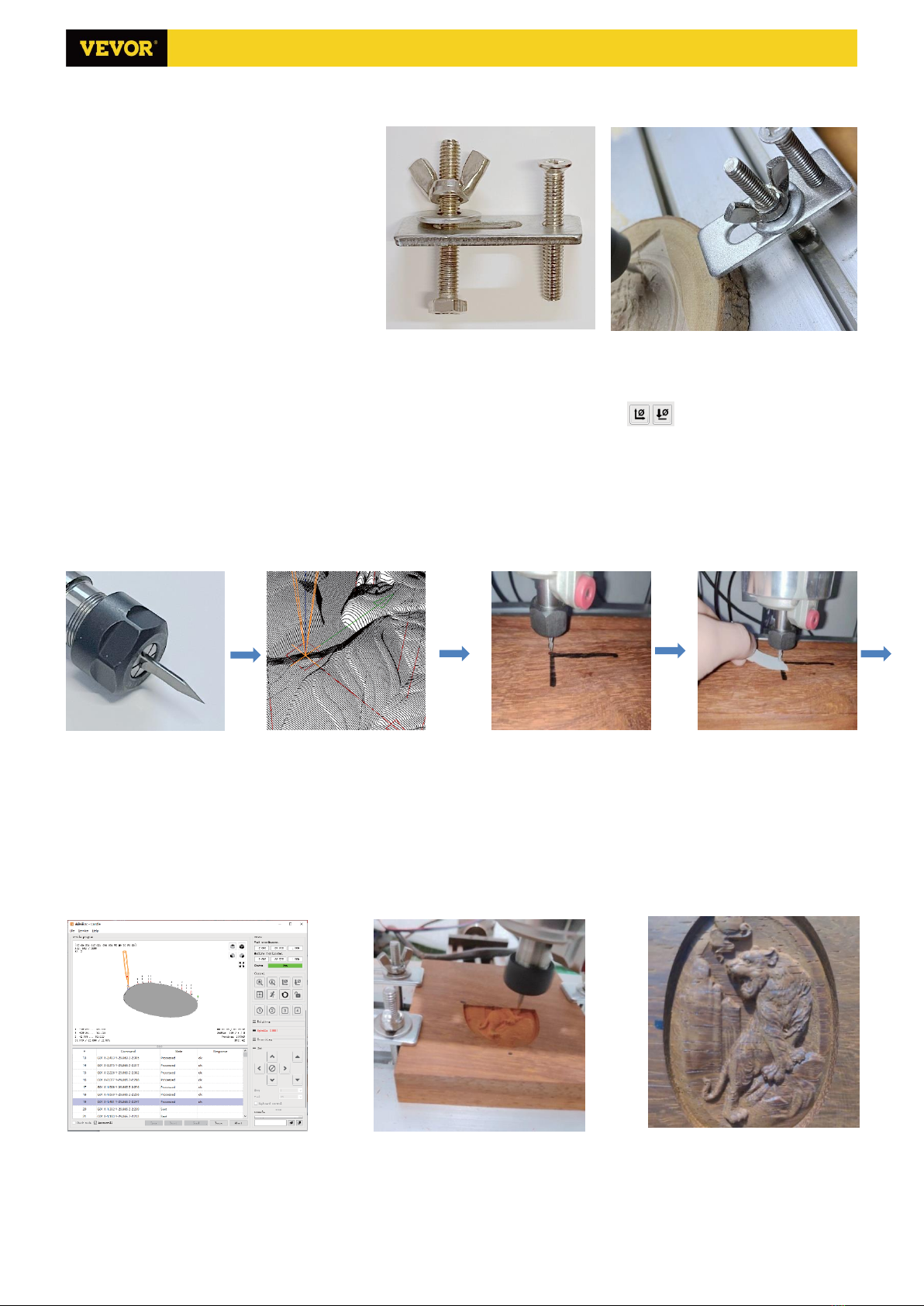

(1). Install the driver

For the first time use, please connect the device to the computer via USB cable, and click the CH340-Driver.exe file in

the driver folder to install the driver. Under normal circumstances, the Win10 system will automatically identify and

install the driver. For Win7 and Win8 systems, please install it manually.

(2) Set the port and connection

After installing the driver, open the device manager of the computer and click on

the port option to see the content inside the red box on the screen shown in the

figure below (the port information is in brackets).

Remember the port information queried above, switch to the Candle software

interface and click the "Settings" option in the upper left corner. Selecting the setting

will pop up the setting window. Under "Connection", select the port name you

queried, select the baud rate 115200, and then click the "ok" to finish the setting.

S1610 Ver 1.2