FLUID COUPLING WITH DELAYED-FILL CHAMBER

ADVANTAGES

4

TRANSFLUID FLUID COUPLINGS WITH A DELAYED FILL

CHAMBER

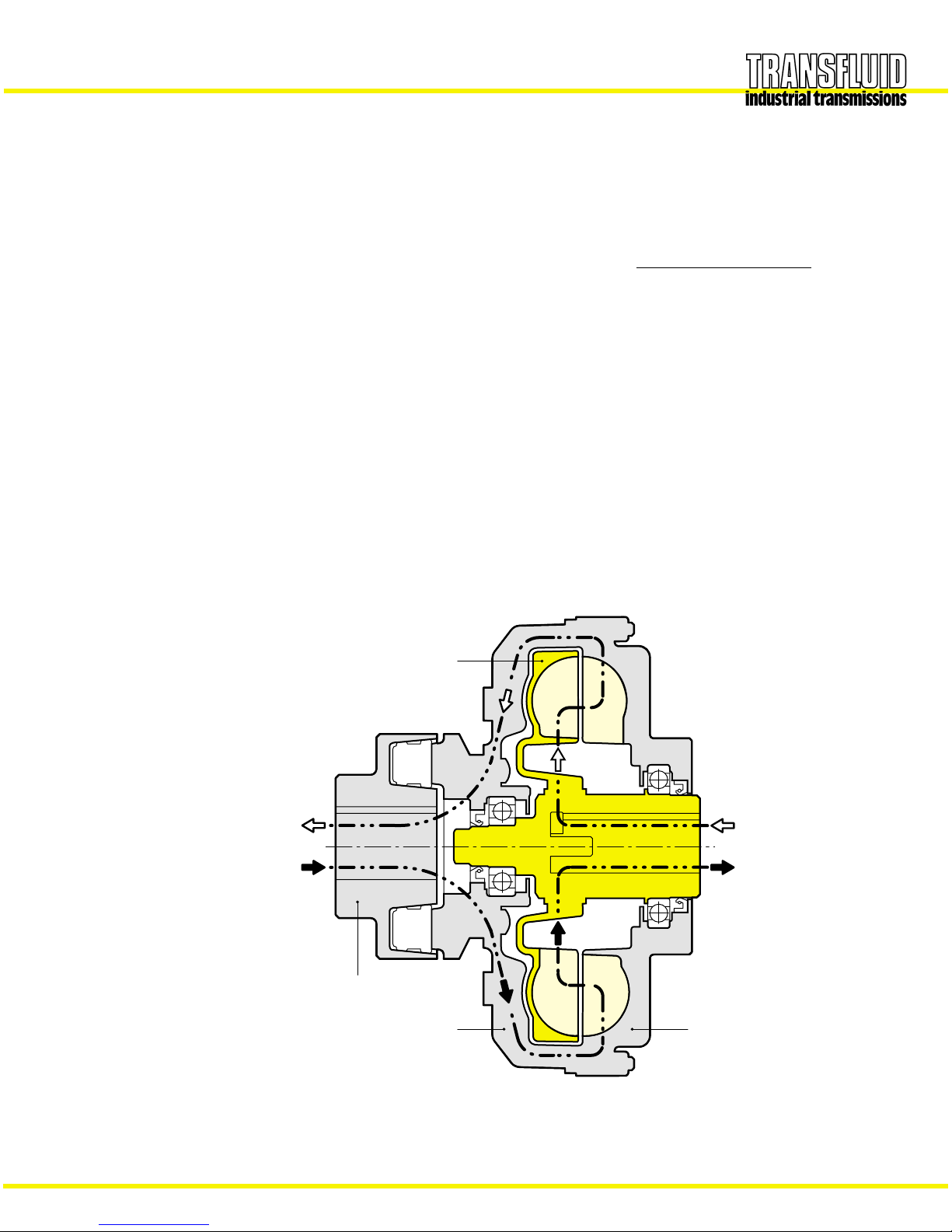

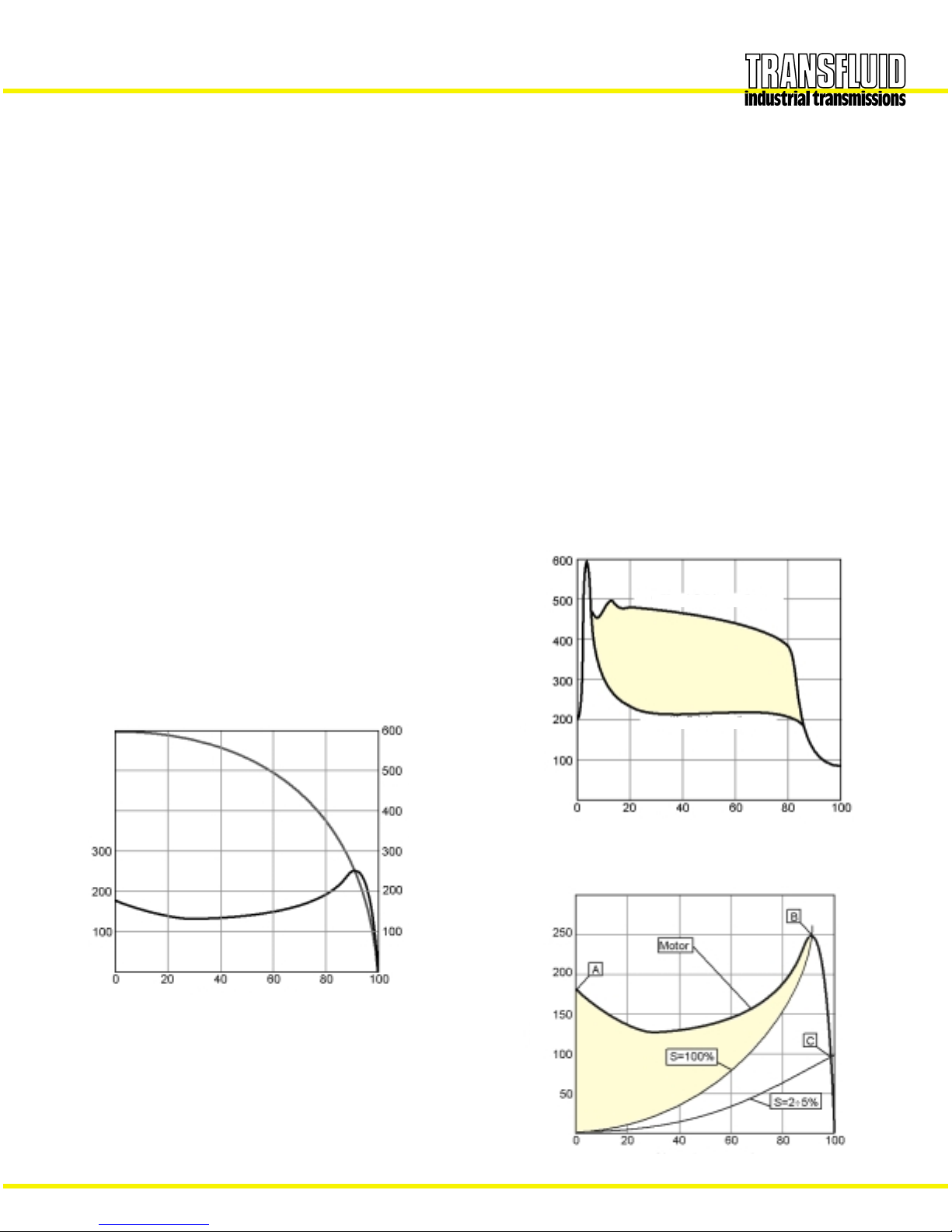

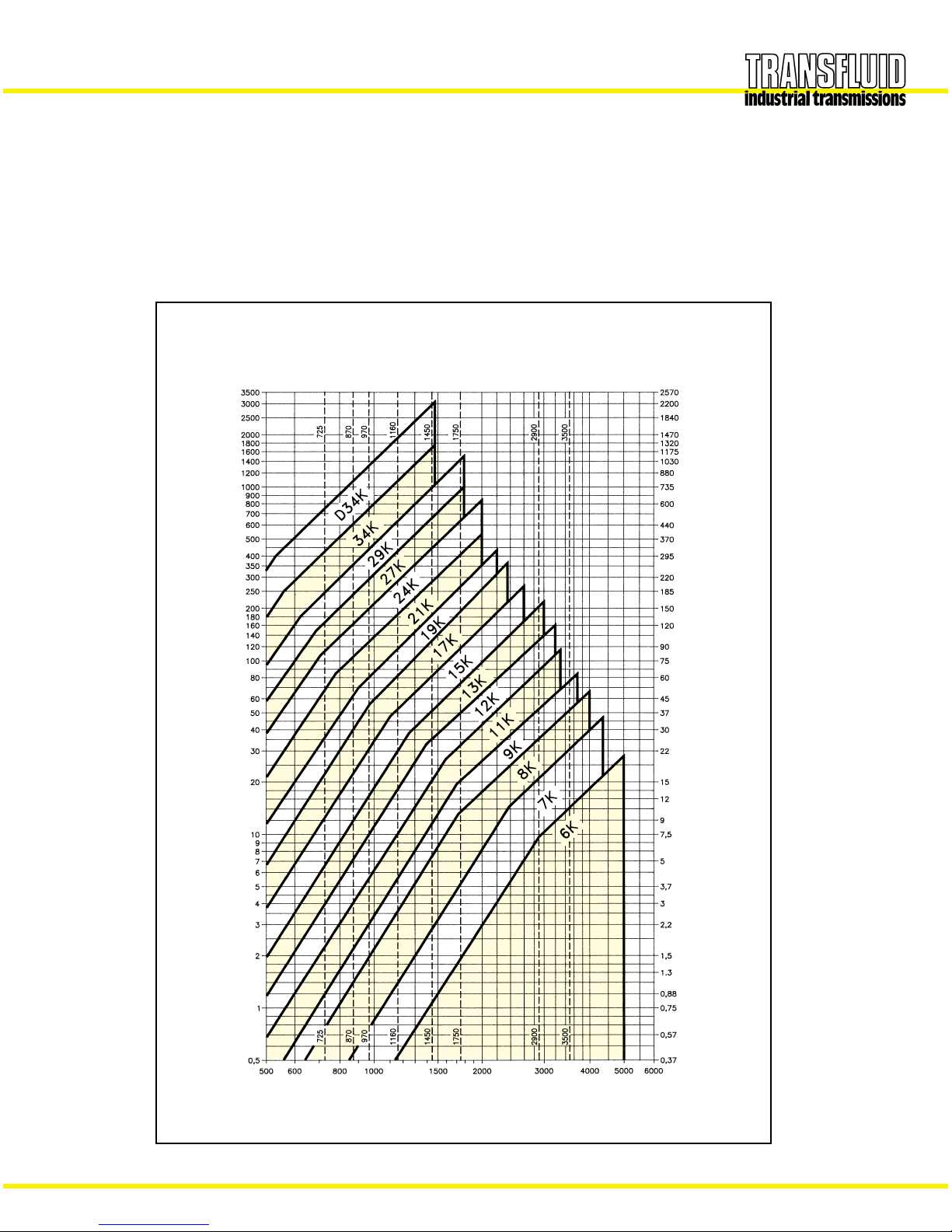

With the standard circuit in a maximum oil fill condition, fluid

couplings may transmit over 200% of the nominal motor torque. It

is possible to decrease the starting torque down to 160% of the

nominal torque, by decreasing oil fill. This, however, leads to higher

slip and working temperature in the fluid coupling, during the

steady running conditions.

The most convenient solution to provide lower starting torque while

maintaining low slip at steady running is to provide a delayed fill

chamber mounted on the main circuit. This chamber holds a

percentage of the oil which at start-up is gradually released into the

main circuit through calibrated bleed orifices as the coupling

spins.For couplings sized 15CK and above these orifices are set in

externally mounted valves.

The external mounting provides easy adjustment of the orifice size

which controls starting time and the maximum transmitted torque.

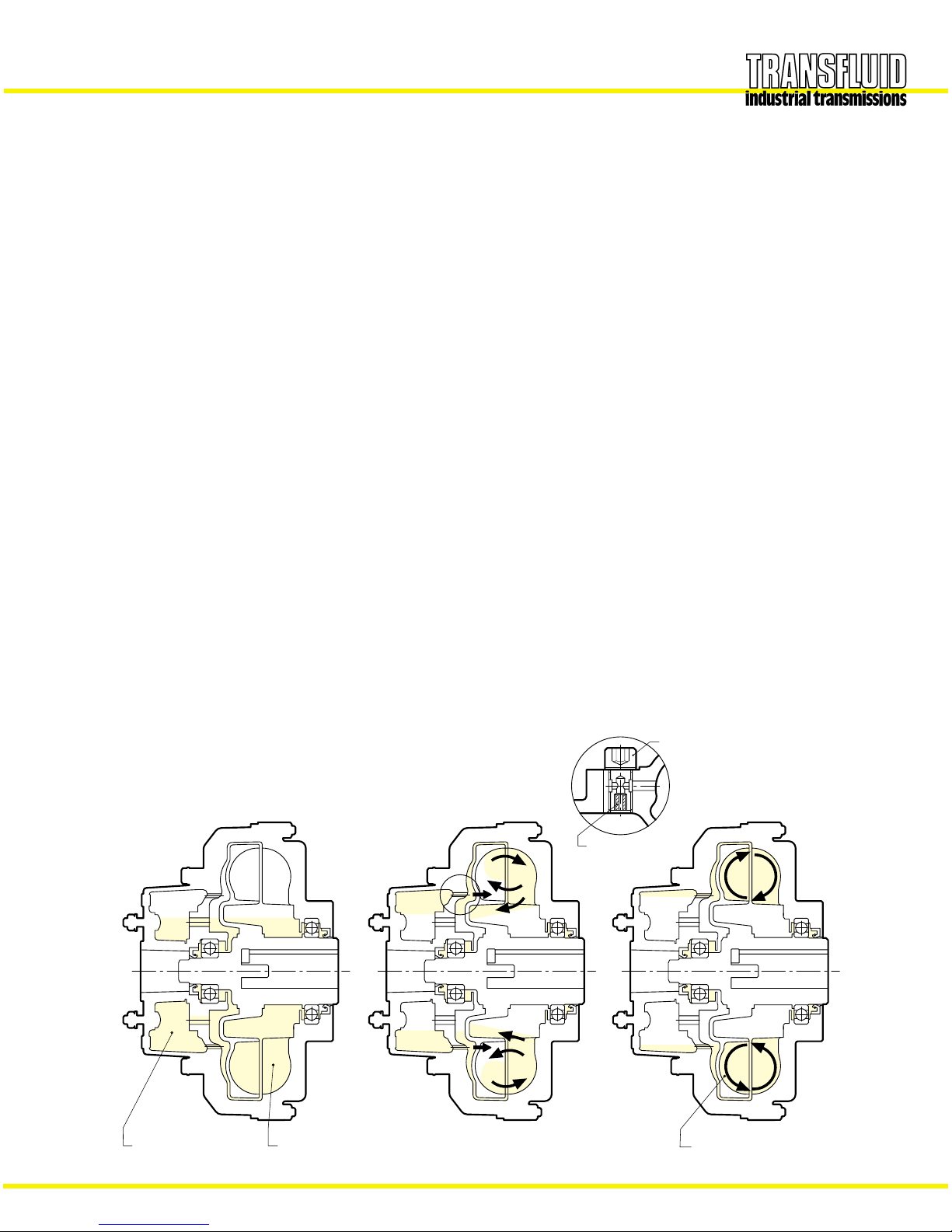

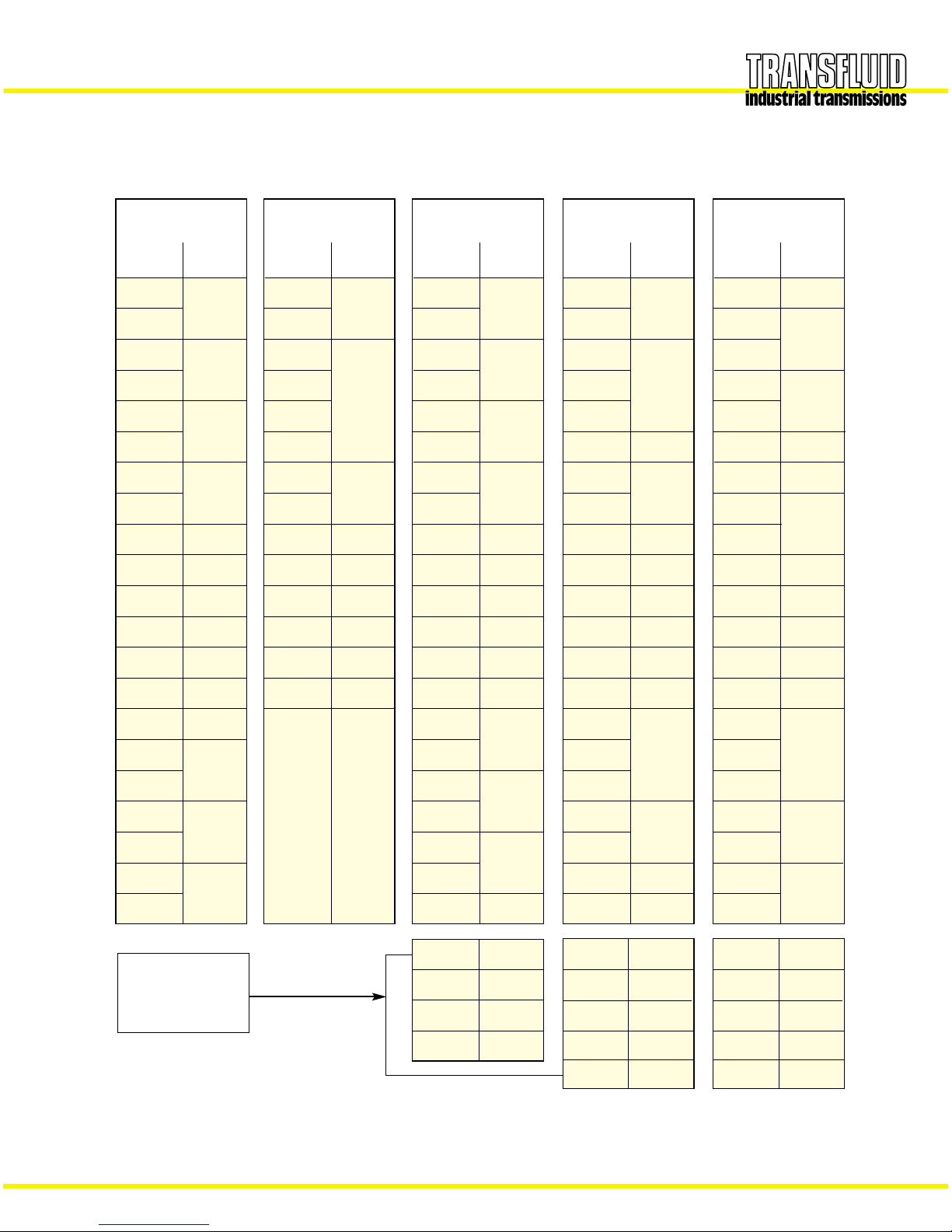

When the coupling is at rest, the delay fill chamber contains a

percentage of oil quantity in the main circuit (Fig. 4a).This reduces

the torque the coupling transmits and allows the motor to quickly

reach its steady running speed, as if it was started without load.

As the coupling accelerates, the oil flows from the delay fill

chamber to the main circuit (Fig. 4b) at a rate proportional to the

coupling’s rotational speed.

The oil continues to transfer from the delay fill chamber the to the

main circuit emptying the delay fill chamber. Once all the oil is in

the main circuit (Fig. 4c) the coupling is then transmitting 100% of

the motor torque and the minimum slip value is reached.

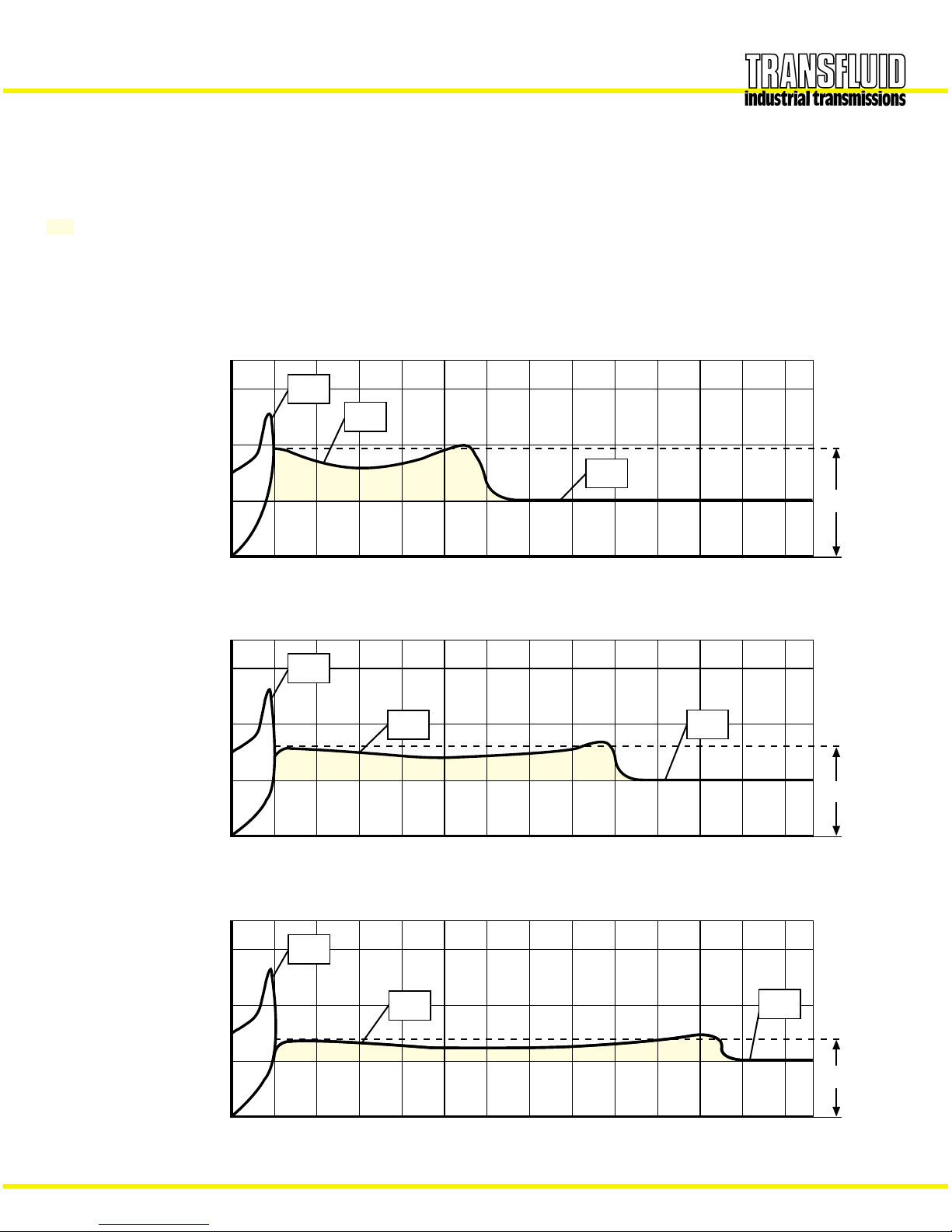

With a single delay fill chamber, the ratio between starting and

nominal torque may reach 150 %.This ratio can be reduced to 120 %

with a double delay fill chamber. This lower start-up torque

results from a smaller amount of oil in the main circuit due to more

oil in the bigger delay fill chamber.

Fluid couplings with single or double delay fill chamber provide

very smooth start-ups with low start-up torque transmission, and

this makes them excellent for applications with high inertia loads

and for use on belt conveyors.

The single size chamber is available from size 11CK and above.

The double size chamber is available from size 15CCK and above

SUMMARY OF THE ADVANTAGES GIVEN BY FLUID

COUPLINGS:

–Very smooth start-ups

–Reduction of absorbed current during the starting phase: the

motor starts with very low load

–Protection of the motor and the driven machine from jams and

overloads

–Utilization of asynchronous squirrel cage motors instead of

special motors with soft start devices

–Longer life and up time of the whole drive train, thanks to the

protection provided by the fluid coupling

–Energy saving, due to current peak reduction

–Limits starting torque to 120% with a double delayed fill

chamber

–Same torque at input and output: the motor can supply the

maximum torque even when load is jammed

–Torsional vibration absorption for internal combustion engines,

thanks to the presence of a fluid as a power transmission

element

–Possibility to achieve a high number of start-ups, or reversal of

the rotational direction.

–Load balancing with dual motor drive: fluid couplings

automatically adjust load speed to the individual motor’s speed

–High efficiency and minimum maintenance

–Viton rotating seals and O-rings

–High resistance to corrosion by using cast aluminum for the

major coupling parts and providing anticorrosion treatment on

smaller cast iron and steel parts