See the entire line of Klamp System

TM

Components at:

WWW.KREGTOOL.COM

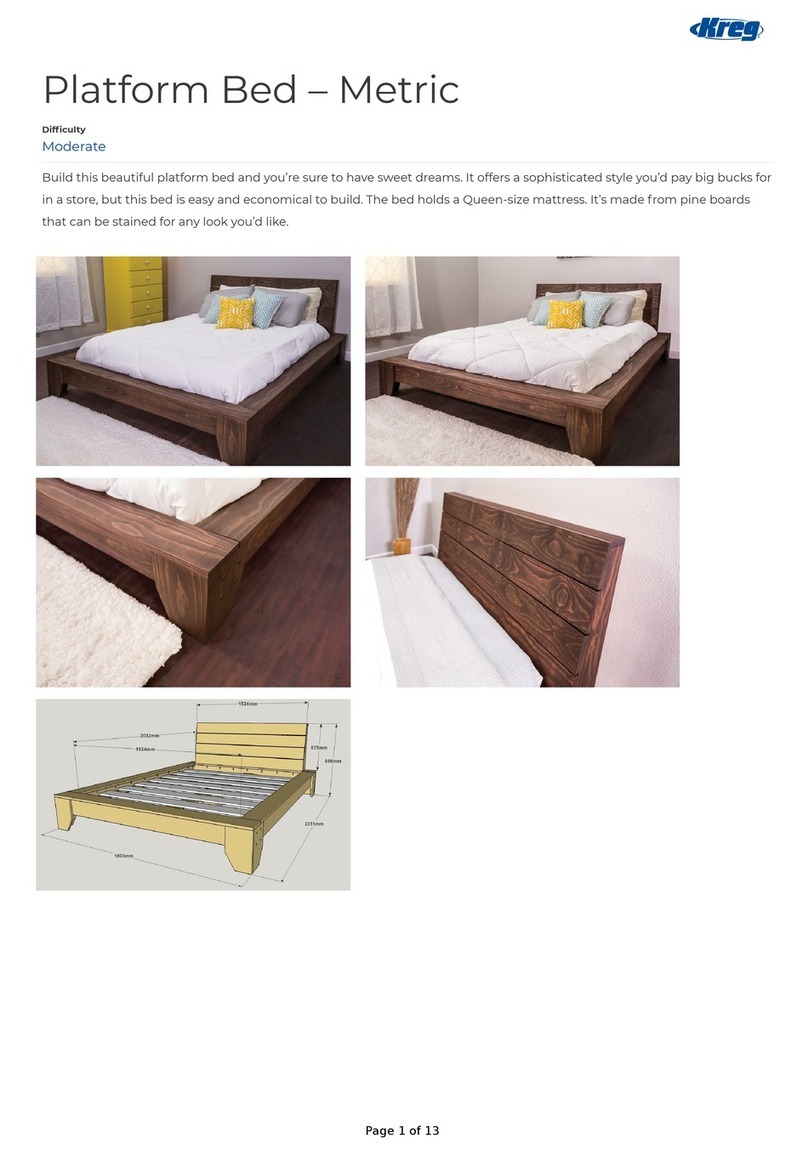

The Glide Pad.

This pad allows the Bench Klamp™ to slide smoothly across the Klamp Trak™ and Klamp Plate™.

Begin by using a dry cloth or paper towel to remove any excess oil from the base of the Klamp.

Separate the Plastic Glide Pad from its paper backing. Then, carefully center and adhere the pad

to the base of the Bench Klamp™, as shown at left. Any part of the pad which extends beyond

the Bench Klamp™’s base may be trimmed off.

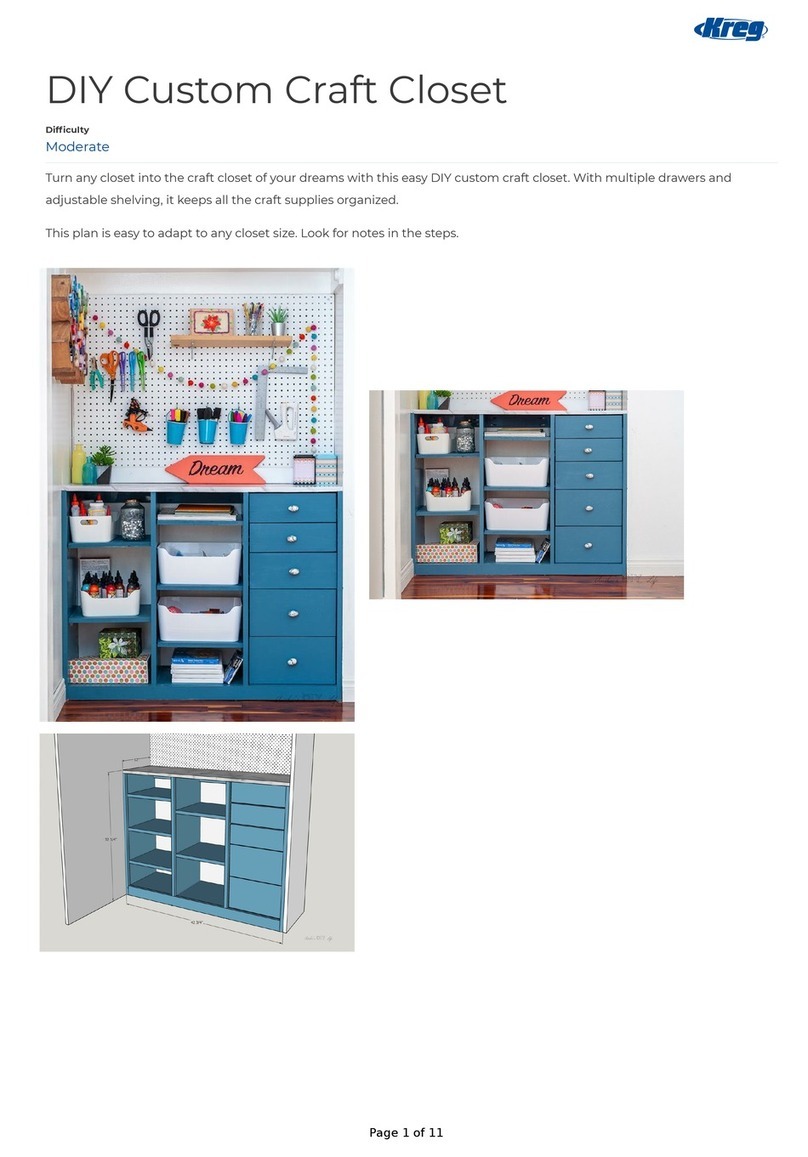

The Clamp Pad.

The Clamp Pad protects your workpieces from being marred or otherwise damaged by the Bench

Klamp™. Depending on the type of work you are doing, and the hardness of your stock, you may

add or remove the Clamp Pad at your discretion.

The Anchoring Screw.

This Inter-Lok Anchoring Screw serves as the foundation of the entire Klamp System™. With it,

the Bench Klamp™ can be moved to the Klamp Plate™ and Klamp Trak™ quickly and easily, and

removed again to retain a flat work surface. Begin by threading the Anchoring Screw into the

base of the Bench KlampTM. Start with the Anchoring Screw roughly ½ of the way in, and test

the fit on the Klamp Plate™ or Klamp Trak™. Continue to adjust the Anchoring Screw until it

‘slip-fits’ into the slot without difficulty, and still rotates freely.

Bench KlampTM Instructions

Introduction

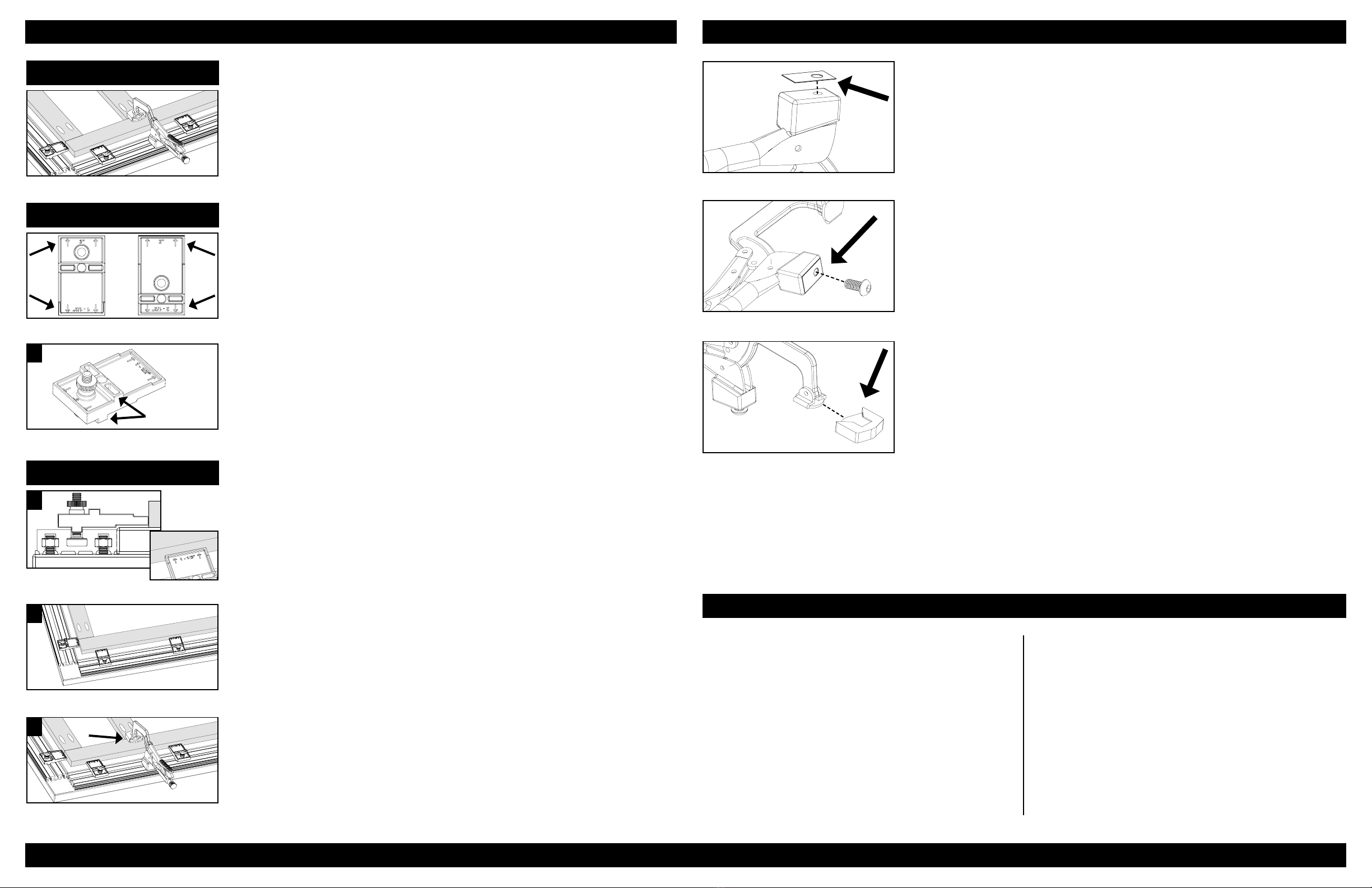

Our Klamp BlocksTM are designed to allow for quick registration of your workpieces to

the edge of the Klamp Trak™ and to precisely center joints under the Bench Klamp’sTM

rubber pad.

To center the Bench Klamp™ on joints in a repeatable fashion, the Klamp BlocksTM must

first be set correctly. There are 4 dimensions listed on each Klamp BlockTM (1-½”, 2”,

2-½”, 3”), which relate to the width of your stock to be joined. For instance, if you

are working with 1-1/2” wide stock, positioning your blocks with the 1-1/2” marking

adjacent to the stock will place the center of your Bench Klamp™ on the joint line

between mating workpieces.

Getting Started

To set your Klamp Blocks™, start by finding your stock’s width and locating the same

dimension on your Klamp Block™. (We will be using 1-1/2” wide stock in this example.)

Then, insert the t-bolt into the Alignment Tab opposite the marking, as shown in

image 1. Once the Bolt is through, thread the plastic nut onto the bolt so that the

bolt slightly protrudes from the other side. Repeat as necessary to the remaining

Klamp Blocks.

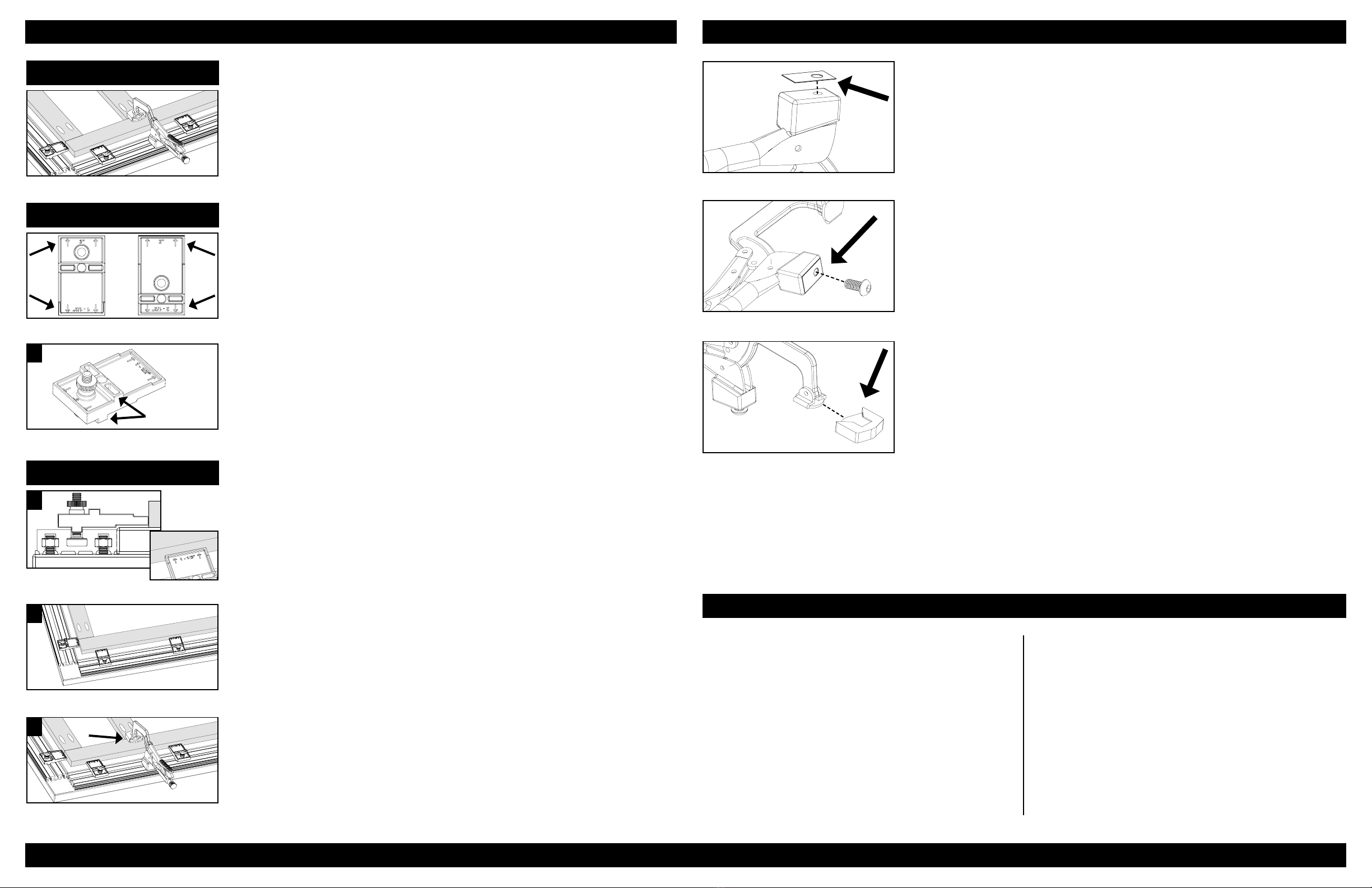

Clamping a Joint

With the correct marking facing your workpiece, insert your Klamp Block™ into the

t-slot of the Klamp Trak™, as shown in image 3.

4.

5.

The Klamp Block™ will now slide in either direction along the length of the trak.

Position the block in its desired location and lock it into place by tightening the plastic

nut. Add a second block to the trak and slide your workpiece up against them, parallel

to the trak, as shown in image 4.

Now that your workpiece is in place parallel to the Trak, the center of the Bench

Klamp’sTM clamp pad will be perfectly centered on the far side of the workpiece, making

it easy to clamp on the center of any joint. This is especially useful for Pocket-Screw

Joinery, as shown in image 5.

3.

1.

Alignment Tabs

Klamp BlocksTM Instructions

Cleaning

The slick melamine coating on the Table Top does a

good job of resisting glue but may need some basic

cleaning from time to time. Cleaning the surface

frequently and keeping it free from build-up will

lengthen the life of the top and keep the surface as

smooth/useful as possible. For additional protection

against glue, we recommend coating the surface with

Bates Glue Release (1-888-363-2628). Be sure to follow

the respective product’s directions during application.

Replacement Top

In the event that a replacement top for your Klamp

Table™ is required, contact Kreg directly. Our customer

service professionals will be able to help you order your

replacement top and will get it sent to you as soon as

possible.

Klamp TableTM Maintenance

800.447.8638