- 9 -

English

5 - USE CONDITIONS AND PERIOD OF USE

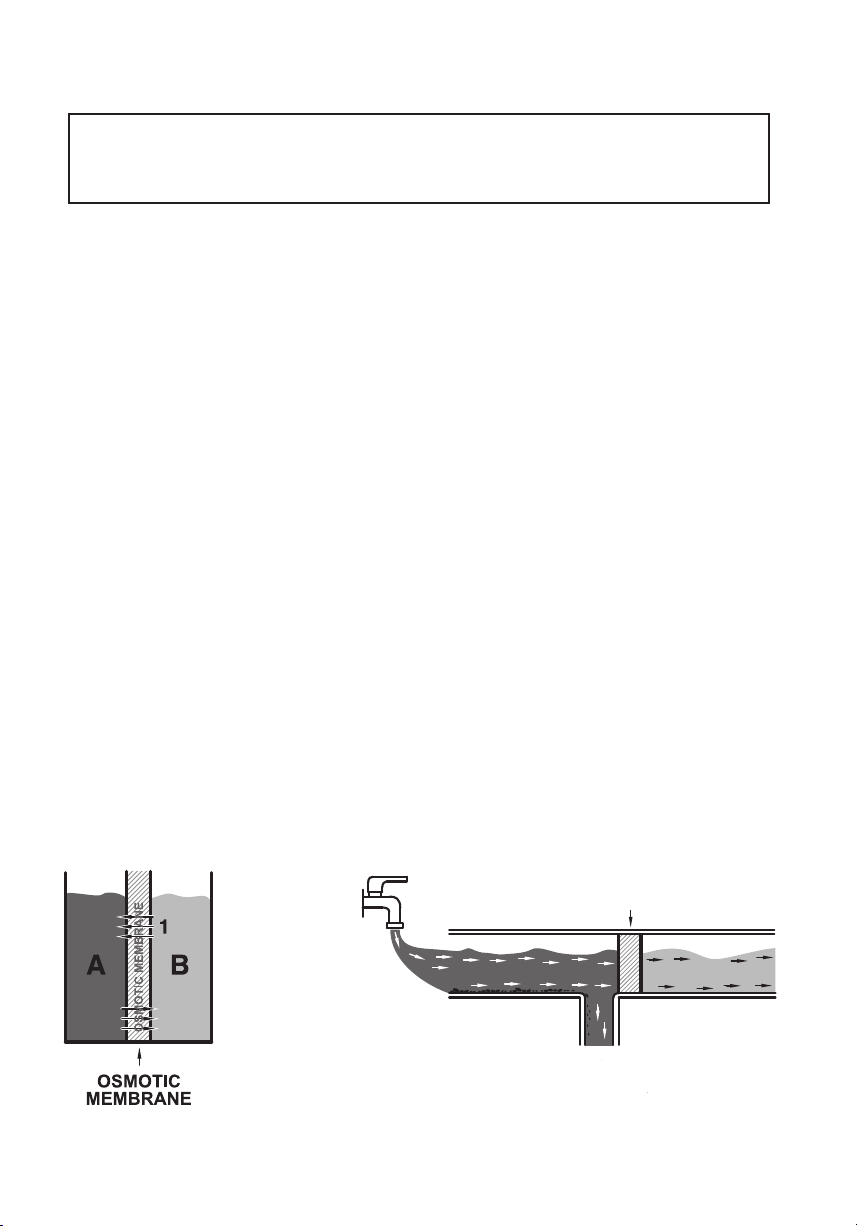

Reverse osmosis system, processing essentially consists of adjustable reduction in xed

residue in treated water.

The machine is intended for use in a closed and protected environment, not outdoors.

Its use consists of treating and supplying drinking water for human consumption and

for technical use. Any other use is not permitted.

Attention: this equipment requires regular, periodic maintenance to

guarantee the requirements of treated drinking water and to maintain the

improvements as declared by the manufacturer of the reverse osmosis

system for domestic use for the treatment of drinking water. Equipment for

the treatment of drinking water. Input water must be drinkable according to

Ministerial Decree no. 31 of 2 February 2001.

Summary table for time of use and maintenance methods

Time Assessment method Intervention to follow

Period of use 10 years Installation booklet

present

Service by

manufacturer or

disposal

Duration active carbon

lters

Most critical condition:

12 months or used up Board signalling Replacement and

sanitisation

Membrane life Most critical condition:

2 years or used up

Installation booklet

present

Replacement and

sanitisation

Machine off without

electrical supply

Over 10 days or time

uncontrolled Ascertain by calendar Filter replacement and

sanitisation

Drainage restrictor Each lter change Board signalling Restrictor replacement

For the maintenance method, see the specic chapter.

To dene the period of use and the maintenance methods, specic tests were carried

out. Furthermore, a water sample was analysed to verify the altered parameters and

compliance with MD 31 on 2 February 2001.

Important: After installation, the machine must be powered for hygiene

reasons (ushing) and to have correct management of the exhausted lter.

Sanitise and replace the pre-lter after periods of disuse longer than 10 days

in the absence of electrical power supply.

The results of drinkability testing of the water taken before and after SO3100K are outlined

below. Both tests, carried out by an accredited institute, conrm the water to be drinkable.

In particular, it is conrmed that treatment efficiently combats various parameters, in

particular conductivity, hardness and various chemical substances.