ENGLISH

3

Page

SERIAL NUMBER LOCATIONS.............................................4

Chassis number................................................................4

Engine number, engine type (125/200)............................4

Engine number, engine type (250/300/380)....................4

OPERATION INSTRUMENTS ...............................................4

Clutch lever .....................................................................4

Hand brake lever..............................................................4

Speedometer, indicator lamp (EXC)..................................5

Odometer (EXC USA).......................................................5

Speedometer, indicator lamps (EGS).................................5

Ignition lock.....................................................................5

Short circuit button (SX)...................................................6

Combination switch (EXC)................................................6

Headlamp switch (EXC USA)............................................6

Flasher switch...................................................................6

Emergency OFF switch (Australia)....................................6

Filler cap...........................................................................7

Refueling, fuel..................................................................7

Fuel tap............................................................................7

Choke knob .....................................................................8

Shift lever.........................................................................8

Kickstarter........................................................................8

Foot brake pedal..............................................................8

Compression damping of fork..........................................8

Rebound damping of fork................................................9

Compression damping of shock absorber.........................9

Rebound damping of shock absorber...............................9

Steering lock ....................................................................9

Center stand ....................................................................9

DRIVING INSTRUCTIONS ..................................................10

PERIODIC LUBRICATION- AND MAINTENANCE-SCHEDULE

.....12

MAINTENANCE WORK ON CHASSIS AND ENGINE ..........13

Changing the original position of the clutch lever

..............13

Checking and adjusting the steering head bearing..........13

Pivot bearing..................................................................14

Check chain tension ......................................................14

Correct chain tension ....................................................14

Chain maintenance ........................................................14

Chain wear ....................................................................15

General informations about KTM disc brakes ................15

Adjusting of free travel at the hand brake lever..............15

Checking of brake fluid level - front brake......................16

Refilling the front brake fluid reservoir............................16

Page

Checking the front brake pads .......................................16

Replacing the front brake pads.......................................16

Changing the basic position of the brake pedal..............17

Checking rear brake fluid level .......................................17

Refilling the rear brake fluid reservoir.............................17

Checking the rear brake pads.........................................18

Replacing the rear brake pads ........................................18

Dismounting and mounting the front wheel...................18

Dismounting and mounting the rear wheel ....................19

Tires, air pressure ...........................................................19

Checking spoke tension..................................................19

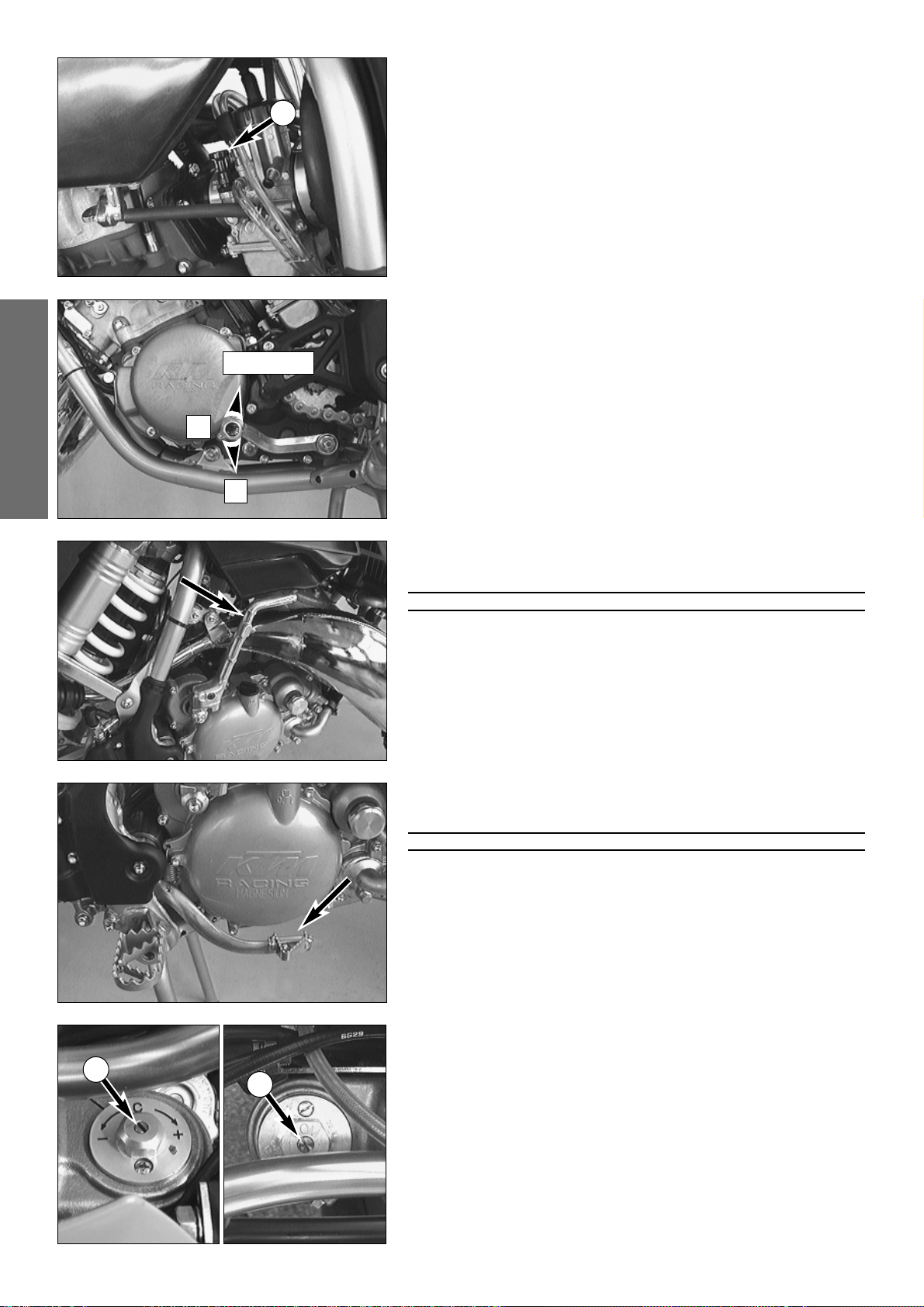

Fuse (CH, Singapore) .....................................................20

Battery (CH, Singapore) .................................................20

Replacing head light lamp (H4)......................................20

Cooling system...............................................................20

Checking the coolant level .............................................21

Bleeding the cooling system...........................................21

Cleaning the air filter......................................................22

Exhaust system...............................................................22

Cleaning the spark arrestor (EXC USA)...........................22

Carburetor adjustment...................................................23

Checking the float level..................................................24

Checking the oil level of the hydraulic clutch..................24

Bleeding of the hydraulic clutch......................................24

Check transmission oil level (125/200)...........................25

Changing the transmission oil (125/200)........................25

Check transmission oil level (250/300/380) ...................25

Changing the transmission oil (250/300/380)................25

CLEANING..........................................................................26

CONSERVATION FOR WINTER OPERATION ....................26

STORAGE...........................................................................26

Use after period of storage .................................................26

TECHNICAL SPECIFICATIONS - CHASSIS (125/200)..........27

TECHNICAL SPECIFICATIONS - ENGINE (125/200)

...................28

TECHNICAL SPECIFICATIONS - ENGINE (250/300/380)

Only USA

........................................................................30

TECHNICAL SPECIFICATIONS - ENGINE (250/300/380)

All models out of USA

.......................................................32

TECHNICAL SPECIFICATIONS - CHASSIS (250/300/380).....34

WIRING DIAGRAMME, CARBURETOR SETTING.......Appendix

INDEX