3 WORK 6

602674-11

–Position the front fender. Mount and tighten screws 2.

Guideline

Remaining screws, chassis M6 10 Nm (7.4 lbf ft)

3.6 Refueling

Danger

Fire hazard Fuel is highly flammable.

–Never refuel the vehicle near open flames or burning cigarettes, and always switch off the engine first. Be careful that no

fuel is spilt, especially on hot vehicle components. Clean up spilt fuel immediately.

–The fuel in the fuel tank expands when warm and may emerge if overfilled. Follow the instructions on refueling.

Warning

Danger of poisoning Fuel is poisonous and a health hazard.

–Fuel must not come into contact with the skin, eyes, or clothing. Do not breathe in the fuel vapors. If contact occurs with

the eyes, rinse with water immediately and contact a physician. Immediately clean contaminated areas on the skin with

soap and water. If fuel is swallowed, contact a physician immediately. Change clothing that is contaminated with fuel.

Warning

Environmental hazard Improper handling of fuel is a danger to the environment.

–Do not allow fuel to get into the ground water, the ground, or the sewage system.

–Switch off the engine.

–Open the filler cap. ( p. 6)

400382-10

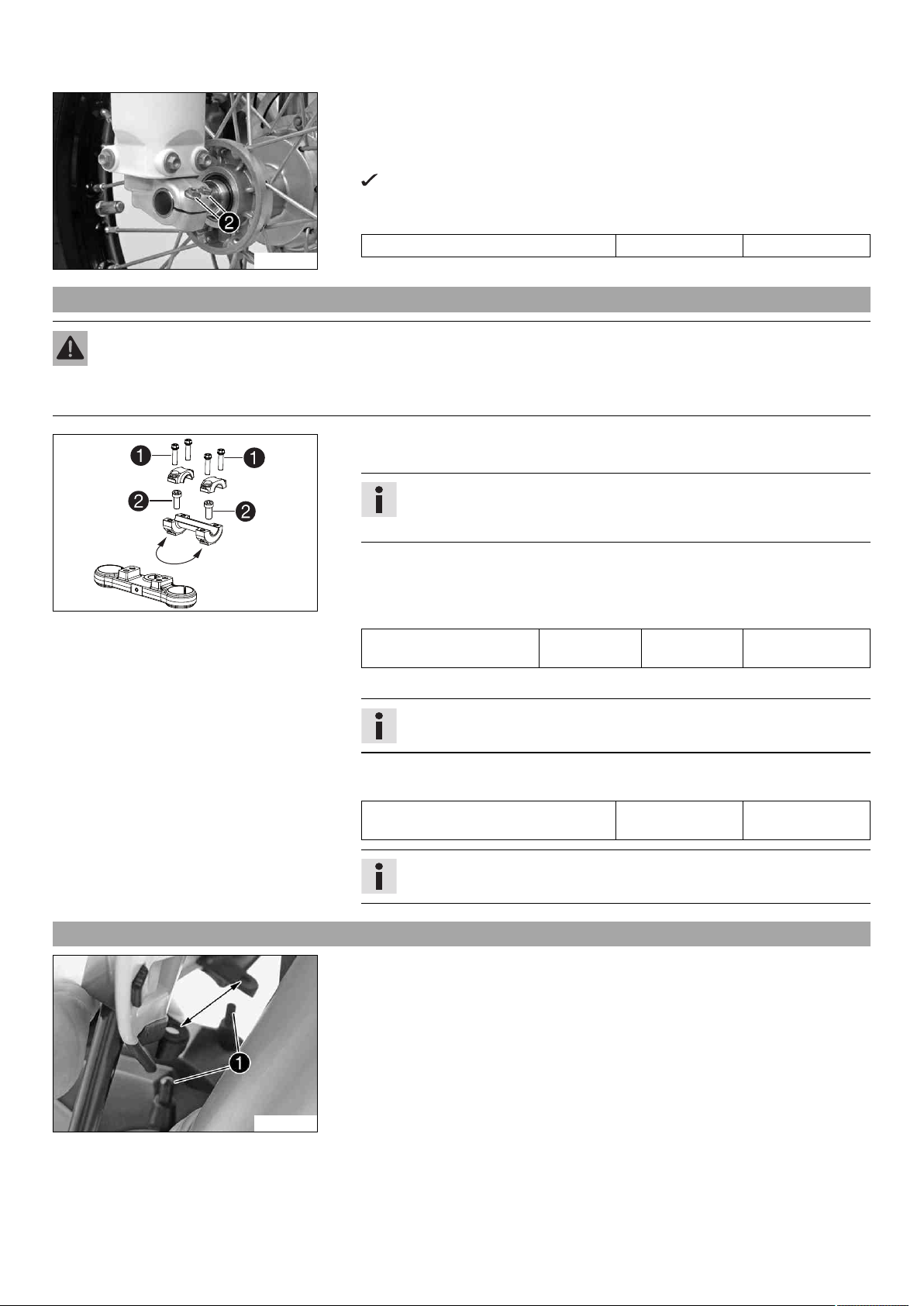

–Fill the fuel tank with fuel up to measurement A.

Guideline

Measurement of A35 mm (1.38 in)

Fuel tank capac-

ity, approx.

3.5 l (3.7 qt.) Super unleaded gasoline (95 octane),

mixed with 2-stroke engine oil (1:60)

( p. 9)

2-stroke engine oil ( p. 9)

–Close the filler cap. ( p. 7)

3.7 Opening the filler cap

Danger

Fire hazard Fuel is highly flammable.

–Never refuel the vehicle near open flames or burning cigarettes, and always switch off the engine first. Be careful that no

fuel is spilt, especially on hot vehicle components. Clean up spilt fuel immediately.

–The fuel in the fuel tank expands when warm and may emerge if overfilled. Follow the instructions on refueling.

Warning

Danger of poisoning Fuel is poisonous and a health hazard.

–Fuel must not come into contact with the skin, eyes, or clothing. Do not breathe in the fuel vapors. If contact occurs with

the eyes, rinse with water immediately and contact a physician. Immediately clean contaminated areas on the skin with

soap and water. If fuel is swallowed, contact a physician immediately. Change clothing that is contaminated with fuel.

Store fuel properly in a suitable canister and keep away from children.

Warning

Environmental hazard Improper handling of fuel is a danger to the environment.

–Do not allow fuel to get into the ground water, the ground, or the sewage system.