Contents

1. Safety Notes .......................................................................................................... 2

Connect the water supply.................................................................................... 2

2. Operation ............................................................................................................... 3

3. Consumption/energy requirements ........................................................................ 4

3.1 Consumption values...................................................................................... 4

4. Function description/Technical Notes .................................................................... 5

4.1 General ......................................................................................................... 5

4.2 Motor control ................................................................................................. 7

4.3 Washing ........................................................................................................ 8

4.4 Fuzzy logic quantity sensing ......................................................................... 8

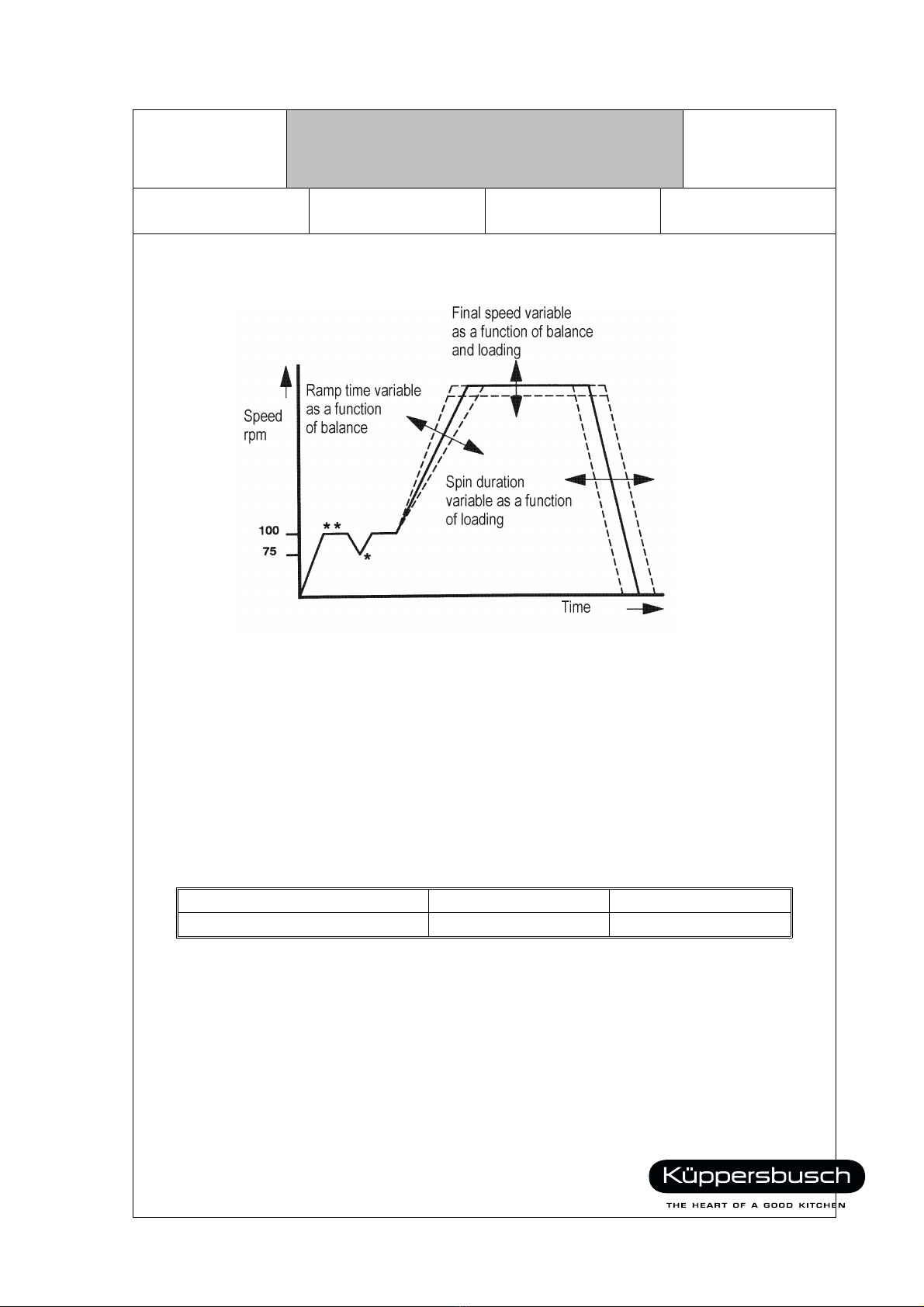

4.5 Fuzzy logic in the spin cycle.......................................................................... 9

5. Maintenance ........................................................................................................ 10

5.1 Variant coding: Service module .................................................................. 10

5.2 Variant coding: Control and power module ................................................. 12

6. Supplement ........................................................................................................ 13

7. Activate test program............................................................................................ 13

8. Select test program .............................................................................................. 14

8.1 Test program - motor .................................................................................. 14

8.2 Test program - solenoids, W-regulator, heater............................................ 15

8.3 Test program keys, speed and program selector........................................ 16

8.4 Test program - variant display..................................................................... 18

8.5 Test program - safety elements .................................................................. 19

8.6 Test program - consumer ............................................................................ 20

8.7 Safety-check ............................................................................................... 20

8.8 DEMO-Program .......................................................................................... 21

8.9 HES - Coupling module............................................................................... 21

9. Circuit digrams...................................................................................................... 21

10. Fault display ......................................................................................................... 32

VKS-H Repair Manual

IW 1409 H6-400-02-01

Responsible: Rutz Phone: (0209) 401-733 Fax: (0209) 401-743 ate: 21.04.1998

1For internal use only