Technical module

1

Copyright © 08/2008,Küschall AG

K-Series

K-Series 05

Changing configurations

Table of contents

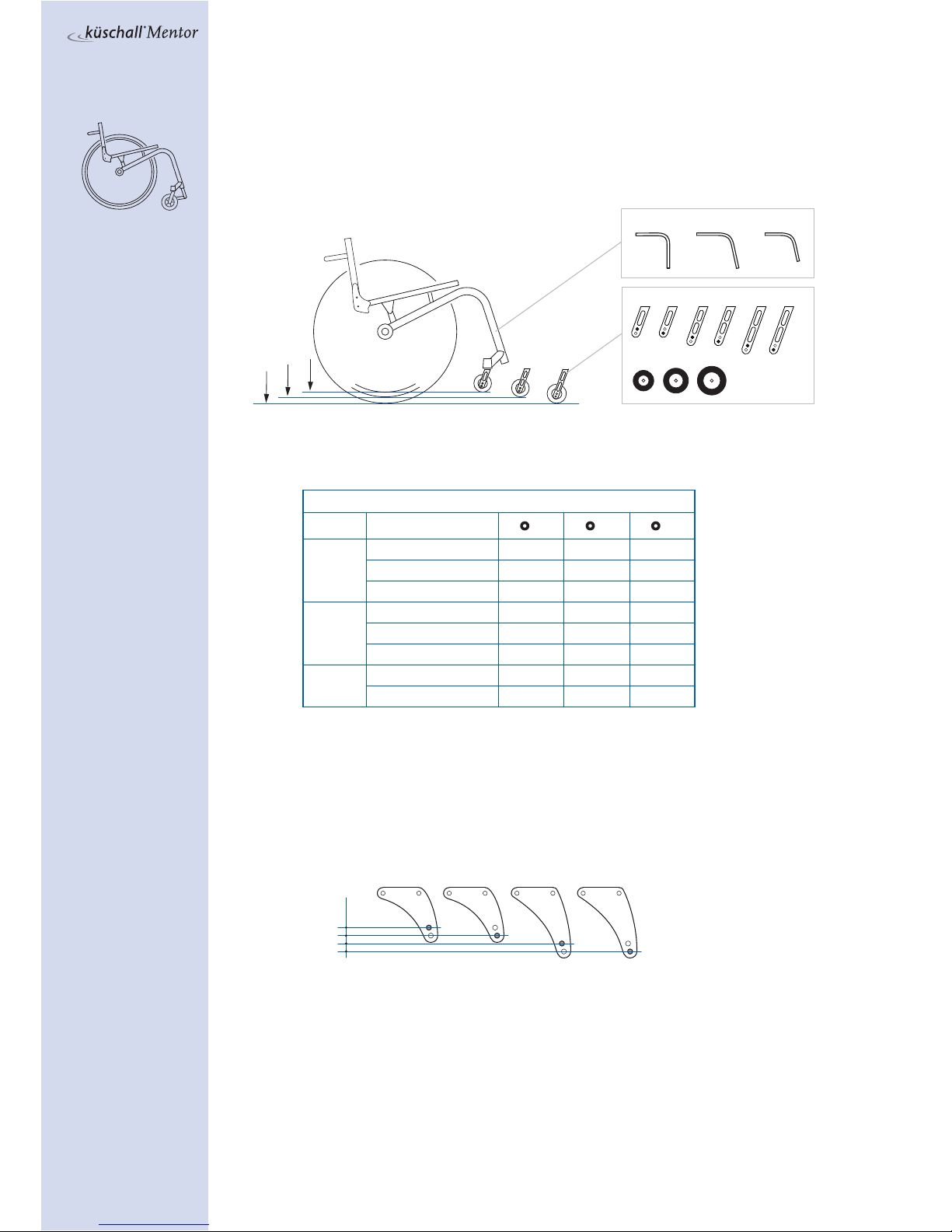

1 Adjustment possibilities 2

1.1 Seat width (SB) 2

1.2 Seat depth (ST) 2

1.3 Leg length (UL) 2

1.4 Rear seat height (SHh) 3

1.5 Front seat height (SHv) 4

1.6 Siderest / Armrest 5

1.7 Clothes guard / Mudguard 5

1.8 Backrest height 6

1.9 Backrest angle 6

2Assembly and adjustment methods 7

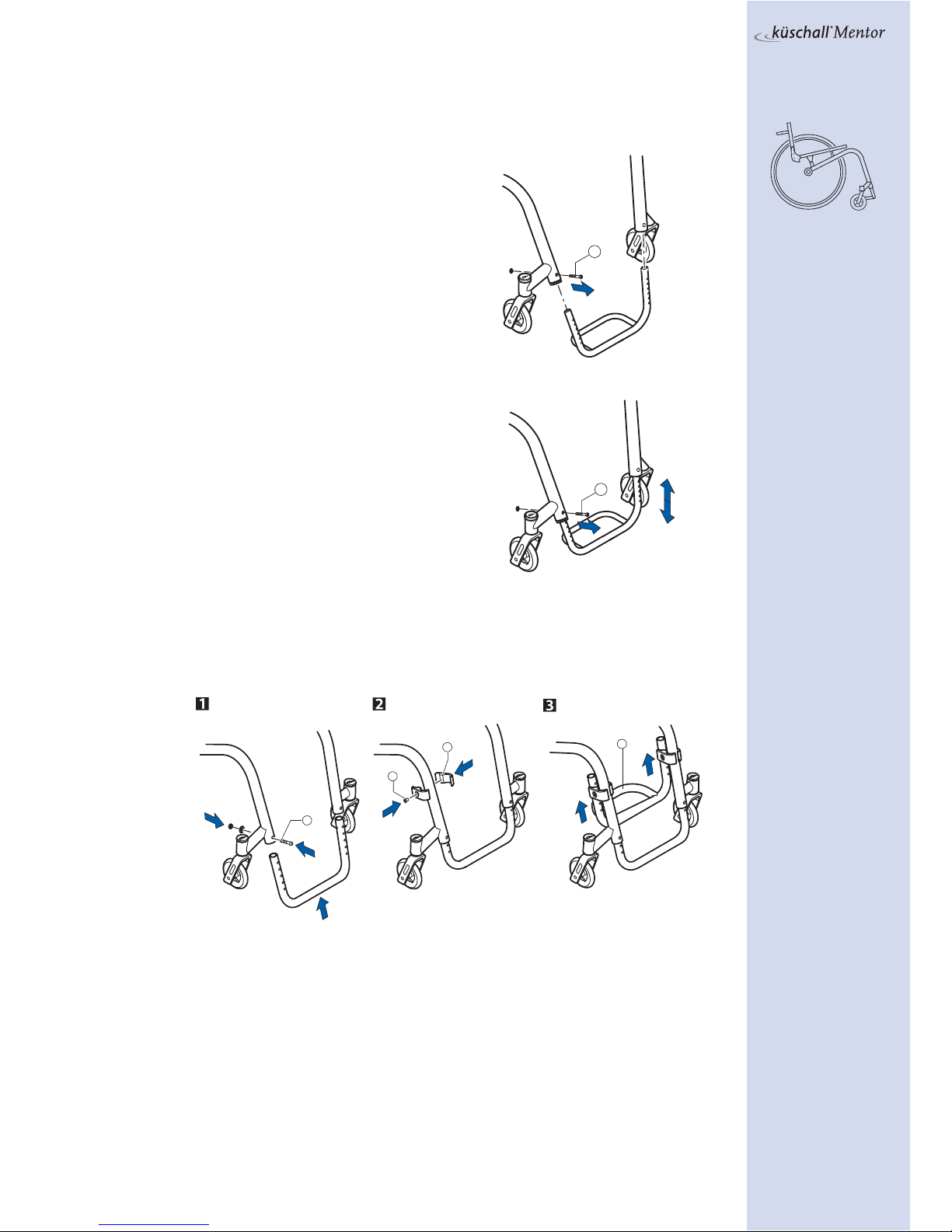

2.1 Footrest replacement 7

2.2 Footrest height adjustment 7

2.3 Footrest mounted in high position 7

2.4 Footplate angle adjustment 8

2.5 Front fork replacement 8

2.6 Quick release fork 9

2.7 Front wheel replacement 9

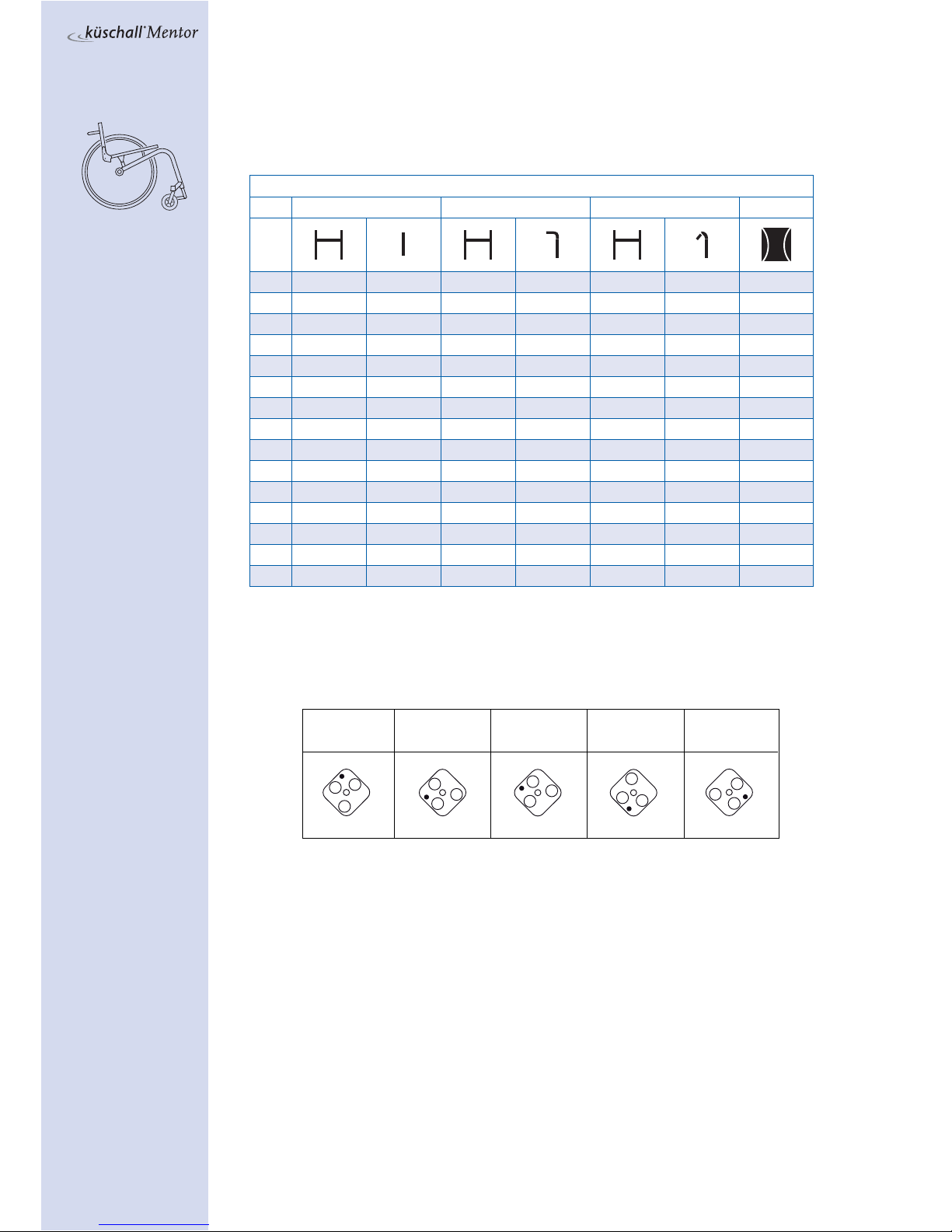

2.8 Rear seat height adjustment 10

2.9 Front seat height adjustment 10

2.10 Tipping Point adjustment 11

2.11 Parking brakes assembly and adjustment 11

2.12 Clothes guard assembly 12

2.13 Mudguard assembly and adjustment 12

2.14 Armrest assembly and adjustment 13

2.15 Siderest assembly and adjustment 13

2.16 Rear wheel extension assembly and adjustment 14

2.17 Rear wheel camber adjustment 14

2.18 Control of rear wheel parallelism 15

2.19 Suspension assembly 16

2.20 Backrest height adjustment 17

2.21 Backrest angle adjustment 19

2.22 Antitipper assembly and adjustment 19

2.23 Active-Antitipper assembly and adjustment 20

2.24 Transit wheels assembly and adjustment 21

4ROUBLESHOOTING