21

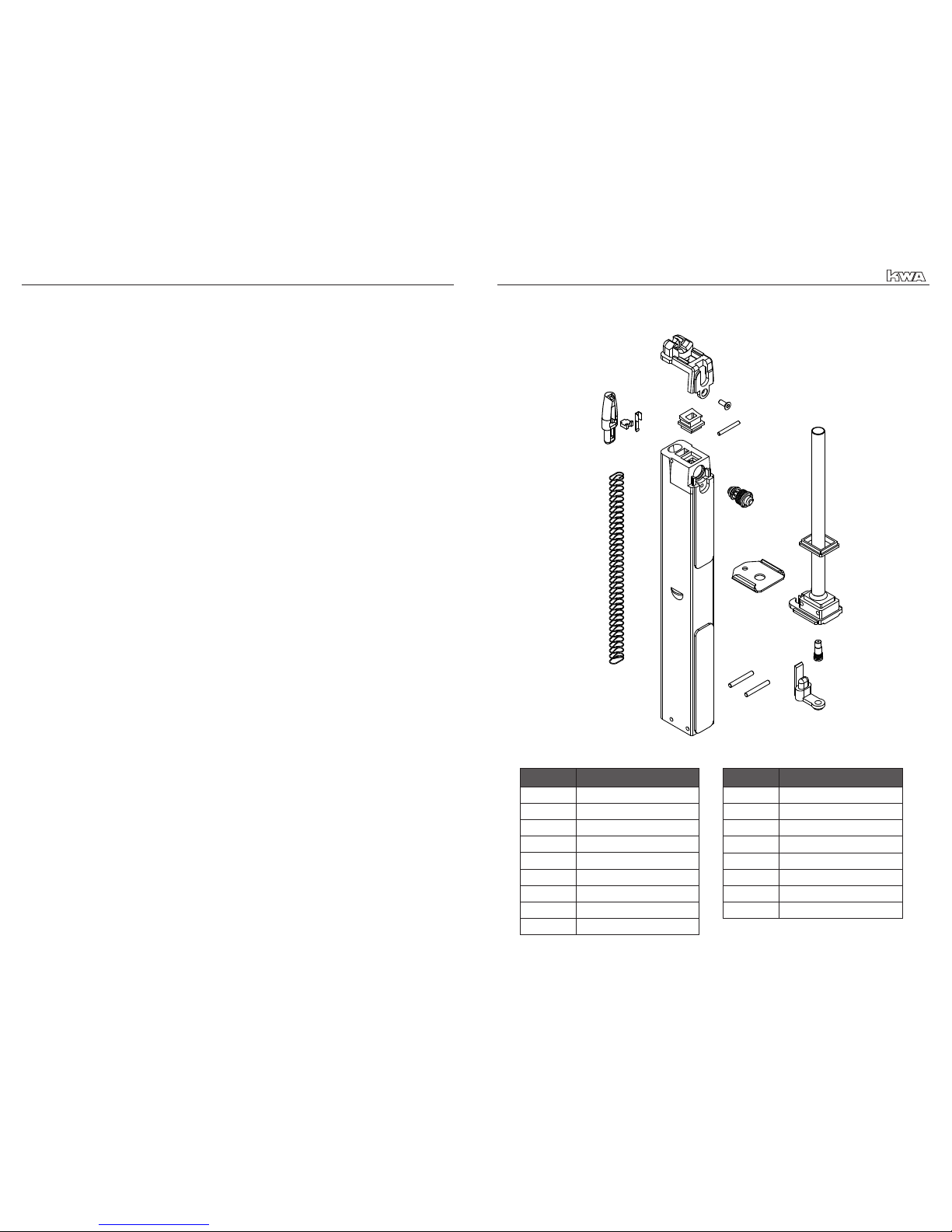

M11A1-93 Breech Buffer (Small)

M11A1-94 Breech Buffer (Large)

M11A1-95 Breech Base Screw (Small)

M11A1-96 Breech Base Screw (Small)

M11A1-97 Breech Base Screw (Large)

M11A1-98 Front Sight Base Screw

M11A1-99 Main Seal Base Screw

M11A1-100 Grip Screw

M11A1-102 Impact Block Housing

Retainer

M11A1-103 Hop Up Cylinder Retaining

Ring E-Clip

M11A1-104 Recoil Spring Guide E-Clip

M11A1-105 Folding Stock Pin E-Clip

M11A1-107 Safety Pin

M11A1-111 Hop Up Ball Bearing

M11A1-112 Safety Switch Ball Bearing

M11A1-121 BB Feed Ramp

M11A1-122 BB Feed Ramp Pin

M11A1-123 Main Seal Base

M11A1-125 Alum Jet Nozzle

M11A1-126 Jet Nozzle Spring

M11A1-128 Main Seal Cap

M11A1-129 Jet Nozzle Pin

M11A1-130 Main Seal

M11A1-132 Main Seal Cap Screw

M11A1-152 Inner Barrel Clip

M11A1-153 Inner Barrel Spring Washer

M11A1-154 Inner Barrel Spring

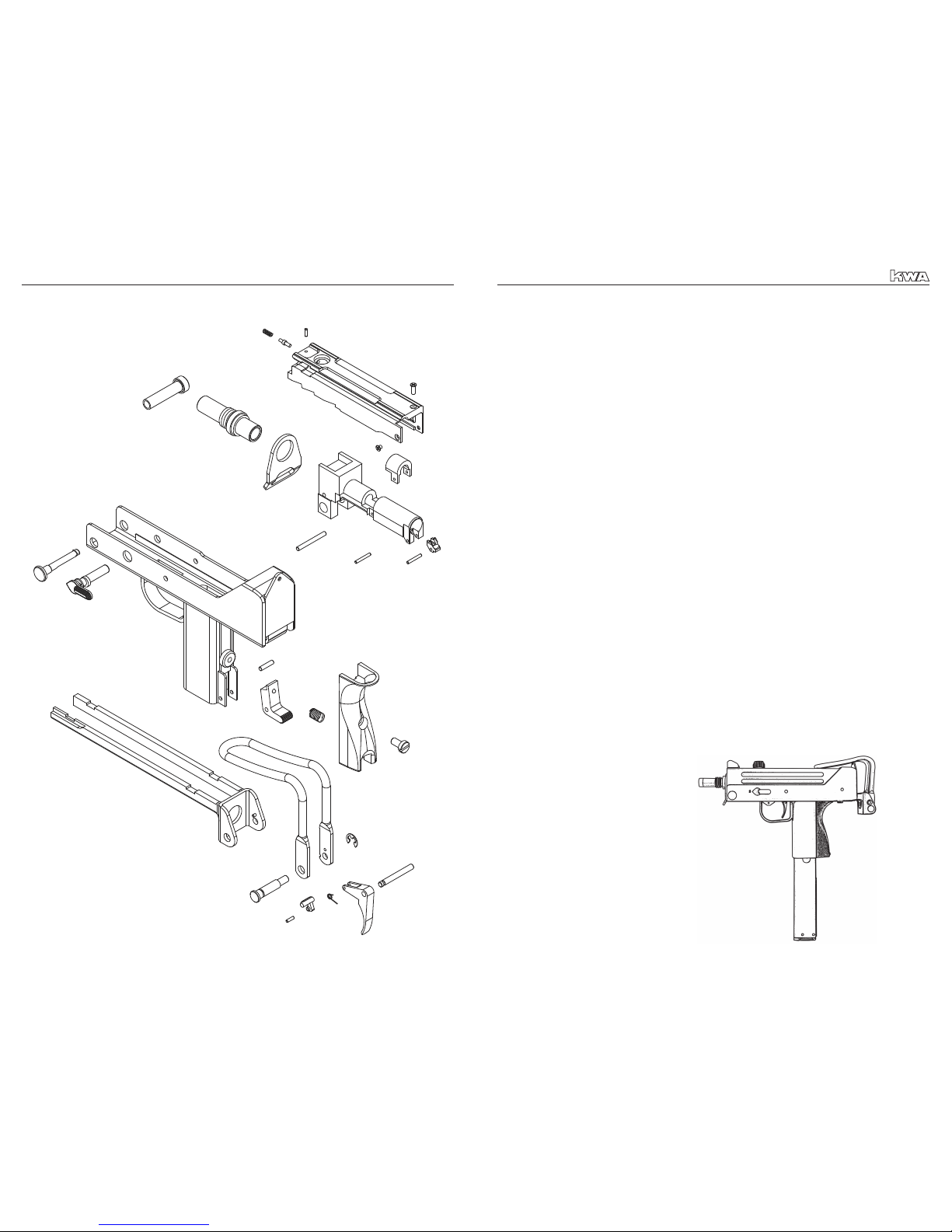

Parts # Description

M11A1-1 Lower Frame

M11A1-2 Upper Frame

M11A1-3 Bolt

M11A1-4 Cylinder

M11A1-5 Front Sight

M11A1-6 Front Sight Base

M11A1-8 Grip

M11A1-9 Hop Up Cylinder Retaining

Ring

M11A1-10 Inner Frame Base

M11A1-11 Wire Stock

M11A1-12 Trigger

M11A1-13 Inner Barrel Base

M11A1-14 Bolt Stop

M11A1-15 Sear

M11A1-16 Impact Block

M11A1-17 Sear Disconnector

M11A1-18 Safety Base

M11A1-19 Breech Base

M11A1-20 Bolt Handle

M11A1-21 Outer Barrel

M11A1-22 Inner Barrel Clip

M11A1-24 Impact Block Reset Button

M11A1-28 Safety

M11A1-29 Magazine Release Lever

M11A1-30 Selector Lever

M11A1-31 Stock Release Button

M11A1-32 Hop Up Cylinder

M11A1-38 Hop Up Bucking

M11A1-40 Inner Barrel

M11A1-44 Recoil Spring Guide

Follower

M11A1-46 Impact Block Pin

M11A1-48 Bolt Handle Plunger

M11A1-49 Recoil Spring Guide Rod

M11A1-50 Take Down Pin

M11A1-51 Take Down Pin Lock

M11A1-52 Trigger Pin

M11A1-53 Stock Pin

M11A1-57 Inner Barrel Clip Pin

M11A1-58 Outer Barrel Retaining Pin

M11A1-60 Sear Pin

M11A1-63 Magazine Release Lever Pin

M11A1-64 Cylinder Return Spring

Retaining Pin

M11A1-65 Impact Block Housing (Left)

M11A1-66 Impact Block Housing

(Right)

M11A1-67 Inner Slide Housing

M11A1-69 Folding Stock

M11A1-70 Swivel

M11A1-71 Main Seal Base Screw

Washer

M11A1-73 Trigger Spring

M11A1-74 Impact Block Housing

Spring

M11A1-75 Impact Block Spring

M11A1-

76-1 Recoil Spring

M11A1-77 Sear Spring

M11A1-80 Bolt Handle Plunger Spring

M11A1-81 Bolt Stop Spring

M11A1-82 Sear Disconnector Spring

M11A1-83 Cylinder Return Springs

M11A1-87 Stock Release Button

Springs

M11A1-88 Magazine Release Lever

Spring

M11A1-89 Safety Spring

M11A1-90 Trigger Pin Retaining Spring

M11A1-92 Impact Block Reset Button

Spring

Parts # Description Parts # Description

2

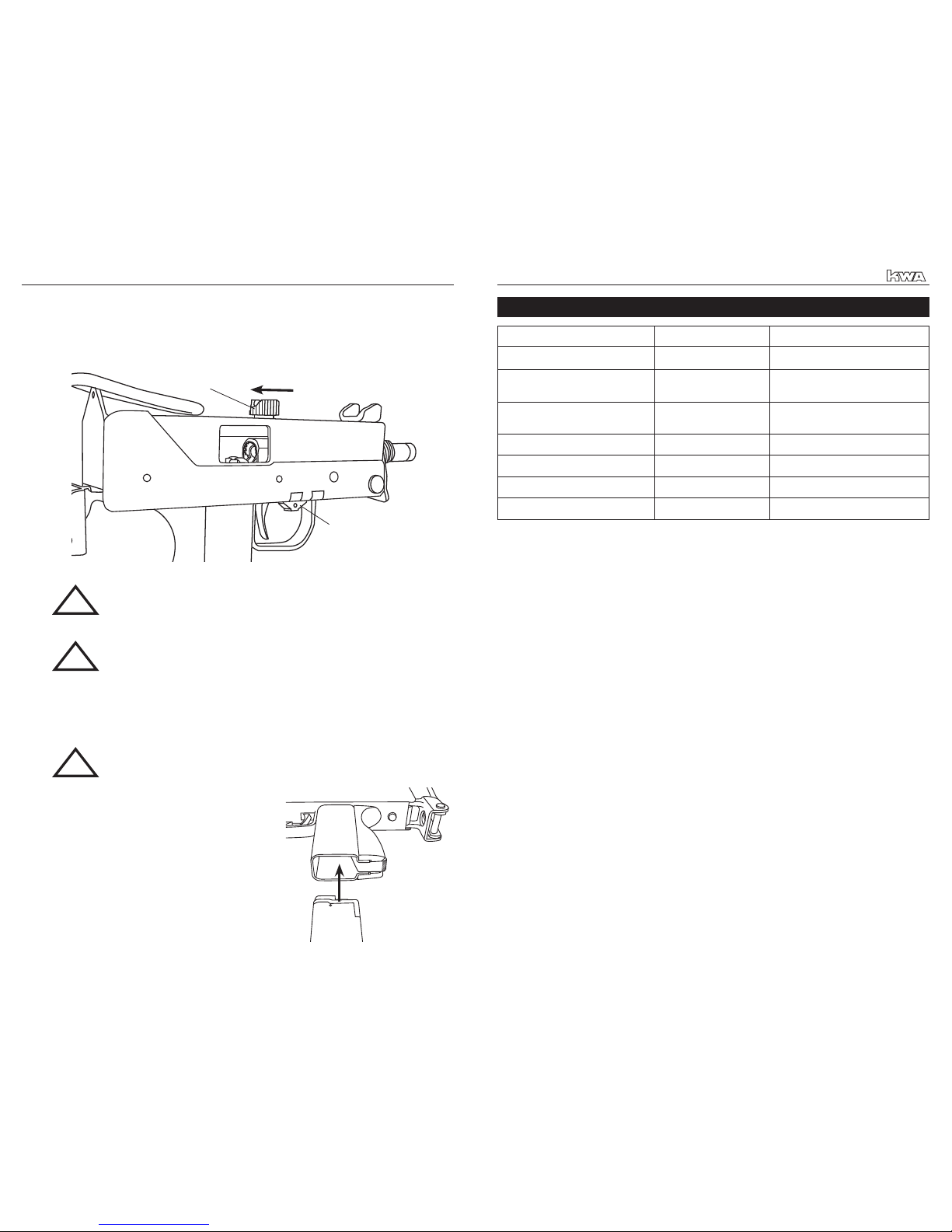

USE OF THIS MANUAL

Before operating the Airsoft gun, read this manual in its entirety. Important safety topics

and tips are discussed throughout all of the chapters. It’s important that the operator know

the principles of gun handling safety and operation prior to ring the Airsoft gun.

SAFETY GUIDELINES

WARNING! Failure to follow safety guidelines may result

in serious injury.

Safety Distance

The effective shooting range is approximately 75 feet. BBs red from this Airsoft gun may

travel further than intended. Make certain that you have an adequate backstop.

Eye Protection

Eye protection should be worn at all times when both shooting and maintaining your Airsoft

gun. Protect your eyes from BBs under pressure while performing maintenance on your

Airsoft gun.

Assume Every Gun is Always Loaded

Until you are certain the chamber is empty, treat every gun as if it were loaded. Do not

assume the chamber is empty based on your memory or someone else’s words. Always

remove the magazine and visually check to conrm the chamber is empty.

Beware of Barrel Obstructions

Ensure the Airsoft gun barrel is free of obstructions before you re the gun. Even the

smallest obstruction such as lubrication or a stuck cleaning patch can cause a misre or

malfunction.

Muzzle Control

Always keep the muzzle of the gun pointed in a safe direction. Never point the muzzle at a

person or object that you do not intend to shoot.

Keep Your Safety On

Keep the gun’s safety on until your sights are aligned on your target and you are ready to

re.

Keep Your Finger Off The Trigger

Keep your nger off the trigger and out of the trigger guard until your sights are aligned on

your target and you are ready to re.

WARNING! Airsoft BBs can be a choking hazard. Keep

them away from children.

!

!

PARTS LIST

M11A1 NS2