CAUTION INSTRUCTIONS FOR L&L KILNS

cautions.pdf REV: 11/1/2016 Page 1

2016 L&L Kiln Mfg, Inc. 505 Sharptown Rd, Swedesboro NJ 08085 P:856.294.0077 F:856.294.0070 [email protected] hotkilns.com CAUTION INSTRUCTIONS

KILNS THESE CAUTIONS APPLIES TO

CURRENT PRODUCTION KILNS

• Easy-Fire Kilns (e Series)

• School-Master Kilns (SM Series)

• Easy-Fire XT Kilns (eXT Series)

• Jupiter Automatic Kilns (JD Series)

• eQuad-Pro Production Kilns (eQ Series)

• JH Crystalline Kilns (JH Series)

• Hercules Front-Loading Kilns (EL-H Series)

• Easy-Load Front-Loading Kilns (EL Series)

• DaVinci Automatic Kilns (X and T Series)

• Doll/Test Kilns (DL and DLH Series)

• Liberty-Belle Kilns (LB Series)

• Fuego Kilns

OBSOLETE MODELS

• Jupiter Manual Kilns (J Series)

• Econo Kilns (K Series and J Series)

• Programmatic Kilns (B Series)

• Robin Kilns

• Dyna-Kilns (C & H Series)

• Dyna-Kilns (SQ Series)

• Dura-Fire Kilns (D Series)

• Enameling Kilns (E48, E49, R Series)

• Oval Kilns (OV Series)

• Genesis Kilns (G Series)

• Most other L&L kilns

RESELLERS ARE NOT AUTHORIZED TO

MODIFY THESE CAUTION INSTRUCTIONS

Distributors and installers of L&L kilns are not authorized

by L&L to make modifications or contradict these Caution

Instructions (or our Installation Instructions). If L&L’s

instructions are not followed, L&L specifically disavows

responsibility for any injury or damage that may result.

DATED INFORMATION

The information in these Caution Instructions is believed

to be correct to the best of our knowledge at the time of

publication (see the date at the bottom of this sheet). You

can view the most recent update from our web site at

hotkilns.com/cautions at any time.

CAUTION INSTRUCTIONS .................................................................. 1

KILNS THESE CAUTIONS APPLIES TO ....................................................................... 1

RESELLERS ARE NOT AUTHORIZED TO MODIFY THESE CAUTION INSTRUCTIONS

1

DATED INFORMATION .................................................................................................. 1

SAFETY NOTICE............................................................................................................ 2

ELECTRICAL SAFETY ........................................................................ 2

GENERAL ....................................................................................................................... 2

ELECTRICAL HAZARDS ..................................................................... 2

SHOCK............................................................................................................................ 2

ARC-FLASH .................................................................................................................... 2

ARC-BLAST .................................................................................................................... 2

SAFETY PRINCIPLES.......................................................................... 2

INSTALLATION CAUTIONS ................................................................ 3

USE A QUALIFIED ELECTRICIAN................................................................................. 3

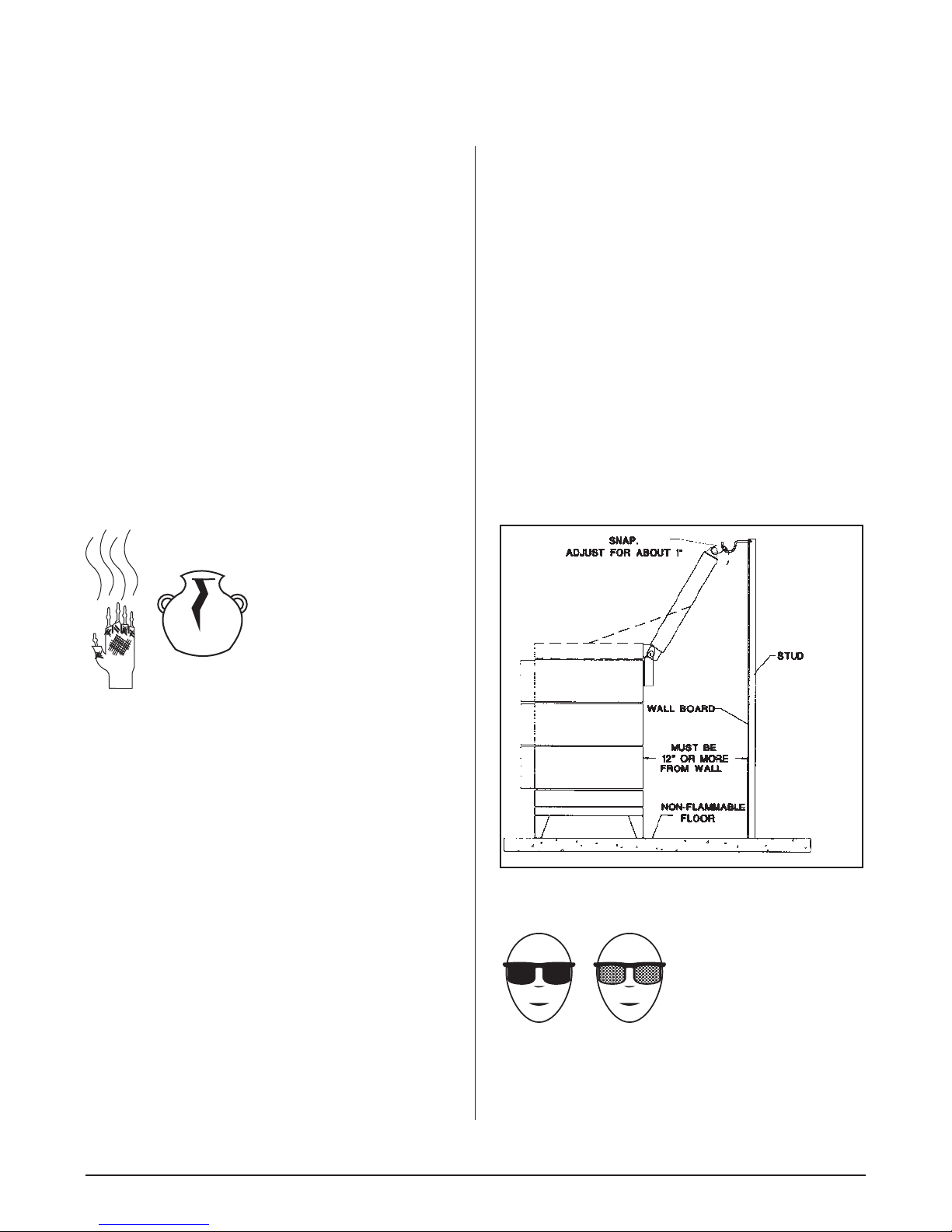

CLEARANCES AND FLAMMABLE SURFACES............................................................ 3

CHECK TEMPERATURES AROUND KILN ................................................................... 3

LEVELING THE KILN...................................................................................................... 3

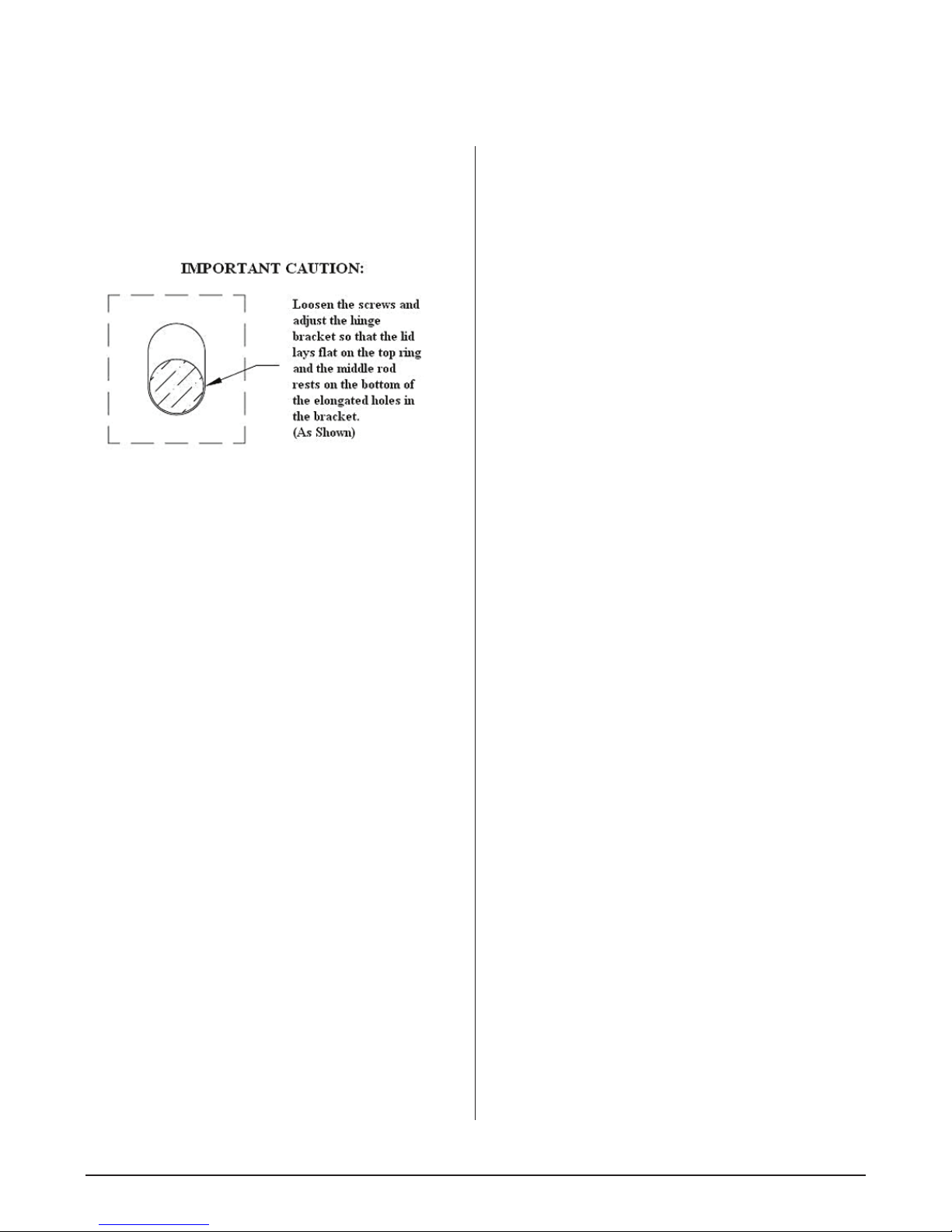

ADJUSTING THE HINGE PROPERLY........................................................................... 3

THERMOCOUPLES........................................................................................................ 4

USE THE SUPPLIED KILN STAND................................................................................ 4

DON’T USE AN EXTENSION CORD ............................................................................. 4

POWER CORD MUST BE PROPERLY RATED ............................................................ 4

USE COPPER WIRE FOR HOOK UP............................................................................ 4

PROTECT POWER CORD FROM KILN CASE ............................................................. 4

KEEP KILN DRY & IN PROTECTED SPACE ................................................................ 5

KEEP A FIRE EXTINGUISHER NEAR KILN.................................................................. 5

SPRINKLER CAUTIONS ................................................................................................ 5

GENERAL ENVIRONMENT CAUTIONS ............................................. 5

VENTILATION IS ESSENTIAL........................................................................................ 5

AMBIENT TEMPERATURES.......................................................................................... 6

SURFACE IS HOT AND CAN CAUSE BURNS.............................................................. 6

KEEP CHILDREN/ANIMALS AWAY FROM KILN .......................................................... 6

KEEP FLAMMABLES AWAY FROM KILN ..................................................................... 6

PRACTICE GOOD HYGIENE......................................................................................... 6

PROPER USE OF KILN WASH...................................................................................... 6

6. Clean off the old wash and reapply new wash each time you fire or when it begins to

chip away. ...................................................................................................................... 6

TRIPPING HAZARDS ..................................................................................................... 7

CLOTHING TO AVOID.................................................................................................... 7

PREFIRING CAUTIONS ....................................................................... 7

KILN WASH CONTAINS SILICA .................................................................................... 7

DO NOT USE SILICA SAND .......................................................................................... 7

NEVER FIRE MOIST GREENWARE.............................................................................. 7

CAUTION WITH USE OF WAX ...................................................................................... 7

DO NOT FIRE TEMPERED GLASS............................................................................... 7

STORE SHELVES IN A DRY LOCATION ...................................................................... 7

DO NOT USE CRACKED SHELVES.............................................................................. 7

DO NOT FIRE TOXIC, FLAMMABLE, OR UNKNOWN MATERIALS ............................ 7

LOADING & UNLOADING CAUTIONS ............................................... 8

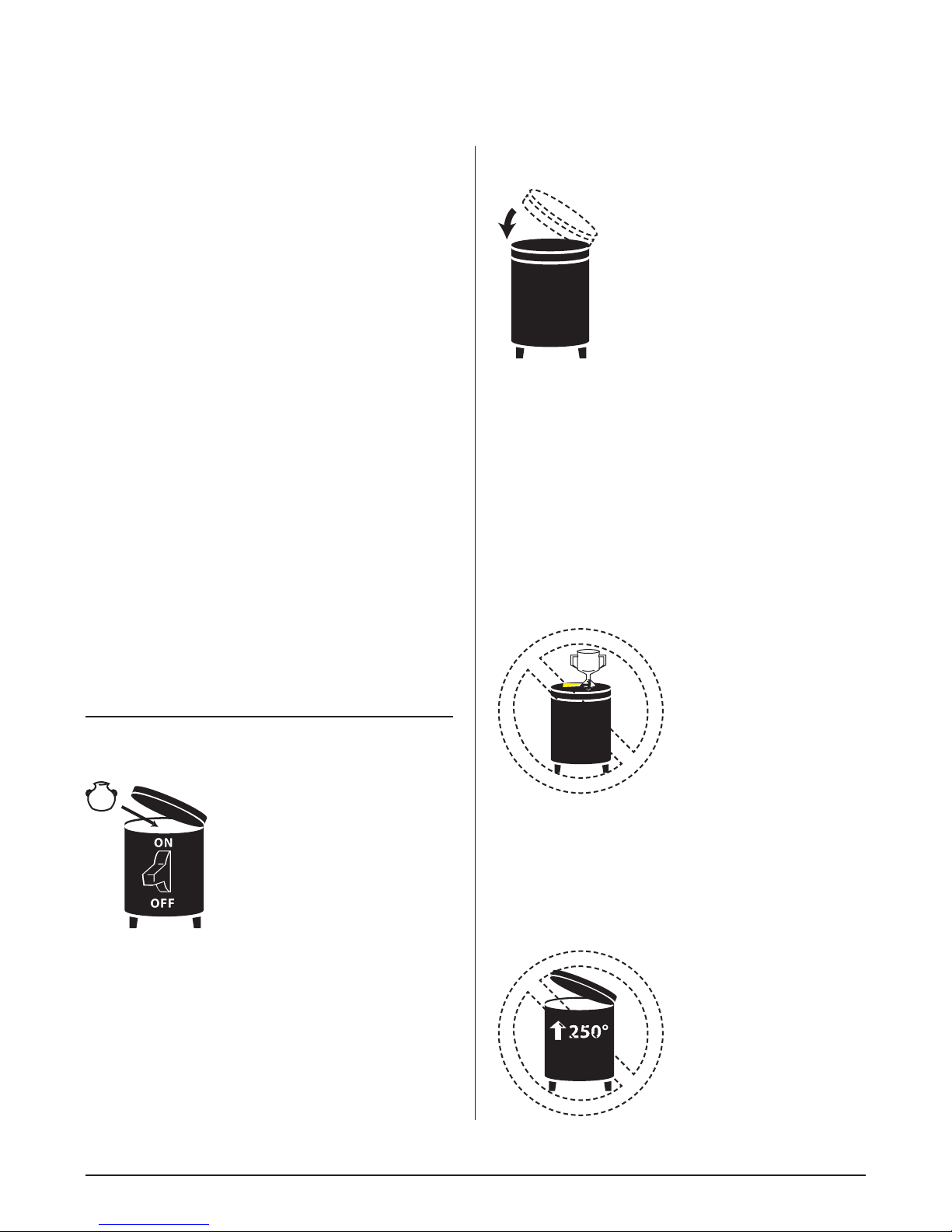

TURN OFF POWER WHILE LOADING.......................................................................... 8

KEEP LID CLOSED WHEN KILN IS NOT IS USE......................................................... 8

DO NOT STORE ANYTHING ON LID ............................................................................ 8

DO NOT OPEN THE DOOR ABOVE 250°F.................................................................. 8

DO NOT UNLOAD KILN WHILE HOT ............................................................................ 9

BE CAREFUL OF SHARP OBJECTS & GLAZE ............................................................ 9

SECURE LID WHILE LOADING OR UNLOADING IF YOU HAVE A SPRING-LOADED

EASY-LIFT HINGE.......................................................................................................... 9

IF YOU HAVE A DAVINCI COUNTERBALANCED LID ................................................. 9

IF YOU HAVE A BASIC HINGE WITH CHAIN SUPPORTS .......................................... 9

VIEWING INTO THE KILN.............................................................................................. 9

FIRING CAUTIONS ............................................................................ 10

ATTEND THE FIRING................................................................................................... 10

MAKE SURE YOUR KILN SITTER IS ADJUSTED ...................................................... 10

USE KILN WASH ON THE CONE SUPPORTS........................................................... 10

UNDERSTAND YOUR CONTROL ............................................................................... 10

PROGRAM REVIEW ON AUTOMATIC KILNS ............................................................ 10

DO NOT CONFUSE CONE NUMBERS ....................................................................... 10

USE THE PROPER THERMOCOUPLE ....................................................................... 10

CHECK THERMOCOUPLE CALIBRATION ................................................................. 11

SHUT OFF KILN AT DISCONNECT OR CIRCUIT BREAKER .................................... 11

DO NOT FIRE KILN ABOVE 2350°F (1290°C, Cone 10) ........................................... 11

POST FIRING CAUTIONS.................................................................. 11

CHECK FOR GLAZE AND CERAMIC CHIPS.............................................................. 11

GENERAL MAINTENANCE CAUTIONS ........................................... 12

ELECTRICAL SAFETY ................................................................................................. 12

CHECK WIRES & TERMINALS.................................................................................... 12

CHECK TEMPERATURE OF CORD............................................................................ 12

CHECK FOR CORRODED CONNECTIONS ............................................................... 12

THE WRONG PARTS CAN BE HAZARDOUS............................................................. 12

VIDEO ABOUT GENERAL MAINTENANCE ................................................................ 12

KILN MODIFICATIONS CAUTIONS .................................................. 13

COATINGS.................................................................................................................... 13

OTHER MODIFICATIONS ............................................................................................ 13

DO NOT OVERINSULATE KILN .................................................................................. 13