2-1

TABLE OF CONTENTS Chapter 2

Component Overview

General

IMPORTANT

First read and understand the operators manual.

Second, always conduct a Receipt Inspection on your

new equipment to verify that it is complete and not

damaged prior to placing it into operation. Report any

findings to the Landoll Trailer Service Contacts at

Landoll.com or phone 800-446-5175 / 888-522-3634.

See Receipt Inspection Checklist on Page 4-6.

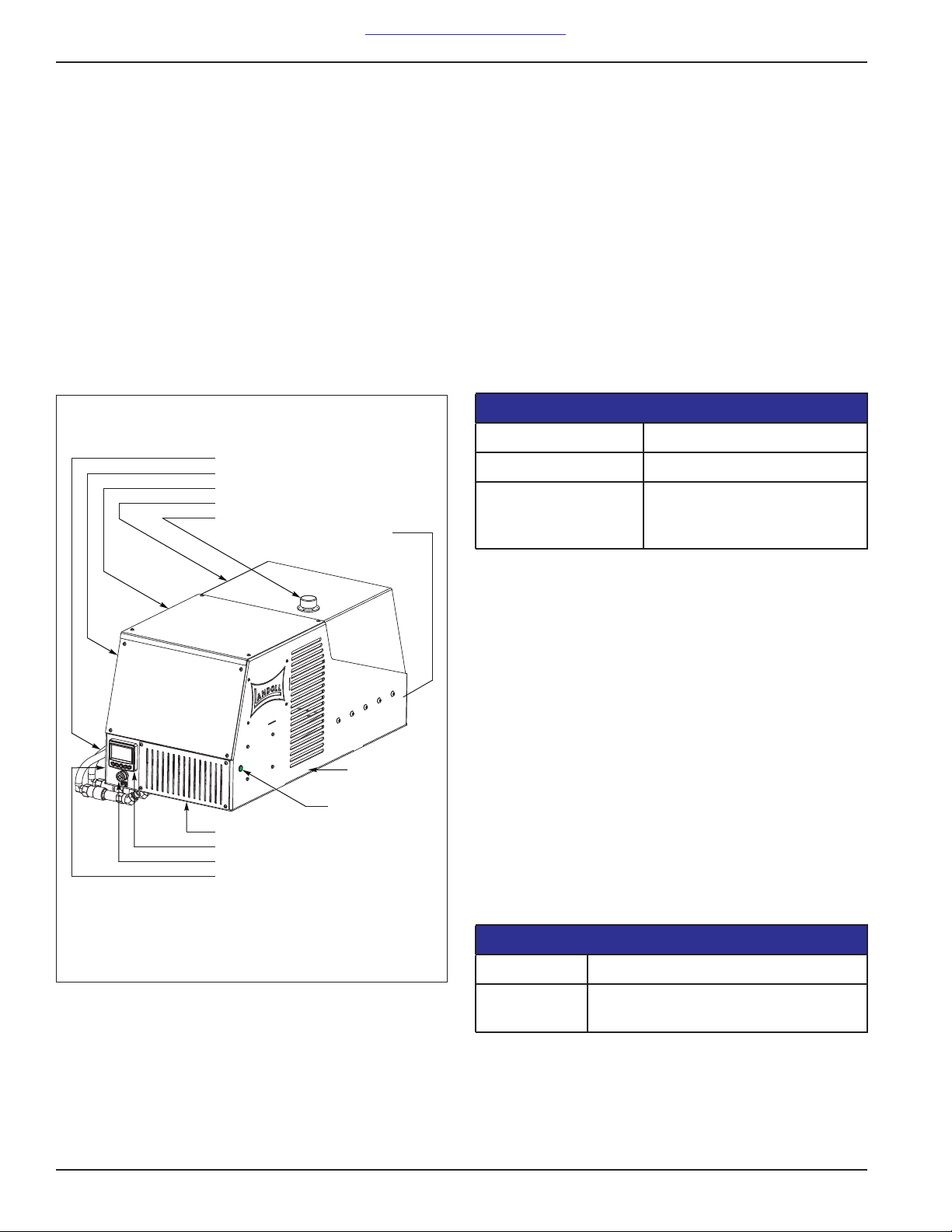

This section provides the component locations and

descriptions for the Electric Hydraulic Power unit.

Operators must be familiar with the components,

instructions and safety statements before operating the

power unit.

The Electric Hydraulic Power option is a quick attach

enclosed rechargeable battery powered electric motor

driven hydraulic pump unit, that supplies external

hydraulic power to a system.

DANGER

DANGER

DANGER

DANGER

WARNING

Enclosure

The metal enclosure can be mounted on the front end of

the Landoll Trailer or above the optional winch. It provides

protection and a mounting surface for the power unit’s

electrical and hydraulic components. The enclosure

measures 52 inches long, 24 inches wide and 24 inches

high (132.08cm x 60.96cm x 60.96cm). DO NOT use high

pressure water to clean on or near the power unit

assembly. This can result in damage to the electrical

components mounted inside and outside of the enclosure.

Failure to comply may lead to death, severe injury

or damage to equipment. Requires complex

electrical system troubleshooting and repair. It is

highly recommended to contact the Landoll

Trailer Service Department at Landoll.com or

phone 800-446-5175 / 888-522-3634.

1. SHOCK HAZARD - Batteries are in a parallel

circuit, this increases the system’s amps,

capacity and energy. Use proper insulated

tools and procedures when working with

batteries.

2. SHOCK HAZARD - DO NOT touch any

terminals, Use proper insulated tools and

procedures when working with batteries.

3. MAGNETIC FIELD - The motor generates high

magnetic fields and are hazardous to

individuals with pacemakers. Individuals with

pacemakers DO NOT work on motor.

4. DO NOT operate the equipment until you have

read the operator’s manual and completely

understand the proper use and function of all

controls

5. DO NOT operate the equipment with broken,

defective or missing parts.

6. REPLACE defective, damaged and leaking

batteries. Exposure to the battery contents

may release flammable liquid and vapors, may

cause allergic skin reactions or damage

organs, and may cause cancer.

7. ALWAYS check above, below and around the

equipment for persons and objects before

moving.

8. To prevent serious injury or death from

pinching: Keep all persons and objects clear

while any part of the machine is in motion.

9. ALWAYS fully couple truck to trailer when

operating the hydraulics. Trailer may become

unstable and lose contact with the ground.

Failure to comply may lead to death, serious

injury or damage to equipment. Requires

complex electrical system troubleshooting and

repair. It is highly recommended to contact the

Landoll Trailer Service Department at

Landoll.com or phone 800-446-5175 /

888-522-3634.

1. MAGNETIC FIELD - The motor generates high

magnetic forces and can attract items quickly.

Wear gloves, hold on to tools / items tightly

and move slowly.

2. ALWAYS connect hydraulic quick couplers

before operating.

3. DO NOT use high pressure water on or near

the enclosure. May cause damage to the

electrical components or wiring of the Electric

Hydraulic Power unit.