landscape structures PlayBooster 100041 User manual

MEO13207Install

MODELNUMBERSNOTFOUND

117957A

© 1994 by Landscape Structures. All rights reserved.

601 7TH STREET SOUTH, DELANO, MINNESOTA 55328-8605 (763) 972-3391 1-888-LSI-INST (1-888-574-4678) FAX (763) 972-3185

SAFETY NOTE

Choose a protective surfacing material that

has a Critical Height Value of at least the

height of the Highest Accessible Part/Fall

Heightoftheadjacentequipment.(Ref.ASTM

F1487, SECTION 9.)

PlayBooster

6-1-95

8

Document #10972201

General Post/Tenderdeck Information

56" 32"

48" 40"

Concrete Footings - Refer to the Typical

Concrete Footing spec sheet for installation.

Deck Hanger Clamp Assembly - Refer to

the appropriate Deck Assembly spec sheet

for installation.“

Decks - Refer to your plan drawing for

heights and orientation. Refer to the appro-

priate deck spec sheet for installation.

Vertical Ladders - Refer to your plan draw-

ingforlocationsandtheVertical Ladder spec

sheet for installation.

Kick Plates - Refer to your plan drawing for

locations and the Kick Plate spec sheet for

installation.

Enclosures/ Components - Refer to your

plan drawing for locations and their respec-

tive spec sheets for installation.

Letter indicates post length as indicated on

your plan drawing.

Numberindicatesheightofdeckabovefin-

ished grade.

Dimension indicates center to center spac-

ing of concrete footings.

Enclosures or components are required on

any decks higher than 28" as indicated on

your plan drawing.

16"

Deck

40"

Deck

42"

1070 42"

1070

42"

1070

42"

1070

Specifications are subject to change without notice.

Installation Instructions

BeforeStarting,ReadtheGeneralConstructionGuidelines,

Installation Hints, All Typical Detail Sheets and Specific In-

stallationInstructionsfor Each ComponentLabeledonYour

Plan.

1) Dig footing holes spaced as shown on the plan and spec sheets. Re-

fer to the Typical Concrete Footing Spec Sheet.

2) Note the post lengths as shown on the plan and set in their appropri-

ate footing holes. The post length is indicated on the finished grade

sticker on each post.

3) Mark the appropriate posts for the deck heights you are installing

and attach decks to posts at marked height. Refer to the appropriate

deck spec sheet for installation.

4) After all the posts are at proper heights and plumb, and the decks are

at proper height and level, pour the concrete footings per the Typical

Concrete Footing Spec Sheet.

5) Continue installing enclosures and components and pour concrete

footings as you progress, making sure everything is plumb and level.

6) When installation is complete, install Drive Rivets in all clamps per

the Typical Offset Hanger Clamp Spec Sheet.

7) Install protective surfacing under and around all equipment before

users are allowed to play on the structure.

PlayBooster General Post/Tenderdeck Information

J:\SPECS\109\10972201.P65

6-1-95 Revision-01 Updated Drawing.

© 1994 by Landscape Structures. All rights reserved.

601 7TH STREET SOUTH, DELANO, MINNESOTA 55328-8605 (763) 972-3391 1-888-LSI-INST (1-888-574-4678) FAX (763) 972-3185

SAFETY NOTE

Choose a protective surfacing material that

has a Critical Height Value of at least the

height of the Highest Accessible Part/Fall

Heightoftheadjacentequipment.(Ref.ASTM

F1487.)

PlayBooster

3-1-94

11002200

9

Document #11002200

5" O.D.

Post

3/8" Tee Nut

3/8" x 1 1/8"

BHCS w/Pin

Tee Clamp Assembly 13

1/4" x 5/8" Drive

Rivet

5" O.D. Horizontal Beam

5" Half Clamp

R

Specifications are subject to change without notice.

Parts List

Part# Description Qty

105327-01 5" Half Clamp, Specify Color .................................. 2

100198-00 3/8" x 1 1/8" BHCS w/Pin, SST ................................... 4

100351-00 3/8" Tee Nut, SST ........................................................ 4

100610-00 1/4" x 5/8" Drive Rivet, SST ....................................... 2

Specifications

Tee/Beam: 356 alloy treated to T-6 hardness and welded to 5"

aluminum beams or mechanically fastened to 5" steel

beams. Finish: Powdercoat, color specified.

HalfClamps: Cast aluminum. Finish: Powdercoat, color specified.

Fasteners: Primary fasteners shall be socketed and pinned

tamperproofindesign,stainless steel(SST)perASTM

F 879 unless otherwise indicated (see specific prod-

uct installation/specifications).

InstallationTime: Approx. 1/2man hour

Weight: 2 lbs.

PlayBooster Tee Clamp Assembly

Installation Instructions

1) Locate and mark center of clamp location on 5" pipe.

2) With beam in position, fasten 5" half clamps to tee clamp using 3/8" x

1 1/8" BHCS w/Pin and tee nuts as shown. Tighten cap screws evenly.

3) IMPORTANT: Install drive rivets in half clamps by drilling holes

in clamps and into 5" pipe using a 1/4" or "F"(only) drill bit. Insert

rivet in hole, and hammer rivet pin in until it is flush with head.

J:\SPECS\110\11002200.P65

R

© 2001 by Landscape Structures. All rights reserved.

601 7TH STREET SOUTH, DELANO, MINNESOTA 55328-8605 (763) 972-3391 1-888-LSI-INST (1-888-574-4678) FAX (763) 972-3185

SAFETY NOTE

Choose a protective surfacing material that

has a Critical Height Value of at least the

height of the Highest Accessible Part/Fall

Heightoftheadjacentequipment.(Ref.ASTM

F1487)

3-29-01

12194700

5

Document #12194700

NOTE:

Surface mounting will not work in all

applications. Consult Landscape

Structures Inc. for your particular re-

quirements.

CONCRETE SLAB SPECS

•Base under slab to be 4" - 6" of sand

over a stable subgrade.

•Depth of concrete slab to be 4" - 6"

with a wire mesh support.

•Minimum of 7 days curing time full cure

after 30 days.

•Surface of concrete to be trowled

smooth and acid etched.

•Concrete: 3000 PSI (Min)

30 Days 3500 PSI

3/4Minus Crushed Rock

3/8" x 8" Square Steel

or Aluminum Plate

Continuously Welded

to Upright Post

Concrete Specs, Surface Mount

1-30-97 Document #12194700 replaces #10971000. Updated notes.

Concrete Surface

Upright

Post

(4)1/2"

Standard

Hex Nuts

DETAIL

6

1

/

2

"

165

8"

200

3/4"

19

3/4"

19 6 1/2"

165

8"

200 3/4"

19

(4)1/2" Flat

Washers

(4)1/2" x 2 3/4"

Expansion

Anchors

Upright

Post

NOTE:

Drill 3" deep hole using hammer drill

and 1/2"masonry bit. Tap anchors into

concreteandsecurewith1/2" standard

hex nuts and 1/2" flat washers.

3/4"

19

NOTE: Sufficient protec-

tive surfacing must cover

hardware to satisfy fall

heightrequirements.

PlayBooster

R

© 1997 by Landscape Structures. All rights reserved.

601 7TH STREET SOUTH, DELANO, MINNESOTA 55328-8605 (763) 972-3391 1-888-LSI-INST (1-888-574-4678) FAX (763) 972-3185 10

Document #12382100

114261Offset Hanger Clamp Assembly

PlayBooster

10-3-97

12382100

Offset Hanger

Clamp Assembly

The Offset Hanger Clamp allows

rails to be installed at same height

for special applications, like at 90o

to each other as shown, or when

there are clamp conflicts, offset

can be positioned upward.

NOTE: A drive rivet is not required in all

applications. See Drive Rivet Addendum

for a listing of components that do not re-

quire drive rivets.

1/4" x 5/8"

Drive Rivet

DETAIL

ASSEMBLED CLAMP

Typical

Post

Rails At

Same

Height

5" Half

Clamp

(2)3/8" x 1 1/8"

BHCS w/Pin

(2) 3/8" Tee Nuts

5/8" x 2 1/4"

BHCS w/Pin

Offset Hanger Clamp

NOTE:Positionwithoffsetfac-

ing down as shown. See De-

tailfor special applications. Rail

R

SAFETY NOTE

Choose a protective surfacing material that

has a Critical Height Value of at least the

height of the Highest Accessible Part/Fall

Heightoftheadjacentequipment.(Ref.ASTM

F1487.)

Specifications are subject to change without notice.

Parts List

Part# Description Qty

100198-00 3/8" x 1 1/8" BHCS w/Pin, SST .................................... 2

100351-00 3/8" Tee Nut, SST ......................................................... 2

100610-00 1/4" x 5/8" Drive Rivet, AL/SST ................................... 1

105327-01 5" Half Clamp, Specify Color..................................... 1

113729-00 Offset Hanger Clamp, Specify Color ......................... 1

100203-00 5/8" x 2 1/4" BHCS w/Pin, SST .................................... 1

Specifications

Clamp: Cast aluminum. Finish: Powdercoat, color specified.

Fasteners: Primary fasteners shall be socketed and pinned

tamperproofindesign,stainless steel(SST)perASTM

F 879 unless otherwise indicated (see specific prod-

uct installation/specifications).

InstallationTime: Approx. 1/4man hour

Weight: 3 lbs.

Installation Instructions

1) Locate and mark position of clamp on 5" post.

2) Position clamp in proper direction and assemble with 3/8" x 1 1/8"

BHCS w/pin and 3/8" tee nuts as shown and lightly tighten. Position

rail against clamp and screw in 5/8" x 2 1/4" BHCS w/pin until rail

bottoms out on clamp. Final tighten all fasteners.

3) IMPORTANT: Drill through hole in 5" half clamp and into 5" post

with a 1/4" or "F" (only) drill bit, insert rivet in hole and hammer

rivet pin in until it is flush with head.

PlayBooster 114261 Offset Hanger Clamp Assembly

10-3-97 Document #123821-00 replaces #114666-00.Added Drive Rivet NOTE:

J:\SPECS\123\12382100.P65

R

© 1999 by Landscape Structures. All rights reserved.

601 7TH STREET SOUTH, DELANO, MINNESOTA 55328-8605 (763) 972-3391 1-888-LSI-INST (1-888-574-4678) FAX (763) 972-3185

11-22-99

129847a0

129847b0

6

Document #12984700

Drive Rivets

General Rules For Use Of Drive Rivets

Rivets are used as "Insurance" to keep clamps from sliding

down the posts. In many cases this "Insurance" is achieved

in other ways; i.e. Panels that attach to the deck face.

Refer to the Spec Sheet Parts List and follow Installation In-

structions for each component.

Decks and Overhead Events always need rivets.

Any component fastened to the Deck does not need rivets.

Benefits of not installing unnecessary rivets: saves time, it

makes clamp adjustments as well as the removal of clamps

for replacement or adding phases much easier, and you will

have fewer damaged clamps or posts due to poor installation

techniques.

•

•

•

•

Typical

PlayBooster

Post

Typical Aluminum

Half Clamp

Rivet Pin

Typical Steel

Half Clamp

Rivet Pin

IMPORTANT:

1/4" Hole

IMPORTANT:

1/4" Hole

Typical

PlayBooster

Post

1/4" x 3/8"

Drive Rivet

100611 INSTRUCTIONS:

NOTE: Use Only Bit Size "F" or 1/4" Drill Bit.

After Play Component Assembly is Complete, Drill Hole into Post Through Half

Clamp, Insert Rivet in Hole, and Hammer Rivet Pin in Until it is Flush with Head.

1/4" x 5/8"

Drive Rivet

100610 ALUMINUM

CLAMPS

STEEL

CLAMPS

11-22-99 Document #12984700 replaces #10972900.Added general rules for use of drive rivets.

PlayBooster

R

SAFETY NOTE

Choose a protective surfacing material that

has a Critical Height Value of at least the

height of the Highest Accessible Part/Fall

Heightoftheadjacentequipment.(Ref.ASTM

F1487.)

© 1999 by Landscape Structures. All rights reserved.

11-22-99

109729a

Drive Rivet Removal

2) Unbolt BHCS w/Pin and Tee Nuts from

Clamp Using Tamperproof Hex Wrench.

Remove Offset Hanger Clamp. LightlyTap

onHalf Clampwith HammerUntil Headof

Drive Rivet PullsAway From Half Clamp.

3) Pull Out Drive Rivet Using Claw End of

Hammer.

1) DriveCenterPinofRivetStraightintoPost

Using 1/8" Diameter Punch and Hammer.

Tools Needed:

•Claw Hammer

•1/8" Diameter Steel Punch

•Tamperproof Hex Wrench

Post

Post

Offset

Hanger

Clamp Half

Clamp

BHCS w/Pin

Tee Nut

601 7TH STREET SOUTH, DELANO, MINNESOTA 55328-8605 (763) 972-3391 1-888-LSI-INST (1-888-574-4678) FAX (763) 972-3185

© 2000 by Landscape Structures. All rights reserved.

601 7TH STREET SOUTH, DELANO, MINNESOTA 55328-8605 (763) 972-3391 1-888-LSI-INST (1-888-574-4678) FAX (763) 972-3185

SAFETY NOTE

Choose a protective surfacing material that

has a Critical Height Value of at least the

height of the Highest Accessible Part/Fall

Heightoftheadjacentequipment.(Ref.ASTM

F1487)

8-25-00

10970900

4

Document #13237300

Minimum 1.2 Cubic Feet of Concrete Required per Support.

Concrete Footings, Components

Concrete

Crushed Rock

Subgrade

12"

300

20" Minimum*

510

34"

860

Typical Component Support

Loose Fill

Protective

Surfacing

*AnExample:

If you are using 12" of

loosefillmaterial,your

concrete footing will

be 22" deep.

8-25-00 Document #13237300 replaces #10970900. Added concrete footing note.

PlayBooster

R

1-1-01

7

Document #13412800

General Construction Guidelines Sheet 1 of 2

PlayBooster Installation

1) Before starting installation, study your PlayBooster plan drawing and all installation instructions carefully for

location of posts, deck heights, components and safety enclosures. Make sure slides are oriented away from the

afternoon sun and that the structure is visible (easily supervised) and accessible.

2) Clear an area large enough for your PlayBooster and at least the required minimum use zone around it, as

shown on your plan drawing. The subsurface must be well drained. If the soil does not drain naturally it must be

tiled or sloped at 1/8" to 1/4" per foot to a storm sewer or a "French Drain". If your PlayBooster is over 30' in

length it is recommended to install more than one "French Drain" or similar system to allow drainage from the

center of the play area and decrease the overall slope. If this is not possible, the structure may need to be

"stepped" to take up the grade change.

3) Overhead Obstructions: Overhead obstructions within the use zones of playground equipment that are not part

of the play structure (for example, tree limbs) shall be at least 84 in. (2130 mm) above each designated play

surface or 84 in. (2130 mm) above the pivot point of swings.All overhead utility line clearances above the use

zone areas shall comply with all local, state, and national codes, such as the National Electical Safety Code.

4) Locate all mainstructure post footing holes according to the dimensions shown on your PlayBooster plan. This

can be accomplished by laying a deck on the ground and measuring from it; by laying out a base line string grid

or using a builders transit. This step is very important and worth taking extra time to be precise. Location of

component footings such as slide supports can be done at a later time.

5) Refer to the Typical Concrete Footing installation sheet. Dig holes to the proper width and depth as shown.

(Only dig enough holes for one day's construction. Do not leave holes open over night.) Pour crushed rock in

each hole level with each other and at least 4" deep as shown. This can be easily accomplished either with a

builders transit or by laying out hole locations with a string grid, leveling the grid, and measuring down from

the grid for each footing. Tamp the crushed rock down until compacted and at proper level. This step is impor-

tant to ensure all posts will be at the proper height relative to each other, and it greatly simplifies installation. If

the soils are loose or unstable, larger diameter holes may be necessary. Check with a local engineer if in doubt.

6) Start with the lowest deck and work your way to the highest deck following instructions on the installation

sheets for typical post/deck assembly. Install barriers and roofs as located on the plan for stability.

7) After the posts are at proper heights and plumb, and the decks are at proper height and level, pour the concrete

footings per the Typical Concrete Footing Detail.

8) During construction, the site and all the material on it must be secured when unattended to prevent children

from playing on them. Do not leave decks with unprotected openings when unattended-use temporary barri-

cades if necessary.

9) Install all other play components per the installation instructions. After all components and enclosures are

properly attached, pour the remaining concrete footings per the Typical Concrete Footing Detail.

10) Install protective surfacing material.

11) Attach play hardware such as 'D' rings and swing seats last, after protective surfacing is in place and footings

have cured at least 3 days.

12) Carefully and thoroughly inspect the entire PlayBooster to be sure all fastening hardware is tight.According to

ASTM F1487, section 6.2 sharp points, edges and protrusions; any exposed bolt ends should not protrude

beyond the face of the nut more than two (2) threads. This condition is not planned, but may exist in some

applications because materials and finishes will vary. To remedy this situation, add a second nut or washer(s),

extras have been added to the spare parts kit. See illustrations on reverse side of this sheet. Children should not

be allowed on the structure until this inspection is complete.

13) Before children are allowed on the structure, the site must be cleaned and free of all construction debris and

packaging material. Do not burn on the site.

© 2001 by Landscape Structures. All rights reserved.

601 7TH STREET SOUTH, DELANO, MINNESOTA 55328-8605 (763) 972-3391 1-888-LSI-INST (1-888-574-4678) FAX (763) 972-3185

PlayBooster

R

SAFETY NOTE

Choose a protective surfacing material that

has a Critical Height Value of at least the

height of the Highest Accessible Part/Fall

Heightoftheadjacentequipment.(Ref.ASTM

F1487.)

PlayBooster

Tools Required

Tools required for installation are an auger, or other equipment for digging 14" diameter footing

holes; shovels, rubber mallet, drill (with 1/4", 7/16", 9/16", 11/16" and 3/8" drill bits), tape measure, hex

keys or allen wrenches, level, 3/8" socket set, hammer, open end wrench set, screw driver, for

surfacemount a hammer drill,3/8" and 1/2" masonry bits and transit or string line to aid in layout.

Some washable felt tip pens are also useful for marking clamp locations.

Materials Required

All PlayBooster materials are supplied except concrete for footings, protective surfacing mate-

rial, and curbing or edging material. With the exception of the special wrenches required (for the

pinned hex fasteners) no other tools are supplied.

Recycling

Many of our packaging materials can be recycled, please take the time to separate and deliver

them to a recycler. Thank You.

Installation Times

Installation times, as noted on the back of the installation sheets, are approximate and will

vary depending on soil conditions, installer's equipment and ability. Times indicated do not

include unloading or unpacking equipment. The man hours given are for one person installing

(unless otherwise noted). Cut time in half for two people.

Technical Services

If you have any questions or concerns about the installation of your structure, call our Technical

Services Department at: 1-800-328-0035 (7:30 - 5:30p.m. CST/M-F).

© 2001 by Landscape Structures. All rights reserved. 1-1-01 Document #13412800 Replaces #12809900. Udated Installations Instructions.

More Than Two (2)

ThreadsExposed AddWashers Add AnotherNut

(AlignFlatArea)

Installation

Illustrations For Note 10, (Reverse Side Of This Sheet)

601 7TH STREET SOUTH, DELANO, MINNESOTA 55328-8605 (763) 972-3391 1-888-LSI-INST (1-888-574-4678) FAX (763) 972-3185

R

CLIMBERS AND

HORIZONTAL

LADDERS

SWINGSPLATFORM

CLIMBERS

SLIDES

HIGHEST

PART

PIVOT

POINT

TOP OF GUARDRAIL OR HIGHEST

PLATFORM WITH BARRIER

HEIGHT OF

TAKEOFF

PLATFORM

1.) Determine the highest accessible part - by definition.

2.) Determine the type of surfacing material desired:

•Unitary - Bound rubber type materials for the accessible areas.

•Loose-fill - Sand, wood chips, etc. for non-accessible areas.

3.) Select a material that has a Critical Height value of at least the height of the highest accessible

part.

•According to the CPSC, Critical Height is defined as the maximum height from

which the instrumented metal headform, upon impact, yields both a peak decelera-

tion of no more than 200 G's and a HIC value of no more than 1,000 when tested in

accordance with the procedure described in the ASTM Test Method F1292.

•Request independent laboratory test results showing the critical height of each

product per the above procedures for commercially available products. The CPSC

has tested some common loose-fill materials that are commonly not tested as a

protective surfacing. (See back page.)

4.) Cover the designated use zone with the desired materials. If a different type of material is used for

the accessible route of travel, make sure the surfaces are maintained flush.

© 2001 by Landscape Structures. All rights reserved.

Selecting Protective Surfacing for Your Playground

Document #13412800

Sheet 2 of 2

601 7TH STREET SOUTH, DELANO, MINNESOTA 55328-8605 (763) 972-3391 1-888-LSI-INST (1-888-574-4678) FAX (763) 972-3185

SAFETY NOTE

Choose a protective surfacing material that

has a Critical Height Value of at least the

height of the Highest Accessible Part/Fall

Heightoftheadjacentequipment.(Ref.ASTM

F1487.)

Critical Heights

© 2001 by Landscape Structures. All rights reserved.

Critical Heights (in Feet)

*

*

*

*

*

*

*

*

NA = Not Available

NOTE: Compressed depths most accurately depict conditions on a playground.

Uncompressed Compressed

Depth Depth

Material 6" 9" 12" 9"

Wood Mulch ................................................ 7' 10' 11'............... 10'

Double Shredded Bark Mulch ...................... 6' 10' 11'................ 7'

Uniform Wood Chips ................................... 6' 7' 12'................ 6'

Fine Sand..................................................... 5' 5' 9'................ 5'

Coarse Sand................................................. 5' 5' 6'................ 4'

Fine Gravel .................................................. 6' 7' 10'................ 6'

Medium Gravel............................................ 5' 5' 6'................ 5'

An approximation of the maximum fall height from which a life-threatening

head injury would not be expected to occur, based on tests in which a headform

yielded both a peak deceleration of less than 200 G's and a HIC of less than

1000 upon impact.

Handbook for Public Playground Safety, published by the U.S. Consumer Prod-

ucts Safety Commission, Section 10, Table 2, page 21.

*

*

*

601 7TH STREET SOUTH, DELANO, MINNESOTA 55328-8605 (763) 972-3391 1-888-LSI-INST (1-888-574-4678) FAX (763) 972-3185

SAFETY NOTE

Choose a protective surfacing material that

has a Critical Height Value of at least the

height of the Highest Accessible Part/Fall

Heightoftheadjacentequipment.(Ref.ASTM

F1487.)

This manual suits for next models

26

Other landscape structures Play Set & Playground Equipment manuals

Popular Play Set & Playground Equipment manuals by other brands

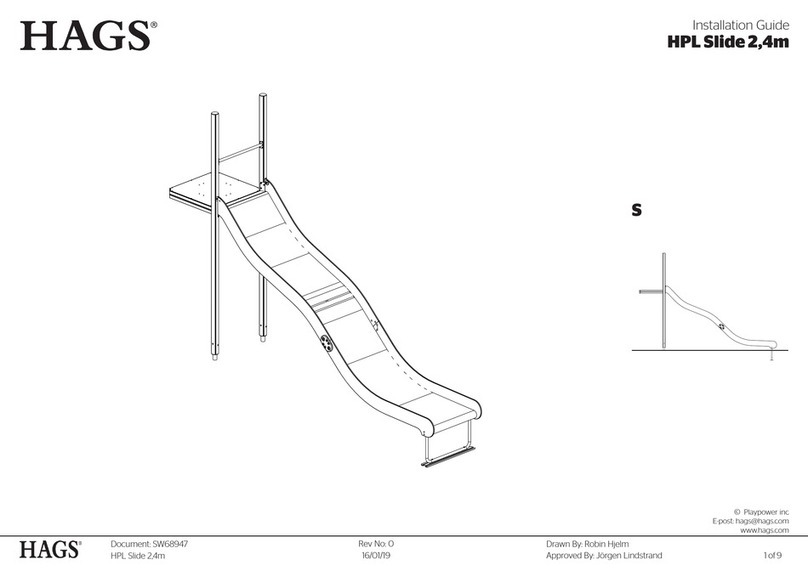

HAGS

HAGS HPL Slide 2,4m installation guide

ultraPLAY

ultraPLAY DC-SAPR manual

TP Toys

TP Toys Treehouse Cargo Net Instructions for assembly, maintenance and safe use

Outsunny

Outsunny 344-061V00 Assembly instruction

TP active fun

TP active fun TP850 Instructions for assembly, maintenance and safe use

COROCORD

COROCORD 2820 Installation instruction