Operation & Maintenance Manual 05

STRUCTURAL DETAILS & GENERAL ARRANGEMENT

3.3 - SF6 GAS SYSTEM

The gas-tight compartments and the gas seals ensure long

service life.

A gas pressure monitor which is temperature compensated

provides accurate readings on the internal gas condition of the

switchgear.

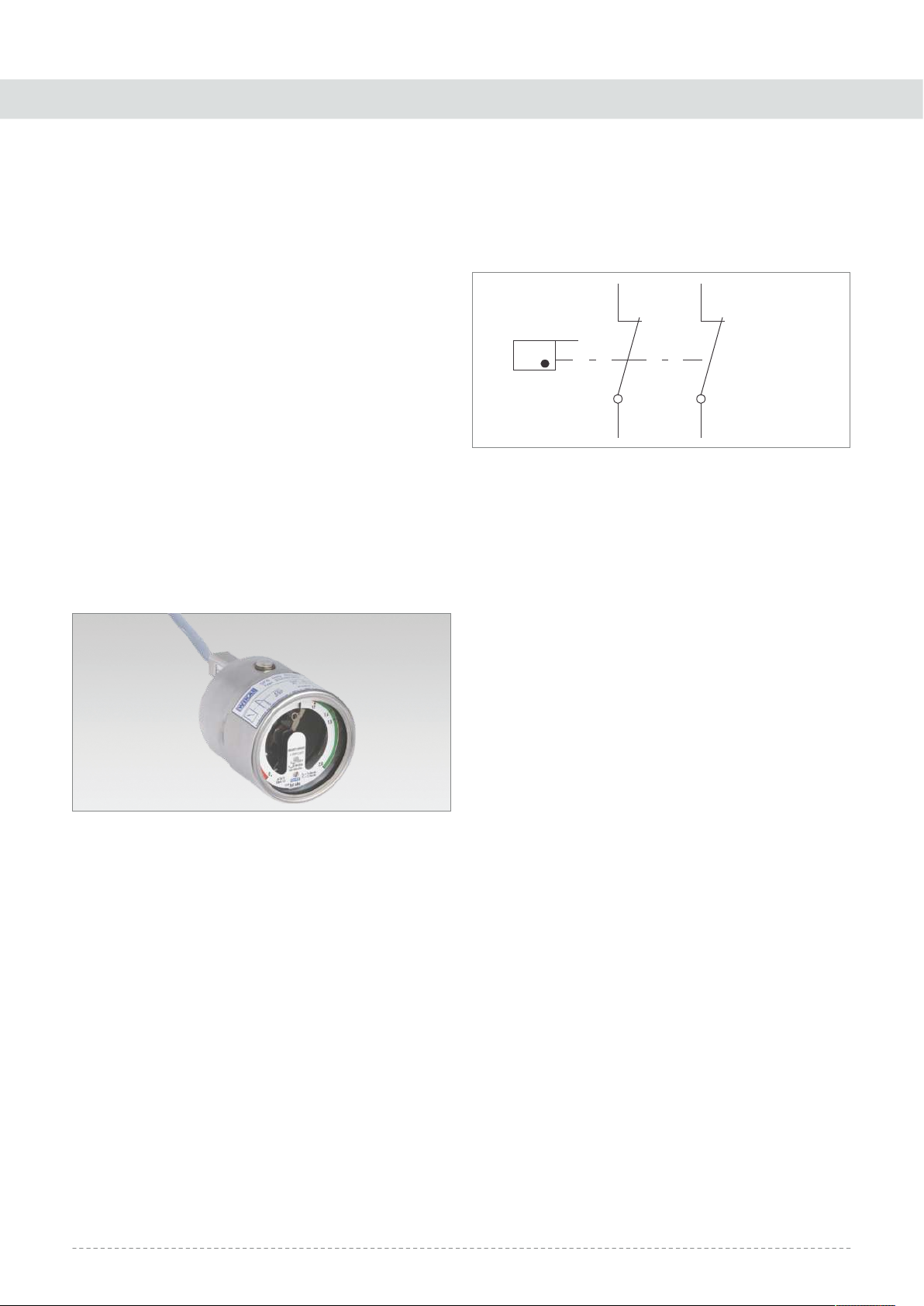

3.3.1 - SF6 Gas Pressure Monitoring Device

The Breaker and Busbar compartment is sealed with SF6 gas at

1.35 kg/cm2 @ 20 deg. C, which is continuously monitored by a

density monitor.

SF6 Gas density monitor shall be provided for each separate

compartment consisting of SF6 gas.

WIKA make Gas density monitor with model number

233.52.063 is as shown in gure 3.3.1 below:

The safe permissible Gas pressure range is between 1.2 to

1.35 bars @ 20 deg. C

Some special features of the gas density monitor are as

follows:

- Hermetically leak tight, therefore no negative impact by

atmospheric pressure uctuations and differences in

altitude.

- Local readout with alarm contacts.

- Temperature compensated.

The Gas Density Monitor is available with maximum two

magnetic snap action switching contacts. These contacts can

be normally close (NC) or normally open (NO).

These 2 contacts can be used for alarm and tripping purpose.

Let us consider switching contacts are normally closed

(NC). The terminal number details are as shown in

gure 3.3.2 :

When gas pressure inside tank is more than 1.25 Kg/cm² then

these two contacts shall be open.

1. When gas pressure decreases to less than 1.25 Kg/cm²,

contact with terminal no. 3-4 becomes Close. This contact

can be used to give an alarm, so that gas can be relled

before gas pressure falls to minimum permissible pressure.

When the gas is relled and the internal pressure exceeds

1.25 Kg/cm² then the switch is automatically reset (becomes

open).

2. When gas pressure decreases to less than 1.20 Kg/cm²,

contact with terminal no. 1-2 becomes Close. This contact

can be used to trip VCB. When the gas is relled and the

internal pressure exceeds 1.20 Kg/cm² then the switch is

automatically reset (becomes open).

Note: The switching point is not adjustable

3.4 - PRESSURE RELIEF DISC

The bursting disc is located on the rear of the breaker chamber

of every panel. For the bus compartment, it is located at the top

rear with an arcing chute for the main busbar direct arcing

produced to the rear. When the gas pressure in the

compartment exceeds 3.5kg/cm² during an arc fault, this disc

will burst.

MOLECULAR SIEVES

For proper working condition of the SF6 insulated switchgear,

the moisture content of the gas must be kept below 150ppm.

Condensation within the gas compartment is taken care of by

the molecular sieve, which absorbs moisture.

3.4.1 - GAS FILLING

During operation or lifetime of the equipment it may happen

that there is leakage in the tank due to some unavoidable

circumstances and the pressure on the SF6 manometer on the

Figure 3.3.1 - Gas pressure monitor (model 233.52.063)

Figure 3.3.2 - Normally closed switching contacts

1

2

3

4

SF6 GAS

LIMIT S/W