SAFETY SYMBOL

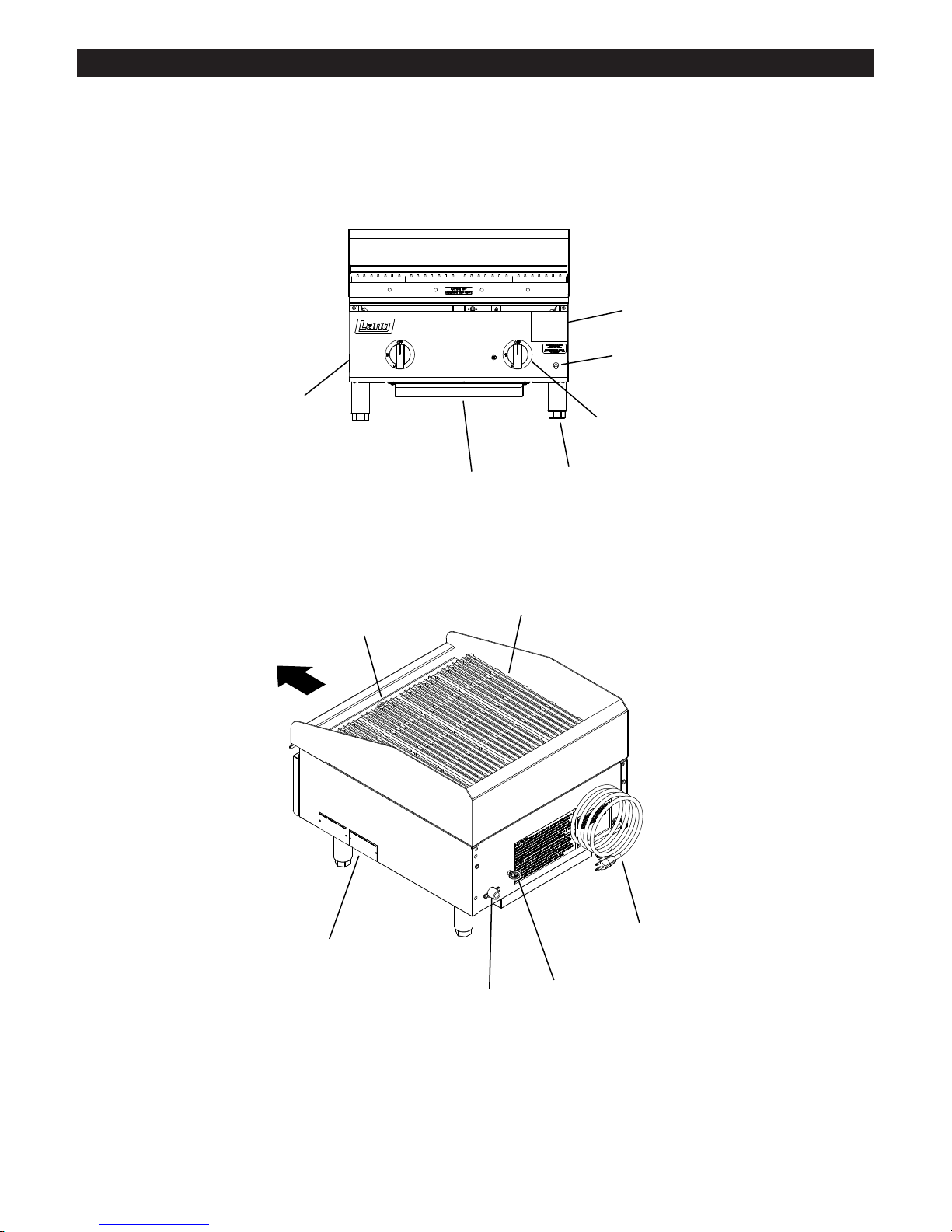

Model No.:

Serial No.:

Voltage:

1-Phase or 3 Phase:

Purchased From:

Location:

Purchase Date:

Installed Date:

These symbols are intended to alert the user to the presence of important operating

and maintenance instructions in the manual accompanying the appliance.

FOR YOUR SAFTEY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

THE VICINTIY OF THIS OR ANY OTHER APPLIANCE.

The installation of the Appliance must conform to the NATIONAL FUEL GAS CODE "ANSI Z223.1 - LATEST

EDITION" AND ALL LOCAL GAS COMPANY RULES AND REGULATIONS.

IN CANADA INSTALLATION SHALL BE IN ACCORDANCE WITH THE CURRENT CAN/CGA-B149.1 NATURAL

GASINSTALLATIONCODEORCAN/CGA-B149.2PROPANEINSTALLATIONCODEANDLOCALCODESWHERE

APPLICABLE. POST IN PROMINENT LOCATION

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT USER SMELLS GAS. THIS INFORMATION

SHALL BE OBTAINED BY CONSULTING YOUR LOCAL GAS SUPPLIER. AS A MINIMUM, TURN

OFF THE GAS AND CALL YOUR GAS COMPANY AND YOUR AUTHORIZED SERVICE AGENT.

EVACUATE ALL PERSONNEL FROM THE AREA.

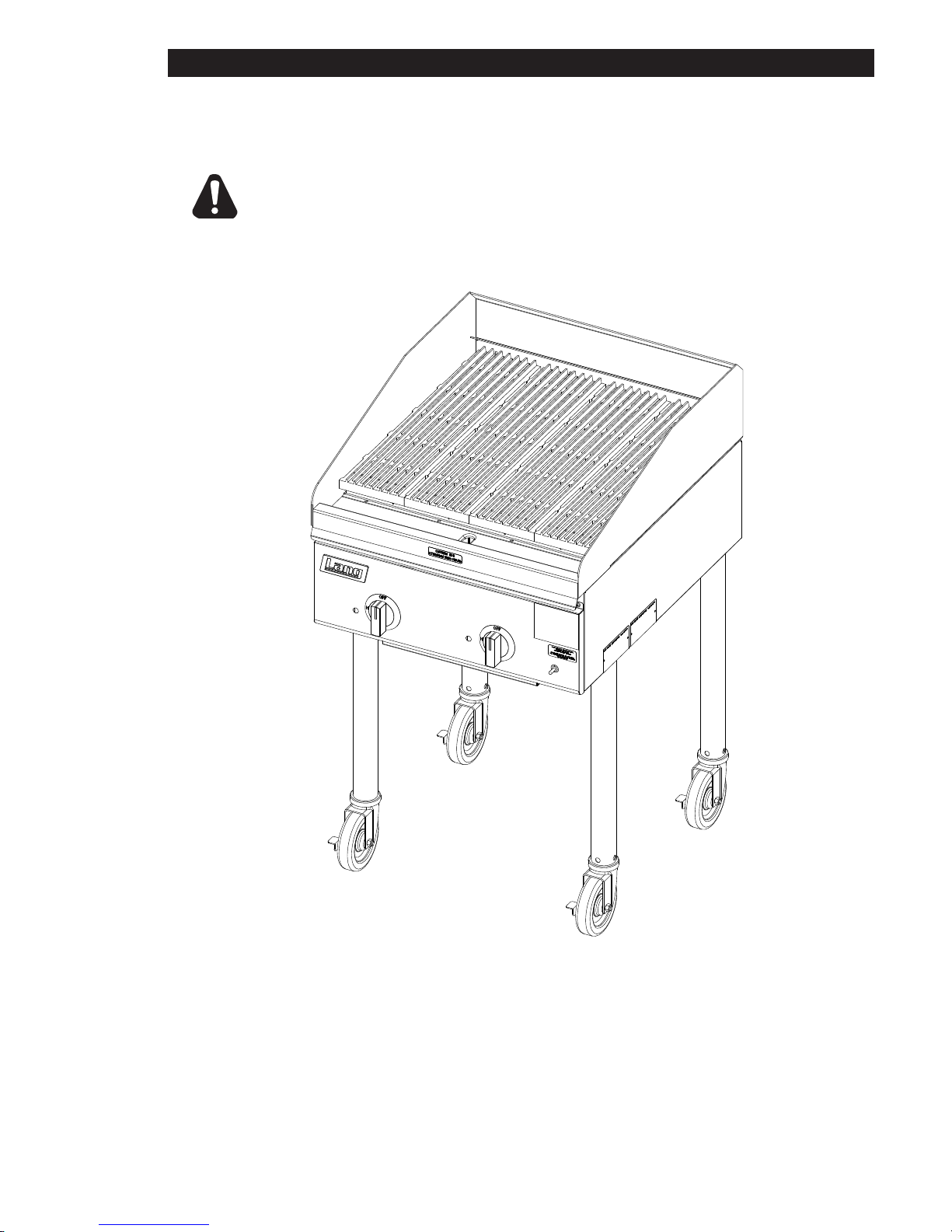

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATION

& MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

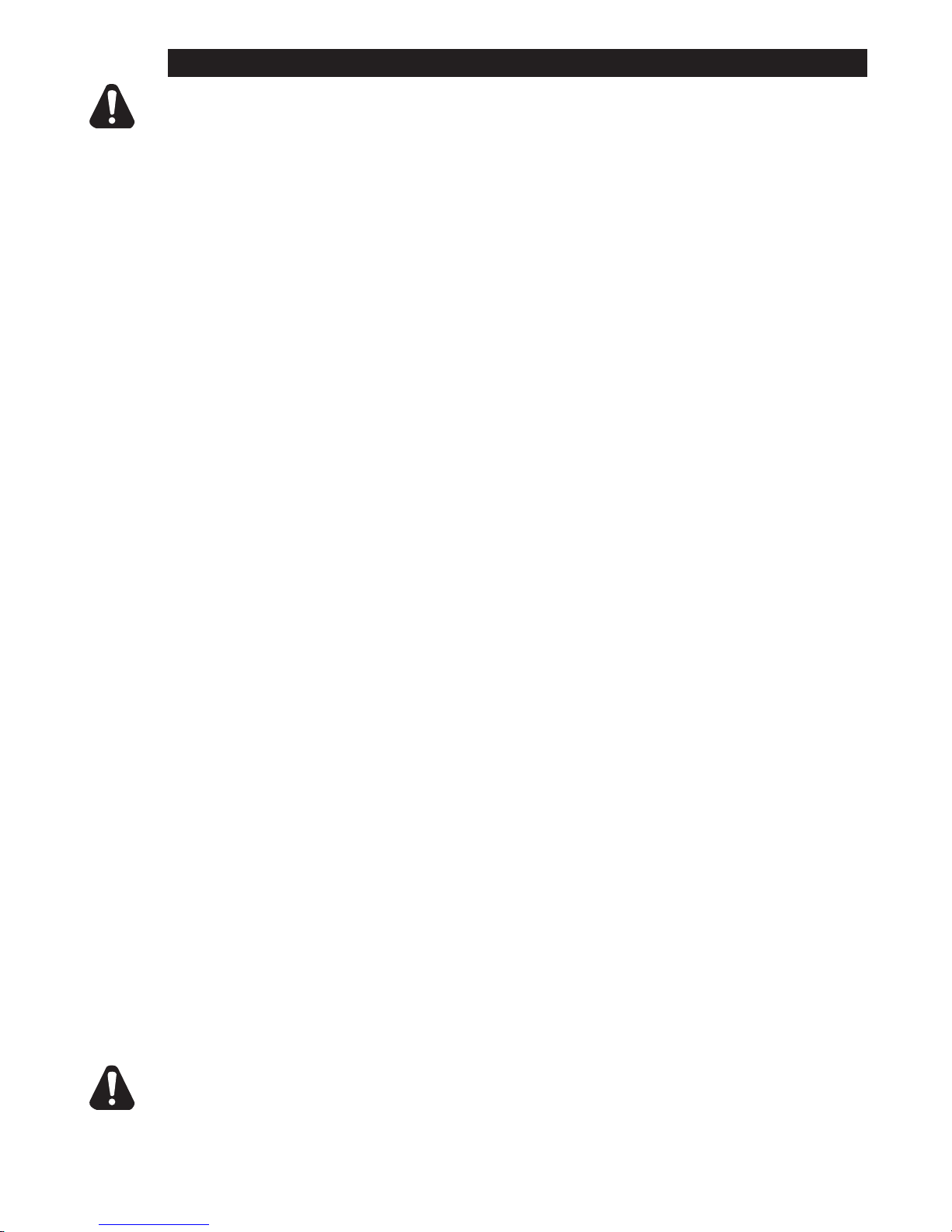

WARNING

RISK OF FIRE OR ELECTRIC SHOCK

DO NOT OPEN

WARNING, TO REDUCE THE RISK OF ELECTRICAL SHOCK, DO NOT REMOVE

CONTROL PANEL. NO USER-SERVICABLE PARTS INSIDE.

REPAIRS SHOULD BE DONE BY AUTHORIZED SERVICE PERSONNEL ONLY.

NOTICE

Using any part other than genuine Lang factory supplied parts relieves the manufacturer of all liability.

Lang reserves the right to change speci cations and product design without notice. Such

revisions do not entitle the buyer to corresponding changes, improvements, additions or

replacements for previously purchased equipment.

Due to periodic changes in designs, methods, procedures, policies and regulations, the

specifications contained in this sheet are subject to change without notice. While Lang

Manufacturing exercises good faith efforts to provide information that is accurate, we are

not responsible for errors or omissions in information provided or conclusions reached as a

result of using the speci cations. By using the information provided, the user assumes all risks in con-

nection with such use.

MAINTENANCE AND REPAIRS

Contact your local dealer for service or required maintenance. Please record the model number, serial

number, voltage and purchase & Installation Information in the area below and have it ready when you

call to ensure a faster service.