3

INSTALLATION

RECEIVING AND UNCRATING

Upon receipt of the equipment, check for

freight damage, both concealed and

visible. Visible damage must be noted on

the freight bill at the time of delivery and

signed for by the freight company's agent.

Concealed loss or damage means loss or

damage which does not become apparent

until the merchandise has been unpacked.

When concealed damage is discovered,

make a written request for inspection by

the carrier’s agent within 15 days of the

delivery date. In either case, do not

return the damaged merchandise to

Star Manufacturing, file your claim with

the carrier.

Before uncrating the equipment confirm

that the voltage marked on the box

matches that of the building. The oven

voltage must match the voltage supplied.

Place the crate as near the intended

installation as possible before uncrating

the equipment. The crate will help protect

the equipment while it is being moved

through doorways and down halls.

Uncrate the oven and set as near the

intended installation as practical. Save

the crating materials as they may be used

during the installation.

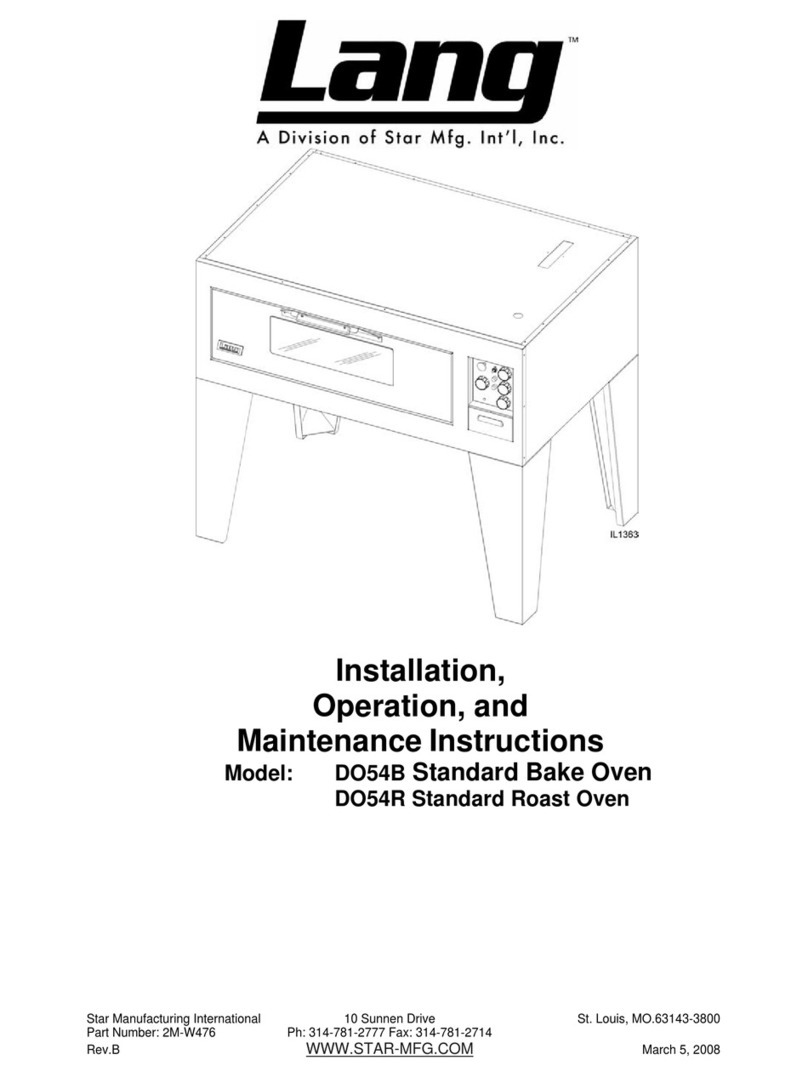

INSTALLING THE LEGS

If the oven is to be assembled as a range

the legs are packaged in with the range

top. If the oven is to be stacked on

another oven the legs are packaged in a

separate box marked "Fabricated Legs".

Place some cardboard on the floor and

gently tip the oven backwards onto it.

The range legs are screwed into 4 nuts

welded to the bottom of the oven. Make

sure the legs are screwed firmly into the

nuts.

The stacked oven fabricated legs attach to

the bottom corners of the oven with the

nuts and bolts supplied with the legs.

Set the oven on the legs, push it into

position, and level it using the adjusters

on the bottom of the legs.

CLEARANCES

THE FOLLOWING CLEARANCES TO

COMBUSTIBLE SURFACES MUST BE

MAINTAINED:

4 INCHES TO SIDES

3 INCHES TO BACK

DECK OVEN ASSEMBLY

STACKING THE OVENS

If the oven is to be assembled as a range,

skip this section refer to the Range Top

Installation Manual.

Remove the envelope labeled "Stacking

Kit" from the oven cavity.

Place some cardboard on the floor and

gently tip the oven that is to be stacked

backwards onto it. Install four pins from

the stacking kit into the threaded holes on

the side flanges of the oven bottom.

Remove the plastic plugs from the top of

the oven on legs so the pins just installed

in the top oven can nest into the holes.

Lift the oven that is lying on its back onto

the oven on legs. Align the pins so they

drop into the holes in the bottom oven.