3

IMPORTANT READ FIRST IMPORTANT

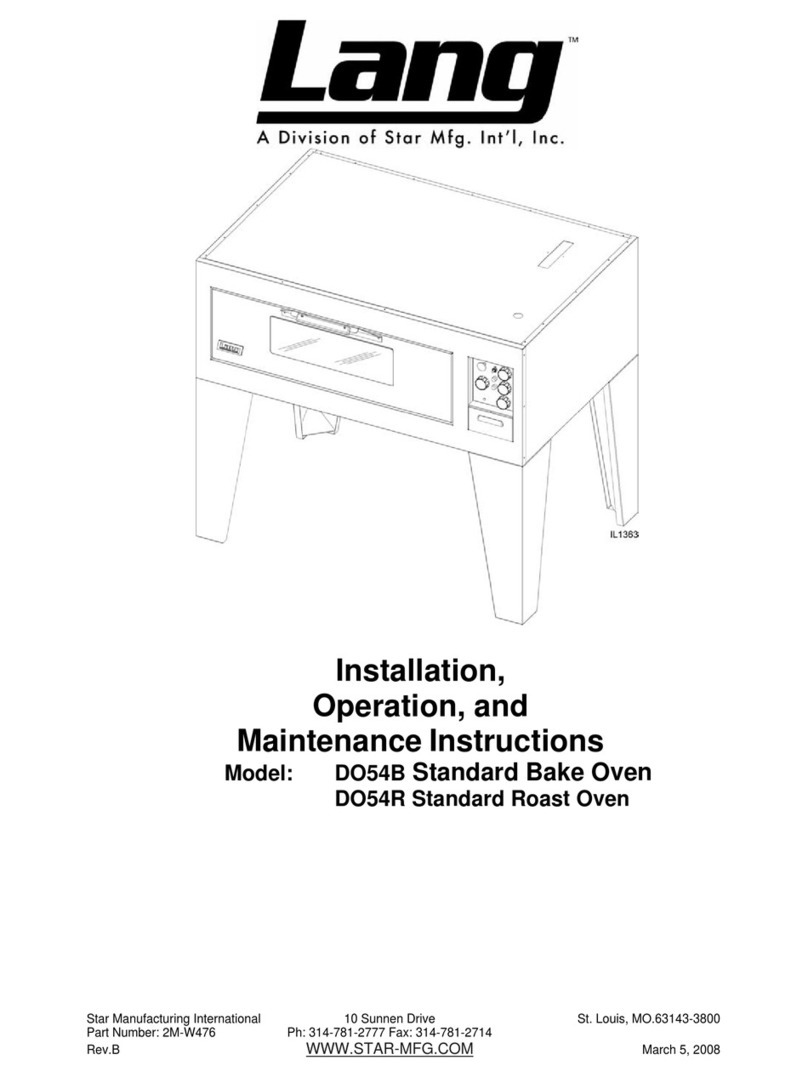

CAUTION THE OVEN WEIGHS 500 LBS. FOR SAFE HANDLING, INSTALLER

SHOULD OBTAIN HELP AS NEEDED, OR EMPLOY APPROPRIATE

MATERIALS HANDLING EQUIPMENT (SUCH AS A FORKLIFT, DOLLY, OR

PALLET JACK) TO REMOVE THE UNIT FROM THE SKID AND MOVE IT TO

THE PLACE OF INSTALLATION.

CAUTION ANY STAND, COUNTER OR OTHER DEVICE ON WHICH THE OVEN WILL

BE LOCATED MUST BE DESIGNED TO SUPPORT THE WEIGHT OF THE

OVEN.

CAUTION SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN

CUT.

WARNING INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL QUALIFIED

TO WORK WITH PLUMBING. IMPROPER INSTALLATION CAN CAUSE

INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT. UNIT MUST

BE INSTALLED IN ACCORDANCE WITH ALL APPLICABLE CODES.

NOTICE The data plate is located above control panel behind wire mesh screen.

The oven serial number, gas specifications, and clearance specifications

are on the data plate. This information should be carefully read and

understood before proceeding with the installation.

NOTICE The installation of any components such as a vent hood, grease

extractors, fire extinguisher systems, must conform to their applicable

National, State and locally recognized installation standards.

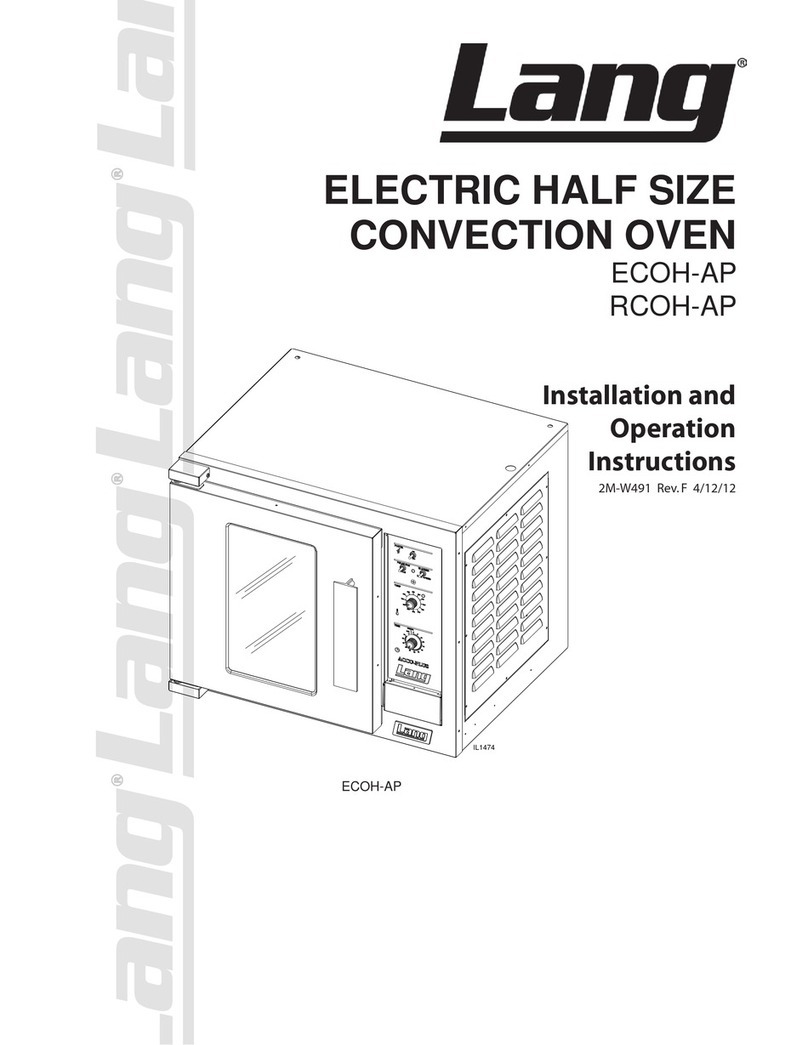

WARNING THIS APPLIANCE IS EQUIPPED WITH A 3-PRONG (GROUNDING) PLUG

FOR YOUR PROTECTION AGAINST SHOCK HAZARD AND MUST BE

PLUGGED DIRECTLY INTO A PROPERLY GROUNDED 3-PRONG

RECEPTACLE. DO NOT CUT OR REMOVE THIS GROUNDING PRONG

FROM THE PLUG.

WARNING CONVECTION OVENS INSTALLED WITH CASTERS MUST HAVE THE

FOLLOWING: A CONNECTOR THAT COMPLIES WITH THE STANDARD

FOR CONNECTORS FOR MOVABLE GAS APPLIANCES ANSI Z21.69

LATEST EDITION, A QUICK DISCONNECT THAT COMPLIES WITH THE

STANDARD FOR QUICK DISCONNECT DEVICES FOR USE WITH GAS

FUEL, ANSI Z21.141 LATEST EDITION, A TETHER OR OTHER MEANS TO

LIMIT APPLIANCE MOVEMENT WITH OUT RELIANCE ON THE GAS

SUPPLY PIPING. SECURELY ATTACH THE TETHER TO THE EYEBOLT

PROVIDED AT THE REAR OF THE APPLIANCE.

NOTICE Kits designed to accommodate ovens from sea level to 5000 feet. Contact

factory for orifice sizes on installations above 5000 feet.

WARNING BEFORE LIGHTING, USE A SOAP AND WATER SOLUTION TO TEST ALL

JOINTS FOR GAS LEAKS.

NOTICE During the first few hours of operation you may notice a small amount of

smoke coming off the oven, and a faint odor from the smoke. This is

normal for a new oven and will disappear after the first few hours of use.

CAUTION ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.