Precautions

Precautions when using a spring compressor - PLEASE READ

• When compressed, a vehicle road spring is storing a very large amount of energy. Whilst all

possible actions have been taken to reduce the risk of slippage this risk will always be present.

• Keep hands and body clear of the spring when operating the spring compressor.

• Do not leave compressed spring unattended.

• Always wear protective head, eye and hand gear. Responsibility for damage or injury lies with the

user.

• Maintain the tool in a clean condition, especially the jaw clamps.

• Do not operate the spring compressor if parts are damaged or missing.

• Do not allow untrained persons to use the spring compressor.

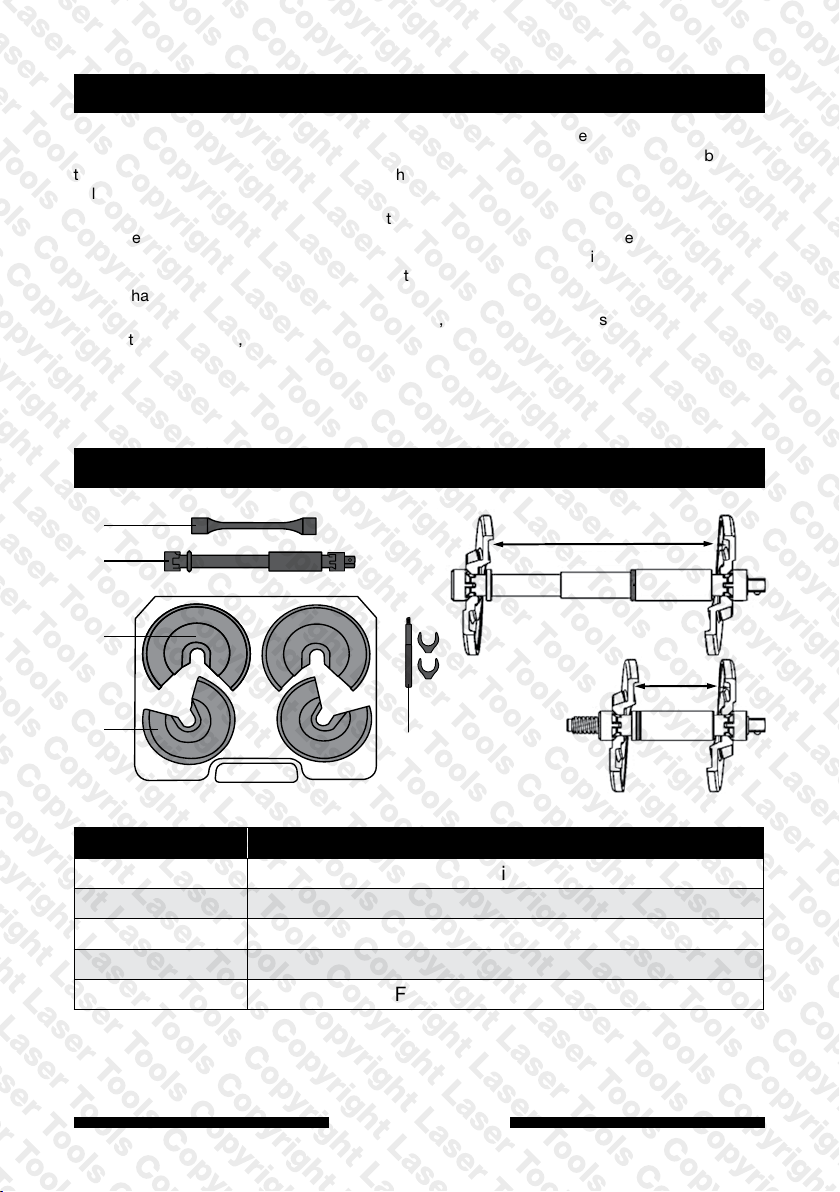

WARNING: To prevent equipment damage and possible injury when fitting the

5931 to a tensioned spring always ensure the cups are positioned to allow the

force screw thread to remain engaged by a minimum of 3 full turns at the free

length of the spring.

Our products are designed to be used correctly and with care for the purpose for which they are

intended. No liability is accepted by the Tool Connection for incorrect use of any of our products, and

the Tool Connection cannot be held responsible for any damage to personnel, property or equipment

when using the tools. Incorrect use will also invalidate the warranty.

If applicable, the applications database and any instructional information provided has been designed

to offer general guidance for a particular tool’s use and while all attention is given to the accuracy

of the data no project should be attempted without referring first to the manufacturer’s technical

documentation (workshop or instruction manual) or the use of a recognised authority such as

Autodata.

It is our policy to continually improve our products and thus we reserve the right to alter

specifications and components without prior notice. It is the responsibility of the user to ensure the

suitability of the tools and information prior to their use.

If this product fails through faulty materials or workmanship, contact our

service department direct on: +44 (0) 1926 818186. Normal wear and tear

are excluded as are consumable items and abuse.

Guarantee

Distributed by The Tool Connection Ltd

Kineton Road, Southam, Warwickshire CV47 0DR

T+44 (0) 1926 815000 F+44 (0) 1926 815888

5931_Instructions_V6