Leader Evaporator Springtech EXTREME 6 User manual

Leader Evaporator Co., Inc.

49 Jonergin Drive

Swanton, VT 05488

Tel: 802-868-5444

www.leaderevaporator.com

EXTREME 6

Reverse Osmosis System

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:2

TABLEOFCONTENTS

INTRODUCTION..........................................................................................................................................................................4

THEORYOFOPERATION..............................................................................................................................................................4

Terms..............................................................................................................................................................................................4

DescriptionofMembrane...............................................................................................................................................................5

EQUIPMENTDESCRIPTION..........................................................................................................................................................6

FRONTVIEW...........................................................................................................................................................................................6

REARVIEW.............................................................................................................................................................................................6

FEEDPUMP............................................................................................................................................................................................7

PRESSUREPUMP.....................................................................................................................................................................................7

RECIRCULATIONPUMPS............................................................................................................................................................................7

CONTROLPANEL.....................................................................................................................................................................................8

FLOWMETERS........................................................................................................................................................................................8

PRESSUREGAUGES..................................................................................................................................................................................8

SAMPLINGPORTS....................................................................................................................................................................................9

V1ANDV2VALVES.................................................................................................................................................................................9

FLOWCONTROLVALVES...........................................................................................................................................................................9

INCLUDEDEQUIPMENT...........................................................................................................................................................................10

OPTIONALSETUPEQUIPMENT,PARTSANDSUPPLIES....................................................................................................................................11

SETUP.......................................................................................................................................................................................12

AREAREQUIRED....................................................................................................................................................................................12

POWERREQUIREMENTS..........................................................................................................................................................................12

GENERALCONNECTIONLAYOUT...............................................................................................................................................................13

Simple3TankRODiagram...........................................................................................................................................................13

STRAINERTOVALVEV6CONNECTION.......................................................................................................................................................14

VESSEL,PUMP,PREFILTERCANISTERANDWASHTANKDRAINS....................................................................................................................14

V3,V4ANDV19CONNECTIONS..............................................................................................................................................................17

V19–ConnectionToDrain...........................................................................................................................................................17

V3–ConnectionToPermeateStorage.........................................................................................................................................17

V4–ConnectiontotheConcentrateStorage...............................................................................................................................18

OPERATION..............................................................................................................................................................................19

STARTUPOFSYSTEMWITHLITTLEORNOFLUID...........................................................................................................................................19

INITIALSYSTEMCLEANING.......................................................................................................................................................................20

DATALOGGING.....................................................................................................................................................................................20

CYCLESANDTIMING...............................................................................................................................................................................21

PERMEABILITYTEST................................................................................................................................................................................22

FLOWVALVEINFORMATION....................................................................................................................................................................25

ADJUSTINGV1ANDV2FOROPERATIONS..................................................................................................................................................26

SAMPLEPORTUSE.................................................................................................................................................................................26

CONCENTRATECYCLE.............................................................................................................................................................................26

DESUGARCYCLE....................................................................................................................................................................................29

RINSECYCLE.........................................................................................................................................................................................31

WASHCYCLE........................................................................................................................................................................................34

HotWaterWash...........................................................................................................................................................................34

AlkalineSoapWash......................................................................................................................................................................34

AcidSoak......................................................................................................................................................................................34

MAINTENANCE.........................................................................................................................................................................37

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:3

PREFILTERS...........................................................................................................................................................................................37

MEMBRANEREMOVALANDINSTALLATION.................................................................................................................................................39

Removal........................................................................................................................................................................................39

→CommonStepsforRemovalofMembranes.............................................................................................................................................39

→StepsforRemovalOfBrineSealClampedMembranes............................................................................................................................41

→StepsforRemovalOfThreadedRodClampedMembranes......................................................................................................................42

Installation...................................................................................................................................................................................43

→StepsforInstallaonofBrineSealClampedMembranes.........................................................................................................................43

→StepsForInstallaonofThreadedRodClampedMembranes..................................................................................................................45

CommonStepsforInstallation.....................................................................................................................................................................47

DAILY..................................................................................................................................................................................................48

PERIODIC.............................................................................................................................................................................................49

ENDOFSEASONSHUTDOWNANDSTORAGE...............................................................................................................................................49

BEGINNINGOFSEASONSTARTUP..............................................................................................................................................................51

TROUBLESHOOTINGCHART......................................................................................................................................................53

ATTACHMENT#1–ELECTRICALSCHEMATIC..............................................................................................................................54

ATTACHMENT#2–OPERATIONSDATALOGSHEET....................................................................................................................56

ATTACHMENT#3‐PERMEABILITYTESTSHEET..........................................................................................................................57

ATTACHMENT#4–WARRANTYINFORMATION.........................................................................................................................58

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:4

INTRODUCTION

ALeaderEvaporatorSpringtechEXTREMEReverseOsmosissystemisdesignedtosignificantlyimprovetheproducer’s

productivitybygeneratinghighsugarpercentagesap.Throughuseofhighpressure,thesystemremoveswaterfrom

thesapresultinginamoreconcentratedsugarsolutionenteringtheevaporator.Thisinturnshortenstheboiltime

requiredresultinginfuelandtimesavings.

SomeofthefeaturesoftheSpringtechEXTREME6are:

Easyaccessibilitytopumpsandmembranes

Stainlesssteelframe,membranehousings,pumpsandpumphousings

Fastwashcycle

Withreasonablesap–theabilitytogeneratehighbrixconcentratewithasinglepass

Flowmetersforthepermeateofeachvesselandoneforthesystemconcentrate

THEORYOFOPERATION

Inreverseosmosis,throughtheuseofspecialsemi‐permeablemembranesandhighpressure,waterisforced,ina

pureform,throughthemembranewhiletheconcentratedsolutionremainsoutsidethemembraneandis

concentrated.Forthesugarmakerthismeanswater(permeate)isremovedfromthesapandasapwithahigher

sugarlevel(concentrate)isproducedfortheevaporationprocess.

Terms

Semi‐permeableMembrane–Unitconsistingofmultilayersofspacersandmembranes

Pre‐FilterUnit–Designedtoremovesuspendedsolidsfromthesapincomingtothereverseosmosissystem

FeedPump–Theinitialpumpdesignedtosupplythereverseosmosisunitwithsapandmaintainpressurein

thesystem

PressurePump–Thepumpdesignedtoprovidethepressureneededtoforcethesapthroughthereverse

osmosismembrane

PressureVessel–Thecontainmentunitforthesemi‐permeablemembrane

Permeate–Purifiedwaterremovedfromthemaplesapduringtheconcentratecycle

Concentrate–themaplesaphavingahigherpercentageofsugarbecausewater(permeate)hasbeen

removed

PermeateHoldingTank–Atankdesignedtoholdaminimumtwicethehourlyoutputofthesystem

ConcentrateCycle–ProcessduringwhichwaterisremovedfrommaplesapresultinginConcentrateand

Permeate

ReverseFlowConcentrateCycle–Concentratecycleinwhichtheflowthroughthesystemisreversed

allowingmoreevenuseofthemembranes

De‐SugaringCycle‐ProcesstoreclaimsugarsfromthemembraneduringwhichPermeateisrunthrough

thereverseosmosisunitusingConcentratecyclevalvesettings

RinseCycle–CleaningprocessofpassingstoredPermeatethroughtheReverseOsmosissystemandout

todrain

ChemicalWashCycle–Processofchemicalwashingthemembranesbyrecirculatingasolutionthrough

thereverseosmosissystem.Dependentonrequirement,chemicalmaybebealkalioracid.

PermeabilityTest–Testtodeterminetheperformanceofthemembranesagainstabenchmark

SapRecirculationLoop–Processofrecirculatingoutputfromtheconcentratecycletotherawsaptank,

increasingtheconcentrationofthesapinthetank

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:5

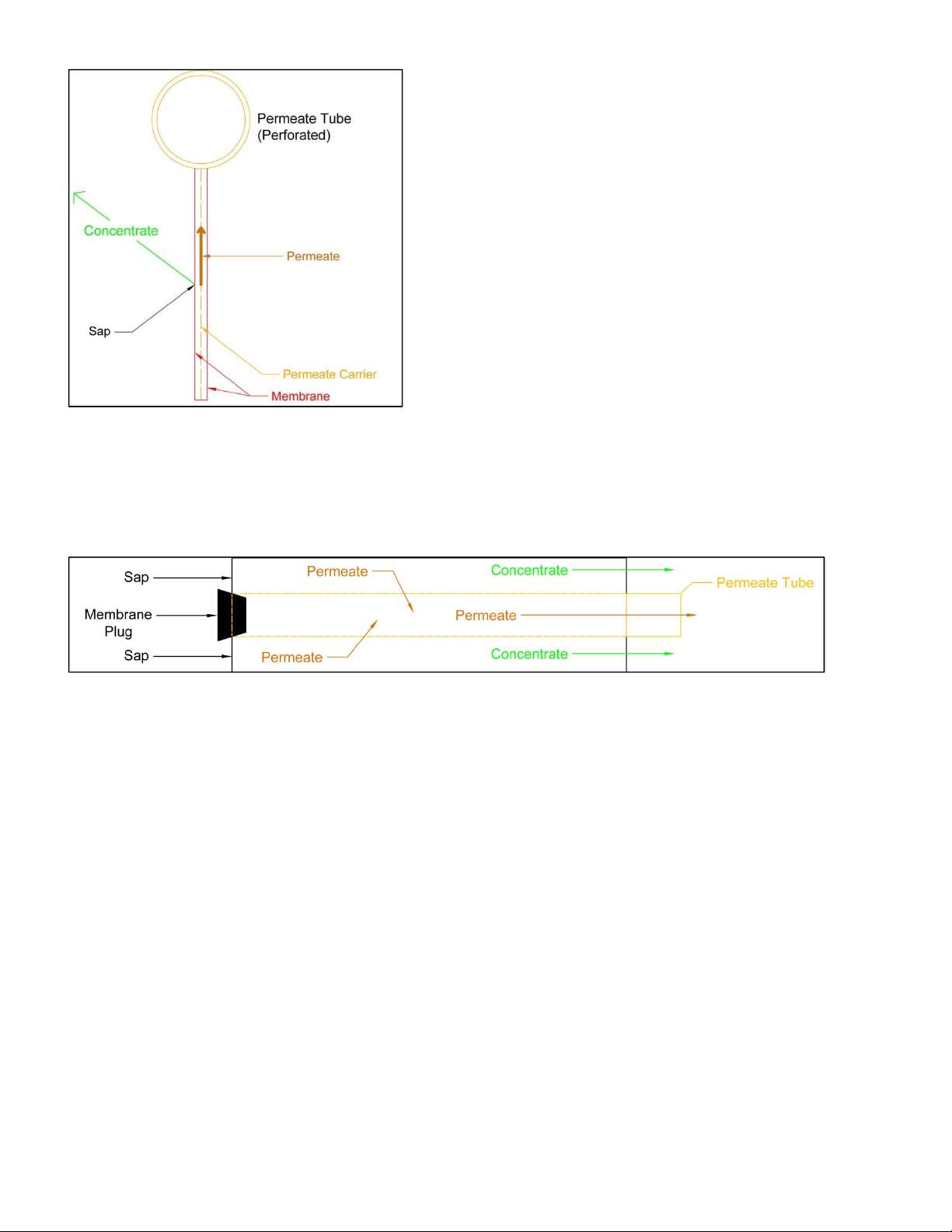

DescriptionofMembrane

Thedrawingaboverepresentstheflowofliquidthroughamembraneinthesystem.Themembraneishoused

inapressurevessel(notshown).

Thebasicunitsofthereverseosmosismembraneare

describedinthecrosssectiondrawing.

Attachedtothepermeatetubeisamembraneunit

consistingofapermeatecarrierbetweentwo

membranes.

Thereareanumberofthesemembraneunitsattached

aroundtheoutsideofthepermeatetube.

Betweeneachofthemembraneunitsisaspacer

throughwhichthesapandconcentratecanflow.

Thepermeatetubeisperforatedsothepermeatecan

becollectedfromthemembraneunit.

Ateachunitasthesapispressurized,thepermeate

canflowthroughthemembraneandbecarriedtothe

permeatetube.Theconcentratecannotpenetratethe

membraneandispushedoutthemembraneassembly.

Themembraneunitsarewoundaroundthepermeate

tubeandanoutsidesupportstructureisplacedaround

thewoundassembly.

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:6

EQUIPMENTDESCRIPTION

TheLEADEREVAPORATORSpringtechEXTREMEReverseOsmosisSystemisdesignedtooffermaximumconcentration

tocostperformance.Throughoptimizingofpumpsandmembranesthereverseosmosissystemsdelivergreaterflow

potentialtotheuser.TheLEADEREVAPORATORSpringtechEXTREMEReverseOsmosissystemisdesignedandbuilt

usingthesameprinciplesofsuperiorqualityappliedtoourevaporators.

TheLEADEREVAPORATORSpringtechEXTREMEReverseOsmosisSystemiscoveredbyamanufacturer’swarranty–

SeeATTACHMENT#4.

NOTES:

1. Pictures,sketchesanddrawingspresentedinthisdocumentarenottoscale.

2. Directions(rightandleft)willbeasfacingthefrontofthesystem.

3. Thefeedpump,prefiltersandwashtankaremountedasaseparateunittobeattachedtothemainsystem.

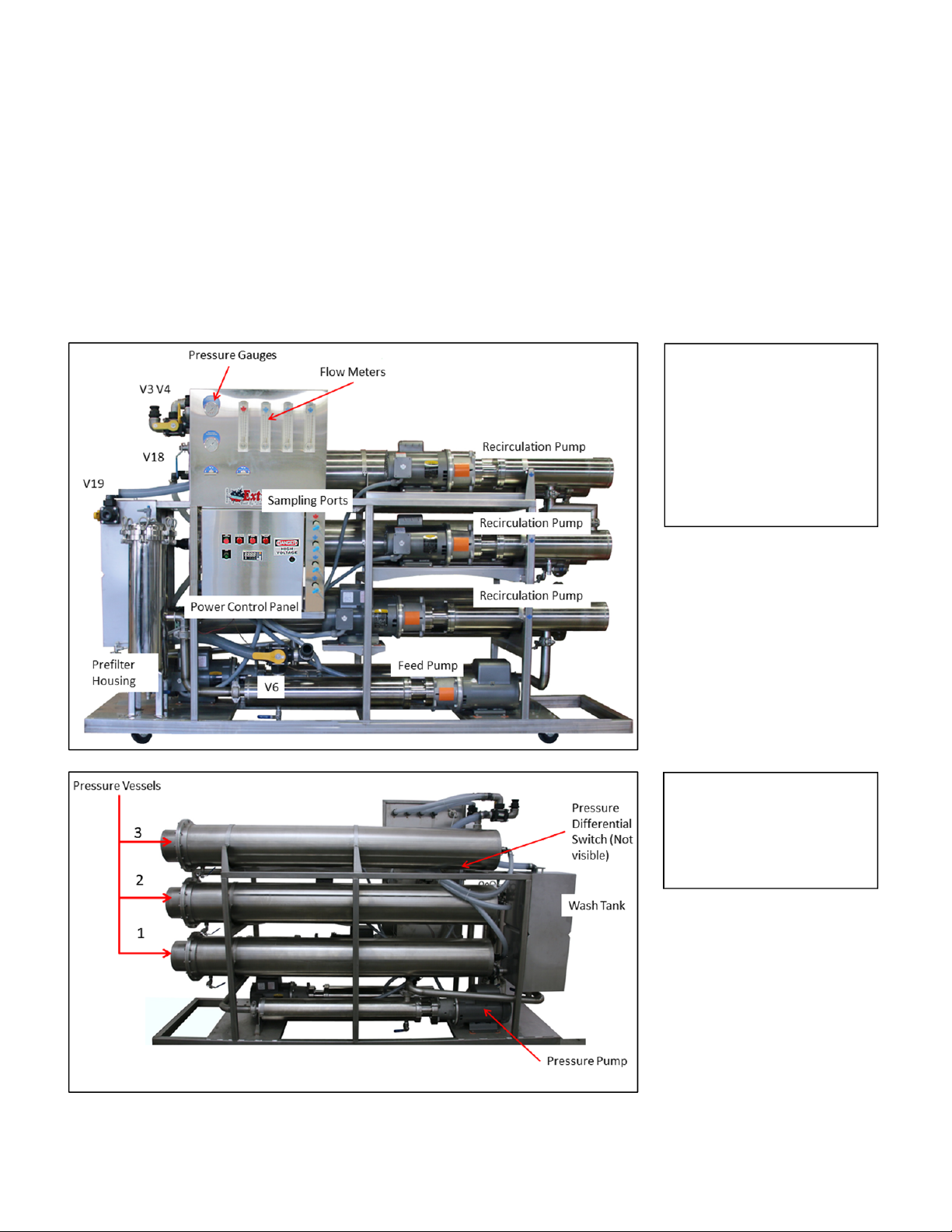

FrontView

Prefilterhousingrequires

five(5)–20”cartridge

filters.

RearView

Washtankisusedtomix

thechemicalsolutionfor

cleaningthesystem

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:7

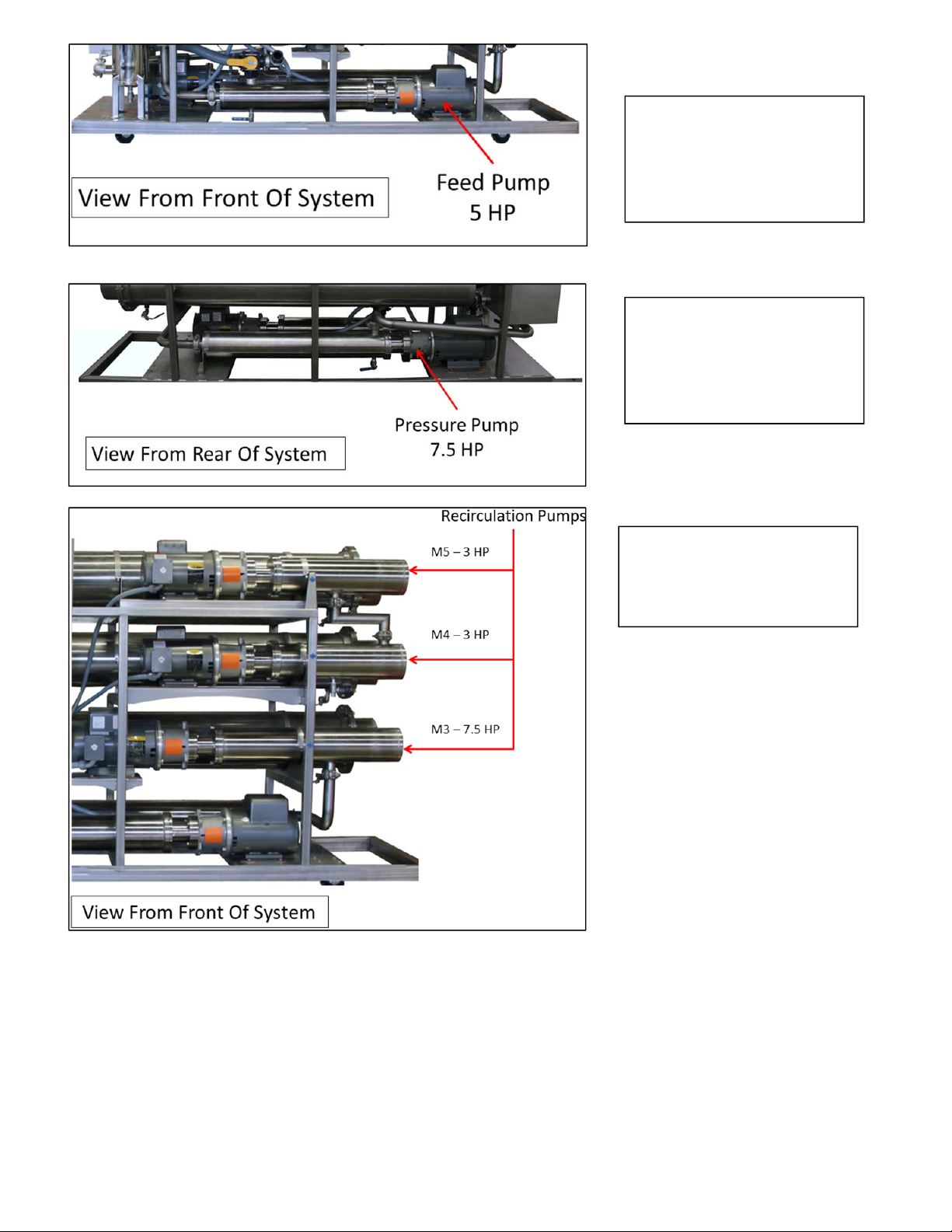

PressurePump

Secondstageofpressurizingthe

systemrequiredtoprocessthe

sapthroughthemembranes

RecirculationPumps

Recirculatesliquidwithinthe

vesseltowhichtheyareattached.

FeedPump

FeedPumpprovidesliquidtothe

systemandisthefirststageof

pressurizingthesystem

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:8

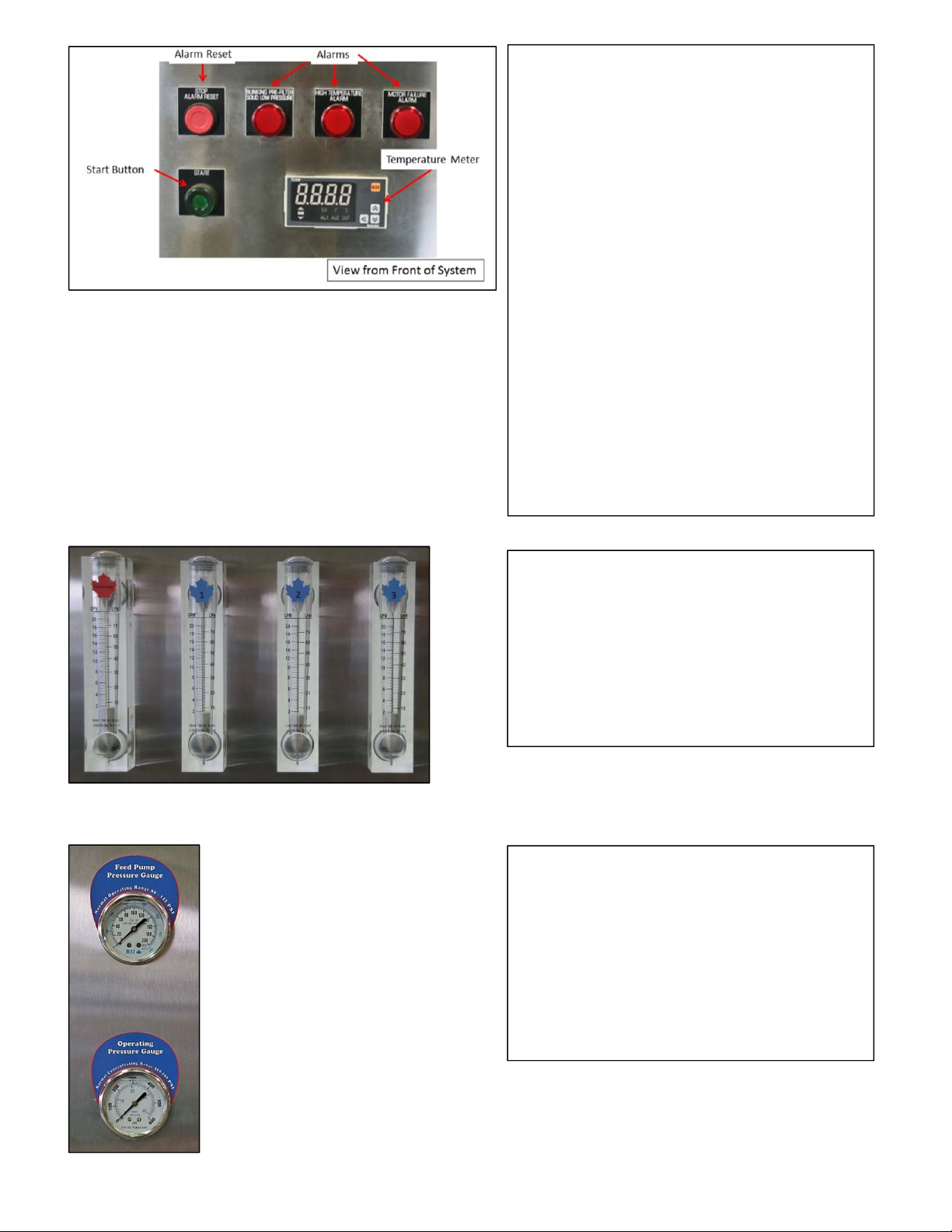

ControlPanel

Startbuttonwhenpressedstartsthesystempumpsin

sequence.

TheSTOPorSTOP/ALARMRESETbuttonisamaster

resetforallthealarmsandwillstopthemachine

whenpressed.

TheTemperatureMeterindicatesthetemperatureof

theliquidflowingthroughthesystem.

PressureAlarmindicatesapressureconditioninthe

systemrelatedtothepressurepumprequirements.

Thealarmlightmaybesolid(lowpressure)orblinking

(prefilter).Thisalarmcanbepartofnormal

operations.Themachinewillshutdownwhenthe

indicatorlightisactivated.

HighTemperatureAlarmindicatestheWashcyclehas

completed.Thisalarmispartofnormaloperations.

Themachinewillshutdownwhenthealarmlightis

on.

MotorFailureAlarmisdueamotorcontactor

tripping.ContactLeaderEvaporator.

FlowMeters

TheConcentrateMeterindicatestheliquidflowfrom

theconcentratesideofthepressurevesselsingallons

perminute.

ThePermeateMetersindicatethepermeateflow

fromeachvesselingallonsperminute.

PressureGauges

Feedpumppressureisreadaftertheprefilters.

Membranepressureisreadafterthelast

membrane.

WARNING:DONOTALLOWTHEOPERATING

PRESSURETOEXCEED550psi.

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:9

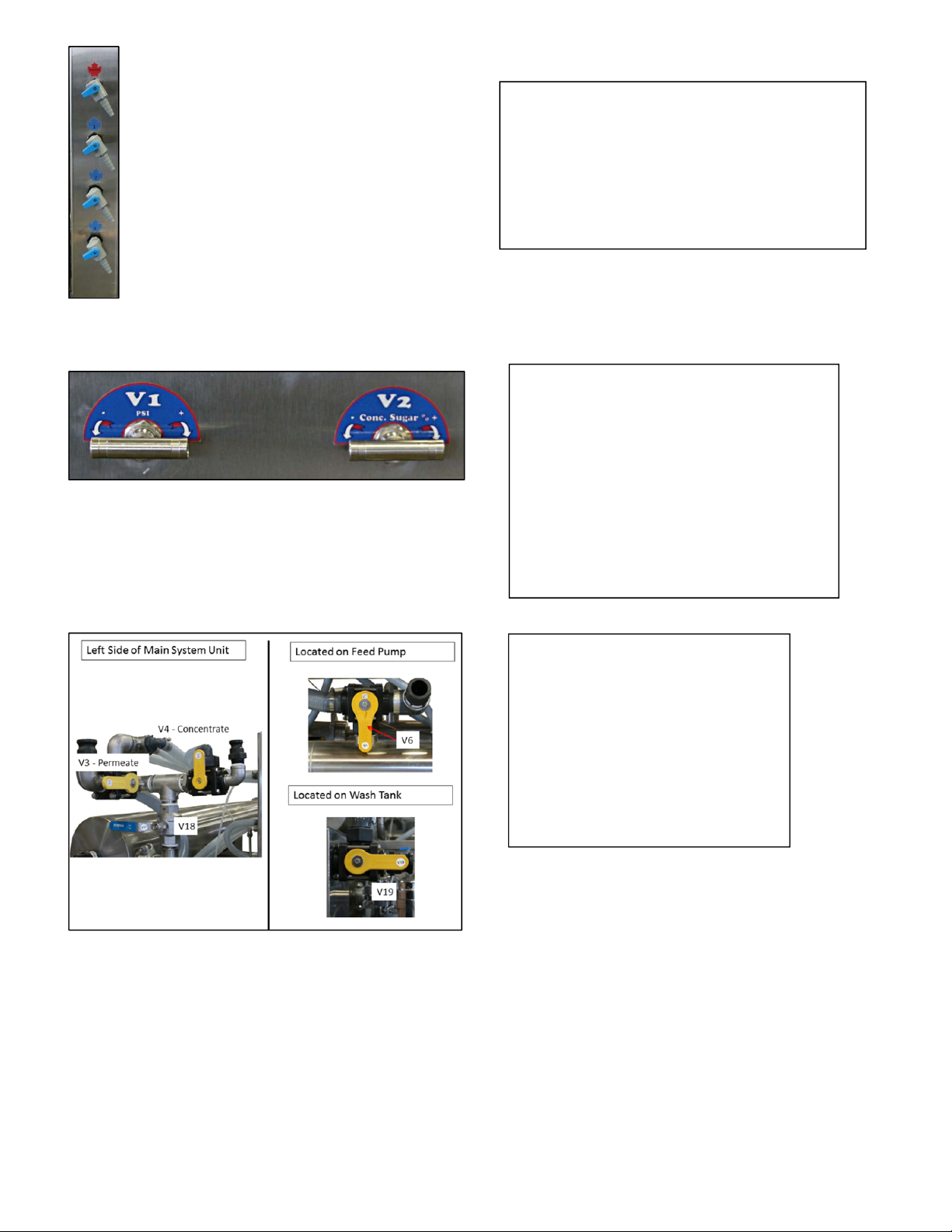

SamplingPorts

Concentrateportisusedtosampletheliquid

concentratetodeterminethesugarpercentage.

ThePermeateportsareusedtosamplethepermeate

fromthevesselstodetermineifthemembranesare

allowingsugartopassthrough.

V1andV2Valves

V1controlsthepressuretothemembranes.It

isopened½waywhenstartingthenadjustedto

reachthepressurewanted.CloseV1toraise

thepressureinthesystem.

V2controlstheflowfromtheconcentrateside

ofthemembranes.Itisopened½waywhen

startingthenadjustedtothedesired

concentrationlevel.

FlowControlValves

Thesevalvescontroltheflowofliquid

throughthesystem

V3–Permeateflow

V4–Concentrateflow

V6–Feedflow

V18–CleaningorConcentrateflow

V19–DrainorWashTank

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:10

VALVETYPE

HANDLE

POSITIONLIQUIDFROM‐TO

HANDLE

POSITIONLIQUIDFROM‐TO

V33‐Way

HANDLE

POINTED

HORIZONTAL

MembranestoPermeate

out

HANDLE

POINTED

VERTICAL

MembranestoValve

V19

V43‐Way

HANDLE

POINTED

VERTICAL

MembranestoConcentrate

out

HANDLE

POINTED

HORIZONTAL

MembranestoValve

V19

V63‐WayHANDLE

VERTICALExternaltoFeedPump

HANDLE

HORIZONTAL

WashTanktoFeed

Pump

V182‐Way

HANDLE

POINTED

HORIZONTAL

NoFlow

HANDLE

POINTED

DOWN

MembranestoValve

V19

V193‐Way

HANDLE

POINTED

HORIZONTAL

MembranestoWashTank

HANDLE

POINTING

VERTICAL

MembranestoDrain

TheLeaderSpringtechEXTREMEReverseOsmosissystemconsistsofthefollowingparts:

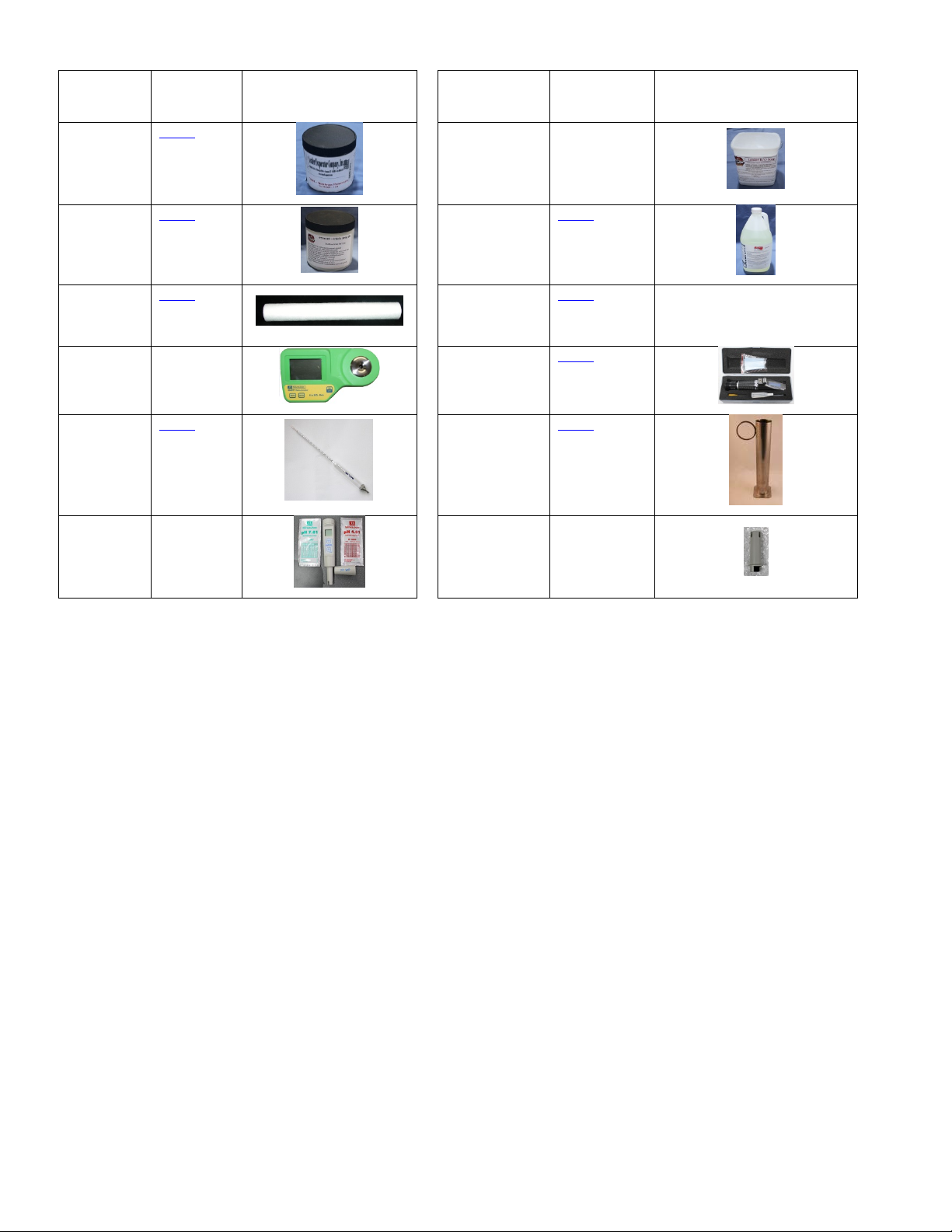

IncludedEquipment

ITEMLEADER

ORDER#DESCRIPTION/PHOTOITEMLEADER

ORDER#DESCRIPTION/PHOTO

Springtech

EXTREME6

700068

Springtech

EXTREME6User

Manual

Springtech

EXTREME6

QuickStart

Guide

1–1/2”Quick

CouplerC

Qty:2

47160

1”Quick

CouplerC

Qty:1

47148

2”Threadedto

3”Slip

Connector

195

StrainerY

3”modified

withbleeder

valve

70141

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:11

OptionalSetupEquipment,PartsandSupplies

ITEMLEADER

ORDER#DESCRIPTION/PHOTOITEMLEADER

ORDER#DESCRIPTION/PHOTO

Membrane

Preservative,

1lb.

70001

ROSoap5Lbs.69992

CitricAcid,1

lb.

70008

Glycol,1gal.70009

20”

Cartridge

Filter

70012

FoodGrade

Grease

55095

Digital

Refractomet

er

61058

Sap

Refractometer

61073

12”Sap

Hydrometer

61061

Long2”

DiameterTest

Cup

59006

pHMeter61060

pHMeter

Replacement

Probe

61060P

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:12

SETUP

NOTES:

Allmaterialsusedshouldbeapprovedforpotablewater.Nocoppershouldbeused.

Wheninstallingplumbingforthesystem,factorinthesystemmayneedtobemovedforsuchitemsas

maintenance.Itisrecommendedtheconnectionsbemadewithfittingssuchasquickdisconnects.

AllfeedpipingtotheSpringtechLeaderExtremesystemmustbeatleastaslargeasthefeedonthesystem

itself–3”minimumisrecommended

Allinstallationsmustmeetapplicablegovernmentalregulations.

AreaRequired

ThespacetobeusedshouldbecapableofpreventingtheROsystemfromfreezing.Additionallyitwillneedtohave

adequateventilationduringoperationstopreventoverheating.

Thedimensionsofthemainsystemunitare

Width–34”

Length–109”

Height–70”

Aminimumoftwofeetaroundthesystemisrecommended.Youmustalsobeabletoobtainanadditional8feetin

lengthinordertoremovemembranesandpumpassemblies.

Theroomshouldhaveadequatedrainage.Thewalls,ceilingandfloorshouldbeeasytoclean.

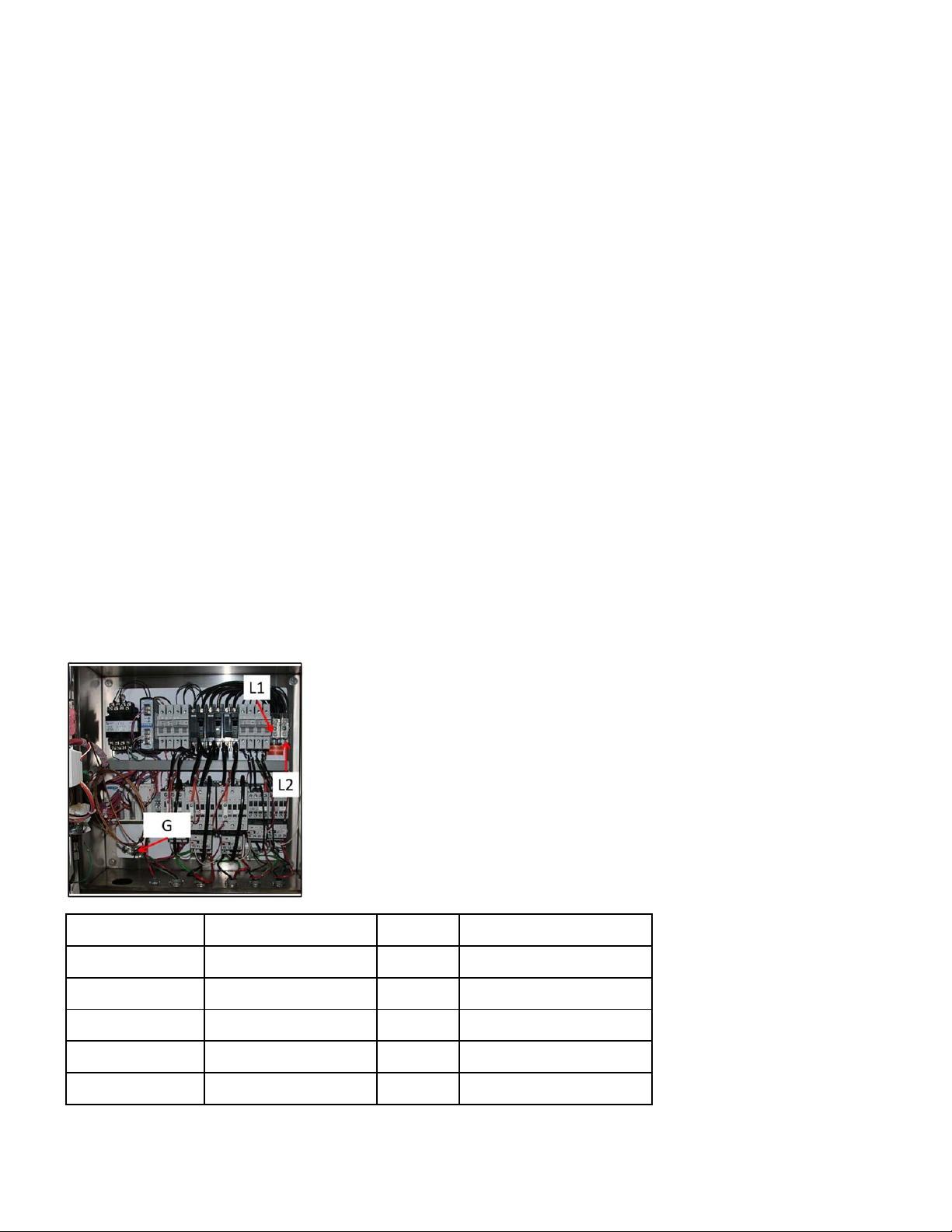

PowerRequirements

Thesystemrequires220V/1Phase,111amps.Allelectricalworkshouldbedonebyalicensedelectricianandmeet

alllocalcodes.

SeeATTACHMENT#1fortheelectricalschematic.

MOTORIDMOTORFUNCTIONSIZE(HP)NAMEPLATEAMPERAGE

M1FeedPump523

M2PressurePump7.530

M3RecirculationPump7.530

M4RecirculationPump314

M5RecirculationPump314

NOTE:Anytimethecontrolpanelisopened,thepowershouldbeturnedoffatthesource.

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:13

GeneralConnectionLayout

ThefollowingillustratesageneralizedlayoutforconnectionswiththeSpringtechEXTREMEROSystem.Thefirst

drawingshowstankconnectionstothesystem.Theseconddrawingshowsanarrangementofvalvestoconnectthe

incomingliquidtothesystem.Dependentonthelocation,otherarrangementsarelikely.Itisbeyondthescopeof

thisdocumenttorecommendthebestlayoutforallsituations.ItisrecommendedyoucontactyourLEADER

EVAPORATORsalespersonoryourlocalDistributor/Dealerforassistanceindecidingthecorrecttanksandlayoutfor

yourneeds.

Simple3TankRODiagram

LiquidSourceSelector

ValvesshouldbeintheR/Oroomforeaseofoperation.Additionalvalvesandtanksmayberequireddependingupon

installation.

NOTE:Wheninstallingthepipingfromthefeedtanksaminimumnumberofelbowsshouldbeused.

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:14

StrainertoValveV6Connection

A3”Y‐strainerissuppliedwiththesystem.Theinputtothestrainerwillneedtobe3”.Plumbingfromthesupply

tanksisrecommendedtobeaminimumof3”ID.Thestrainerisnotmountedtothesystem.Itwillneedtobe

mountedbytheuser.

TheinputtovalveV6is2”.Thesystemissuppliedwitha3”to2”reducingadapter.

Wheninstalling‐maketheconnectionfromthestrainertovalveV6.

Y‐Strainer

Reducingadapter

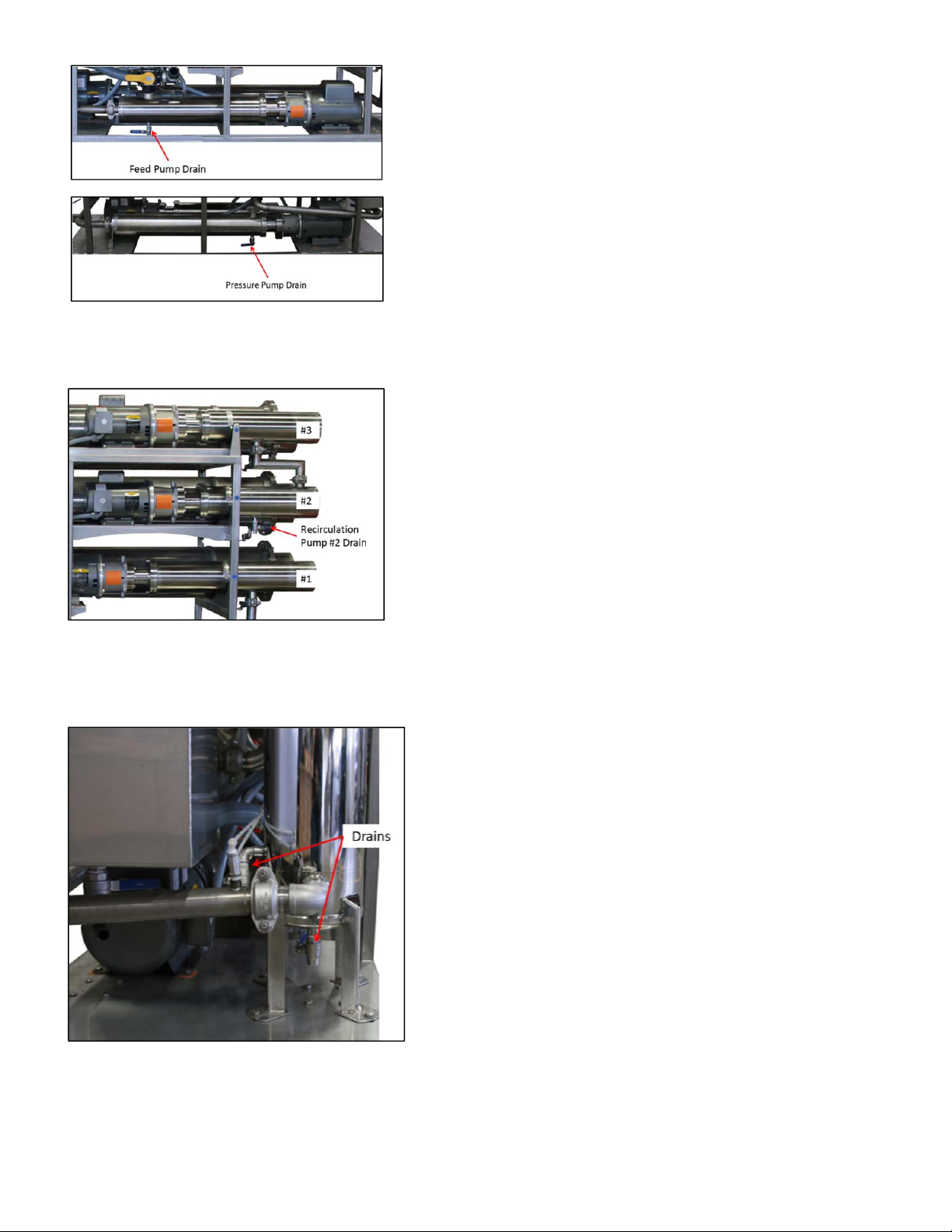

Vessel,Pump,PreFilterCanisterAndWashTankDrains

Thedrainsarelocated:

1undereachpressurevessel

Vesselandpumpdrainsareprovidedwitha½”stainlesssteelballvalve.Vesselsandpumpsbeing

drainedmaycontainconcentrate.Itisrecommendedthesedrainsbesetuptoallowcollectionofthe

liquid.Youwillneed(itemsnotincluded);

8–½”PVCadapters‐optionallytoallowfor90°connectionusecomboelbows

8–½”StainlessSteelbandclamps

8piecesof½”hoselongenoughtoconnecttothedrainadapterandtoreachthecollection

point

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:15

1underthefeedpump

1underthepressurepump

1underrecirculationpump#2.Recirculationpump#1willdrain

throughthepressurepumpdrain.Recirculationpump#3will

drainthroughrecirculationpump#2drain.

1undertheprefiltercanister

1onthesideoftheprefiltercanister

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:16

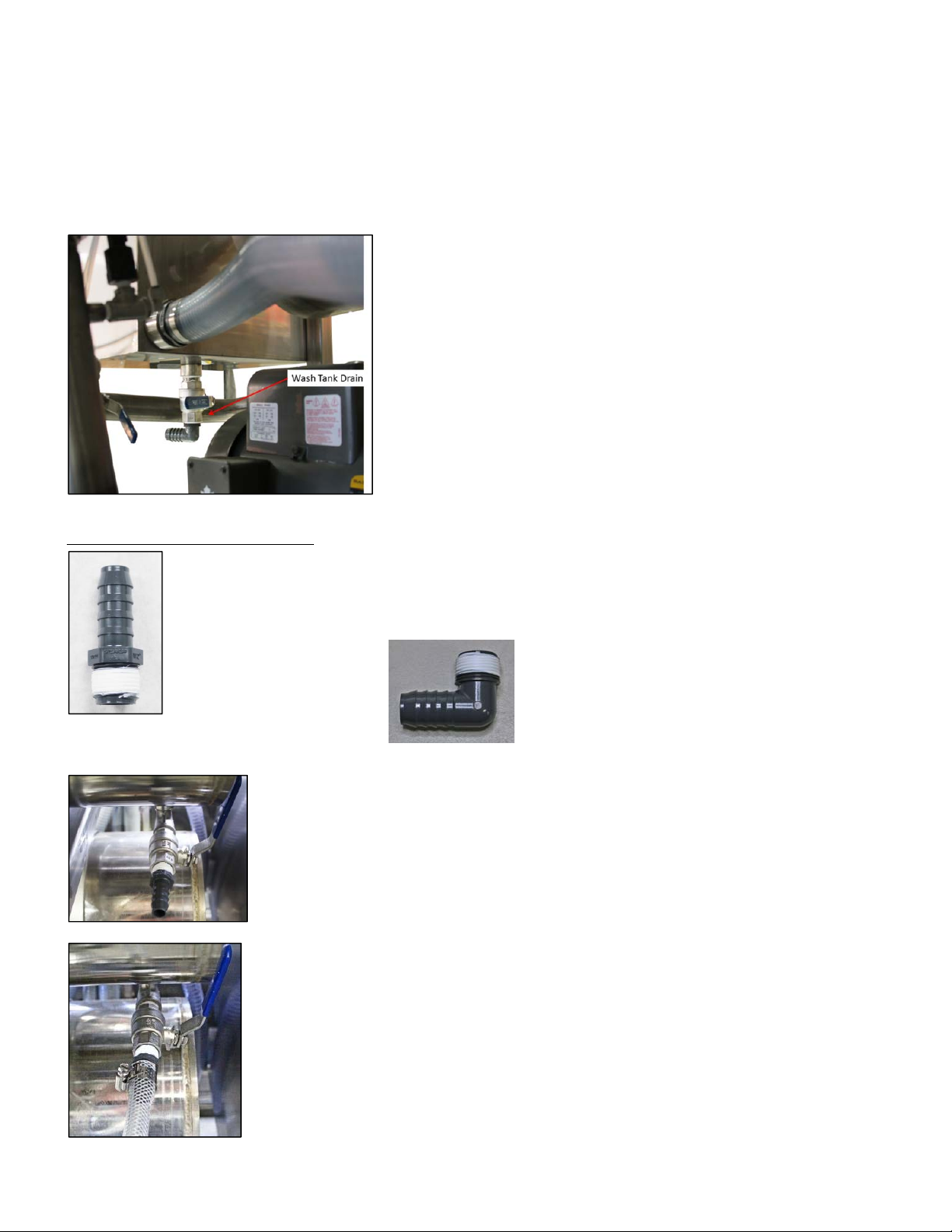

Thedrainislocated:

Underthewashtank

Installdrainconnectionsasfollows:

1. TeflontapethePVCadapter.Optionallyifa90°connectionis

preferred,Teflontapeacomboelbowanduseitinplaceofthe

straightadapterswheredesired.

Thewashtankdrainisprovidedwitha1”stainlesssteelballvalve.Tosetupthedrainyouwillneed

(itemsnotincluded);

1–1”StainlessSteelbandclamps

1pieceof1”hoselongtoconnecttothedrainadapterandtoreachthecollectionpoint

2. ThreadthePVCadapterintothestainlesssteelballvalve.

3. Cutthehosetolength(toreachfromtheballvalvetothepointwhereyouwillbe

collectingtheliquid).Placeastainlesssteelbandclampoveroneendofthehose.

SlidethehoseontothePVCadapter.Positionthestainlesssteelbandclampoverthe

hoseontheadapterandtightenthebandclamp.

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:17

V3,V4andV19Connections

V3,V4andV19valvesaretobesetupsotheconnectionscanbeeasilydisconnectedandreconnectedasnecessary.

Thefollowingistherecommendedconnectiondetail.

Inordertoassembletheconnectionsyouwillneed(braidedhoseandclampssoldseparately);

3–CstyleQuickCouplers(two1–½”,one1”)

3(minimum)stainlesssteelbandclamps–(two(minimum)1–½”,one(minimum)1”)

1”IDbraidedfoodgradehosewithlengthtomaketheconnectiontotheConcentratetank.1–½”IDbraided

foodgradehosewithlengthtomaketheconnectiontothePermeatetank.Theconnectiontothedraincanbe

madewithflexiblehose.

V19–ConnectionToDrain

V3–ConnectionToPermeateStorage

1. Cut1–½”IDflexiblehosetoreachfromthevalveV19tothedrain

connection.

2. Placeatleastone1–½”stainlesssteelbandclampoveroneendofthe

hose.

3. Slidethehoseontothe1–½”Cstylequickcoupler.

4. Positionthestainlesssteelbandclamp(s)overthehoseonthecoupler

andtightenthebandclamp(s).

5. Securetheotherendofthehosetothedrainconnection.

6. ConnectthequickcouplersbyopeningthelatchesontheCstylecoupler

(positionthemetallatcharmsoutperpendiculartothebodyofthe

coupler)thenslidingtheCcouplerontotheFcoupler.Pullthemetal

latcharmsbackdowntothesidesoftheCcoupler.

1. Cut1–½”IDfoodgradebraidedhosetolength–fromvalveV3tothe

fillconnectionforthepermeatetank.

2. Placeatleastone1–½”stainlesssteelbandclampoveroneendofthe

hose.

3. Slidethehoseontoa1–½”Cstylequickcoupler.

4. Positionthestainlesssteelbandclamp(s)overthehoseontheadapter

andtightenthebandclamp(s).

5. Securetheotherendofthehosetothepermeatetankfillconnection.

6. ConnectthequickcouplersbyopeningthelatchontheCstylecoupler

(positionthemetallatcharmsoutperpendiculartothebodyofthe

coupler)thenslidingtheCcouplerontotheFcoupler.Pullthemetal

latcharmsbackuptothesidesoftheCcoupler.

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:18

V4–ConnectiontotheConcentrateStorage

1. Cut1”IDfoodgradebraidedhosetolength–fromvalveV4tothefill

connectionfortheconcentratetank.

2. Placeatleastone1”stainlesssteelbandclampoveroneendofthe

hose.

3. Slidethehoseontoa1”Cstylequickcoupler.

4. Positionthestainlesssteelbandclamp(s)overthehoseontheadapter

andtightenthebandclamp(s).

5. Securetheotherendofthehosetotheconcentratetankfillconnection.

6. ConnectthequickcouplersbyopeningthelatchontheCstylecoupler

(positionthemetallatcharmsoutperpendiculartothebodyofthe

coupler)thenslidingtheCcouplerontotheFcoupler.Pullthemetal

latcharmsbackuptothesidesoftheCcoupler.

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:19

OPERATION

WhenstartingtheReverseOsmosisunitthereisasequenceinwhichthepumpswillactivate.PressingtheSTART

buttonwillfirstactivatethefeedpump.Innormaloperationswithin30secondsthefirstpressurepumpwillstart

followedbythesecondpressurepumptheneachofthefeedrecirculationpumps,oneatatime.

Duringanycycleifpermeateisnotavailable,usenonchlorinatedwellorspringwater.

StartupofSystemwithLittleorNoFluid

1. Setthesystemvalvesforarinsecycle(seepage31).

2. Turnoffthepowertothesystematthesource.

3. Openthecontrolboxbyturningthelatchontherightsideofthepanelthenopeningthedoorcarefullytothe

left.

4. Turnoffthepressureandrecirculationpumpbreakers:

NOTE:Breakersarenotshowninthecorrectposition.

BREAKERIDCIRCUITSTARTPOSITION

CB1FeedPumpON

CB2PressurePumpOFF

CB3RecirculationPumpOFF

CB4RecirculationPumpOFF

CB5RecirculationPumpOFF

5. Closethecontrolboxcoverandturnthelatchtofasten.

6. Turnonthepowertothesystematthesource.

7. Ensureyoursourcevalves(waterorpermeate)areopentofeedthesystem.

8. PresstheSTARTbuttontostartthefeedpump.

9. Runthefeedpumpuntilmostofthebubblesaregonefromtheflowmeterslocatedonthefrontofthe

system.Thiswilltake3to4minutes.Notallthebubblescanberemoved.

10. PresstheSTOPbuttontostopthefeedpump.

11. Turnoffthepowertothesystematthesource.

12. OpenthecontrolboxandpositionbreakersCB1,CB2,CB3,CB4andCB5totheONposition.

13. Closethecontrolboxcoverandrefastenthelatches.

14. Turnonthepowertothesystematthesource.

15. Openthepressurepumpfeedbackballvalve.

16. ProceedtotheinstructionsfortheInitialSystemCleaning.

LeaderEvaporatorSpringtechEXTREME6ReverseOsmosisSystemManual Page:20

InitialSystemCleaning

Topreparethesystemaftersetup;

NOTE:IFthesystemhasnotbeenfilledwithfluid,followtheinstructioninthesection“StartupofSystemwithLittleor

NoFluid”.

1. Putapproximately3600USgallonsofnon‐chlorinatedwellorspringwaterintoacleanpermeatestoragetank.

2. Setthevalvesforandrunarinsecycle(seepage31)usingaminimum1800USgallonsofwaterfromthe

permeatetank.Whilethiscycleisrunningcheckallfittings,piping,connectionsandhosesforleaks.Repairas

necessary.

3. AttheendoftherinsecyclechangethepositionofvalveV19sotheliquidflowisdirectedtothewashtank.

Whenthewashtankisapproximately⅔full,returnV19tothedrainposion.

4. MixalkalineR/OsoapwiththeliquidinthewashtankuntiltherequiredpHisreached.Todeterminethe

requiredpH,refertotheMachineSerialNumberDataSheetthatinitiallyaccompaniedthesystem.NOTE:If

themembraneischanged,referencethedatasheetaccompanyingthenewmembrane.

5. Setthevalvesforandrunanalkalinewashcycle(seepage34)allowingthesystemtorununtiltheautomatic

temperatureshutdownat118°F.

6. Setthevalvesforandrunarinsecycle(seepage31)usingaminimum1800USgallonsofwaterfromthe

permeatetank.

7. Runthebenchmarkpermeabilitytest(seepage22).

DataLogging

Dataontheoperationofthesystemshouldberecordedandkept.SeeATTACHMENT#2forthedatasheetformat.

Thefollowingdataisrecorded:

Date–datetheinformationiscollected

Activity–Concentrationcycle(enteraC)orTest(enteraT)

Sap%‐thesugarconcentrationoftherawsap

Concentrate%‐thesugarconcentrationoftheconcentratefromthesystem–testresultsfromthe

concentrateport

Vessel1Flow–gallonsperminuteofpermeatefrommembranes1and2–readingfromthetopofthe

stainlesssteelfloatinthepermeateflowmeter

Vessel2Flow–gallonsperminuteofpermeatefrommembranes3and4–readingfromthetopofthe

stainlesssteelfloatinthepermeateflowmeter

Vessel3Flow–gallonsperminuteofpermeatefrommembranes5and6–readingfromthetopofthe

stainlesssteelfloatinthepermeateflowmeter

ConcentrateFlow–gallonsperminuteofconcentrationfromthesystem–readingfromthetopofthe

stainlesssteelfloatintheconcentrateflowmeter

Temperature–readingfromtemperaturegaugeonthecontrolpanelofthesystem(°F)

FeedPressure–readingfromthepressuregaugeonthecontrolpanelofthesystem(psi)

MembranePressure–readingfromthepressuregaugeonthecontrolpanelofthesystem(psi)

WaterRemoval%‐percentofwaterremovedfromincomingsap–calculatedasfollows

oPERMEATEFLOW–AddallPermeateFlowstogether

oTOTALFLOW‐AddallPermeateFlowsandConcentrateFlowtogether

oDividePERMEATEFLOWbyTOTALFLOWandmultiplytheresultby100

oRecordthisnumberastheWaterRemoval%

GPHProcessed–gallonsperhourbeingprocessedbythesystem‐calculatedasfollows

oTOTALFLOW–AddallPermeateFlowsandConcentrateFlowtogether

oMultiplyTotalFlowby60andrecordtheresultingnumberastheGPHProcessed

Table of contents

Popular Water Filtration System manuals by other brands

Pure Pressure

Pure Pressure Axis Service manual

ubbink

ubbink BioPressure 3000 manual

amiad

amiad AMF-36K Installation and operation instructions

Water Right

Water Right UltroWater Installation, operation & service manual

Anetsberger Brothers

Anetsberger Brothers GoldenFRY FFM-80 Specifications

Filters itm

Filters itm HYDRAULIC-100-V user manual