2. Service Tools & Equipment

Tools for the Job

While there are plenty of tools available to setup and maintain your equipment, the following tools are necessary to have for

complete and accurate assembly and tune-up of the machine. PurePressure recommends the use of these tools to help

prevent damage to the machine caused by using inappropriate techniques or non-advised tools.

Note: Use of any grease must be food-grade,

regardless of the manufacturer!!!

3

Tool Name Description & Recommended Sizes Illustration

Thread Locker Semi-permanent adhesive for securing nuts, bolts, and studs during

vibrational loads.

Recommendation: Loctite 248 in 0.32oz glue stick (or something equivalent)

Food-Grade Grease Food-grade lubricant for mechanical components.

Recommendation: Molykote G-0051 FM (or something equivalent)

Allen Wrenches

Tools to quickly tighten & loosen fasteners.

Recommendation: Allen wrench set, T-handle sets, or hex key with ball end

and short arm.

Bolt Drivers Manual tools for installing and removing bolts.

Recommendation: Flathead & Phillips

Hex Drivers Tool to drive bolts & loosen frozen bolts/nuts.

Recommendation: 5/16” Hex Socket Nut Driver

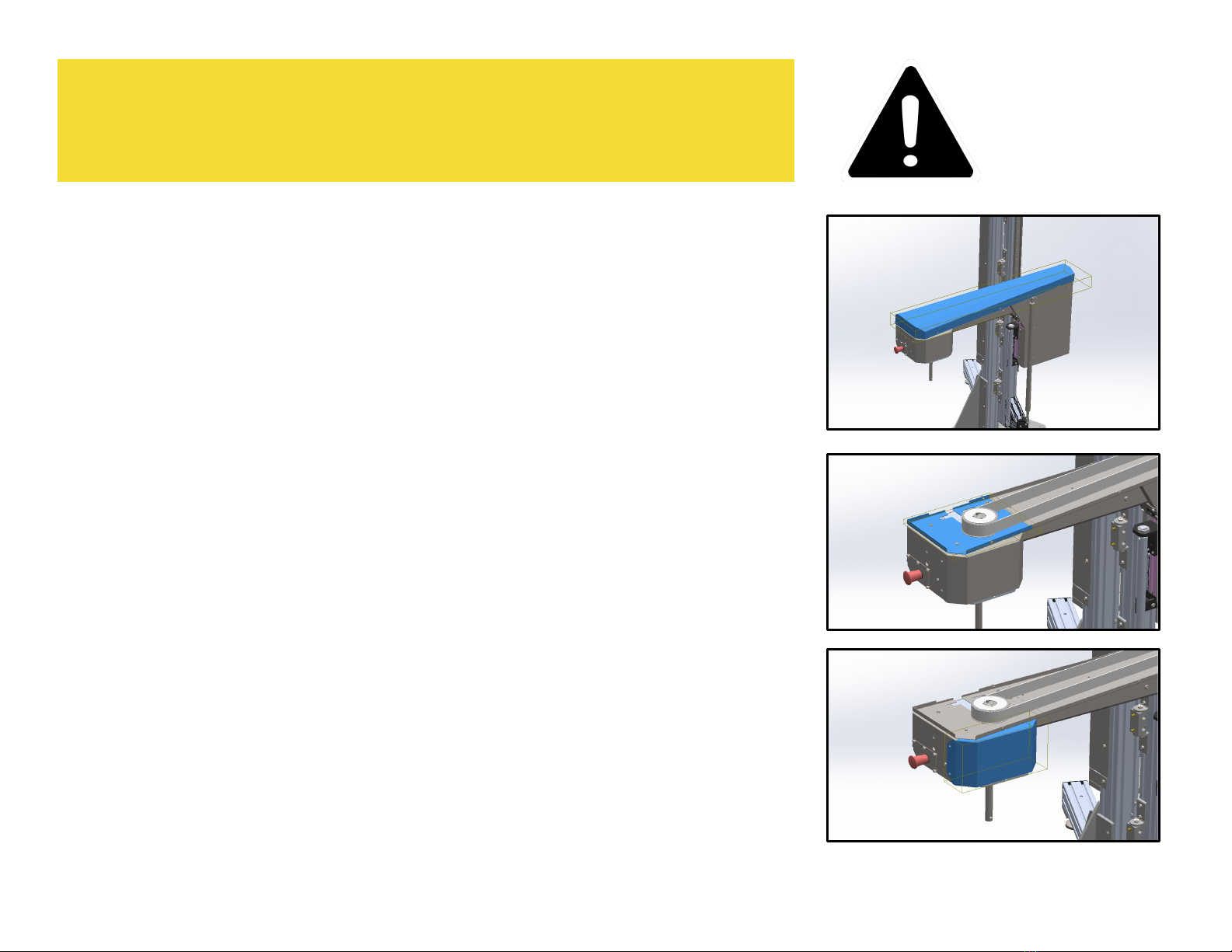

Belt Tension Meter Tool to measure the static tension of the belt.

Recommendation: Universal Belt Tension Meter SM5

5/16

OR