0

1

2

3

4

PARTS LIST (4s)

Machine bolts

1 - 7/16 X 3½" (12 mm 90 mm)

1 - ¼" x 3" (lams)

Round head screw

2 - #12 x 1½" (shelf)

6 - #14 X 2" (breast beam,

lower cross member

8 - # 12 x 1½" (jack box)

2 eye screws

Tacks for canvas

1 book Warp&Weave

1 VHS Video cassette

mounting instructions

PAGE 5

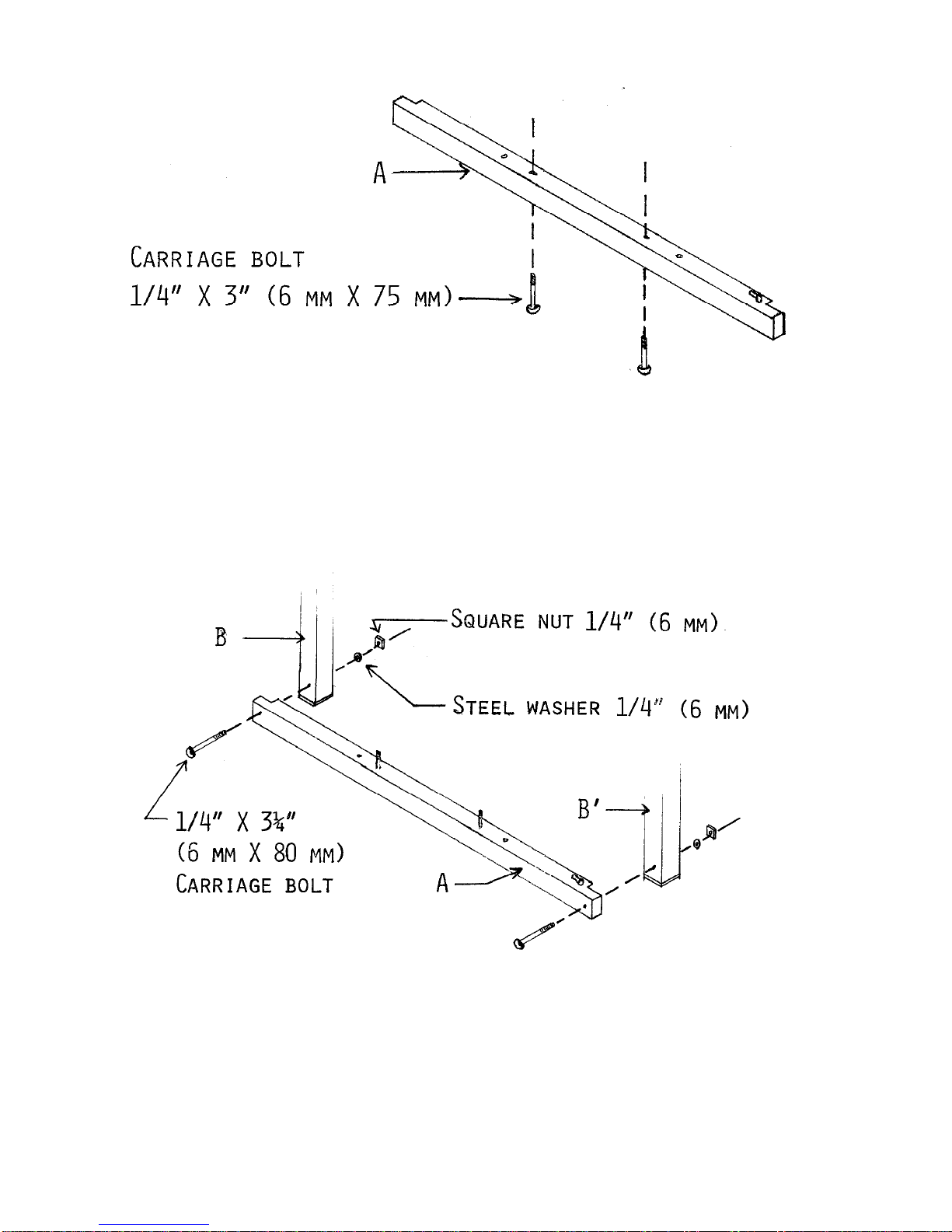

Carriage Bolts

2 - ¼ X 3¼" (6 mm x 80 mm)

2 - ¼" X 3" (6 mm x 75 mm)

2 - ¼" X 1¾" (6 mm x 45 mm)

4 - 5/16 X 2½" (8 mm x 65 mm)

Nuts

3 - ¼" (6 mm) (lam, treadle cross-member)

2 - 5/16" (8 mm)(batten handtree)

Wing nuts

4 - ¼" (6 mm) (treadle block(2), frame hooks)

2 - 5/16" (8 mm)(batten handtree)

Washers

4 - 5/16" (8 mm)(batten)

5 - ¼" ( 6 mm)

2 - 9/16' (15 mm)(treadle block)

Wooden spacer

5X

1½"