3

Cast Resin Transformers

Installation, use and maintenance manual

Index

The supplier does not assume any responsibility for the use or inappropriate use of the products mentioned in this

manual.

This guide does not cover all the details or possible variations of the entire series of connections, installation and possible

operations. For further information or to solve specific problems that are not included in this guide, contact Legrand.

THIS ENTIRE DOCUMENT BEFORE YOU COMMENCE THE INSTALLATION.

1 Safety guidelines 4

2 Reference standards 6

3 Rating plate 6

3.1 Conditions for the correct operation of the transformer 6

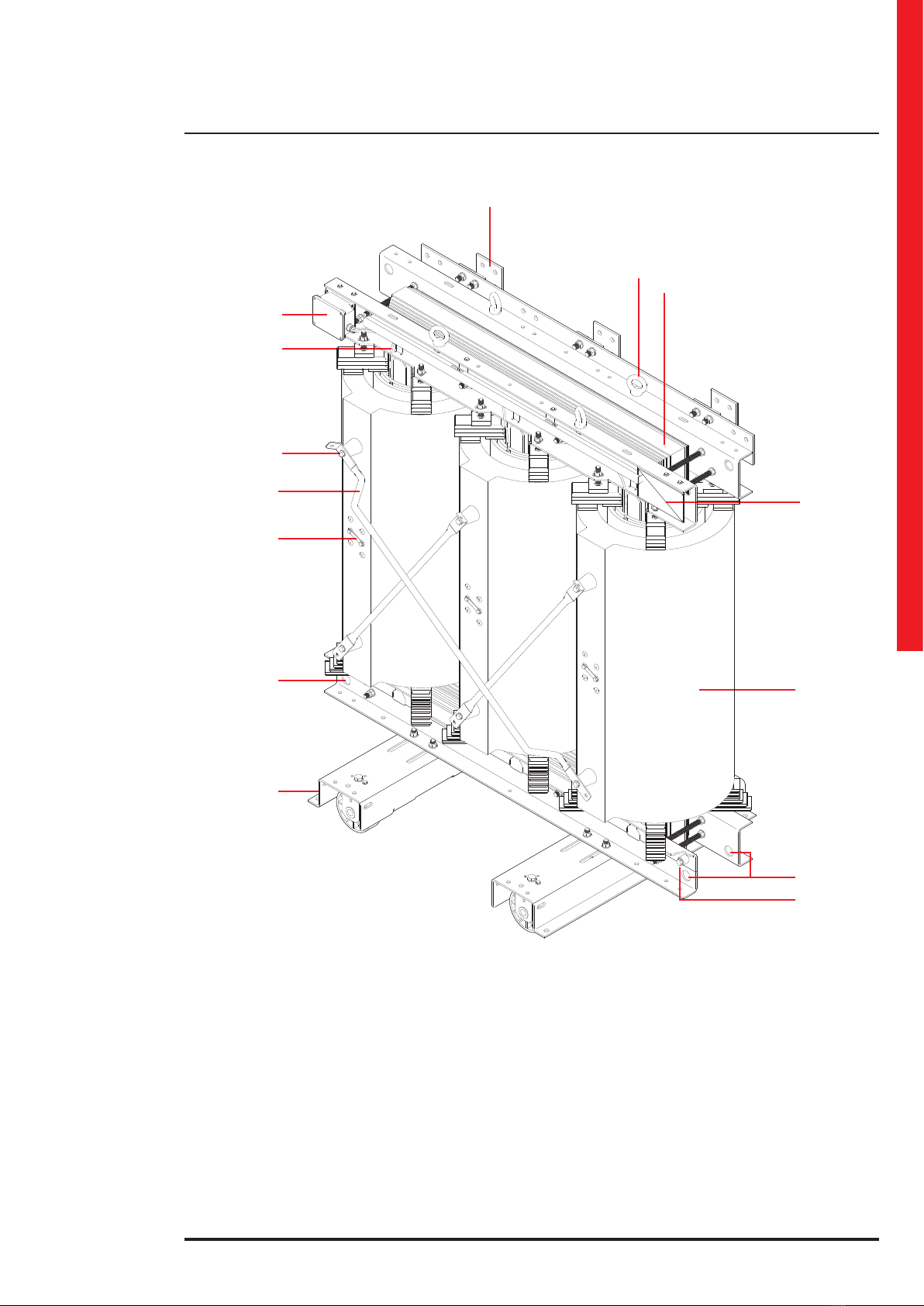

4 Transport, receipt and storage 7

4.1

Lifting the transformer

8

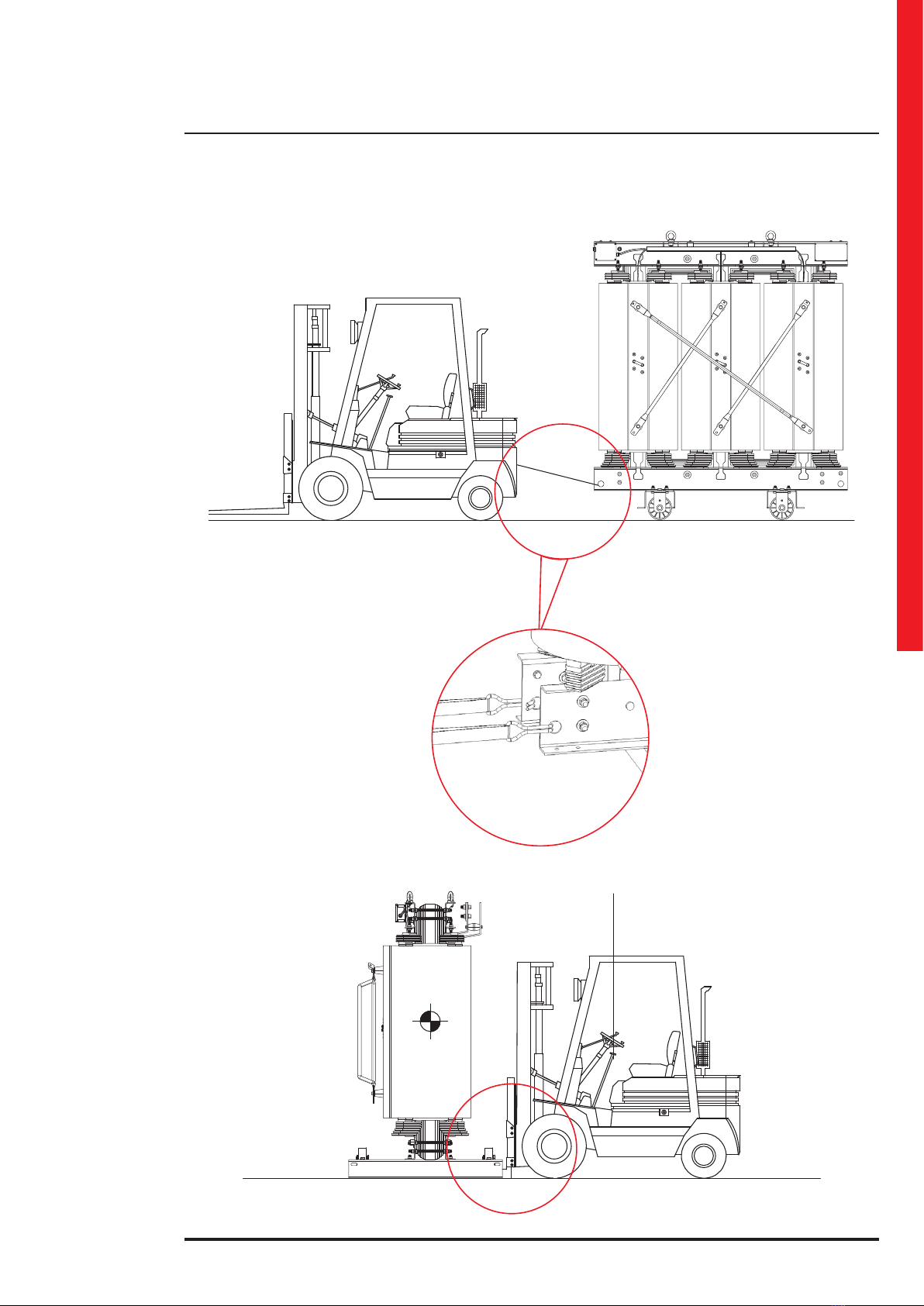

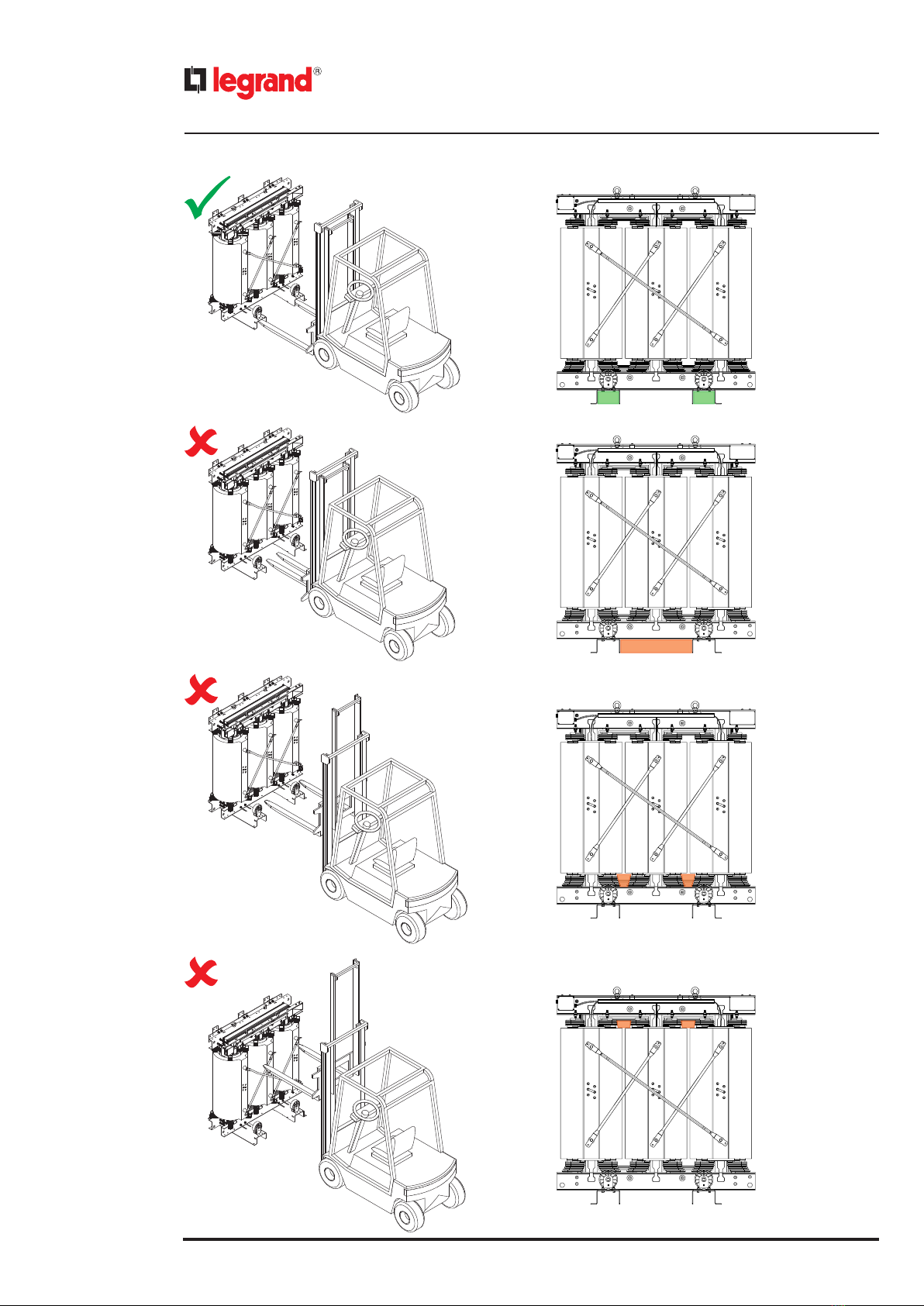

4.2 Moving the transformer 11

4.3 Storing the transformer 12

5 Installation 13

5.1 Installation examples 13

5.1.1 Installation in protection enclosure 13

5.1.2 Installation without protection enclosure/box (IP00) 14

5.1.3 Examples of wrong installation 15

5.2 Connections on the Low Voltage side - LV 16

5.3 Connections on the High Voltage side - HV 16

5.4 Tightening torque for electrical and mechanical connections 17

5.5 Positioning 17

5.6 Ventilation 18

5.7 Protection against overvoltages 18

5.8 Temperature monitoring systems 19

6 Commissioning 20

6.1 Earth Connection 20

6.2 Tappings for voltage setting on HV windings 21

6.3 Cleaning 22

6.4 Measurement of windings earth resistance 22

6.5 Energising 22

7 Reception, installation and initial energising of the transformer 23

8 Maintenance 24

8.1 Indicative table on the main maintenance operations 24

8.2 Guide for trouble-shooting 26

8.3 Customer Care 26

9 Additional information 27

10 Environmental aspects 28