1997-2001 FLH Renegade– Rev. 3

Preparing Motorcycle

The following instructions are a guide to preparing the motorcycle to accept the Lehman Trike Conver-

sion Kit. This will assist you in removing the necessary parts to install the kit.

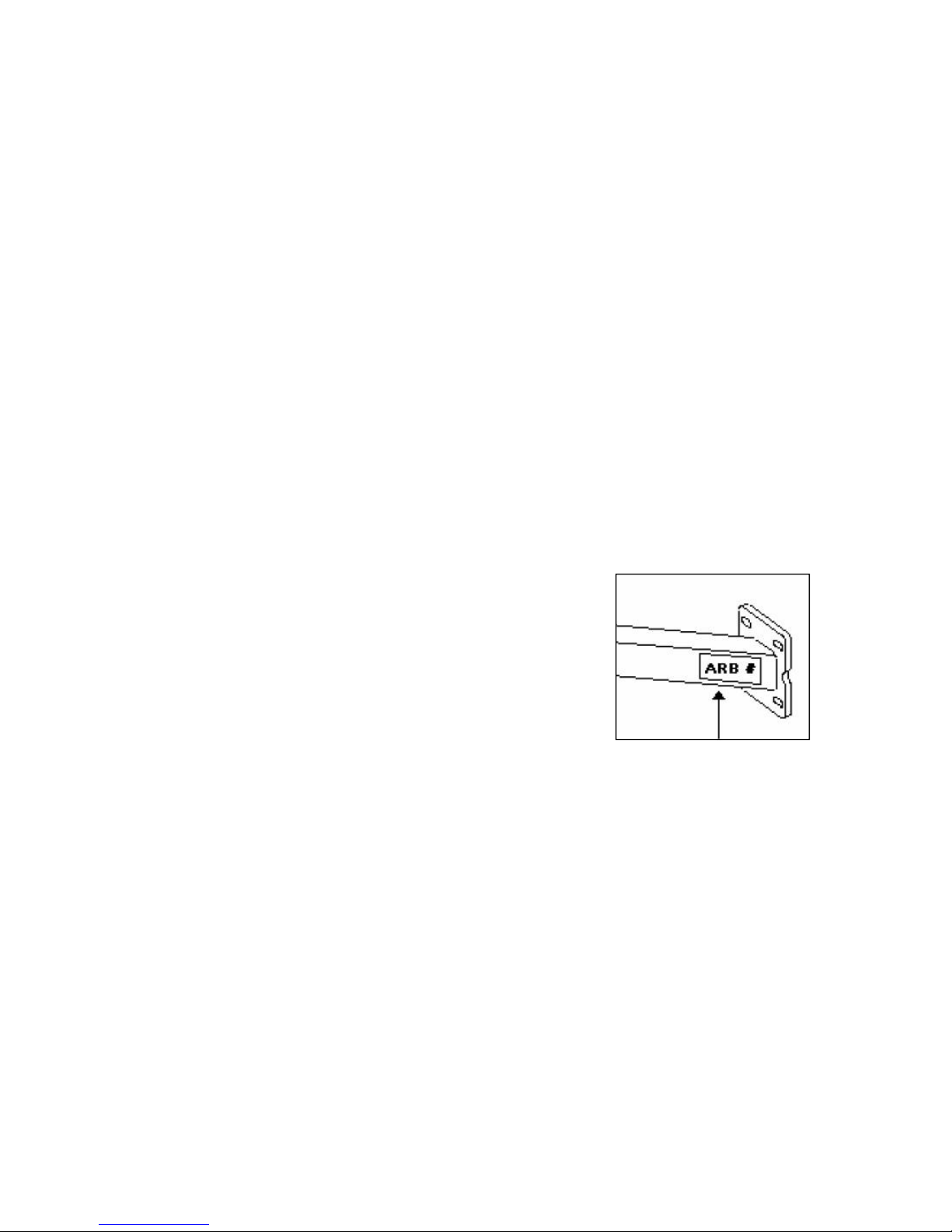

1. Note motorcycle year, model and serial number, as well as Lehman serial number, located

inside body, on left-side of swingarm and on warranty registration form in owner’s manual.

2. Make sure motorcycle is standing straight up and handlebars are centered. Support motorcycle un-

der rear of transmission so it is straight up and down and handlebars are straight. The front forks or

handlebars should be anchored to hold bike.

**NOTE**

Use a small spirit level on rear wheel or disc brake to stand bike straight up. Any movement of

handlebars will move bike off level. Locate reference point on bike frame that is level and check

it frequently.

3. Remove seat and save mounting screw.

4. Disconnect battery.

**CAUTION**

Always disconnect negative battery cable first. If positive cable should contact a grounded ob-

ject while negative cable is installed, resulting sparks may cause an explosion.

5. Remove tour pack. Save mounting bar, spacers and hardware for rear hole.

6. Raise motorcycle lift to working height.

7. Remove side stand mounting bolt and separate side stand from bracket.

8. Remove passenger footboards. Save boards and hardware for re-installation.

9. Remove side covers.

10. Remove rear side cover grommets from motorcycle for use with Lehman side cover mounts.

11. Remove saddlebags (if equipped).

12. Remove mufflers and saddlebag mounts. Keep all muffler mounting hardware including rubber iso-

lators located in saddlebag mounts. These parts will be re-used.

13. Remove rear heat shields from exhaust pipes and loosen head pipe bolts.

14. Remove carriage bolt from lower RH exhaust bracket and save bolt.

15. Support bike on center stand.

16. Disconnect airlines from shocks and remove shocks. Stand shocks upright to prevent oil leaks.

Save air valve plate and discard original shock mounting bolts.

17. Remove rear fender. Save two front mounting bolts. Save turn signal lights and fender mounting

hardware, including stud plate for grab rail. These parts will be re-used.

18. Remove brake line from caliper and remove caliper.

19. Remove clip from rear axle and remove axle nut with 36mm socket. Axle can now be removed.

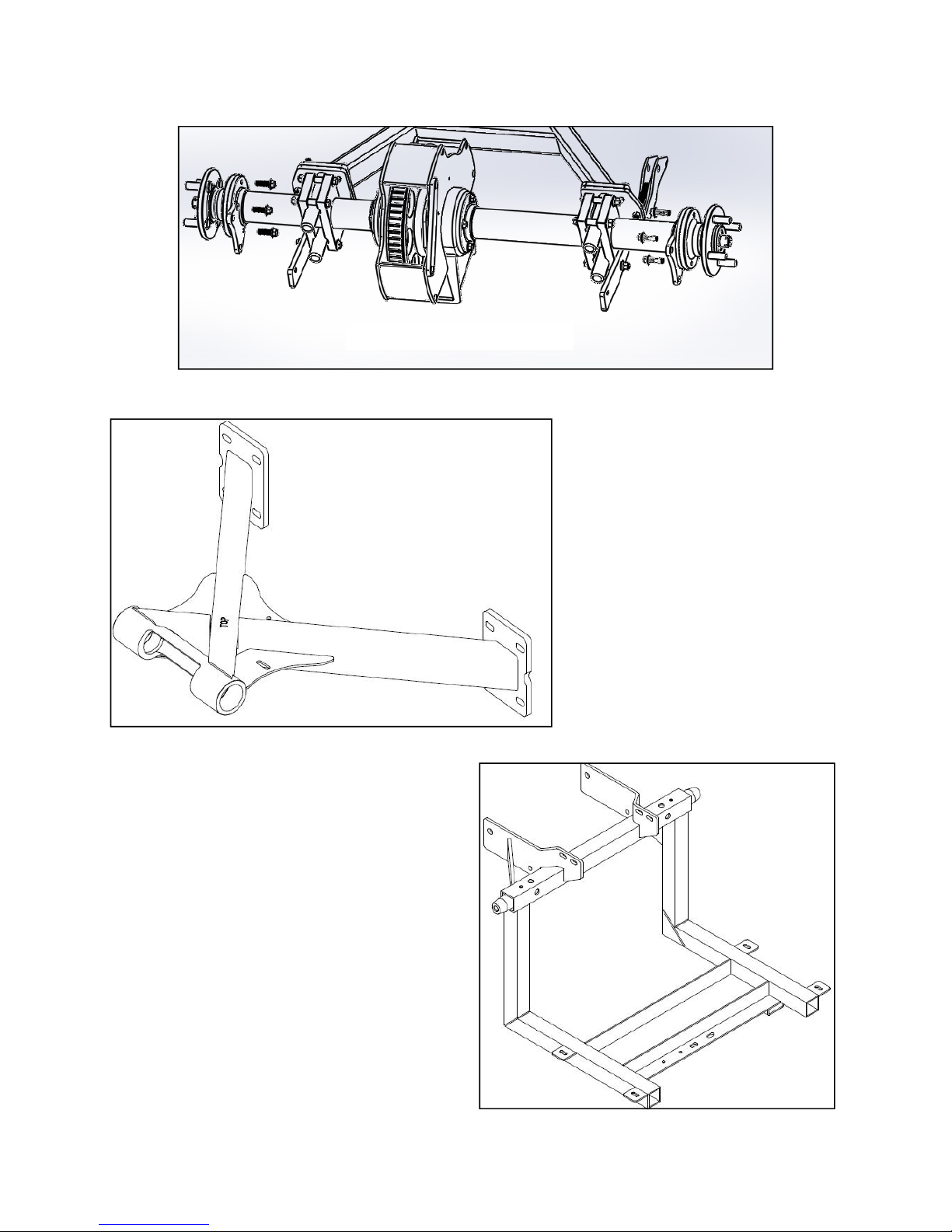

20. Remove rear wheel assembly.

21. Support transmission from below with jack and padded block.

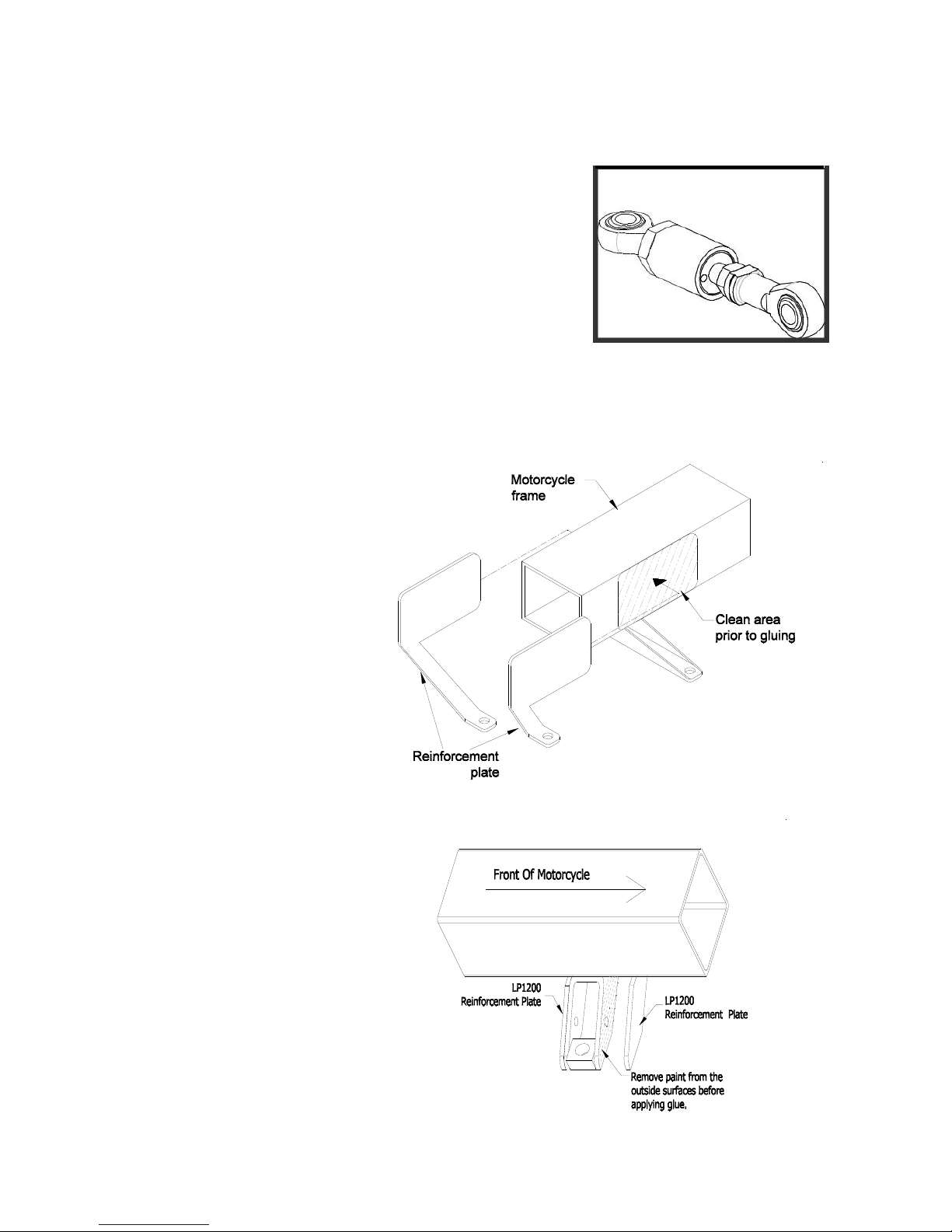

22. Remove pivot shaft nut from LH side of bike. Remove two swingarm brackets. Tap shaft out of

swingarm and remove from RH side. Swingarm may now be removed.

23. For 1997-2001 models, fuel tank must be removed. Refer to HD service manual for procedure.

7