3

SHOOT-THRU-HULL

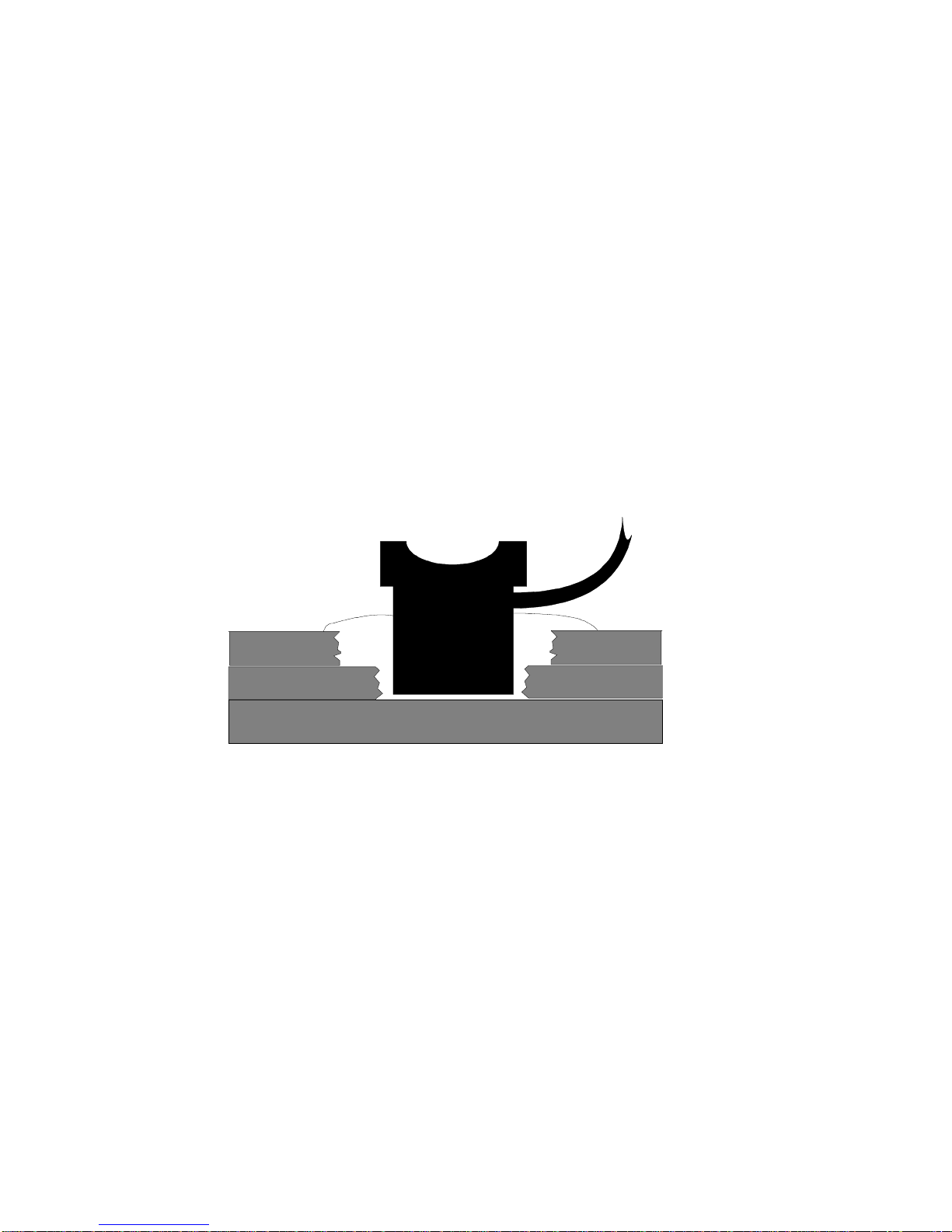

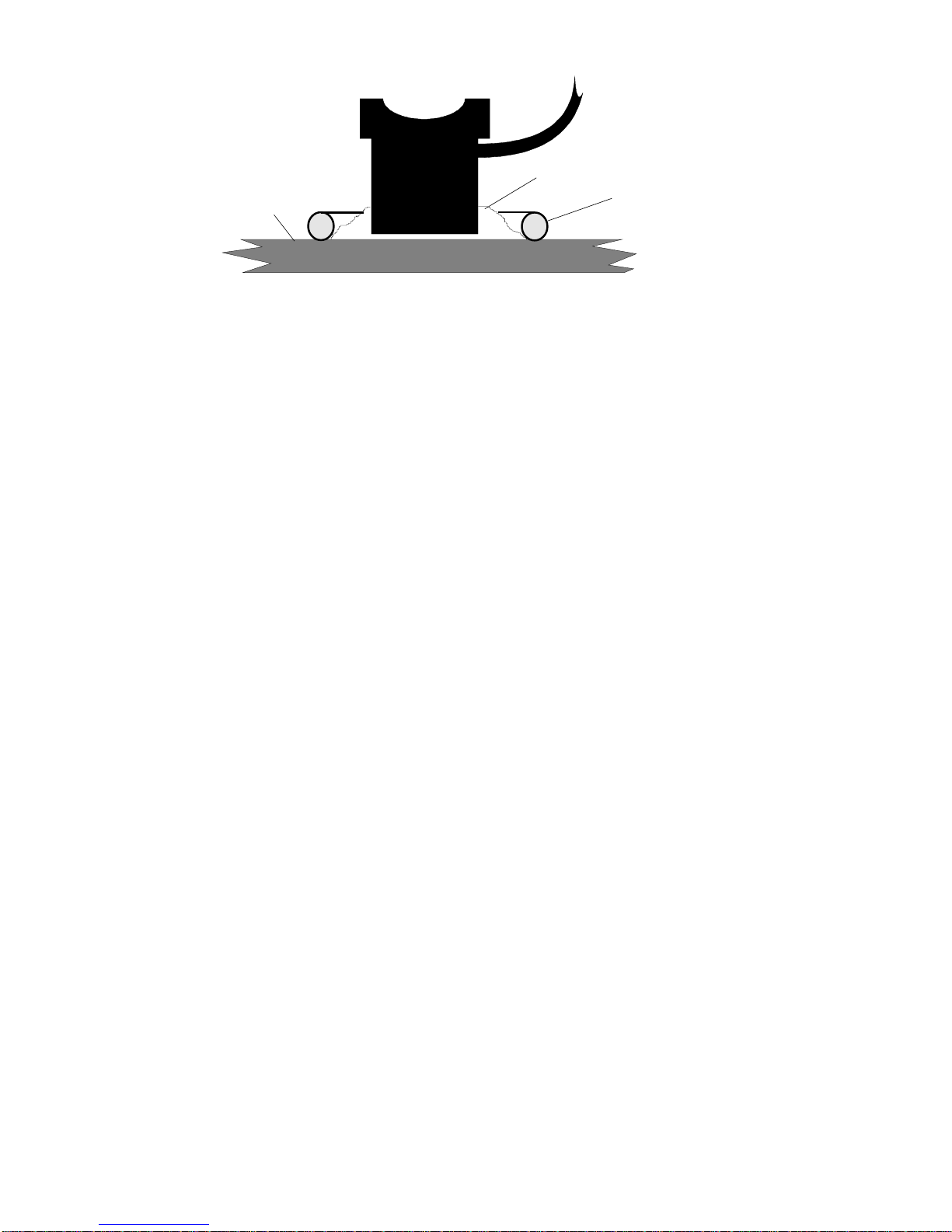

The transducer installation inside a fiberglass hull must be in an area

that does not have air bubbles in the resin or separated fiberglass

layers. The sonar signal must pass through solid fiberglass. A success-

ful transducer installation can be made on hulls with flotation materials

(such as plywood, balsa wood, or foam) between layers of fiberglass if

the material is removed from the chosen area. For example, some

manufacturers use a layer of fiberglass, then a core of balsa wood,

finishing with an outer layer of fiberglass. Removing the inner layer of

fiberglass and the balsa wood core exposes the outer layer of fiberglass.

The transducer can then be epoxied directly to the outer layer of fiber-

glass. Epoxy is poured into the hole and the transducer is then placed

into the epoxy. After the epoxy cures, the hull is watertight and structur-

ally sound. Remember, the sonar signal must pass through solid fiber-

glass. Any air bubbles in the fiberglass or the epoxy will reduce or

eliminate the sonar signals.

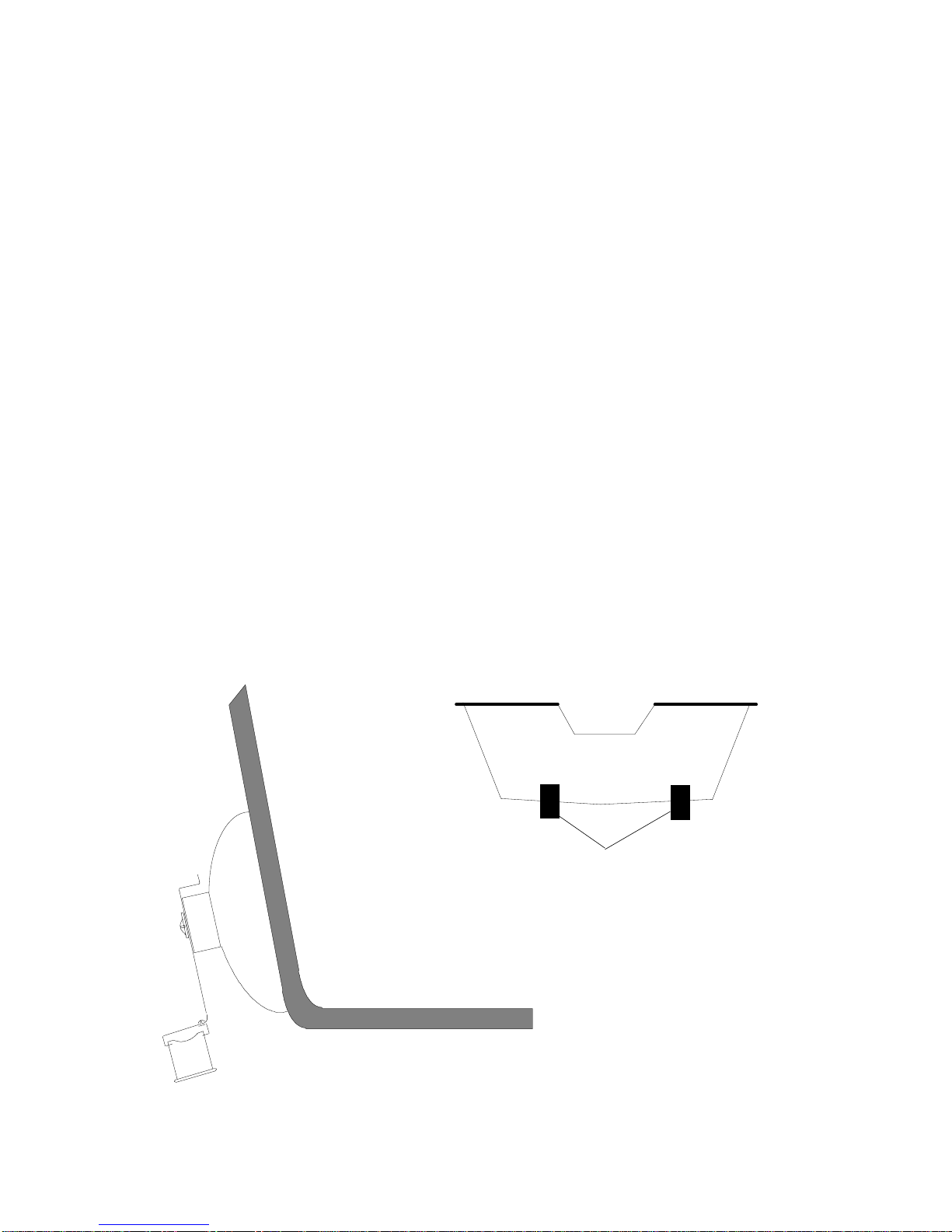

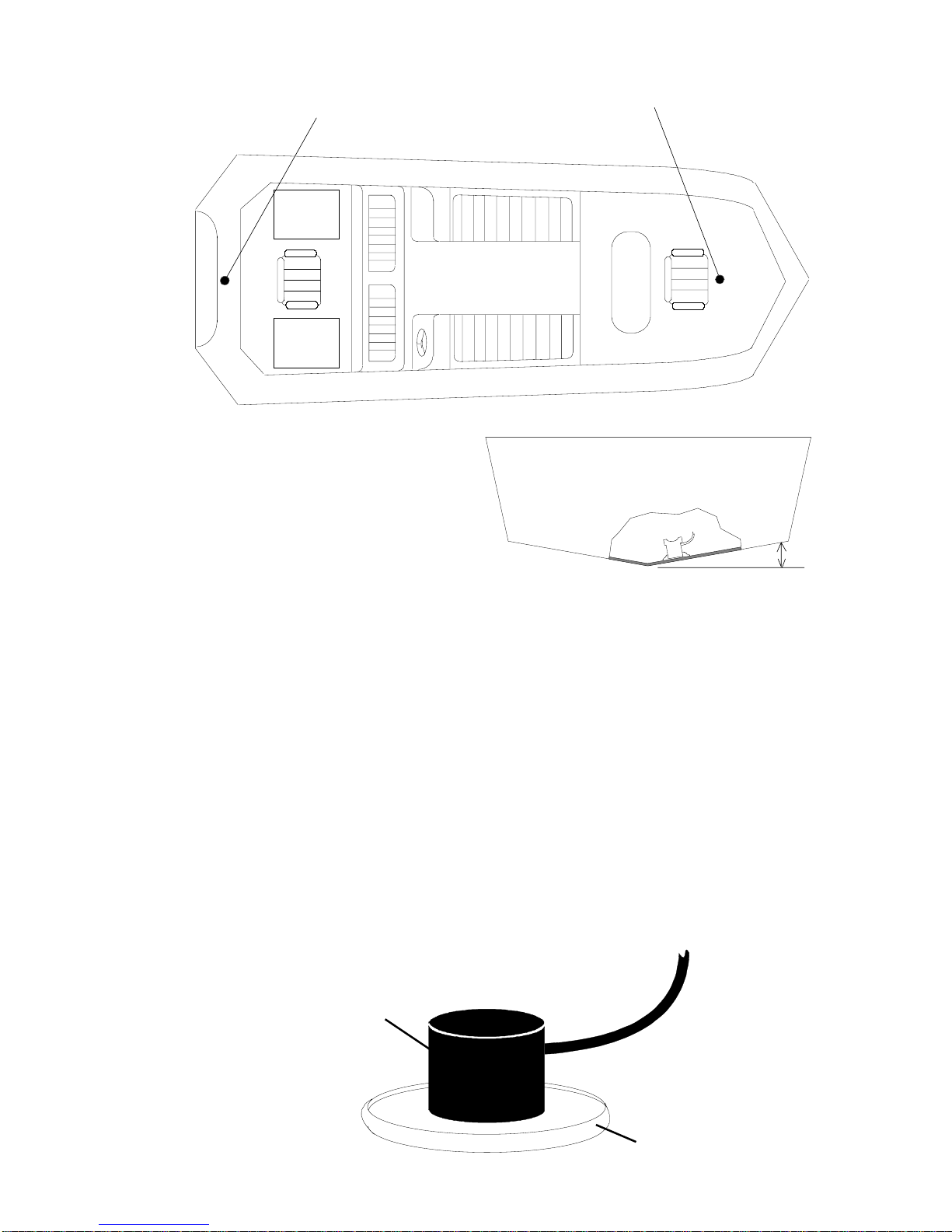

To choose the proper location for thru-hull mounting, anchor the boat in

60 feet of water. Add a little water to the sump of the boat. Plug the

transducer into the sonar unit, turn it on, then hold the transducer over

the side of the boat. Adjust the sensitivity and range controls until a

second bottom echo is seen on the display. (you will need to turn the

automatic and ASP functions off on L.C.G. units.) Don’t touch the

controls once they’ve been set. Next, take the transducer out of the

water and place it in the water in the sump of the boat. Observe the

sonar signal to see if there is a noticeable decrease in sensitivity. The

second bottom signal may disappear and the bottom signal may de-

crease in intensity. Move the transducer around to find the best location.

If the sensitivity control has to be increased greatly to compensate, then

a different type of transducer should be mounted on the outside of the

hull. If not, then mark the location that shot through the hull the best and

follow the instructions below for a thru-hull mounting.