IMPORTANT!

If you are using the One Touch, Digital Control, or Wall Timer in conjunction with an Air Switch, it is recommended that you

locate the steam generator within 25 feet of the showe

r or tub area. If this is not possible, please contact your local dealer or call

the factory so we can provide longer cables.

1.

The One Touch control panel can be installed either inside or outside the

steam room. It is recommended that the panel be located approximately 5

feet above the floor, but not directly over the steam head. Drill a 1-1/4"

diameter hole at this location.

2. From inside the steam room, slip the telephone style cable through the

hole drilled above.

3. Remove the protective backing on the One Touch control panel exposing

the adhesive foam. Carefully position the control panel on the wall

making sure the gray, half moon shape design is on the top. The foam

backing creates a water tight seal and is not designed to be placed into

position and then taken off and re-positioned.

Note: If you must re-position the control panel, it may be

necessary to apply a small amount of 100% silicone caulk to

secure the panel to the wall. This will be needed if you think

the foam adhesive is no longer making an adequate seal

because the foam adhesive is not sticky enough. Wipe any

excess silicone off with denatured alcohol. Tape the control

panel in place while the silicone hardens.

4. String the control cable from this location through 1/2" holes drilled in the

wall studs or ceiling joists to the location of the steam generator. Note:

Do not staple through or damage the control cable. Use the factory

supplied control cable only.

5. Plug the telephone style cable into the coupler module located on t

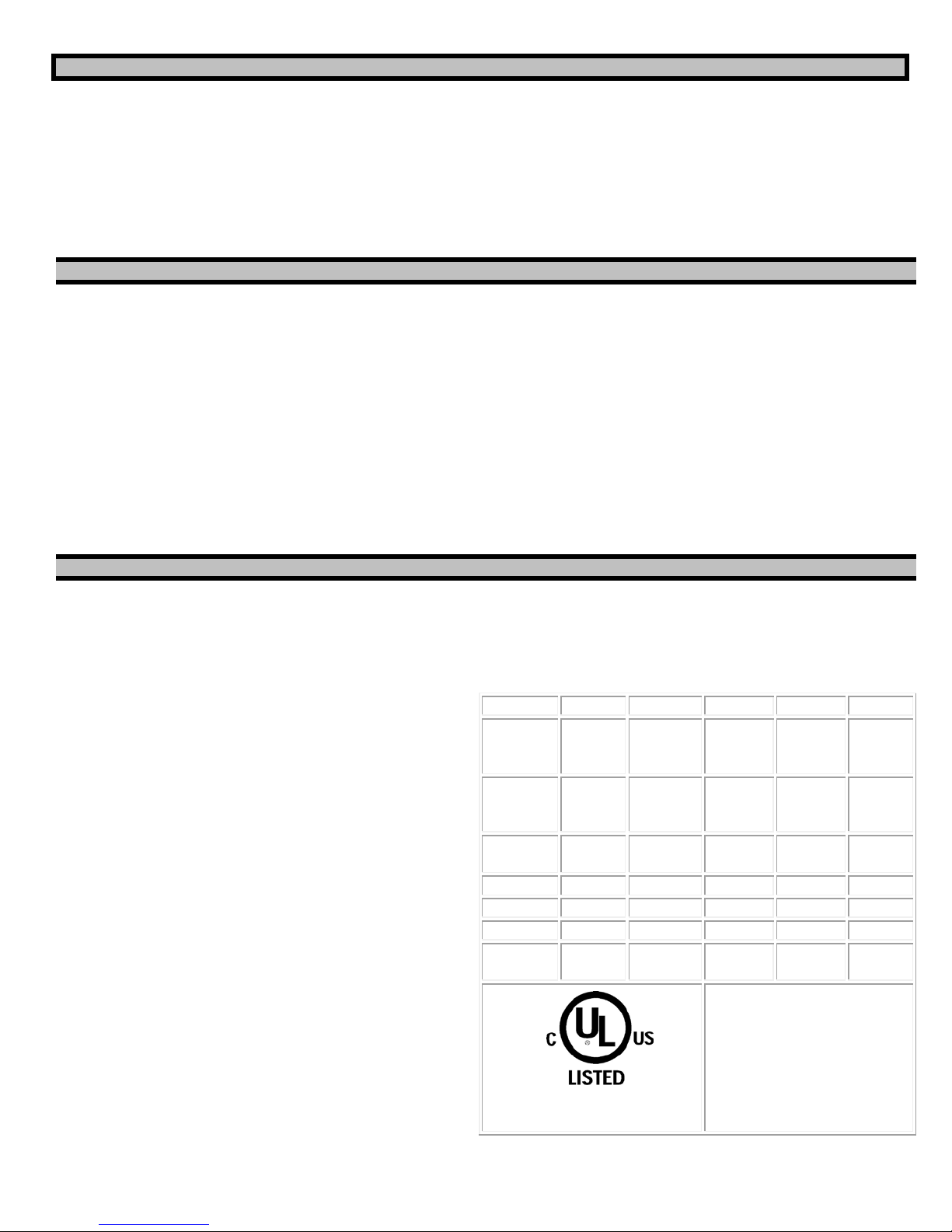

the steam generator. Please refer to Figure 1.

1. Digital Control Panel and Cable Rough-in.

A. The Digital Control panel can be mounted either

inside or outside the steam room. It is

recommended that the control panel be located

approximately 5 feet above the floor, but not

directly over the steam head. Drill a 3-1/2" x 1-1/4"

rectangular hole at this location.

B. From inside the steam room, slip the telephone style

cable through the hole drilled above.

C. Remove the protective backing on the Digital

Control panel exposing the adhesive foam.

Carefully position the control panel on the wall

making sure the control panel is level and

completely covers the rectangular hole drilled

above. The foam backing creates a water tight seal

and is not designed to be placed into position and

then taken off and re-positioned.

Note: If you must re-position the control panel, it

may be necessary to apply a small amount of 100%

silicone caulk to secure the panel to the wall. This

will be needed if you think the foam adhesive is no

longer making an adequate seal because the foam

adhesive is not sticky enough. Wipe any excess

silicone off with denatured alcohol. Tape the

control panel in place while the silicone hardens.

D. String the control cable from this location through

1/2" holes drilled in the wall studs or ceiling joists

to the location of the steam generator. Note: Do

not staple through or damage the control cable. Use

the factory supplied control cable only.

E. Plug the telephone style cable into the coupler

module located on the lid to the steam generator.

Please refer to Figure 1.

2. Temperature Sensor and Cable Rough-in.

A. Locate the temperature sensor 6 feet above the

floor, but not directly over the steam head. Drill a

1-5/16" diameter hole at this location.

B. From inside the steam room, push the metal probe

end of the sensor cable into the temperature sensor

housing securing it firmly with the nut and o-ring

supplied. Slip the rest of the sensor cable through

the hole drilled above.

C. Apply 100% silicone caulk around the threads and

back side of the temperature sensor housing. Insert

the temperature sensor housing into the hole drilled

above and push it against the wall. Wipe any

excess silicone off with denatured alcohol. Tape

the sensor in place while the silicone hardens.

D. String the sensor cable from this location through

1/2" holes drilled in the wall studs or ceiling joists

to the location of the steam generator. Note: Do

not staple through or damage the sensor cable. Use

the factory supplied sensor cable only.

E. Plug the sensor cable into the temperature sensor

plug-in located on the lid to the steam generator.

Please refer to Figure 1.

1. Locate the position for the air switch and drill a 1-1/4" diameter hole.

2. From inside the steam roo

m, push the flexible tubing over the stem on the

back of the air switch housing.

Slip the rest of the tubing through the hole

drilled above.

3. Apply 100% silicone caulk around the threads and back side of the air

switch housing. Insert the air switch housing into the hole drilled above

and push it against the wall. Wipe any excess silicone off with denatured

alcohol. Tape the air switch housing in place while the silicone hardens.

4. String the flexible tubing through 1/2" holes drilled in the wall studs or

ceiling joists to the location of the steam generator. Note: Do not staple

through or damage the flexible tubing. Use the factory supplied flexible

tubing only.

5. Push the flexible tubing over the black plastic stem protruding from the

top of the electrical junction box. Please refer to Figure 1.