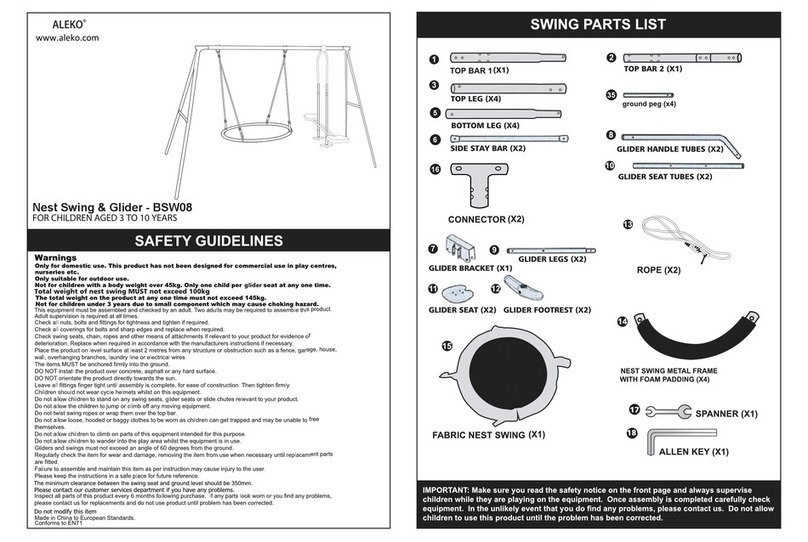

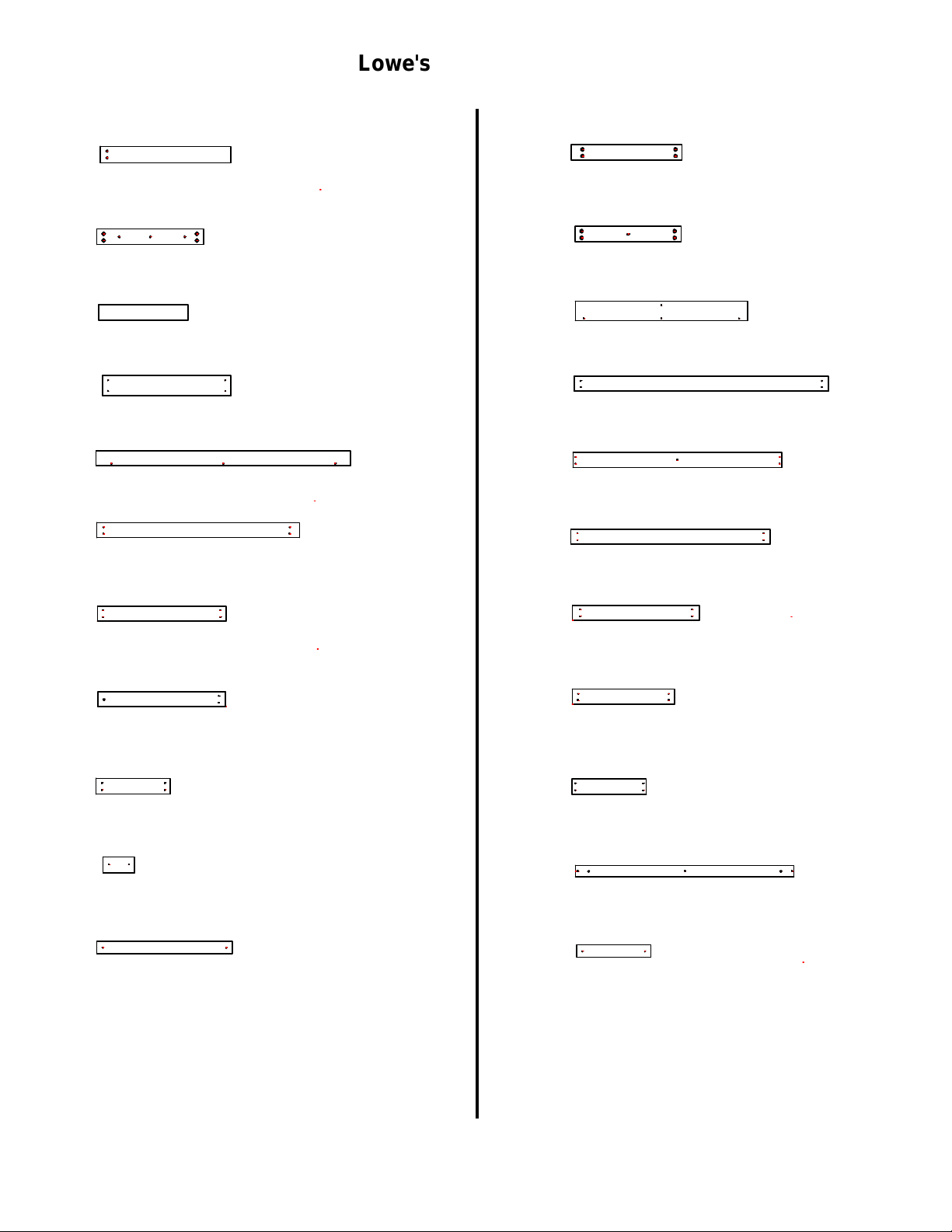

Priortoassemblingyourplayproduct,takea installation and at least once per year.

thorough inventory of all components using There are many excellent products,such

thepartslist. as Thompson's Waterseal, Behr Wood

Conditioner, Olympic Water Guard or

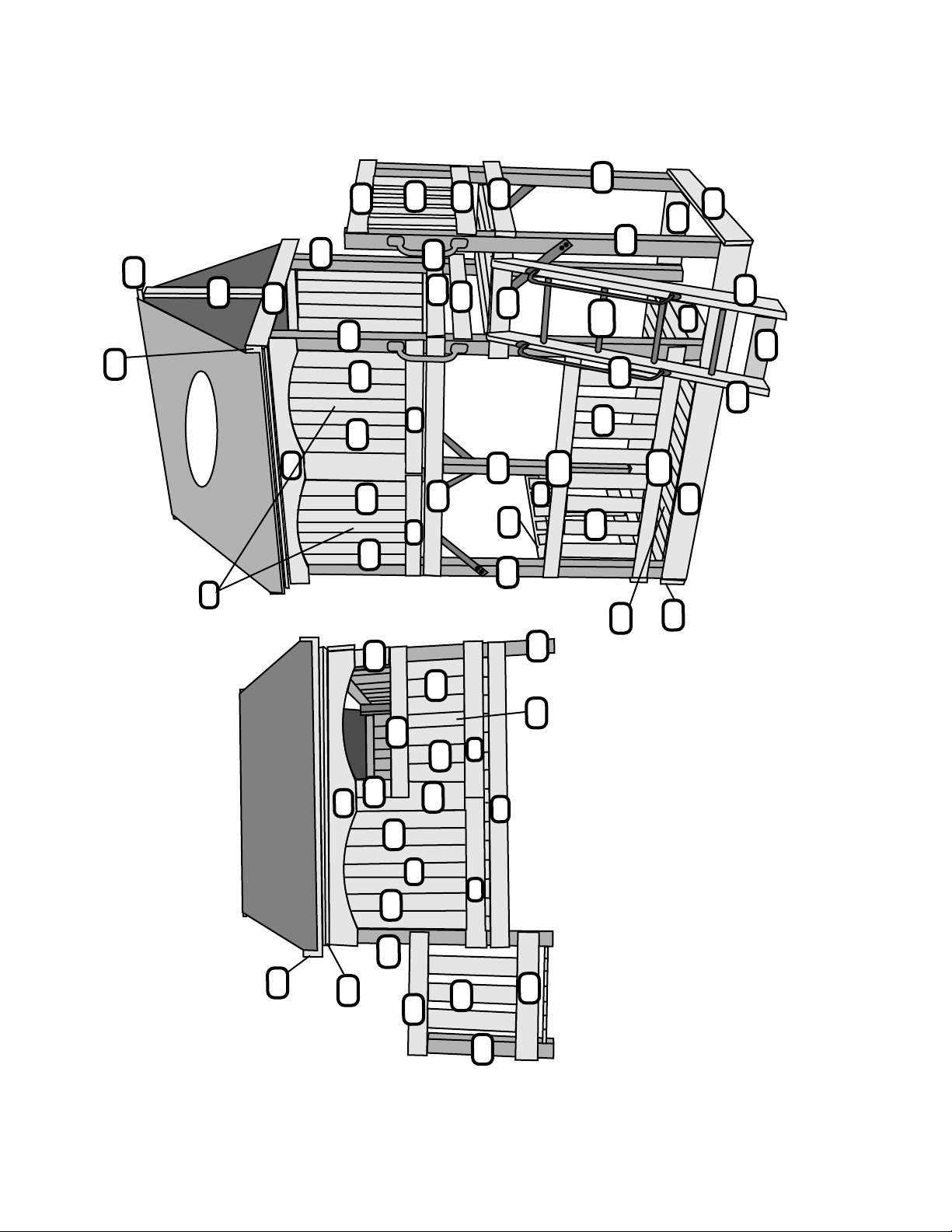

Sort and lay out all wood pieces, matching Olympic Wood Protector. Please check

identicalpiecesintopiles. Markallpiecesof with your local home improvement

wood using masking tape, write board letter center to see what they recommend for

on tape and adhere to each piece of wood your area conditions. Proper care and

forquickreferenceandidentification. maintenance will help maintain the

beauty of the set as well as gain the

Sort all hardware according to size.Refer to maximumlifeoftheunit.

parts identification section. Selecting the

wrong hardware during early assembly will Metal plates: The structural integrity of the

lead to shortages.Finding extra hardware is play product is dependent upon the proper

not cause for alarm. We often include extra installationofthemetalplates. Asnotedand

hardware in case parts are lost during diagramed in these assembly instructions,

assembly. the installation of these metal plates must

also be followed precisely. If your play set

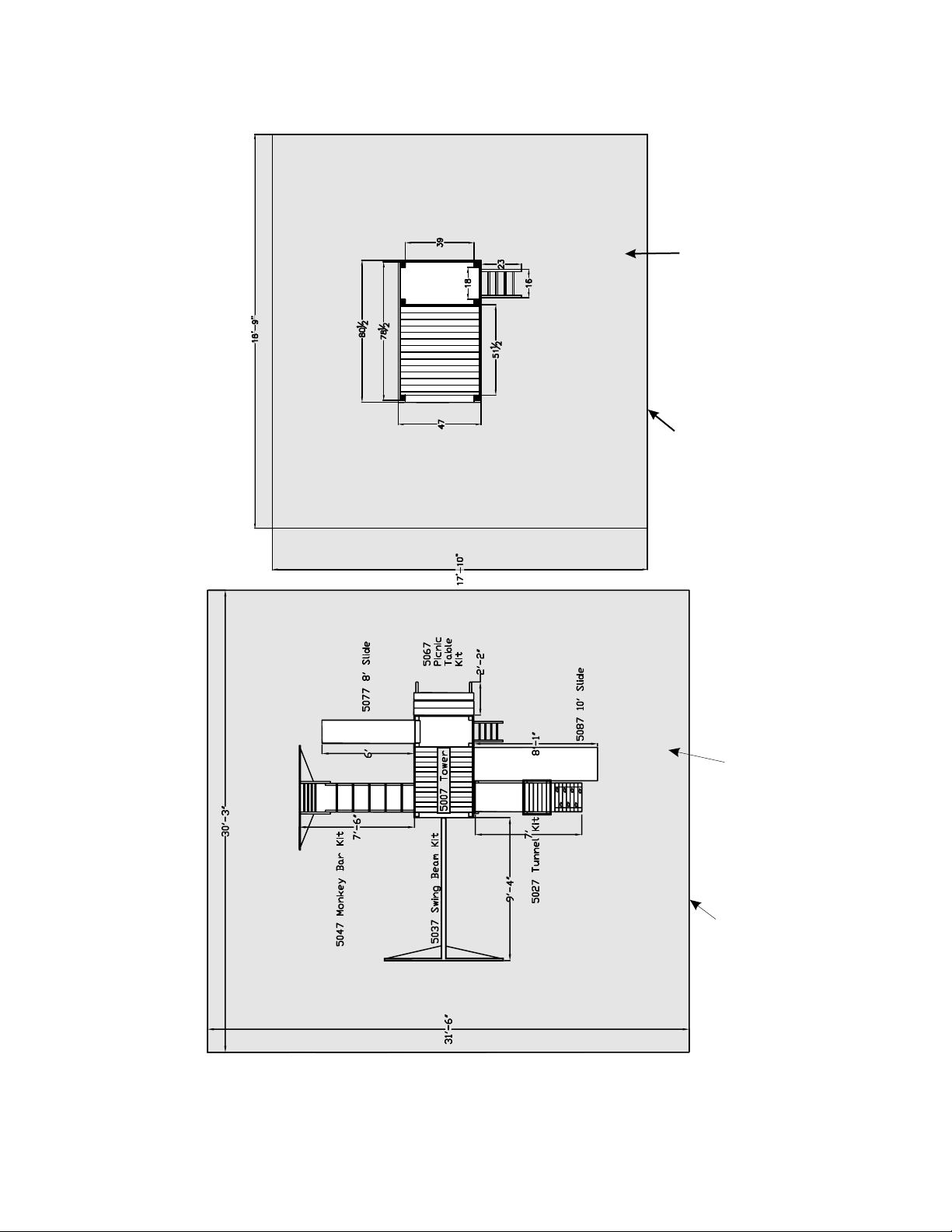

Selecting the correct location for your has end ladders or swing beam supports,

playset product is very important for your make sure they are angled away from the

children's safety and for the play product's top ladder or swing beam. If a play product

longevity.Your playset must be installed on has one or two climbing towers, the metal

level ground. Installation on sloping ground plates must be installed so that each

willcause yoursetto"lean"and,in time,this climbing tower is perpendicular to the top

leaning will put stress on all the joints. This ladder.

stress will cause the set to become loose

and unstable. Once this occurs, it becomes Ground stakes: Metal stakes are

difficult to correct, and Playground, Inc. provided and are to be installed as

cannot assume responsibility for any failure outlined in the assembly manual.

from incorrect installation. Uneven ground Cementing is recommended and

mustbeproperlyleveledbeforeinstallation. required if you have loose or sandy soil

or if you live in an area that is prone to

Warping: Occasionally, some wooden highwindsorseverestorms.

components may twist or warp in the carton

after packaging. This is not necessarily a On site adult supervision is required at all

cause for alarm. In most instances, these timesforchildrenofallages.

parts straighten out when assembled.

Seasonal checking or cracking of the grain Ensure that suspended climbing ropes,

onwoodenpartsisalsoquitenatural. Water chainsorcablesarekepttightenoughso

and heat are the two most frequent causes they cannot be looped back on

ofexpansionand contractionofwoodfibers. themselves and are kept secure at both

We recommend that you apply a wood ends.

sealant or protectant at the time of

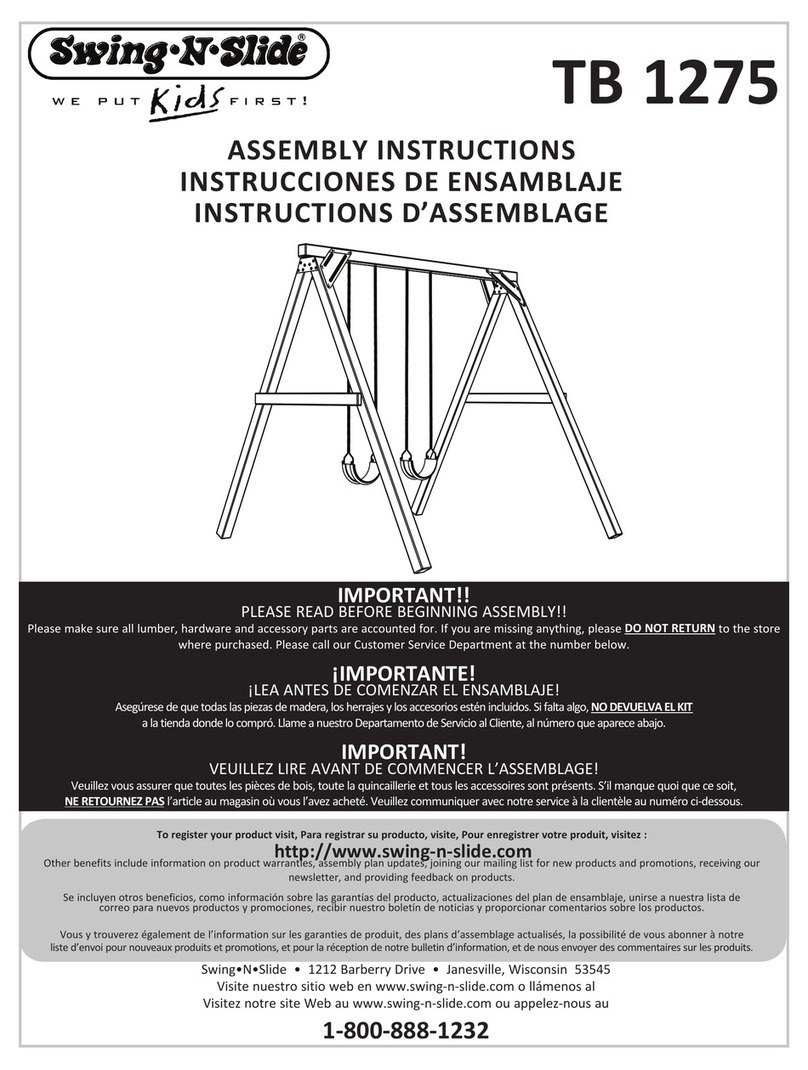

IMPORTANT TIPS FOR ASSEMBLY

SEE PAGES 34THRU 36 FOR MAINTENANCETIPS

Page 1 - SAFETY & ASSEMBLY INFO © Copyright Playground Inc

Next Generation 5007 061206