8. After all of the liquid refrigerant has been recovered,

switch the recovery machine to vapor recovery so that

all of the HCFC-22 vapor is recovered,

NOTE -A single system flush should remove all of the

mineral oil from the existing refrigerant lines and in-

door coil. A second flushing may be done (using clean

refrigerant) if insufficient amounts of mineral oil were

removed during the first flush. Each time the system

is flushed, you must allow the recovery machine

to pull a vacuum on the system at the end of the

procedure.

9. Close the valve on the inverted HCFC-22 drum and

the gauge set valves. Pump the remaining refrigerant

out of the recovery machine and turn the machine off,

10. Use dry nitrogen to break the vacuum on the refriger-

ant lines and indoor coil before removing the recovery

machine, gauges and HCFC-22 refrigerant drum. Re-

install pressure tap valve cores into 13HPX service

valves.

11. Install the provided check/expansion valve (approved

for use with HFC-410A refrigerant) in the liquid line at

the indoor coil.

13HPX units are used in check expansion valve (TXV) sys-

tems only, See the Lennox Engineering Handbook for ap-

proved TXV match-ups and application information.

NOTE -HFC-410A systems will not operate properly with

an HCFC-22 valve.

Check expansion valves equipped with Chatleff fittings are

available from Lennox. Refer to the Engineering Hand-

book for applicable check expansion valves for use with

specific match-ups, See table 3 for applicable check ex-

pansion valve kits,

Table 3. Indoor Check Expansion Valve Kits

Model Kit Number

13HPX-018, -024, -030, -036 49L24

13HPX-042, -048 49L25

13HPX-060 91M02

IMPORTANT

If you install a check expansion valve with an indoor coil

that includes a fixed orifice, remove the orifice before the

check expansion valve is installed. See figure 13 for instal-

lation of the check expansion valve.

/STRAINER

DISTRIBUTOR _"(_ LITQUBIDLINE

NOTE - If necessary, remove HCFC-22 flow control device (fixed

orifice/thermal expansion valve) from existing line set before instal-

ling HFC-410A approved expansion valve and o-ring,

Figure 13. Metering Device Installation

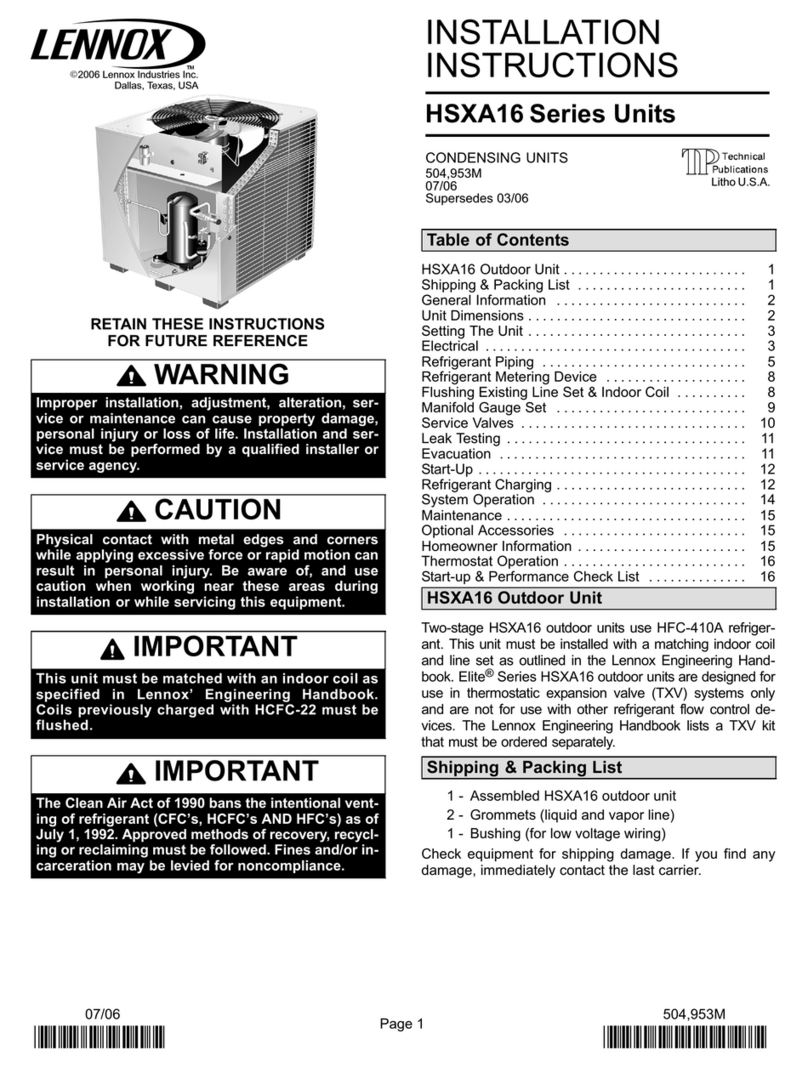

Manifold gauge sets used with systems charged with

HFC-410A refrigerant must be capable of handling the

higher system operating pressures, The gauges should be

rated for use with pressures of 0 - 800 on the high side and

a low side of 30" vacuum to 250 psi with dampened speed

to 500 psi. Gauge hoses must be rated for use at up to 800

psi of pressure with a 4000 psi burst rating,

The service valves (liquid line - figure 14, vapor line - figure

15) and gauge ports are used for leak testing, evacuating,

charging and checking charge, Each valve is equipped

with a service port which has a factory-installed Schrader

valve. A service port cap protects the Schrader valve from

contamination and serves as the primary leak seal.

SCHRADER

VALVE [OPEN TO

LINE SET WHEN

VALVE IS CLOSED

]FRONT SEATED)]

TO

OUT-

STEM INSERT HEX

CAP

_TO

INDOOR

SERVICE COIL

PORT CAP ]VALVE FRON%SEATED)

Valve in closed position Valve in open position

Figure 14. Liquid Line Service Valve

TO ACCESS SCHRADER PORT:

1. Remove service port cap with an adjustable wrench,

2. Connect gauge to the service port,

3. When testing is completed, replace service port cap and

tighten finger tight; then tighten per table 1 (on page 2).

TO OPEN FRONT-SEATED SERVICE VALVES:

1, Remove stem cap with an adjustable wrench,

2. Use a service wrench with a hex-head extension

(3/16" for liquid-line valve sizes; 5/16" for vapor-line

valve sizes) toback the stem out counterclockwise as

far as it will go,

3. Replace the stem cap. Tighten finger tight; then tighten

per table 1 (on page 2).

TO CLOSE FRONT-SEATED SERVICE VALVES:

1. Remove the stem cap with an adjustable wrench.

505325 03/08

Page 10