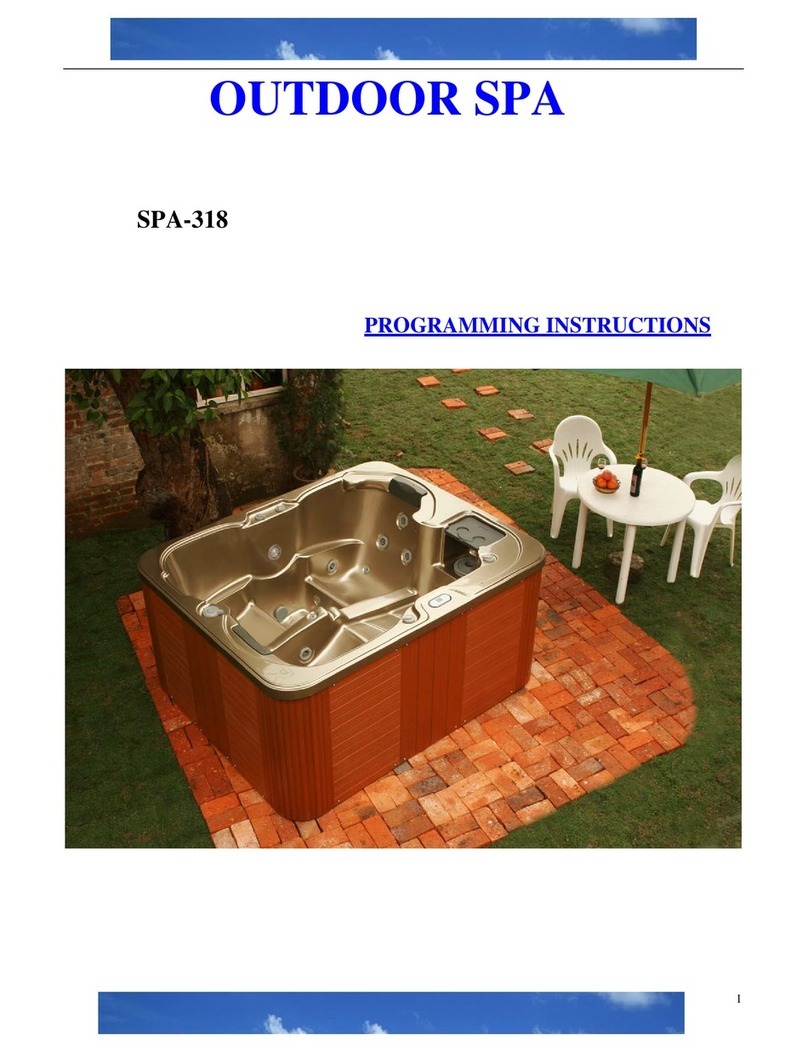

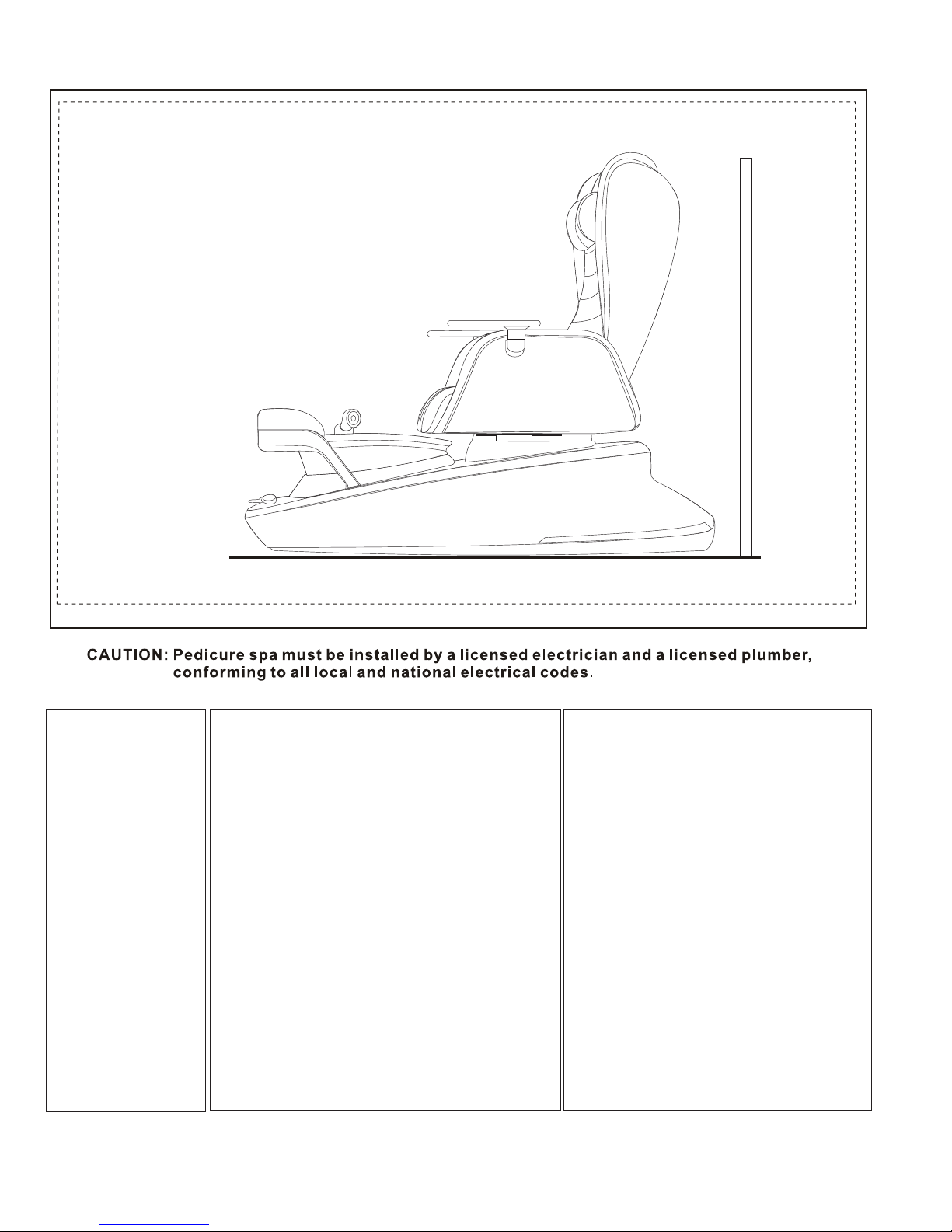

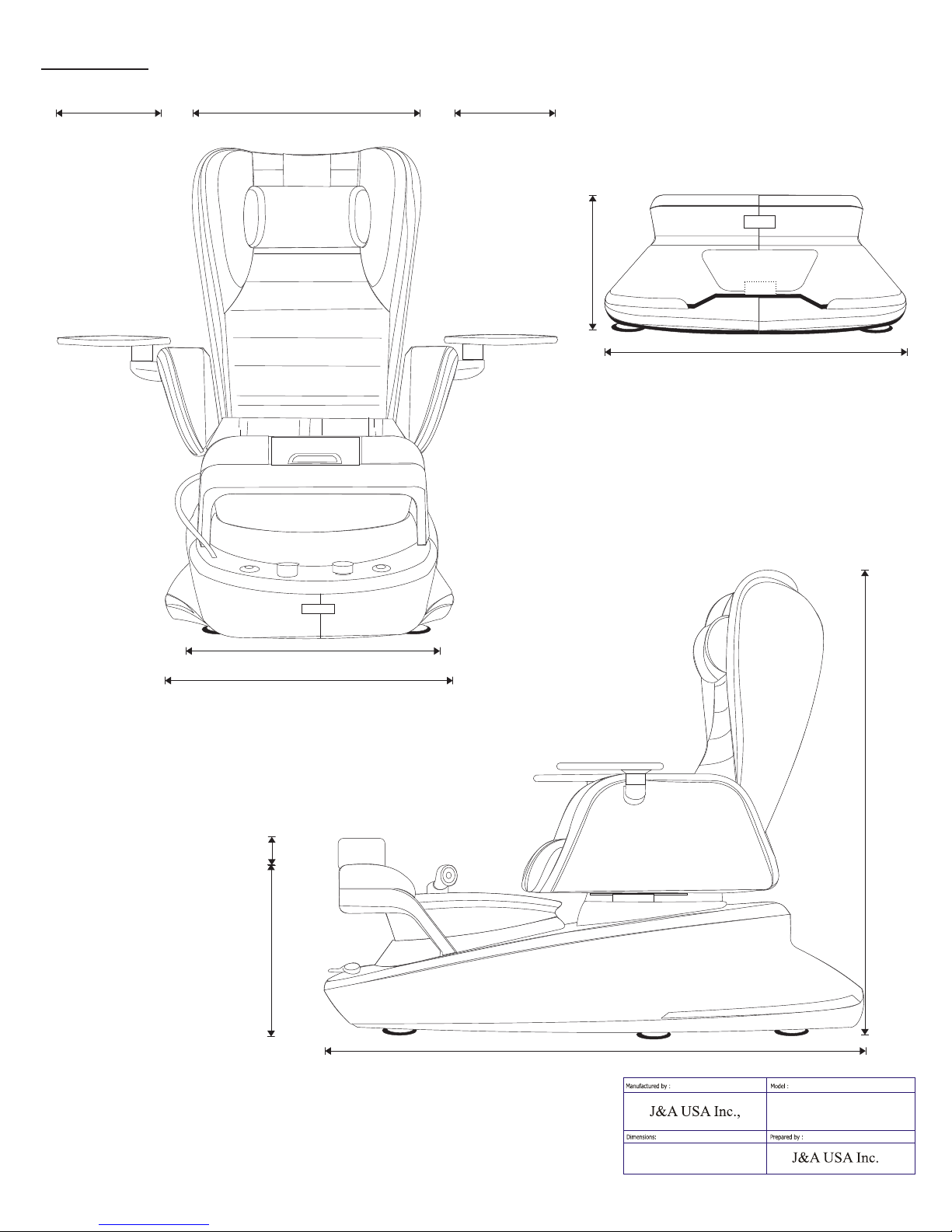

Important Considerations For Installation

Electrical Service

Water Supply

All plumbing connections must conform to local codes.

Water supply to the spa should be provided with adequate water pressure and water temperature.

Water pressure

To fill the basin correctly up to level, Normal water pressure of 30 to 80 P.S.I is required.

Water temperature

The hot water supply temperature must not exceed 140 . Adjust your hot water accordingly. For hot and cold water supply

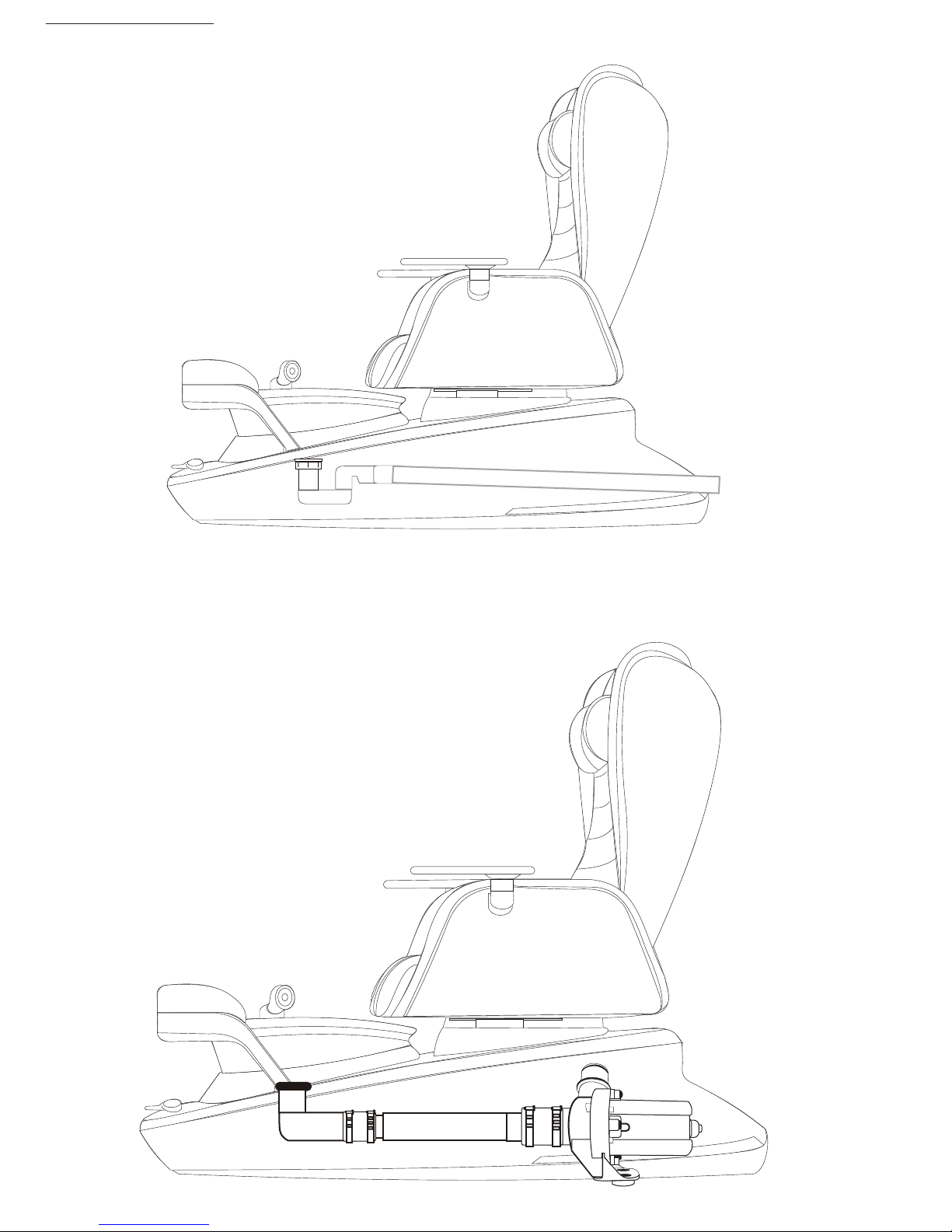

fittings and drain fittings location, see below diagram .Carefully connect the water supply line to the appropriate fittings

located on the rear of the pedicure spa.

The pedicure spa Drain must meet local plumbing codes. Check valve for Drain (not Provided) Must be installed by a licensed

plumber. Also Pedicure spa must be securely fasten to the floor.

UL LISTED / CE CERTIFIED

Compliance with following Code (s): Uniform Plumbing Code, National Plumbing Code of Canada and international

Plumbing Code. Also, Compliance with following Standard (s): ASME A112.18.3M / A112.18.1M, CSA B125, NSF /

ANSI 61

Drain Facilities

ANSI - American National Institute, ASME - American Society of Mechanical Engineers, CSA - Canadian Standard

Association IAPMO - International Association of Plumbing and Mechanical Officials, UL - Underwriters Laboratory

110V, 60Hz, 15Amp GFCI protected grounded circuit MUST be used to supply power each individual pedicure spa.

And the main circuit breaker MUST be at 25Amp.

Pressure / Temperature

Maximum Pressure: 150 psi (10 bars)

Minimum Pressure: 10 psi (69kPa)

Working Temperature: 33F to 140F constant; intermittent to 180f

(0.6C to 60C sustained; intermittent to 82.2C)

Maximum Recommended Flow: 1.5gpm

Due to Town and / or State requirement/s are varies in building code, if the Town and / or State requires

Vaccum Breaker, As the Plumber MUST provide Vaccum Breaker according to building code

requirement.

Installation Summary

The installation must comply with local, state, and federal building, plumbing and electrical codes, where applicable. A

licensed plumber should complete the plumbing of the pedicure spa.

Note: Failure to comply with federal, state, or local codes and ordinances will result in warranty being nullified and

void.

** Backflow Protection device

All J&A USA products has been compliance with requirements for Whirlpool bath appliances contained in ASME / ANSI

A122.19.7M-1995, CSA C22.2 No. 68-69