The manufacturer is not responsible for any damages caused by inappropriate installation,

not maintaining the proper environmental conditions and using the unit contrary to its

assignment.

Installation should be conducted by qualified personnel . During installation all available

safety requirements should be considered. The fitter is responsible for executing the

installation according to this manual, local safety and EMC

regulations.

GND input of device should be connected to PE wire;

The unit must be properly set-up, according to the application. Incorrect configuration can

cause defective operation, which can lead to unit damage or an accident.

If in the case of a unit malfunction there is a risk of a serious threat to the safety of people

or property additional, independent systems and solutions to prevent such a threat must be

used.

The unit uses dangerous voltage that can cause a lethal accident. The unit must be

switched off and disconnected from the power supply prior to starting installation of

troubleshooting (in the case of malfunction).

Neighboring and connected equipment must meet the appropriate standards and

regulations concerning safety and be equipped with adequate overvoltage and interference

filters.

Do not attempt to disassemble, repair or modify the unit yourself. The unit has no user

serviceable parts. Defective units must be disconnected and submitted for repairs at an

authorized service center.

The unit is designed for operation in an industrial environment and must not be used in

a household environment or similar.

2. GENERAL CHARACTERISTICS

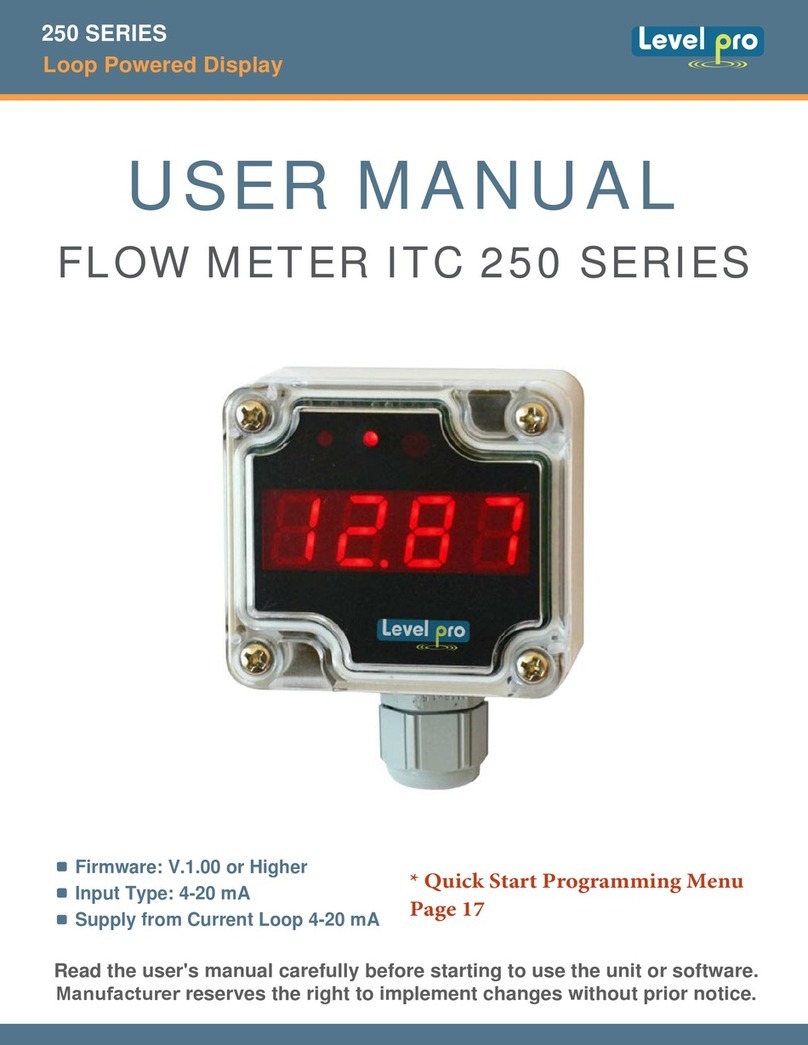

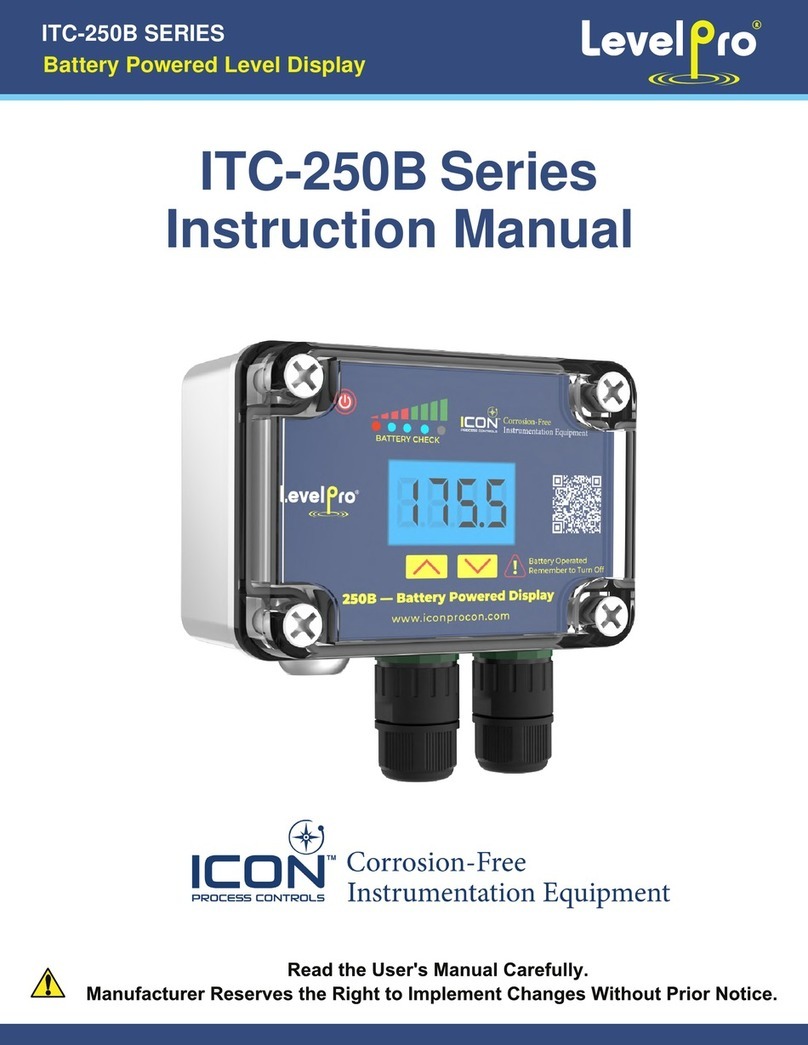

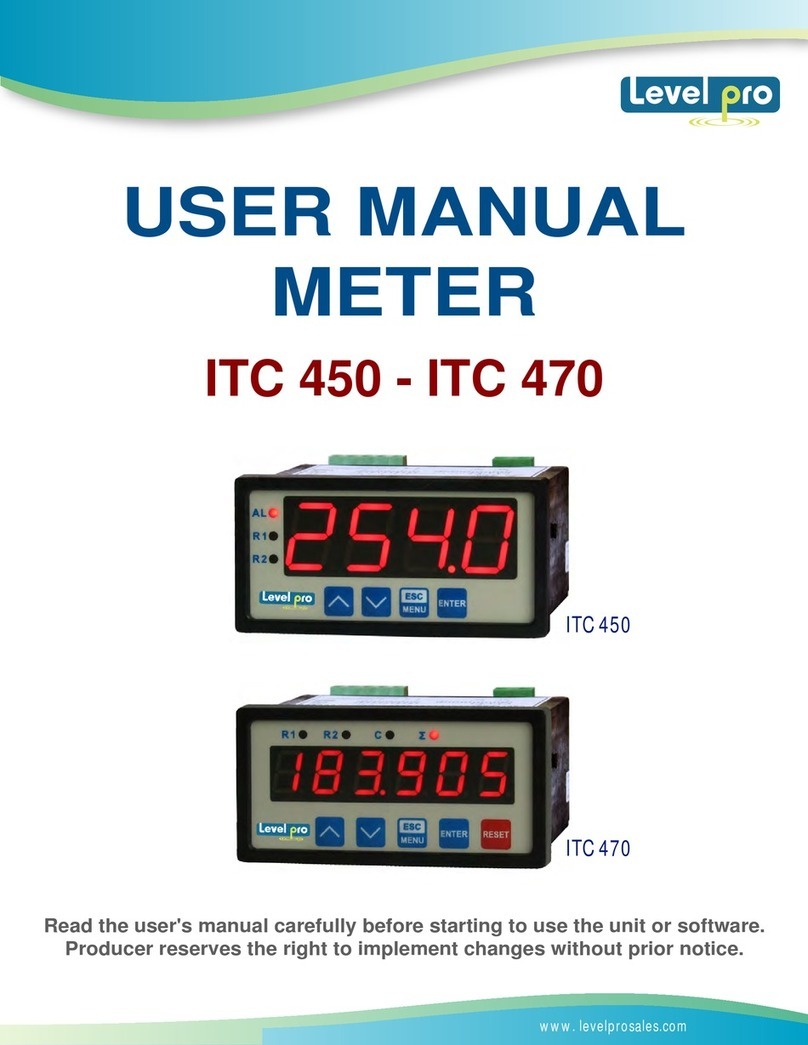

Main task of TVF Series is measurement of instantaneous flow (flow rate), and counting of

total flow, The device can be used as regulator, to control industrial process. Measurement of

instantaneous flow can be indicated in range: 0 to 9999 (plus decimal point) and can be

expressed in combination of flow measurements (Gallon, litre and m3) and in three time

measurements (second, minute, hour). Total flow can be indicated in range from 0.000 to 16

digits with maximum resolution of 0.001 L.

TVF Series can cooperate with flow sensors with current output (0-20mA or 4-20mA).

Sensors can be powered from sensor supply output (stabilized, 24VDC +5%, -10% 100mA).

The device can be equipped with: two relay outputs, two OC type outputs, one relay and one

passive isolated current output or one OC type and one passive isolated current output,

which can be driven due to instantaneous flow, total flow or batcher counter value. Build in

RS 485 interface enables access to all internal registers, and supports MODBUS RTU

communication protocol. The controller can be ordered in two power supply versions.

R

Display / Flow / Batcher / Totalizer

TVF SERIES