Ultrapro-1000 © Levelpro, s.r.o.

9

7 .

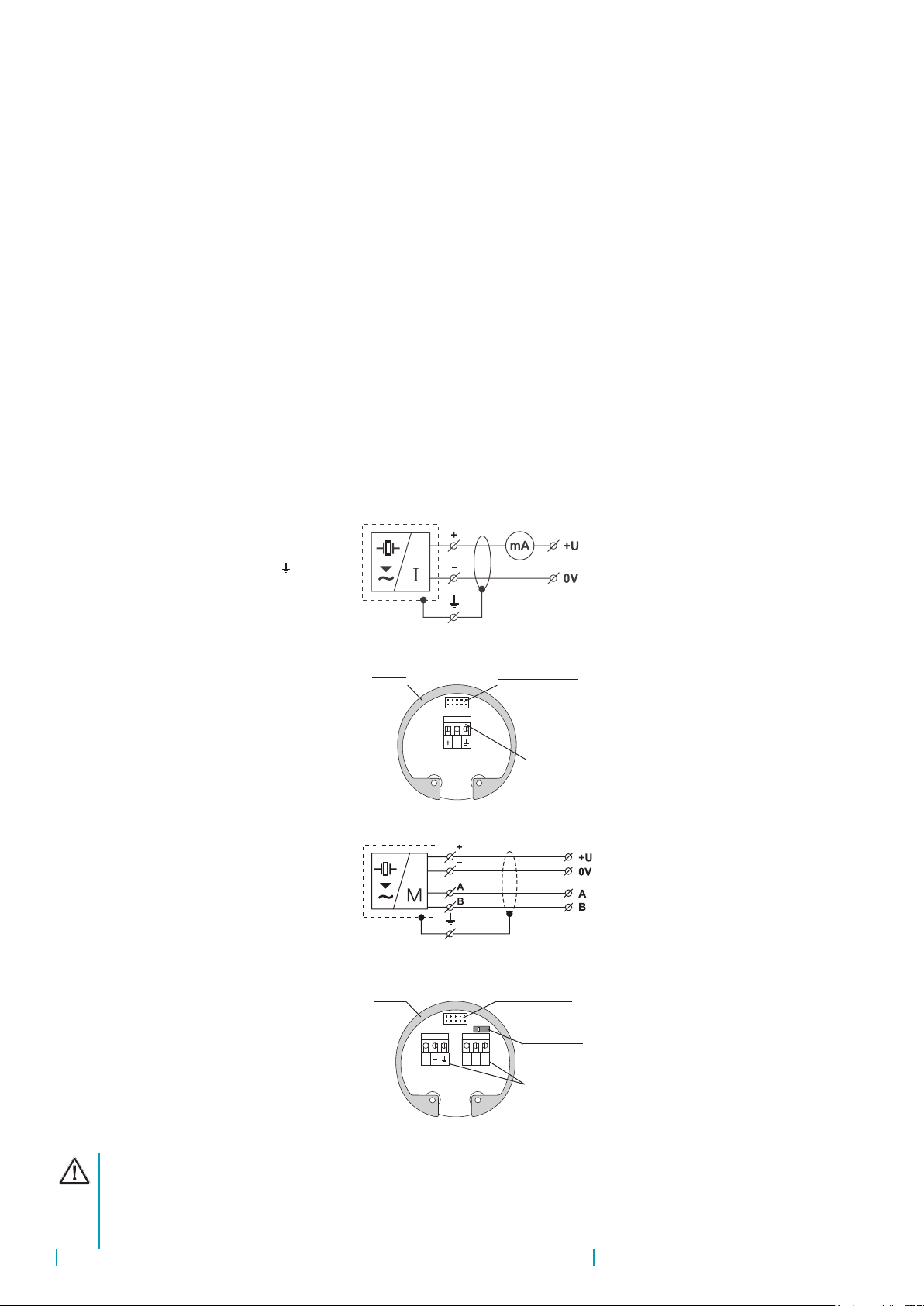

Thelevelmeterisconnectedtoconsequential(evaluating)devicewithasuitablecablewiththe

outerdiameterof6to8mmusingscrewterminalslocatedunderthedisplaymodule.Therecom-

mendedcrosssectionofcoresforthecurrentversion2x0,5÷0,75mm2 and for the version with

Modbuscommunication2x2x0,25mm2 (twistedpair,

shielded).Pluspole(+U)isconnectedtotheterminal

(+),minuspole(0V)totheterminal(-)andtheshielding

(onlyforshieldedcables)totheterminal().Commu-

nicationwiresAandBofthelineRS-485(forversion

"M"-Modbus)areconnectedtotheterminalsAandB.

Procedure to connect the cable to the level meter:

1. Unscrew the nut of the upper transparent lid.

2. Take the upper edge of the display module and

takeitoutcarefullybymildswingingup.

3. If you cannot grasp the module, you can use

a small screwdriver. Insert it as far as the seam and

usefromseveralsidestoslightlyliftthemodule.

4. Release the cable outlet and thread the stripped

supplycablein.

5. Connectthecabletothescrewterminalsaccord-

ingtothediagraminFig.17or18.Firmlytighten

theterminalsandthecableoutlet.

6. If the level meter with Modbus is involved as a

terminalforRS-485,werecommend(toavoidre-

flections ontheline)toconnect120Ωtermination

resistor. This is done by moving a small lever of

theswitchmarked120ΩtotheONposition.Onthe

levelmetersconnectedtothelineRS-485as an

intermediatedevice, the termination resistorsare

notconnected(switchremainsoff).

7. Insert the display module back into the head so

thattheconnectorisproperlyconnected.

8. Slidesiliconesealonthethreadofthelevelmeter

body,thentightenthenutoftheupperlid.Connect

thecabletoconsequentialdevice.

Fig. 16: Wiring diagram of the level meter

with current output UPS 1000 _-_-_- I

metal clip display unit connector

Terminal block

Electrical connection must be done in de-energized state!

With regard to possible occurrence of electrostatic charge on non-conductive parts of the

level meter, all level meters for explosive spaces (UPS–70Xi type) must be grounded. It

will be done using a screw placed on the head of the level meter under the cable outlet.

Fig. 17: Inside view of screw terminals of the

level meter with current output UPS 1000_-_-_-I

+ABIS

GND

ON

120

display unit connector

Terminal block

metal clip

120Ω switch

Fig. 18: Wiring diagram of the level

meter with Modbus UltraPro

1000_-_-_-M

Fig. 19: Inside view of screw terminals of the

level meter with Modbus UPS 1000_-_-_-M