Table of Contents

Overview .......................................................................................................................................................................................................... 5

Installation Checklist........................................................................................................................................................................................ 5

Markings and Symbols:.................................................................................................................................................................................... 5

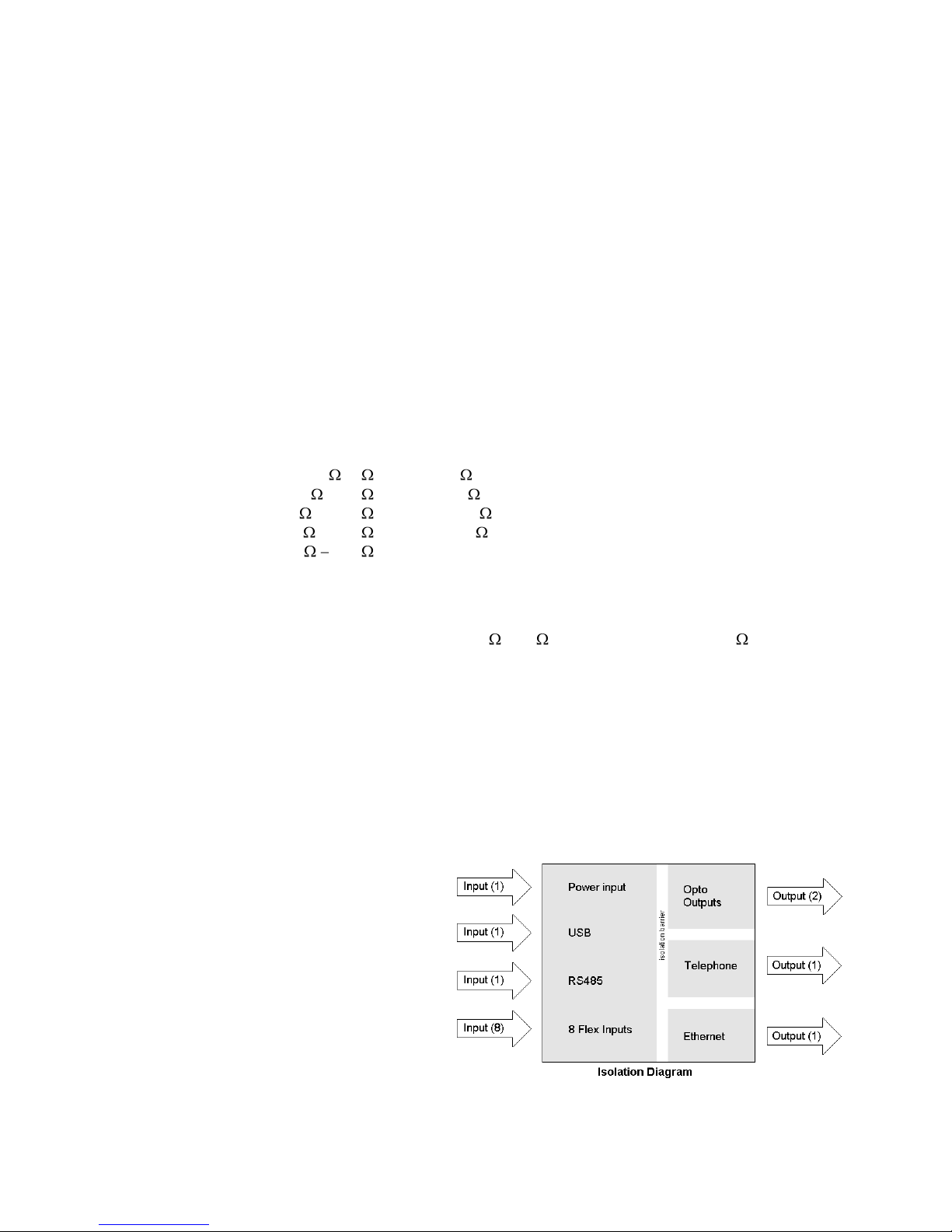

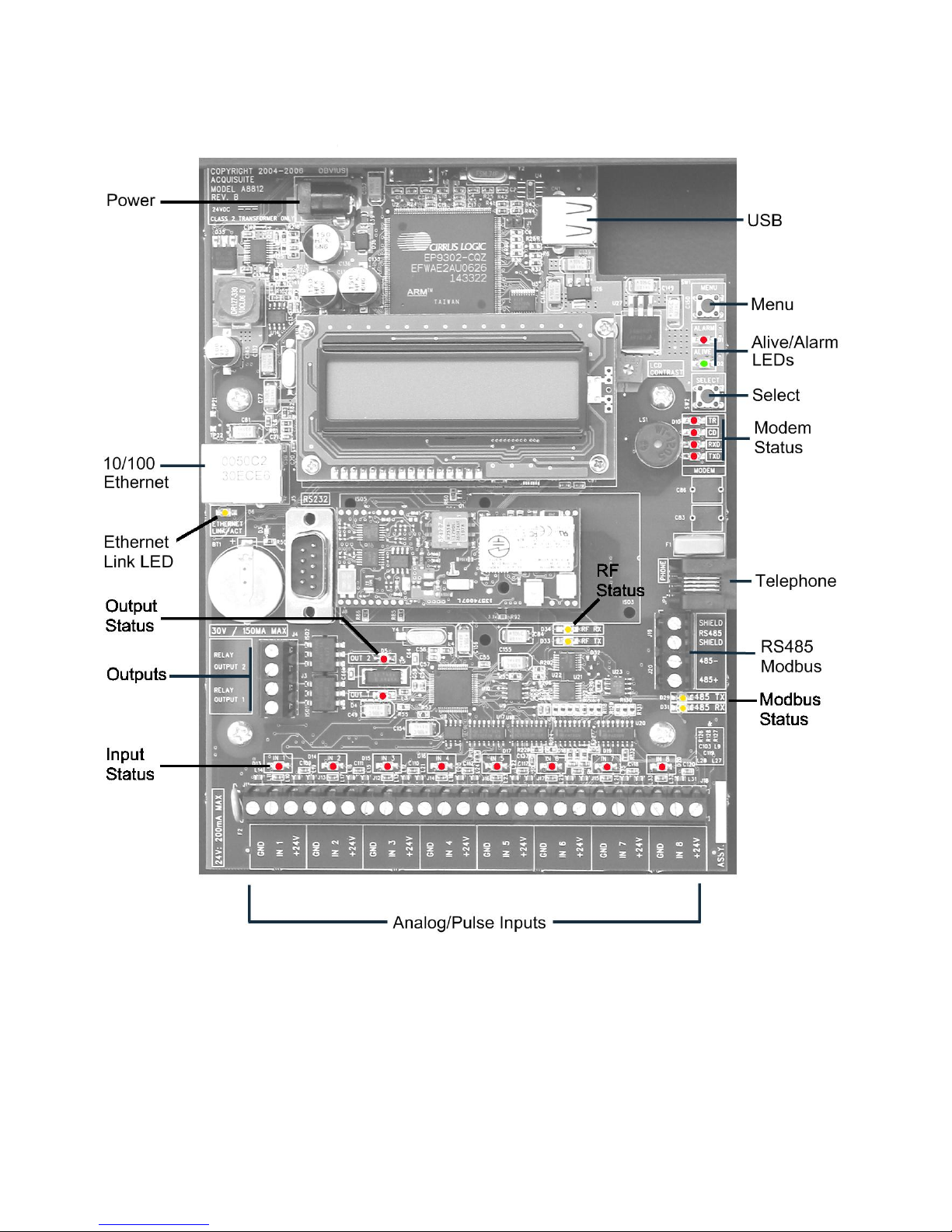

Hardware Overview.......................................................................................................................................................................................... 6

A8812 Features and Specifications ......................................................................................................................................................6

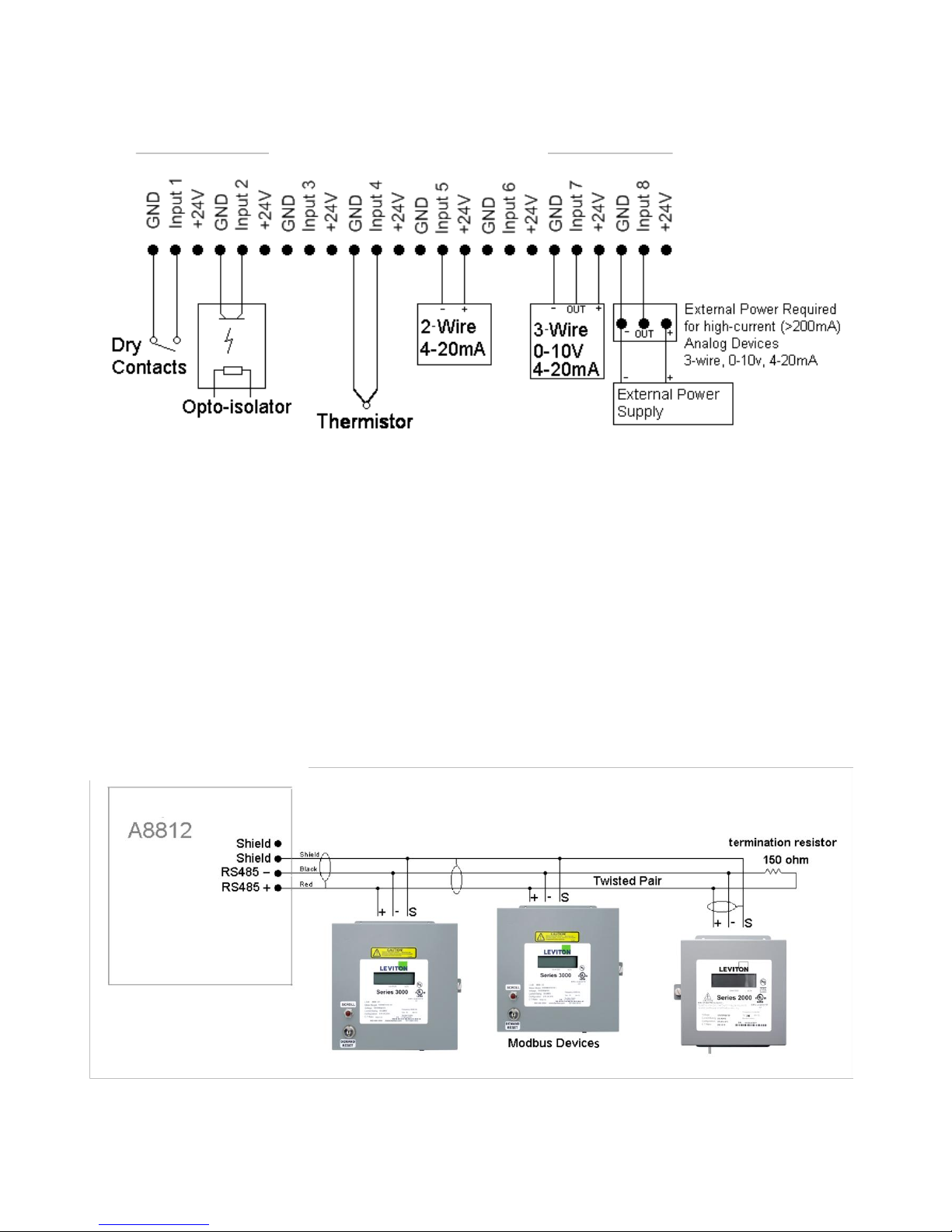

Electrical Connections..........................................................................................................................................................................7

Hardware Installation ...........................................................................................................................................................................7

Basic Network Configuration......................................................................................................................................................................... 10

Laptop/Computer Setup......................................................................................................................................................................11

Energy Monitoring Hub Administration Overview ........................................................................................................................................ 13

Security........................................................................................................................................................................................................... 14

Modbus........................................................................................................................................................................................................... 14

Modbus Device List ...........................................................................................................................................................................14

Device List Options................................................................................................................................................................15

Device Details........................................................................................................................................................................16

Device Configuration.............................................................................................................................................................16

Advanced Configuration Options...........................................................................................................................................16

Manual Device Add Options..................................................................................................................................................17

Internal IO Configuration.......................................................................................................................................................18

Troubleshooting Modbus Devices......................................................................................................................................................20

Modbus Setup.....................................................................................................................................................................................20

Alarm Setup........................................................................................................................................................................................21

Modbus Framework............................................................................................................................................................................22

Wireless.......................................................................................................................................................................................................... 22

Sensor List..........................................................................................................................................................................................22

ModHopper Map................................................................................................................................................................................22

Networking..................................................................................................................................................................................................... 23

Network Status...................................................................................................................................................................................23

Ethernet setup.....................................................................................................................................................................................23

Troubleshooting Ethernet Problems ...................................................................................................................................................23

System Options............................................................................................................................................................................................... 24

Status..................................................................................................................................................................................................24

Processes ............................................................................................................................................................................................24

Date and Time....................................................................................................................................................................................24

Universal Time Is Your Friend...............................................................................................................................................24

System logs ........................................................................................................................................................................................25

Firmware Update................................................................................................................................................................................25

Diagnostics..................................................................................................................................................................................................... 26

Host Lookup.......................................................................................................................................................................................26

Connection Test..................................................................................................................................................................................26

LCD Console.................................................................................................................................................................................................. 27

Log File Data.................................................................................................................................................................................................. 28

Log File Status....................................................................................................................................................................................28

Log File Format..................................................................................................................................................................................29

Log Storage Capacity.........................................................................................................................................................................30

Uploading data to the LEM website...................................................................................................................................................31

Retrieving Data from the Energy Monitoring Hub......................................................................................................................................... 32

HTTP Direct from the Energy Monitoring Hub .................................................................................................................................32

FTP Direct from the Energy Monitoring Hub ....................................................................................................................................32

Enertrax download direct from the Energy Monitoring Hub..............................................................................................................32

HTTP/Post Upload To Energy Manager ...........................................................................................................................................33

HTTP/Post Upload To Your Database Server....................................................................................................................................34

Removing Data from the Energy Monitoring Hub.............................................................................................................................34

Linking to Energy Monitoring Hub Device Status Pages...................................................................................................................34

Mechanical Drawings..................................................................................................................................................................................... 35

Shop for Power Metering products online at: 1.800.561.8187

www.PowerMeterStore.ca