14

42..

To

remove

bobbin

case

,

we

recommend

that

the

presser

f

oot

be

rem

ove

d

first

as

per

ins

truc

ti

ons

in

Paragraphs

38

and

39.

Figu

re

G

Corr

ec

t

Po

s i

tio

n

of

Hook

for

Re

-

moving

Gib

Screws

and

Gib.

Figure

H

Gib

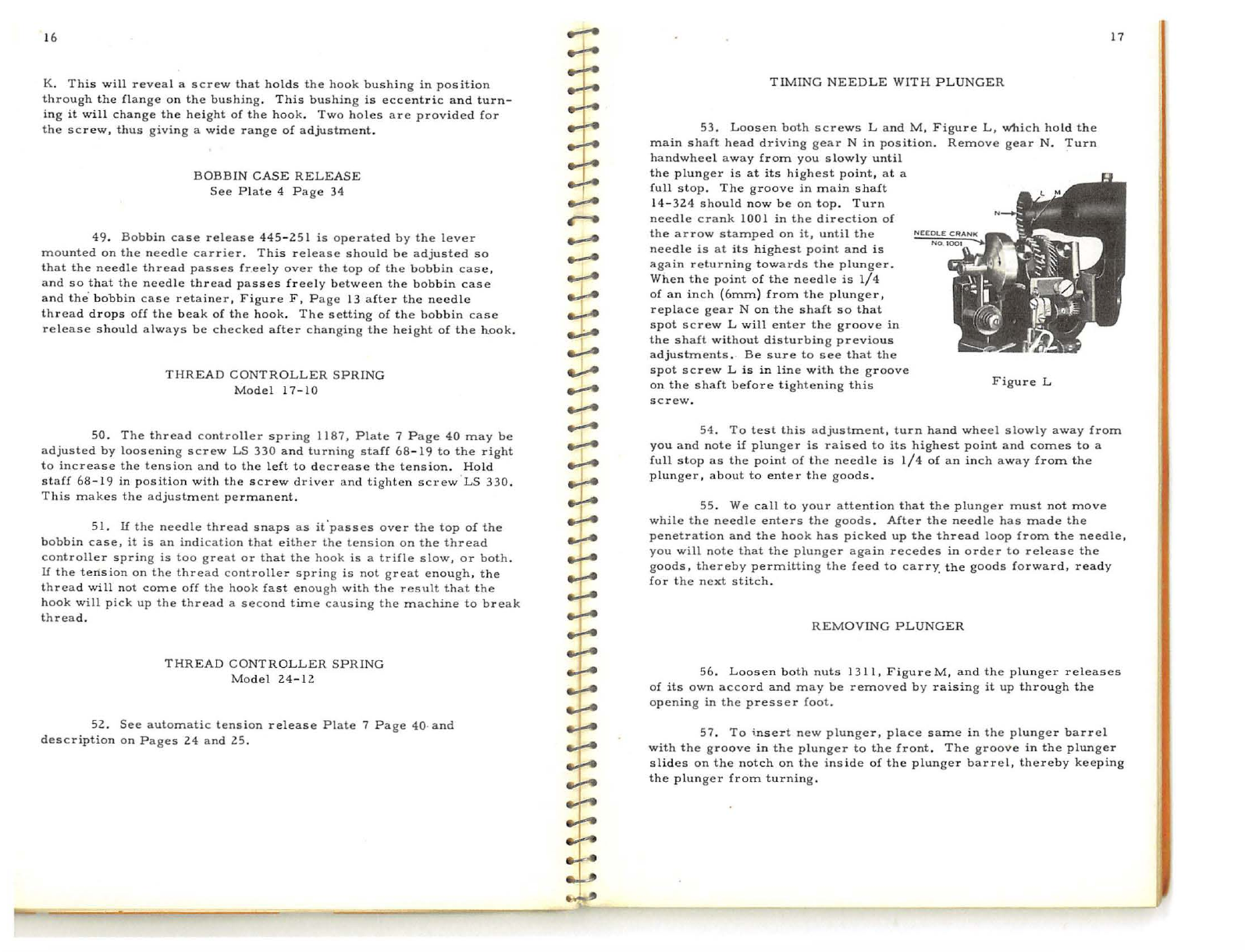

an

d

Scr

ew s

Removed

for

Bobbin

C

ase

Repl~cement.

Fi

gure

Rela

ti

ve

Position

of

the

Latch

to

t

he

Point

of

the

H

ook

For

Removing

Bobbin

Case.

43

.

See

th

at

the

p

oint

of

th

e

hook

is

at

its

low

es

t p

oint

as

per

illustration

above.

Th

en

re

m

ove

both

g

ib

screw

s 1

039

which

holds

gi

b

1

037

in

p

os

ition

on

the

hook

. S

ee

Figur

e H.

After

re

m

ovi

ng

gi

b,

turn

bobbin

case

to

the

left

one

-qu

arter

turn

.

This

releases

the

b

obb

in

case

fr

om

the

hook.

44.

Inasmu

ch

as

the

·

bobbin

case

fits

snugly

in

the

r

aceway

of

the

hook

,.

it

may

be

necess

ary

to

use

slight

pr

essu

re

to

cause

it

to

release

.

Use

fingers

only

to

remove

the

b

obb

in

case

and

do

not

insert

screw

driver

or

any

other

object

as

a l

ever,

as

this

is

apt

to

break

the

b

obb

in

case

.

To

insert

bobbin

case

in

hook

,

see

that

the

latch

is

in

lin

e

with

the

point

of

the

hook

as.

per

illustration

,

Figure

I.

Replace

hook

gib

in

position,

and

secure

ly

tighten

screws

1039.

Turn

bobbin

case

so

that

the

groove,

Fi

gu

re

A,

is

at

the

bottom

and

fi

ts

into

the

n

otch

on

the

bobbin

case

retainer

as

no

ted

in

paragraph

40

.

REPLACING

AND

TIMING

HOOK

45

.

Re

mo

ve

gear

cap

1072.,

which

is

in

back

of

the

m

achine

in

lin

e

with

the

hook

.

Rem

ove

gear

1030,

Plate

3,

P

age

32.

,

by

loosening

both

screws

holding

same.

Remove

needle

and

presser

foot,

a s

per

inst

r

uc

-

tions

in

Pa

rag

raphs

38

and

39.

Remove

Bobbin

case

releas

e

445

-

2.51

by

removing

screw

which

ho

l

ds

same

in

position

.

With

these

various

parts

out

of

the

way

,

the

hook

can

be

withdrawn

from

Figure

J

Hook

10

40A

~

.......

~

~

.......

..,:.-e

.,.:...e

~

.,....

.,_;....e

.....-..

~

~

....-...

..,

--r-

..,

..,

--1

..,:..e

..;-.-

~

.-i-4

~

--0

.,;..e

.,;...e

...;-e

..,::A

~

~

~

~

~

..

.J_,

~

the

machine.

See

Plate

4,

Page

34.

46

.

To

repla

ce

the

hook

preceding

instruc.tion

apply,

with

the

a

dded

ca

ution

regarding

timing

the

hook.

Th

is

is

a

simple

matte

r b y

noting

the

lin

es

on

both

the

upper

a

nd

lower

gears

102.8 a

nd

1030

,

Figure

K.

Both

of

th

ese

gears

have

lines

which

must

meet

and

make

a

strai

ght

line

.

The

groove

in

the

hook

shaft

must

also

be

in

st

r

aight

line

with

the

two

lines

on

gears

102.8

and

1030

,

so

that

the

po

int

of

spot

screw

1031

will

fit

into

the

groove

on

the

h

ook

shaft.

When

inser

ting

a

new

hook,

the

gr

oove

may

not

be

in

t

he

same

r

elative

posit

ion

as

in

the

one

removed,

which

will

throw

the

hook

out

of

time.

To

complete

the

adjustment

it

may

be

ne

ces

s a

ry

to

lo

osen

the

two

screws

that

hold

gear

102.8

in

posit

i

on

.

Turn

the

hook

slightly

to

the

r

ight

in

order

to

pick

up

th

e

threa

d

loop

more

q

uick

ly

from

t

he

needle;

or

tu

rn

the

hook

p i

ck

up

the

needle

thread

loop

more

slowly,

whichever

may

be

r

equi

r

ed

.

Figure

K

15

Tighten

the

t~o

screws

in

gear

102.8, m

aking

sure

this

with

gear

1030

but

without

excessive

backlash

.

gear

runs

freely

47

.

You

will

note

that

the

point

of

th

e

hook

when

prope

rl

y

timed,

will

be

at

its

lo

wes

t

po

in

t

or

i

mmediately

above

the

needle

a

nd

about

1/16

of

an

inch

from

th

e

eye

of

the

needle

when

the

need

le

is

on

its

return

or

back

stroke.

In

this,

as

with

all

other

ad

justments,

be

very

ca

re

fu

l

to

see

that

all

screws

are

securely

tightened

and any

parts

that

have

been

r

emoved

are

ca

ref

ul

ly

repl

ac

es

in

position

.

CAUTION:

Before

t

im

ing

hook,

make

sure

that

n

eed

le

is

co

rr

ectly

timed

wi

th

plunger,

see

p

arag

r

aph

53,

page

17.

RA

I

SING

AND

LOWERING

H

OOK

48.

The

hei

ght

of

the

hook

re\ative

to

the

needl

e

is

set

at

the

factory

and

gene

r

ally

r

equi

r

es

no

adjust

m

ent

.

In

case

it

does

become

necessary

t~

change

the

height

of

the

hook,

remove

gear

1030,

Figure

~

~

----~

------------~~

=

~~-

~--~------~--------

-

·-~~------------------------------------------------~-'

From the library of: Superior Sewing Machine & Supply LLC