Service Manual 163

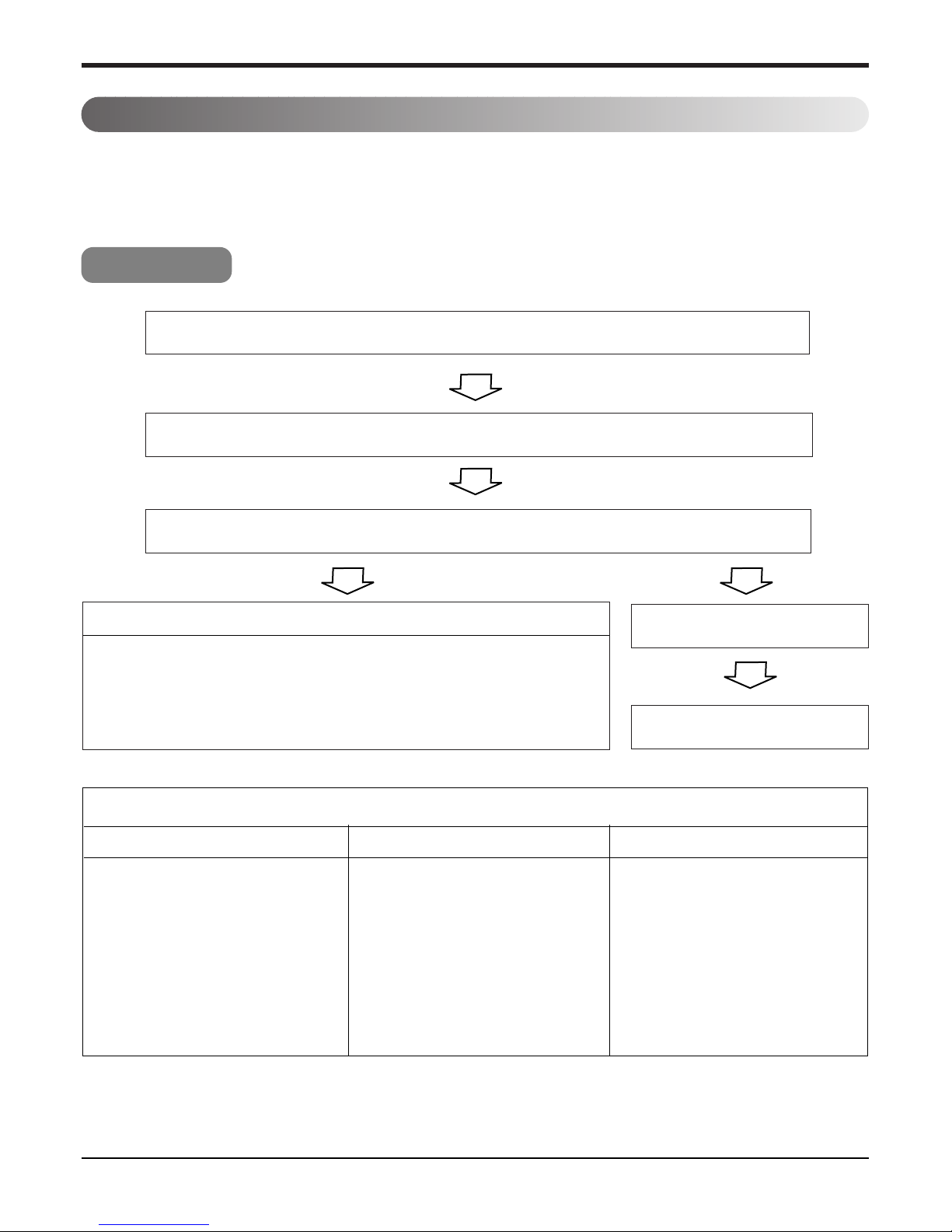

■Error Indicator

•The function is to self-diagnoisis airconditioner and express the troubles identifically if there is any trouble.

•Error mark is ON/OFF for the operation LED of evaporator body in the same manner as the following table.

•If more than two troubles occur simultaneously, primarily the highest trouble fo error code is expressed.

•After error occurrence, if error is released, error LED is also released simultaneously.

•To operate again on the occurrence of error code, be sure to turn off the power and then turn on.

•Having or not of error code is different from Model.

Troubleshooting Guide

Self-diagnosis Function

Indoor Error

Error code Description INV TPS LED 1

(Red) LED 2

(Green) Indoor

Status

00 No Error ON

01 Indoor Room themistor error 1time OFF

02 Indoor in-piping sensor error 2times OFF

03 Remote controller error 3times OFF

04 Drain Pump error 4times OFF

05 Communcation error between in and out 5times OFF

06 Indoor Out-Piping sensor error 6times OFF

07 Differnt mode operation 7times OFF

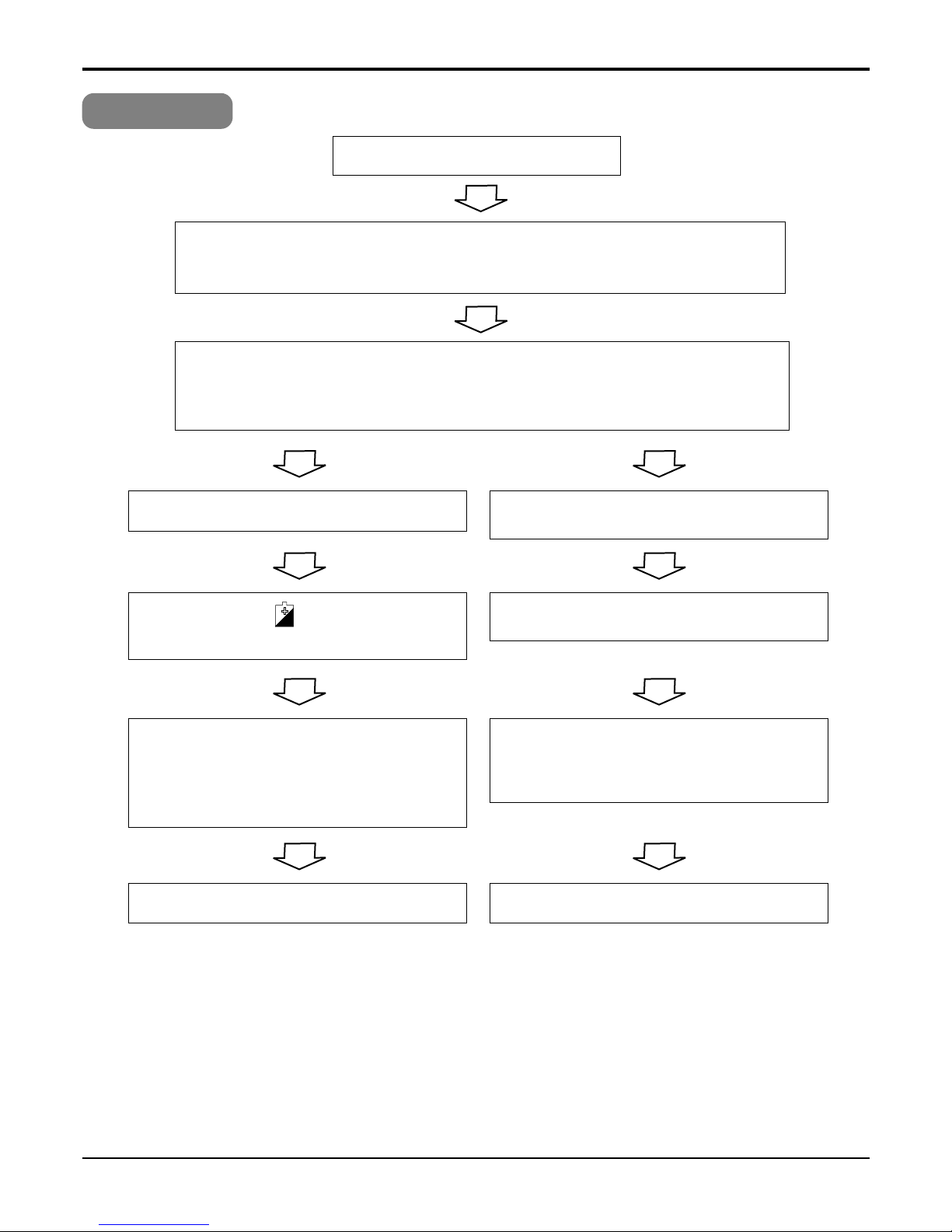

Outdoor Error

Error Code Description INV TPS LED 1

(Red) LED 2

(Green) Indoor

Status

21 DC Peak (IPM Fault) 2times 1time OFF

22 CT 2(Max CT) 2times 2times OFF

23 DC Link Low Volt. 2times 3times OFF

24 L_P/Heater Sink 2times 4times OFF

25 Low voltage / Over voltage 2times 5times OFF

26 DC Comp Position Error 2times 6times OFF

27 PSC Fault Error 2times 7times OFF

28 DC Link High Volt 2times 8times OFF

32 D-Pipe High (INV) 3times 2times OFF

33 D-Pipe High (Normal) 3times 3times OFF

40 CT Sensor (Open/Short) 4times OOFF

41 INV. D-PipeTh Error(Open/Short) 4times 1time OFF

44 Outdoor air Th Error(Open/Short) 4times 4times OFF

45 Cond. Pipe Th Error(Open/Short) 4times 5times OFF

46 Suction Pipe Error(Open/Short) 4times 6times OFF

47 Const D-pipe Th Error(Open/Short) 4times 7times OFF

51 Capacity over 5times 1time OFF

53 Signal error (Indoor ↔Outdoor) 5times 3times OFF

60 EEPROM Check Sum Error 6times OOFF

61 Cond. Pipe High 6times 1time OFF

62 Heatsink High 6times 2times OFF

63 Cond. Pipe Low 6times 3times OFF

65 Heatsoml Th error (Open/Short) 6times 5times OFF