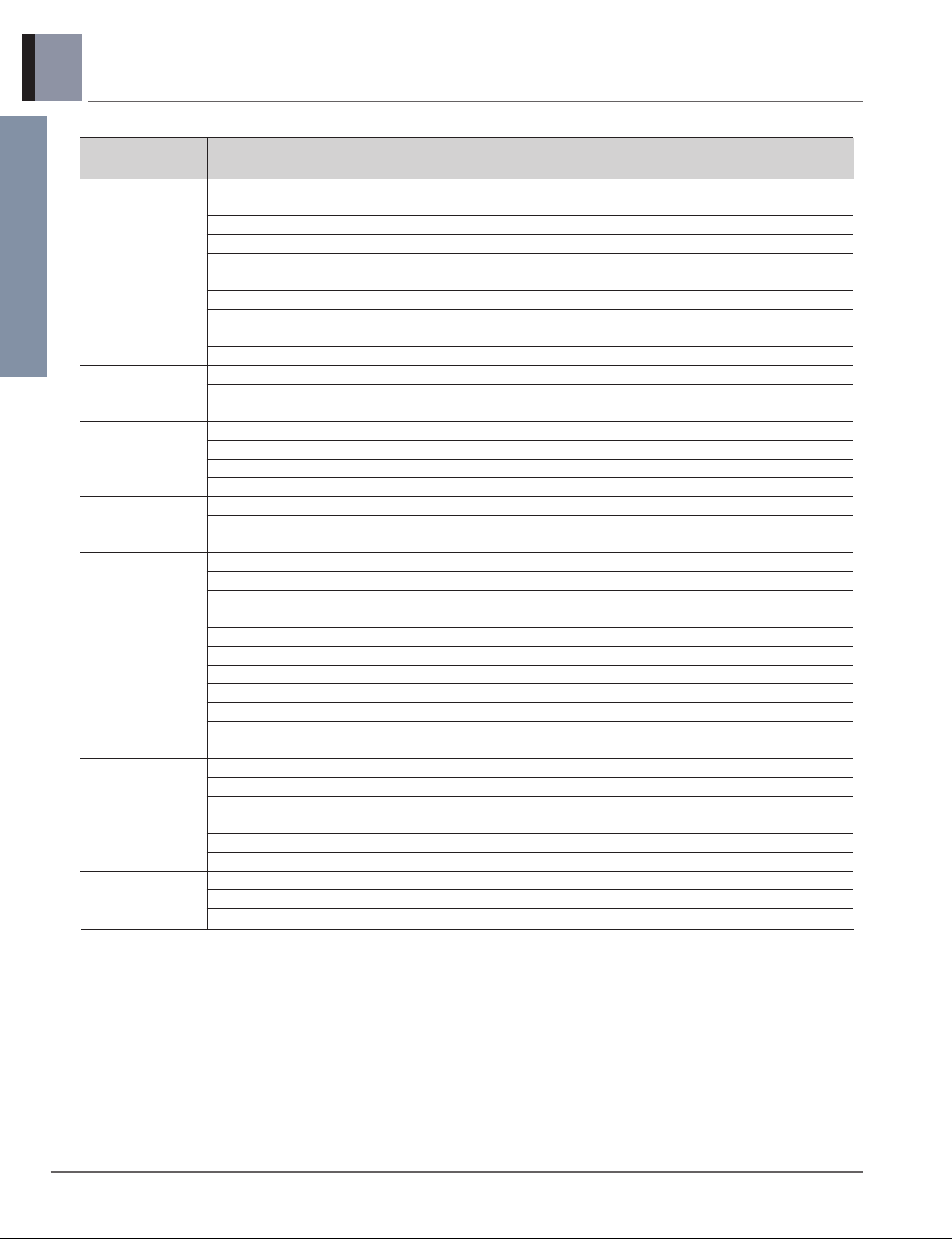

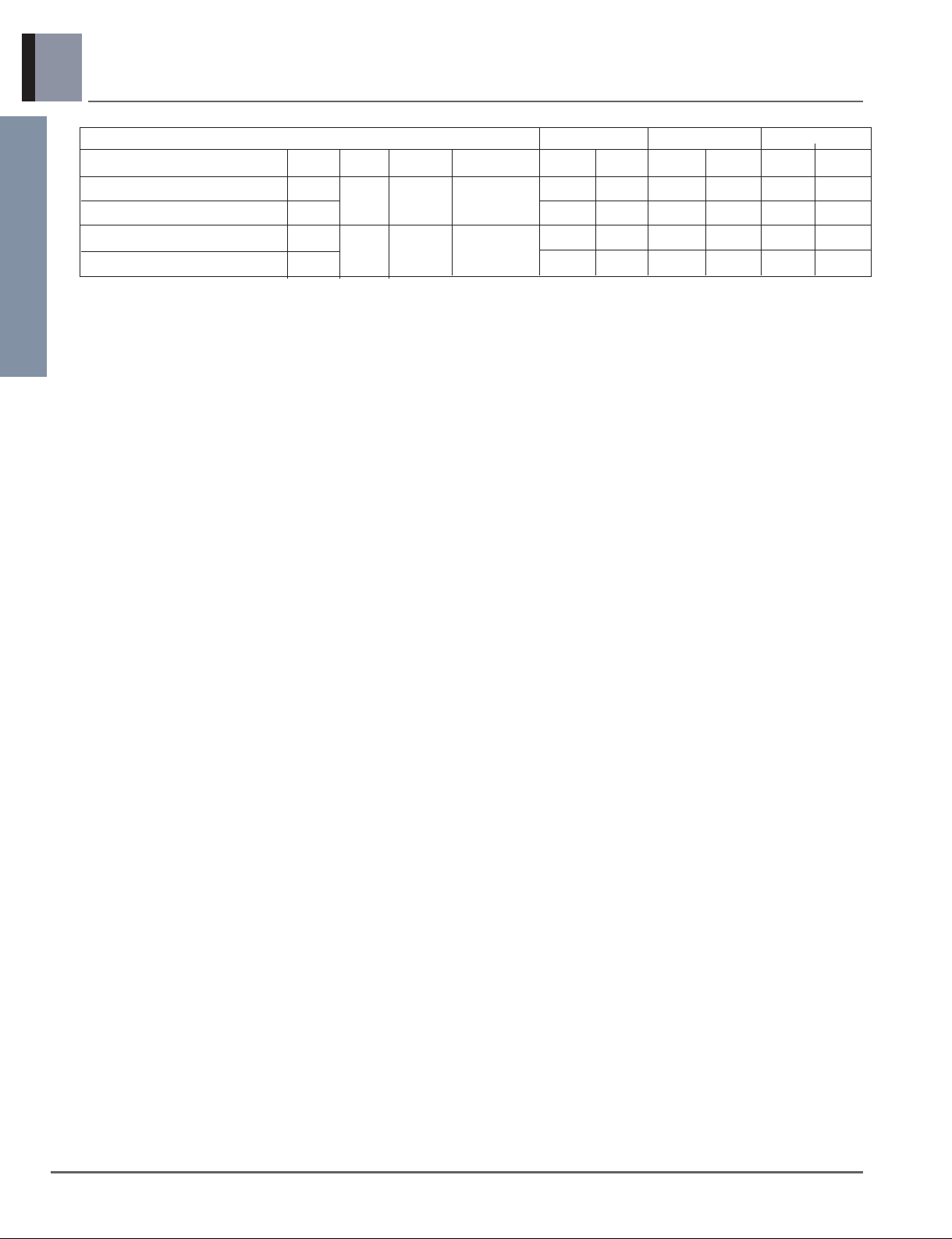

6. Capacity Tables

6.2 Heating Capacity Heating Capacity

Notes: TC: Total Capacity(kW)

Capacity

Index

Outdoor air

temp.

DB(°C) WB(°C)

Indoor air temp. (DB, °C)

16 18 20 21 22 24

TC TC TC TC TC TC

kW kW kW kW kW kW

-19.8 -20.0 4.2 4.2 4.2 4.2 4.2 4.2

-18.8 -19.0 4.3 4.3 4.3 4.3 4.3 4.3

-16.7 -17.0 4.6 4.6 4.6 4.6 4.6 4.5

-14.7 -15.0 4.9 4.8 4.3 4.8 4.8 4.8

-12.6 -13.0 5.1 5.1 4.5 5.0 5.0 5.0

-10.5 -11.0 5.4 5.4 4.8 5.4 5.3 5.3

-9.5 -10.0 5.4 5.4 4.9 5.4 5.4 5.4

-8.5 -9.1 5.5 5.5 5.0 5.5 5.5 5.4

-7.0 -7.6 5.7 5.7 5.1 5.6 5.6 5.5

-5.0 -5.6 6.0 6.0 5.4 5.8 5.8 5.5

-3.0 -3.7 6.2 6.2 5.5 6.1 5.9 5.5

0.0 -0.7 6.6 6.6 5.8 6.1 5.9 5.5

3.0 2.2 7.0 6.7 6.2 6.1 5.9 5.5

5.0 4.1 7.1 6.7 6.3 6.1 5.9 5.5

7.0 6.0 7.2 6.7 6.3 6.1 5.9 5.5

9.0 7.9 7.2 6.7 6.3 6.1 5.9 5.5

11.0 9.8 7.2 6.7 6.3 6.1 5.9 5.5

13.0 11.8 7.2 6.7 6.3 6.1 5.9 5.5

15.0 13.7 7.2 6.7 6.3 6.1 5.9 5.5

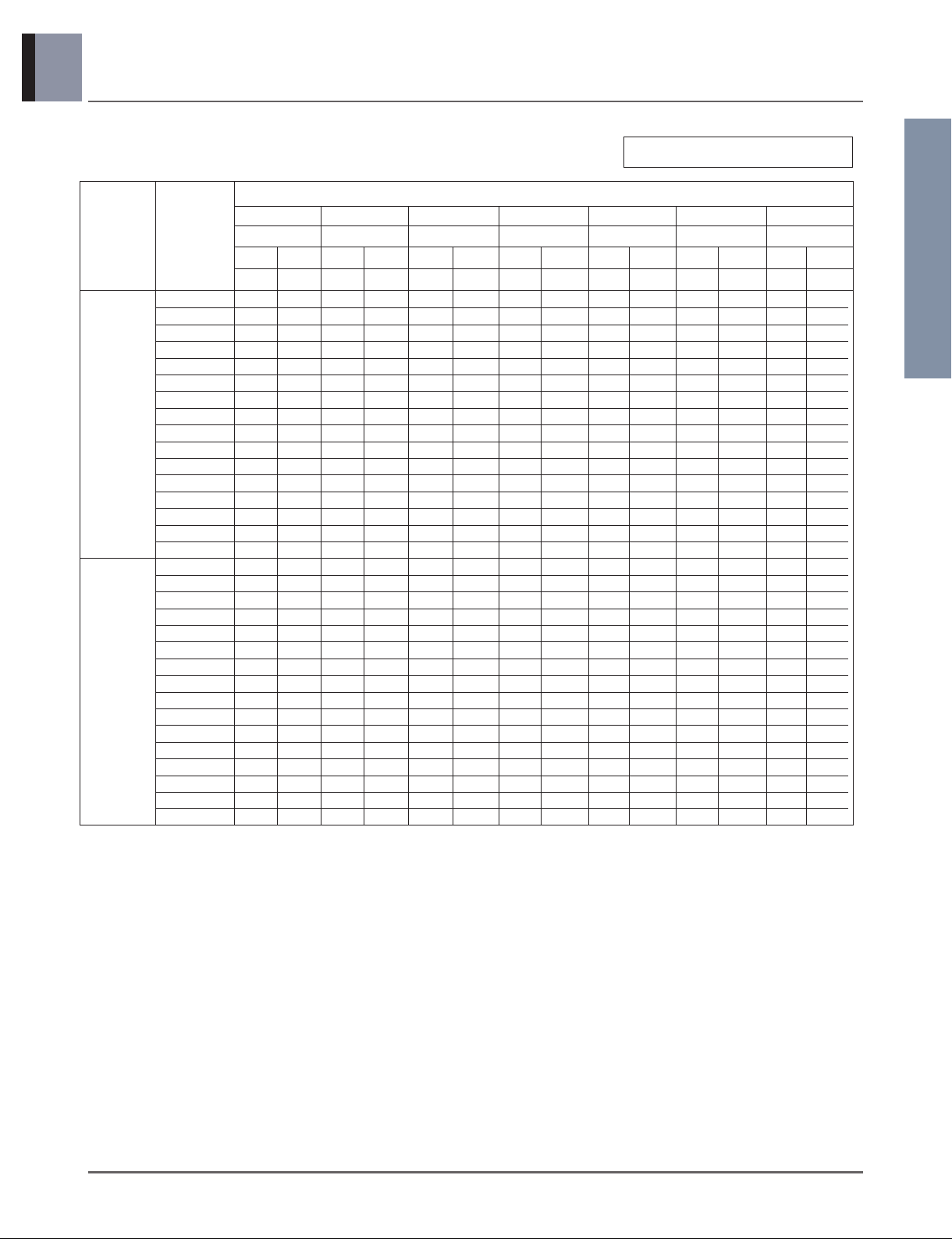

-19.8 -20.0 5.4 5.4 5.4 5.3 5.3 5.3

-18.8 -19.0 5.5 5.5 5.5 5.5 5.4 5.4

-16.7 -17.0 5.8 5.8 5.8 5.8 5.8 5.8

-14.7 -15.0 6.2 6.1 5.5 6.1 6.1 6.1

-12.6 -13.0 6.5 6.5 5.8 6.4 6.4 6.4

-10.5 -11.0 6.8 6.8 6.0 6.8 6.7 6.7

-9.5 -10.0 6.9 6.9 6.2 6.9 6.9 6.8

-8.5 -9.1 7.0 7.0 6.3 7.0 7.0 6.8

-7.0 -7.6 7.3 7.3 6.5 7.1 7.1 7.0

-5.0 -5.6 7.6 7.6 6.8 7.4 7.4 7.0

-3.0 -3.7 7.9 7.9 7.0 7.7 7.5 7.0

0.0 -0.7 8.4 8.4 7.4 7.8 7.5 7.0

3.0 2.2 8.9 8.6 7.8 7.8 7.5 7.0

5.0 4.1 9.0 8.6 8.0 7.8 7.5 7.0

7.0 6.0 9.2 8.6 8.0 7.8 7.5 7.0

9.0 7.9 9.2 8.6 8.0 7.8 7.5 7.0

11.0 9.8 9.2 8.6 8.0 7.8 7.5 7.0

13.0 11.8 9.2 8.6 8.0 7.8 7.5 7.0

15.0 13.7 9.2 8.6 8.0 7.8 7.5 7.0

5.6

7.1