3

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

TABLE OF CONTENTS

Safety Precautions ............................................................................. 4-7

Unit Nomenclature................................................................................. 8

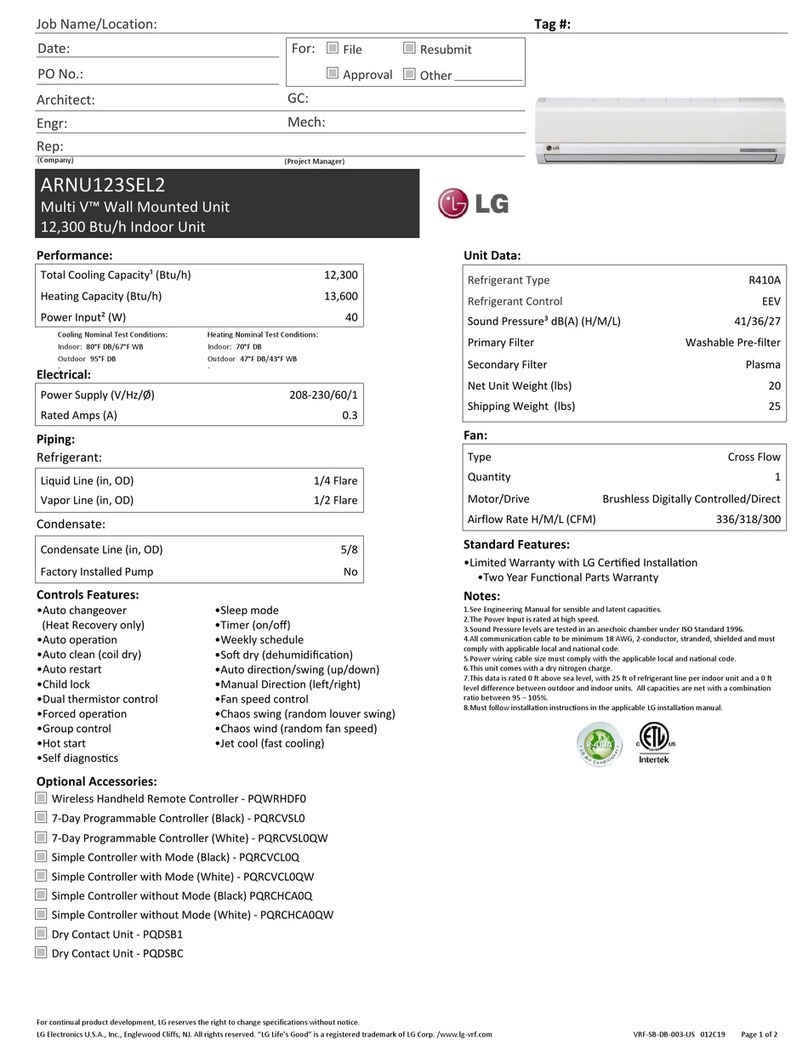

Outdoor Unit Specications............................................................ 9-18

208-230V Outdoor Units................................................................. 9-13

460V Outdoor Units...................................................................... 14-18

Electrical Data................................................................................. 19-20

208-230V Outdoor Unit Electrical Data ............................................. 19

460V Outdoor Unit Electrical Data..................................................... 20

Heat Recovery Specications / Electrical Data ................................ 21

Outdoor Unit Dimensions.............................................................. 22-25

Heat Recovery Unit Dimensions ................................................... 26-28

Transporting / Lifting .......................................................................... 29

Placement Considerations ............................................................ 30-37

Selecting the Best Location for the Outdoor Unit(s) ..................... 30-31

Outdoor Unit Clearance Requirements ............................................. 32

Installing Outdoor Units Indoors ................................................... 33-34

Installing and Setting Outdoor Units in Dual /

Triple Frame Systems........................................................................ 35

Selecting the Best Location / Clearance Requirements for the

Heat Recovery Unit(s) .................................................................. 36-37

Mounting / Anchoring the Outdoor Unit(s)................................... 38-39

Mounting / Anchoring the Heat Recovery Unit(s)............................. 40

General Refrigerant Piping System Information ......................... 41-53

LG Air Conditioner Technical Solution (LATS) .............................. 41-42

Refrigerant Safety Standards / Device

Connection Limitations ...................................................................... 43

Selecting Copper Piping.................................................................... 44

Copper Expansion and Contraction.............................................. 45-47

Piping Handling ................................................................................. 48

Refrigerant System Engineering................................................... 49-51

Flaring and Brazing Procedures................................................... 52-53

Installing for Heat Pump Operation .............................................. 54-67

Indoor Unit Y-Branch Kits..............................................................54-55

Outdoor Unit Y-Branch Kits........................................................... 56-57

Header Kits................................................................................... 58-59

Sample Layouts............................................................................ 60-63

Piping Connections / Pipe Routes..................................................... 64

Knock Outs ....................................................................................... 65

Removing the Leak Prevention Caps................................................ 66

Service Ports ..................................................................................... 67

Installing for Heat Recovery Operation........................................ 68-89

Indoor Unit Y-Branch Kits..............................................................68-69

Outdoor Unit Y-Branch Kits........................................................... 70-71

Header Kits................................................................................... 72-73

Heat Recovery Units..................................................................... 74-79

Sample Layouts............................................................................ 80-85

Piping Connections / Pipe Routes..................................................... 86

Knock Outs ....................................................................................... 87

Removing the Leak Prevention Caps................................................ 88

Service Ports ..................................................................................... 89

Refrigerant Piping for Separated Outdoor Units......................... 90-92

Insulation......................................................................................... 93-95

Electrical........................................................................................ 96-110

General Information...................................................................... 96-97

Power Wiring and Communication Cable Terminations................ 98-99

Power Wiring and Communication Cable Connections................... 100

Power Wiring and Communication Cable

System Layout................................................................................. 101

Power Supply / Power Wiring Specications............................ 102-105

Communication Cable Specications....................................... 106-110

Pre-Commissioning.....................................................................111-157

Triple Leak / Pressure Check .................................................... 111-113

Triple Evacuation Procedure .....................................................114-116

Vacuum Mode (Option).....................................................................117

Pre-commissioning Start / Outdoor Unit

DIP Switch Settings ..........................................................................118

DIP Switch Settings for Use With Gen 4 Indoor Units......................119

Setting the Optional Modes ...................................................... 120-134

Self Diagnostics Check.................................................................... 135

Indoor Unit Auto Addressing ..................................................... 136-138

Group Controlling Indoor Units........................................................ 138

Central Control ......................................................................... 139-141

Addressing with Heat Recovery Units ...................................... 141-153

Temperature Sensing Location................................................. 154-155

Setting External Static Pressure............................................... 155-156

Package Pre-commissioning Documents /

Initiate a Request............................................................................. 157

Error Codes................................................................................. 159-168

LG Monitoring View (LGMV) Diagnostic Software .................. 169-170

Maintenance Recommendations...................................................... 171

Checklists.................................................................................... 172-182