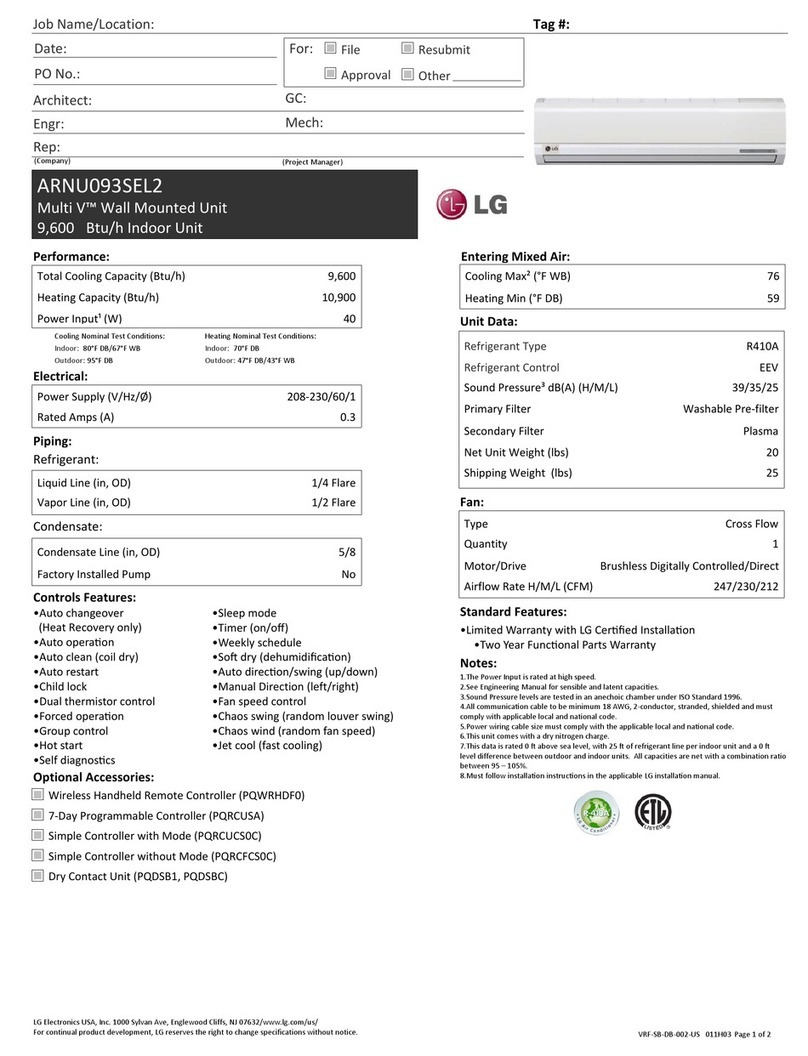

LG LK Series Packaged Air Conditioners are

designed and manufactured to meet the

requirements of the Gulfs severe climatic con-

ditions and are built specifically for outdoor

installations, either on ground or roof level.

The LK Series Packaged Air Conditioners are

ideal for warehouses, large halls, schools,

mosques, or wherever the requirement is for

a heavy duty unit with a Scroll compressor.

Units are designed to operate in a wide ambi-

ent temperature rang from 21 °C to 52 °C.

LK Series Packaged Air Conditioners are com-

pletely assembled, internally wired, charged

with R-22 refrigerant at factory, tested before

dispatch and ready for installation. All that is

required on site is fixing filters and connecting

ducting and power supply. Units are designed

for ducted systems which will enable them to

be installed on roof tops or on the ground.

Points to remembered

Being an electromechanical machine, the unit

may fall or cause difficulties. Remembering

the following few points will ensure correct

and prompt rectification and continued optimal

performance:

- A correct installation ensuring proper clear-

ances for correct condenser air flow and

maintenance as per the drawings shown for

recommended clearance

- Proper level base on foundation with appro-

priate vibration mount. All connections and

hook up to be followed as per instructions,

which ensures long term trouble free opera-

tion and performance.

- If power fuse is blown off, be sure to replace

the same with a new fuse having pre

designed Amperage. Do not use a steel wire

or copper wire instead of proper fuse.

Genuine fuse ensures safety and proper pro-

tection. Incorrect fusing may cause fire or

trouble with your equipment. Before replac-

ing any fuse or opening any electrical

panel door, make sure the main switch is

OFF

- Do not spray or sprinkle water directly over

or into the air conditioning equipment for

cleaning because electric insulations and ter-

minal of the components are opened

- This Air conditioning equipment is meant to

be installed out doors and suitable to normal

environment elements. Do not try to cover

or block any inlets or discharge openings to

condenser

- Periodical maintenance of the unit will give

better performance in the long run than

only break down maintenance.

NOTE

!

LG reserves the right to change, in part

or in whole the specifications of its Air

Conditioning Equipment at any time in

order to add the latest technology.

Therefore, the enclosed information may

change without any prior notice.

UNIT DESCRIPTION

8UNIT DESCRIPTION:

ENGLISH