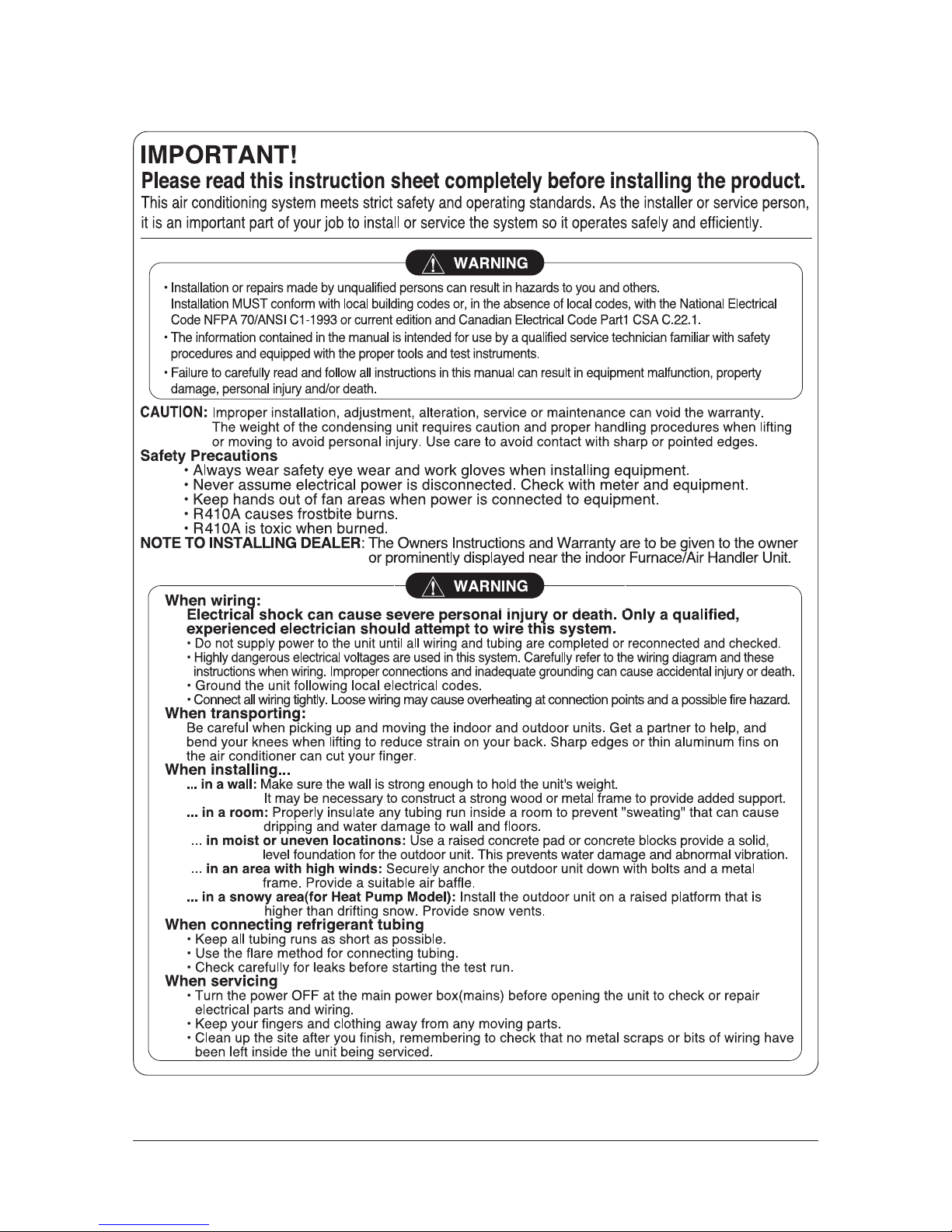

■Installation

Always check for gas (refrig-

erant) leakage after installa-

tion or repair of product.

• Low refrigerant levels may

cause failure of product.

Install the drain hose to

ensure that water is drained

away properly.

• A bad connection may cause

water leakage.

Keep level even when

installing the product.

• To avoid vibration or water

leakage.

Do not install the product

where the noise or hot air from

the outdoor unit could dam-

age the neighborhoods.

• It may cause a problem for your

neighbors.

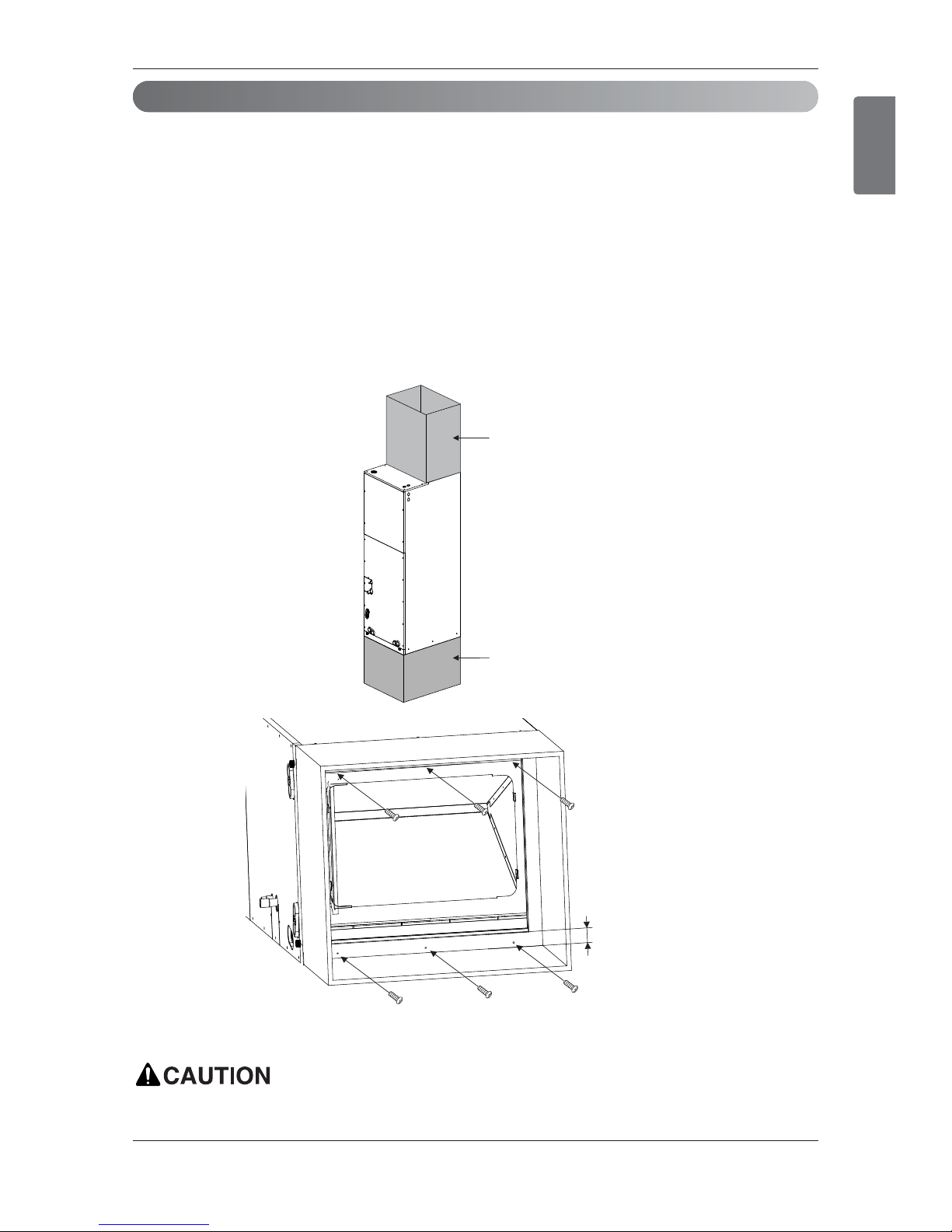

Use two or more people to lift

and transport the product.

• Avoid personal injury.

Do not install the product

where it will be exposed to

sea wind (salt spray) directly.

• It may cause corrosion on the

product. Corrosion, particularly on

the condenser and evaporator

fins, could cause product malfunc-

tion or inefficient operation.

If you eat the liquid from the

batteries, brush your teeth and see doctor. Do

not use the remote if the batteries have leaked.

• The chemicals in batteries could cause burns or

other health hazards.

Safely dispose of the packing materials.

• Packing materials, such as nails and other metal or

wooden parts, may cause stabs or other injuries.

• Tear apart and throw away plastic packaging bags

so that children may not play with them. If children

play with a plastic bag which was not torn apart,

they face the risk of suffocation.

Safety Precautions

■Operation

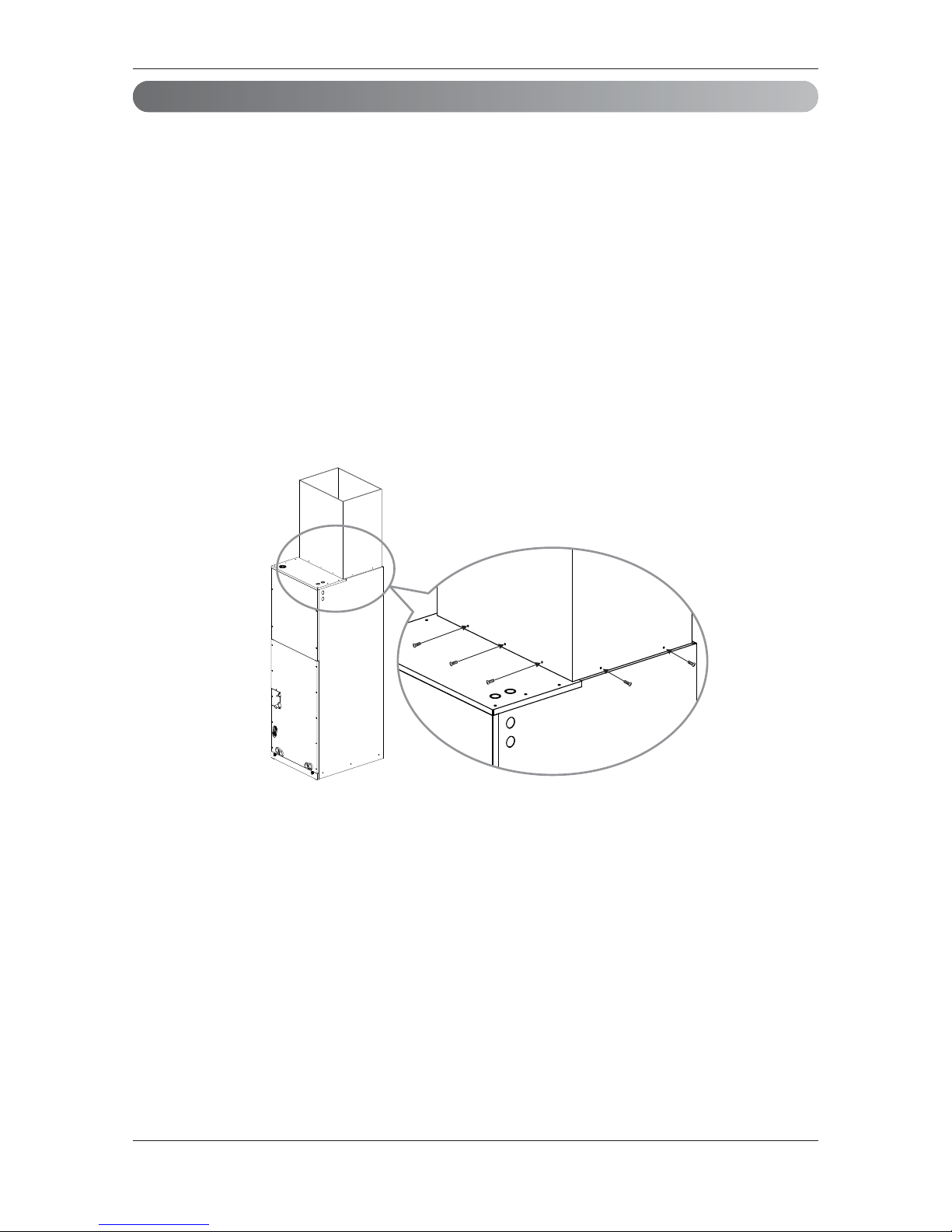

For installation, always con-

tact the dealer or an

Authorized Service Center.

• There is risk of fire, electric

shock, explosion, or injury.

Do not install the product on

a defective installation stand.

• It may cause injury, accident,

or damage to the product.

Be sure the installation area

does not deteriorate with age.

• If the base collapses, the air

conditioner could fall with it,

causing property damage,

product failure, and personal

injury.

Do not store or use flammable gas or combustibles near the product.

• There is risk of fire or failure of product.

ENGLISH

Installation Manual 7