- 10 - LGE nternal Use OnlyCopyright ©2010 LG Electronics nc. All rights reserved.

Only for training and service purposes

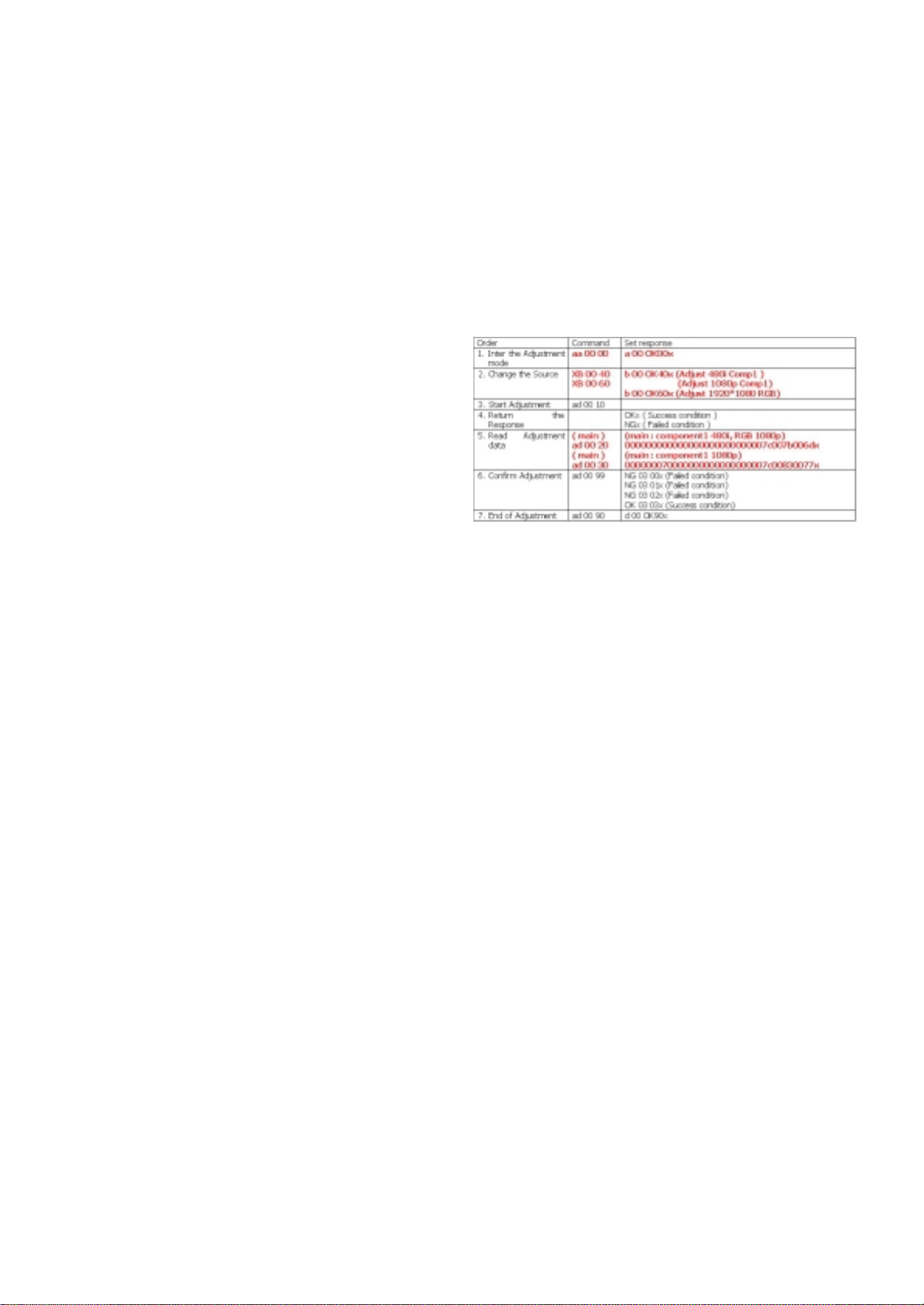

O wb 00 00”: Start Auto-adjustment of white balance.

O“wb 00 10”: Start Gain Adjustment ( nner pattern)

O“jb 00 c0” :

O…

O“wb 00 1f”: End of Adjustment

* f it needs, offset adjustment (wb 00 20-start, wb 00 2f-

end)

O“wb 00 ff”: End of white balance adjustment (inner pattern

disappear)

V Adjustment Mapping information

OWhen Color temperature (White balance) Adjustment

(Automatically)

- Press “Power only key” of service remocon and

operate automatically adjustment.

- Set BaudRate to 115200.

OYou must start “wb 00 00” and finish it “wb 00 ff”.

Of it needs, then adjustment “Offset”.

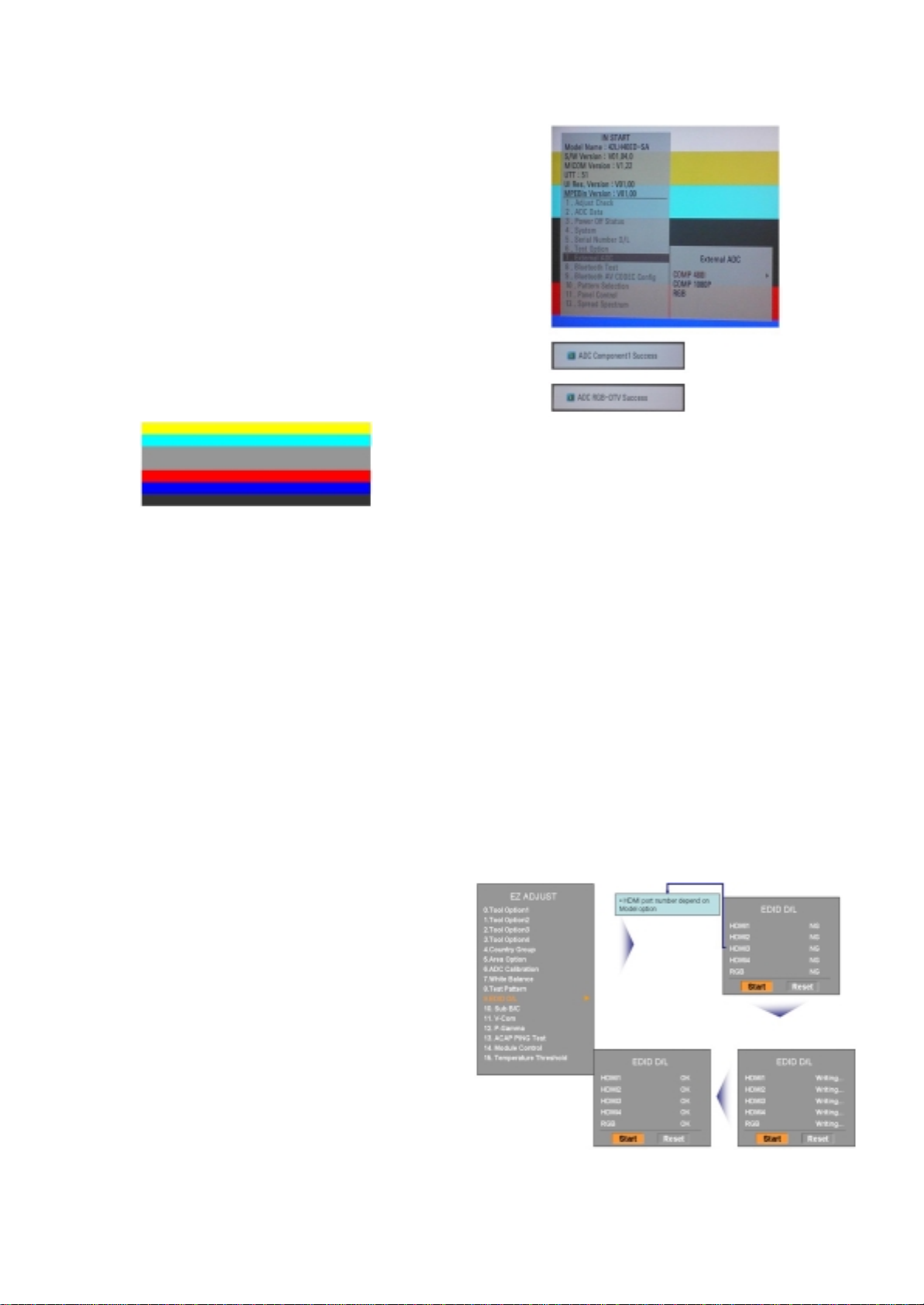

(4) White Balance Adjustment (Manual adjustment)

1) Test Equipment: CA-210

- Using PDP color temperature, Color Analyzer (CA-210)

must use CH 10, which Matrix compensated (White,

Red, Green, Blue compensation) with CS-2100. See

the Coordination bellowed one.

2) Manual adjustment sequence is like bellowed one.

- Turn to “Ez-Adjust” mode with press ADJ button of

service remocon.

- Select “10.Test Pattern” with CH+/- button and press

enter. Then set will go on Heat-run mode. Over 30

minutes set let on Heat-run mode.

- Let CA-210 to zero calibration and must has gap more

10cm from center of PDP module when adjustment.

- Press “ADJ” button of service remocon and select

“7.White-Balance” in “Ez-Adjust” then press “G” button

of navigation key. (When press “G” button then set will

go to full white mode)

- Adjust at three mode (Cool, Medium, Warm)

- f “cool” mode

Let B-Gain to 192 and R, G, B-Cut to 64 and then

control R, G gain adjustment High Light adjustment.

- f “Medium” and “Warm” mode Let R-Gain to 192 and

R, G, B-Cut to 64 and then control G, B gain

adjustment High Light adjustment.

- All of the three mode

Let R-Gain to 192 and R, G, B-Cut to 64 and then

control G, B gain adjustment High Light adjustment.

- With volume button (+/-) you can adjust.

- After all adjustment finished, with Enter (_ key) turn to

Ez-Adjust mode. Then with ADJ button, exit from

adjustment mode

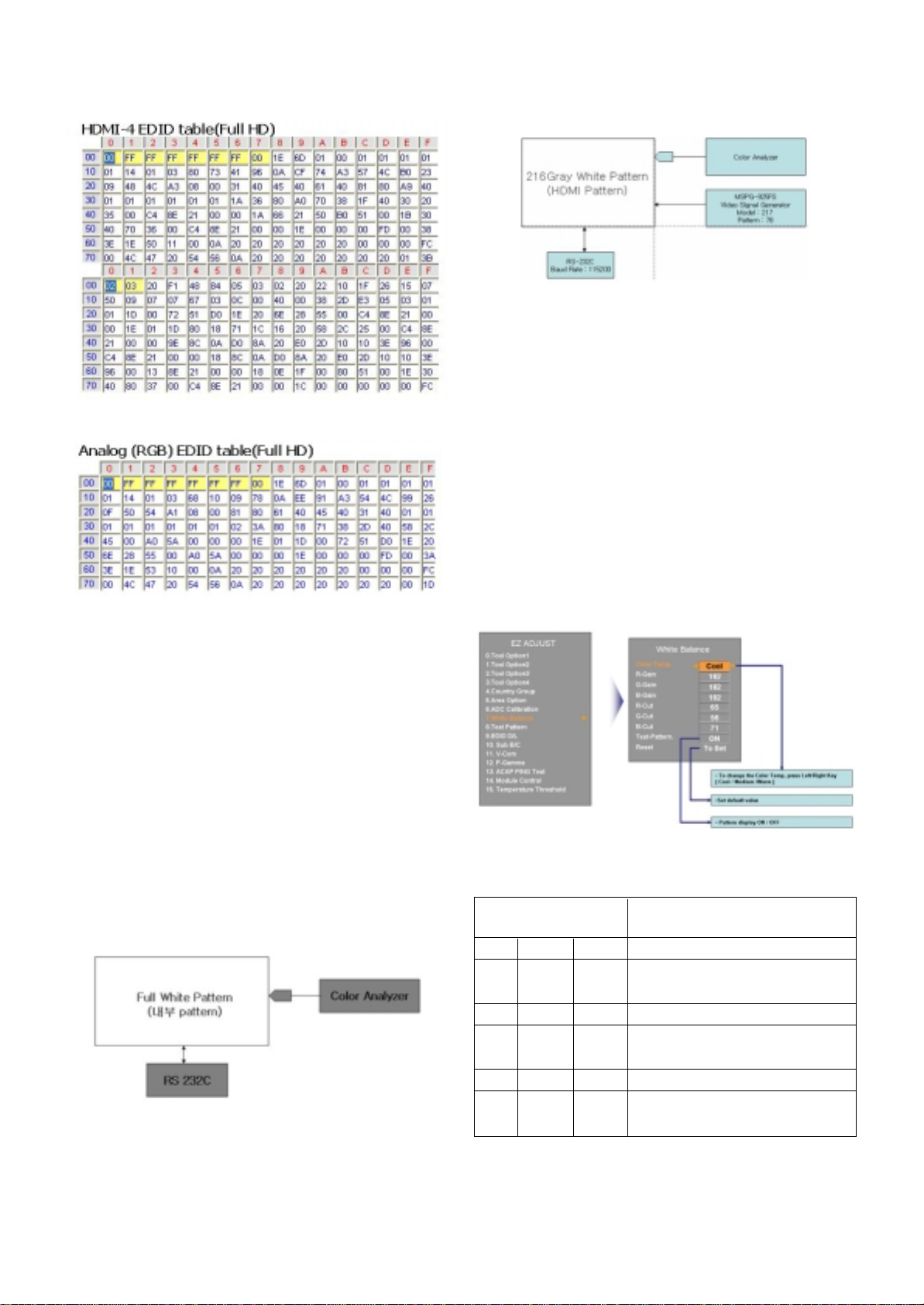

* Attachment: White Balance adjustment coordination and color

temperature.

OUsing CS-1000 Equipment.

- COOL : T=11000K, _uv=0.000, x=0.276 y=0.283

- MED UM : T=9300K, _uv=0.000, x=0.285 y=0.293

- WARM : T=6500K, _uv=0.000, x=0.313 y=0.329

OUsing CA-210 Equipment. (10 CH)

- Contras value : 216 Gray

- Brighness spec.

6. Test of RS-232C control.

- Press n-Start button of Service Remocon then set the “4.Baud

Rate” to 115200. Then check RS-232C control and

7. Selection of Country option.

- Selection of country option is allowed only North American

model (Not allowed Korean model). t is selection of Country

about Rating and Time Zone.

(1) Models: All models which PB82C Chassis (See the first

page.)

(2) Press “ n-Start” button of Service Remocon, then enter the

“Option” Menu with “P P CH-“ Button

(3) Select one of these three (USA, CANADA, MEX CO)

defends on its market using “Vol. +/-“button.

Caution : Don’t push The NSTOP KEY after completing the

function inspection

Caution : nspection only PAL M

RS-232C COMMAND

CENTER

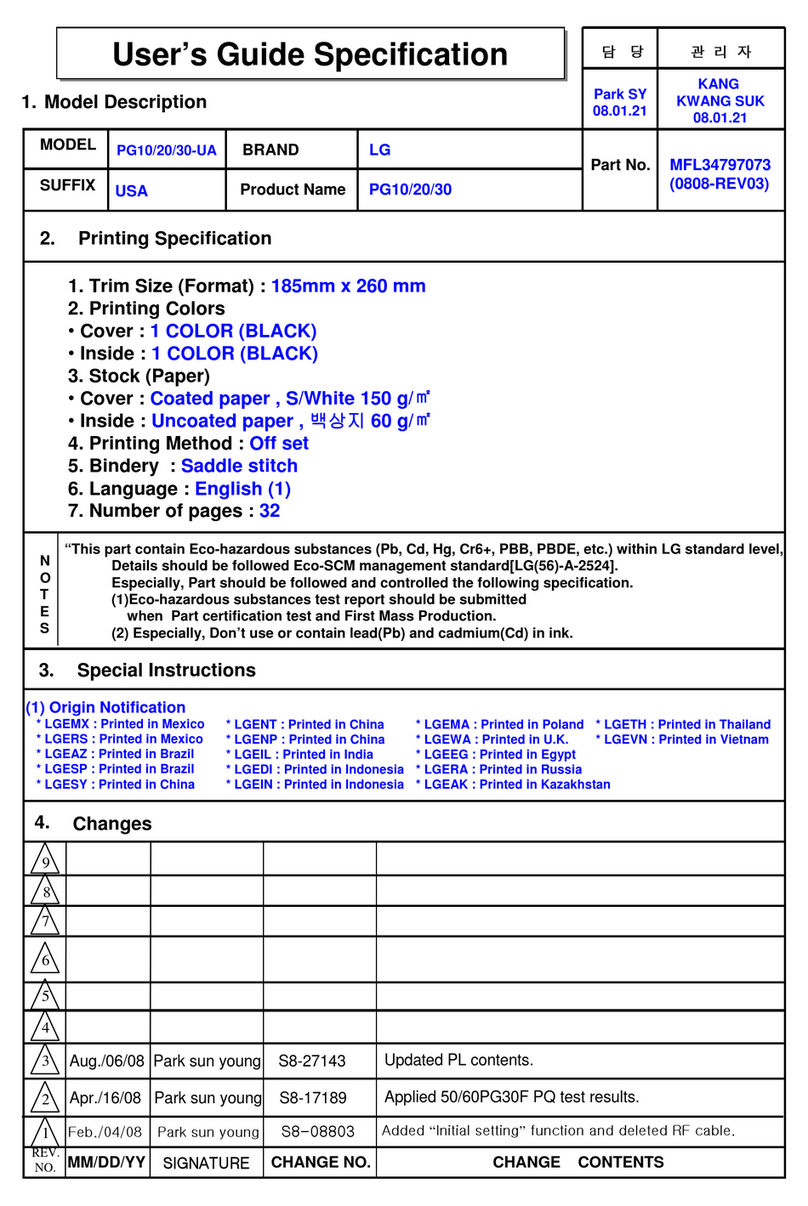

[CMD D DATA] M N (DEFAULT) MAX

Cool Mid Warm Cool Mid Warm

R Gain jg Ja jd 00 184 192 192 192

G Gain jh Jb je 00 187 183 159 192

B Gain ji Jc jf 00 192 161 95 192

R Cut 64 64 64 127

G Cut 64 64 64 127

B Cut 64 64 64 127

Color Test Color Coordination

temperature Equipment x y

COOL CA-210 0.276±0.002 0.283±0.002

MED UM CA-210 0.285±0.002 0.293±0.002

WARM CA-210 0.313±0.002 0.329±0.002

tem Min Typ Max Unit Remark

White 49 60 - cd/m - 100%Window White

average Pattern

brightness - 100 RE(255Gray)

- Picture: Vivid(Medium )

Brightness -20 +20 % - 85 RE(216Gray) 100%

uniformity Window White Pattern

- Picture: Vivid(Medium)