- 8 - LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only or training and service purposes

( ) Component1, RGB adjustment method.

1) Select Component1, RGB as the input with Color Bar

Pattern in 1080p 60Hz mode and select ‘Component1’

as input mode.

2) A ter receiving signal or at least 1 second, press the

ADJ Key on the Service R/C to enter the ‘Ez - Adjust’

and select the ‘2. ADC 480i Comp1/RGB’. Pressing the

Vol+ Key to adjust the component1.

3) When the adjustment is normally completed, the

message ‘ADC Component1 Success’ is displayed, or i

not, the message ‘ADC Component1 1080P Fail’ is

displayed. A ter adjusting the Component1 is

completed, it is automatically switched to the RGB-DTV

mode, and the RGB adjustment starts. I adjusting is

normally completed, the message ‘ADC RGB 1080P

Success’ is displayed.

4) When the adjustment is not normally completed, check

the pattern or the adjustment condition, and then adjust

it again. The error message is same to (4)) o (1)

5) A ter adjustment is complete, exit the adjustment mode

by pressing the ADJ KEY.

(MSPG-925FA : -> model : 225, pattern : 65)

5. Video Set Adjustment

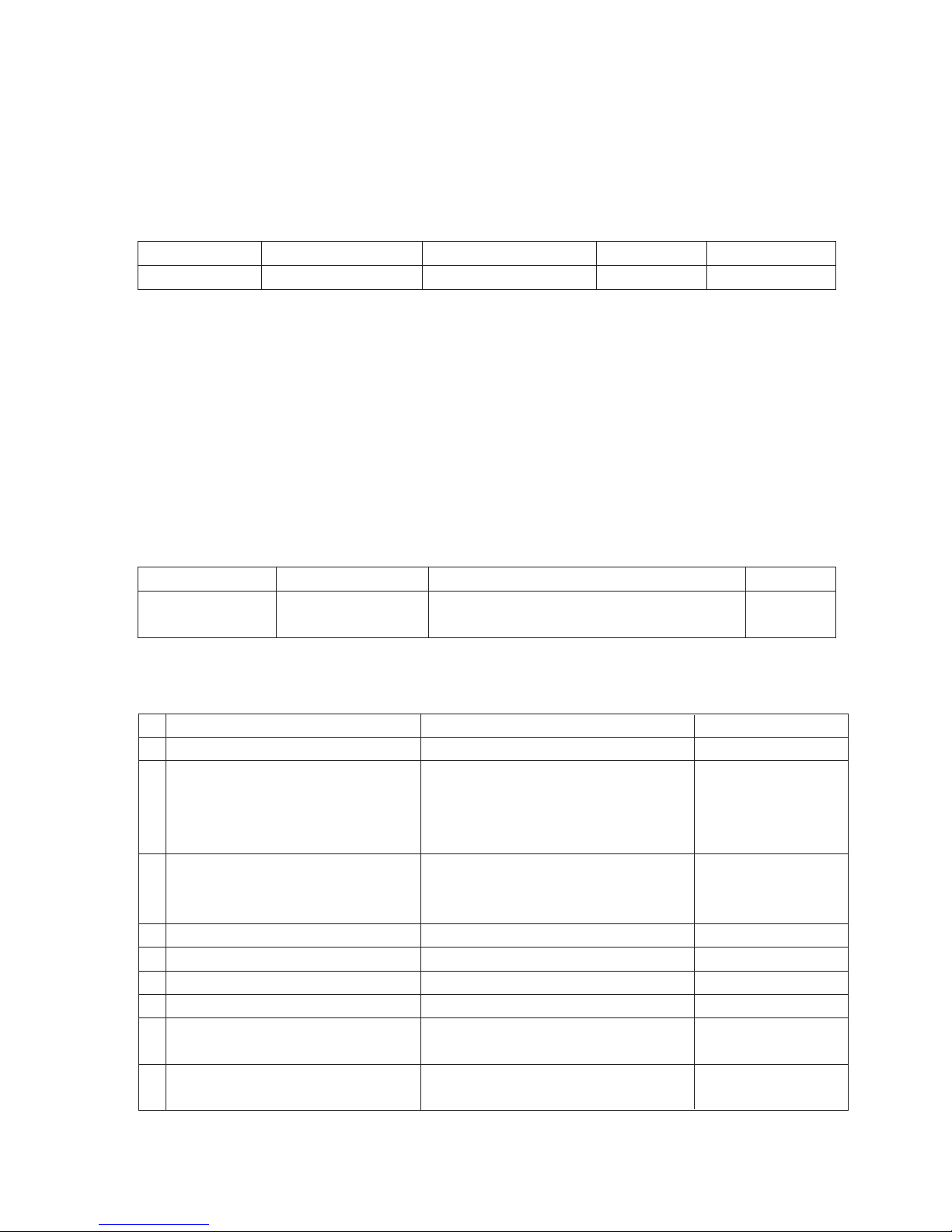

It is the adjustment to reduce the color di erence o the RF

and the video signal, which adjusts Analog RF, AV-PAL, and

AV-NTSC.

5-1. Adjustment method

(1) Analog RF and AV-PAL adjustment method.

1) Connect the Video Signal Generator (Master) to the AV

input o the TV via the AV output. At this time, when

entering the input pattern with Model : 202(PAL) and

Pattern : 33(100% color Bar), the ollowing screen is

displayed.

* It should be checked because the above pattern may be

di erent according to the model and the pattern o the used

equipment.

2) A ter entering the in-house signal, when it is checked

that the signal is received, press the ADJ KEY o the

adjusting R/C to enter into ‘EZ-ADJUST’ Select ‘3.

Adjust RF and AV_PAL’ and press the right arrow key

(G) to enter into the adjustment mode.

3) When it enters into the adjustment mode, the screen is

automatically switched to TV 3CH and the ollowing

window is displayed.

4) When the automatic adjustment starts, the main screen

is adjusted, and i adjusting is completed, the message

‘RF-PAL Con iguration Success’ is displayed. I

adjusting is ailed, the message ‘RF-PAL Con iguration

Fail’ is displayed.

5) When the automatic adjustment o the RF signal is

completed, it is automatically switched to AV1 Mode

and the automatic adjustment is per ormed to the AV-

PAL. When the automatic adjustment is completed, the

message ‘AV-PAL Con iguration Success’ is displayed.

I the adjustment is ailed, the message ‘AV-PAL

Con iguration Fail’ is displayed.

( ) AV-NTSC adjustment method.

1) Connect the Video Signal Generator (Master) to the AV

input o the TV via the AV output. At this time, when

entering the input pattern with Model : 201(NTSC) and

Pattern : 33(100% color Bar), the ollowing screen is

displayed.

* It should be checked because the above pattern may be

di erent according to the model and the pattern o the used

equipment.

2) Press the ADJ KEY o the adjusting R/C to enter into

‘EZ-ADJUST’ Select ‘4. Adjust AV_NTSC’ and press the

right arrow key (G) to enter into the adjustment mode.

3) When the automatic adjustment is completed, the

message ‘AV-NTSC Con iguration Success’ is

displayed. I the adjustment is ailed, the message ‘AV-

NTSC Con iguration Fail’ is displayed.

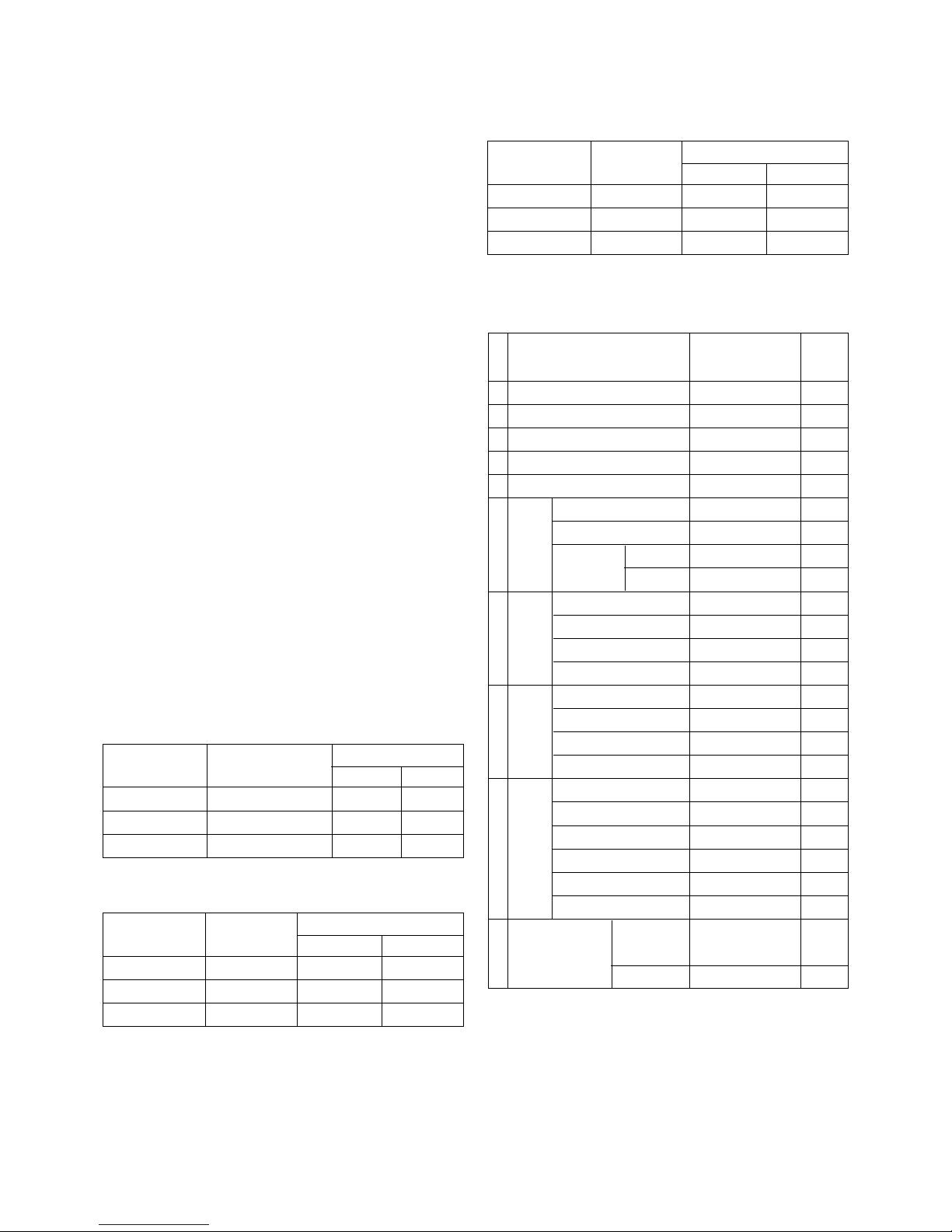

<Fig.3> Model : 202(PAL), Pattern : 33(100% Color Bar)

<Fig.4> Model : 201(NTSC), Pattern : 33(100% Color Bar)