Chapter 1 Safety Warning and Cautions ..........................................................................................3

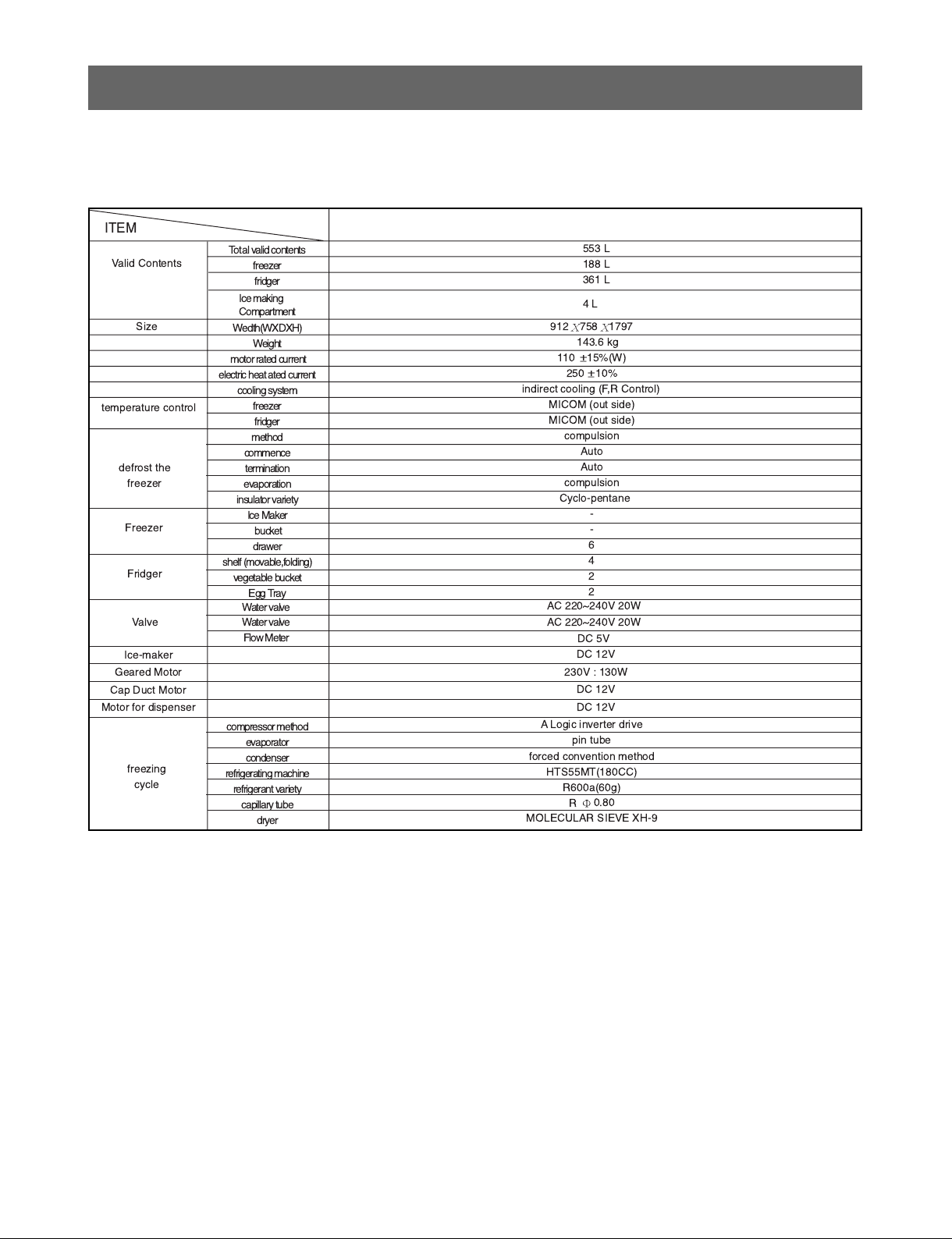

Chapter 2 Product Standards ...........................................................................................................8

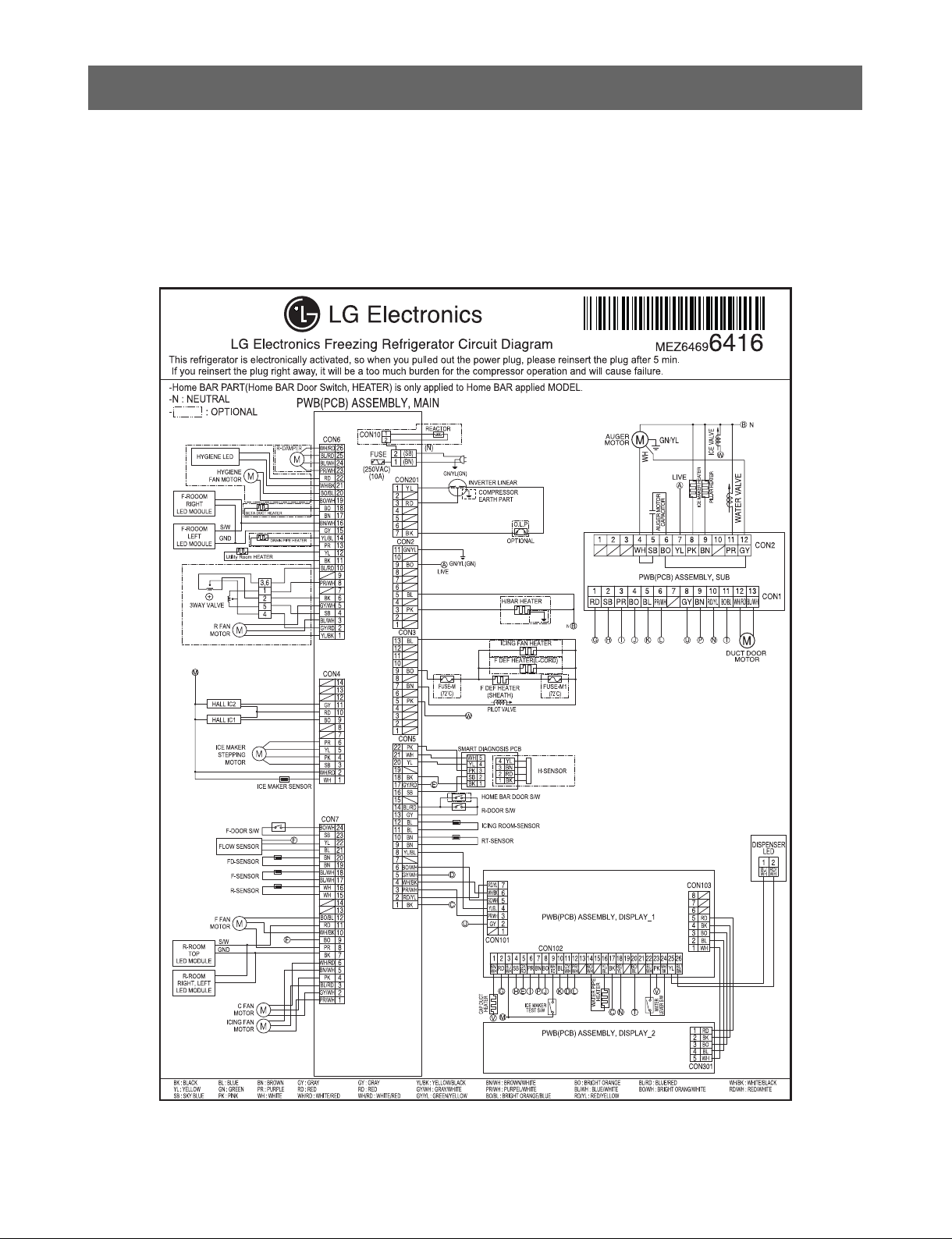

Chapter 3 Circuit Diagram ...............................................................................................................10

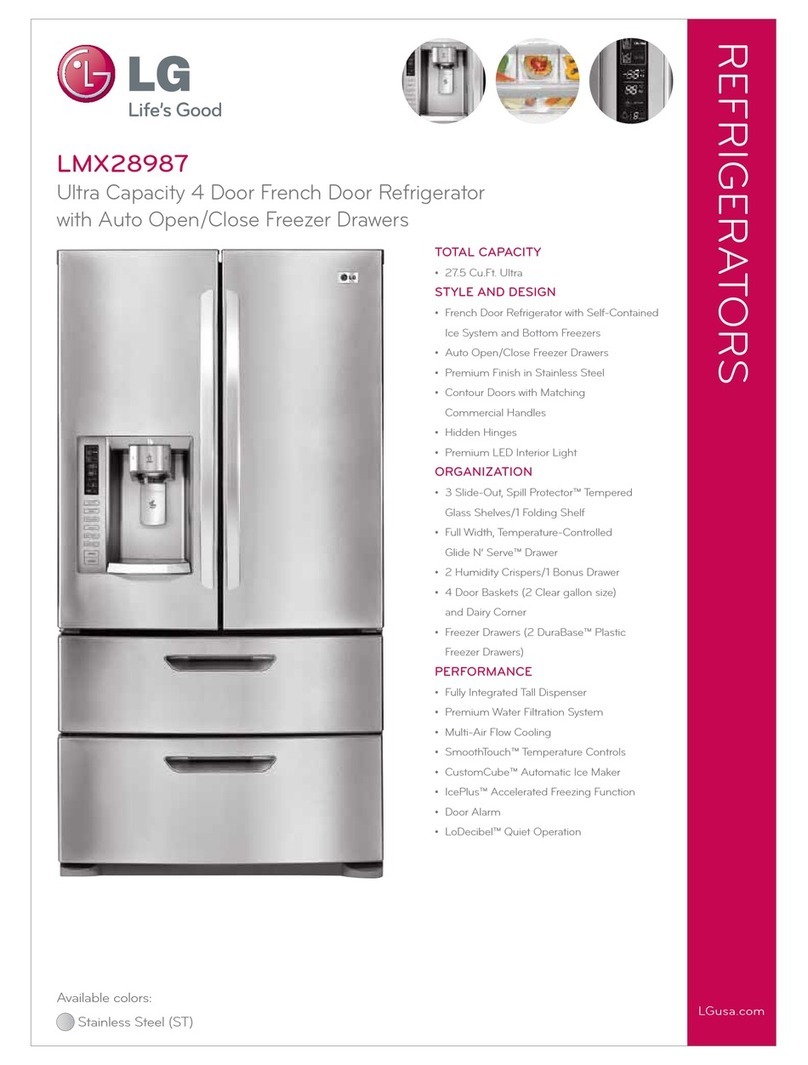

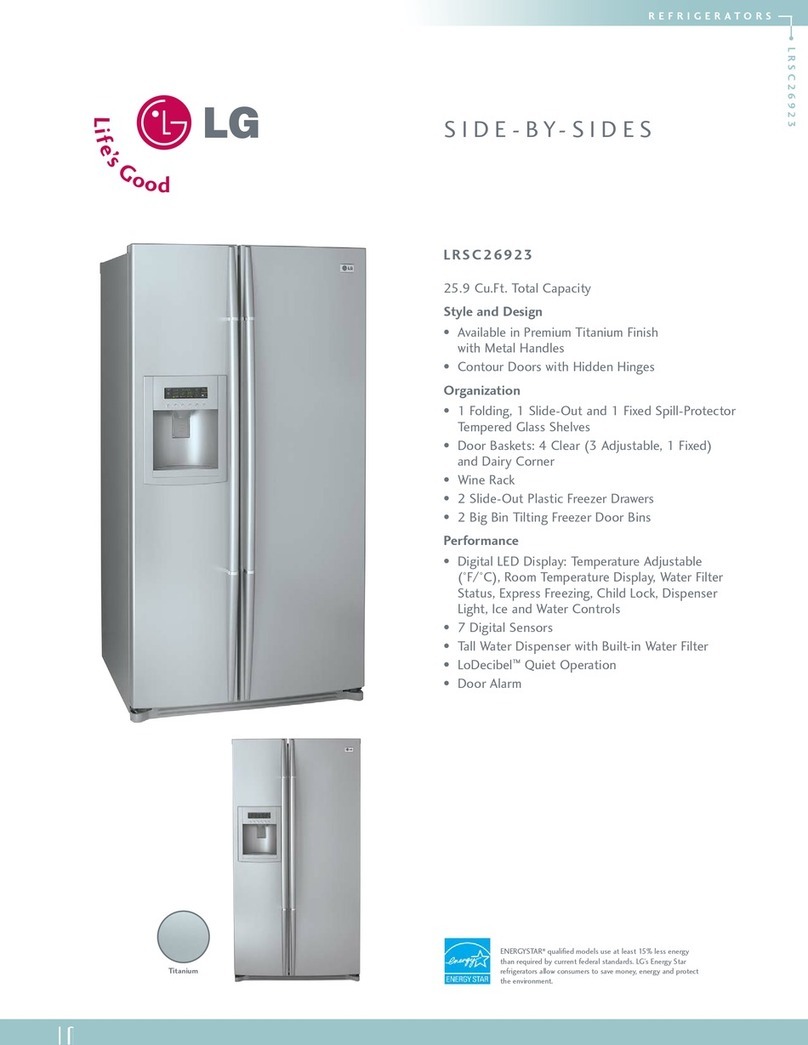

Chapter 4 Appearance Size of Refrigerator and Name of Every Part .........................................11

1. Appearance Size of Refrigerator ...............................................................................................11

2. Major Names ............................................................................................................................12

Chapter 5 Micom Function...............................................................................................................13

1. Operating panel drawing ..........................................................................................................13

2. Function description .................................................................................................................14

Chapter 6 PCB Picture......................................................................................................................21

Chapter 7 Trouble Shooting.............................................................................................................23

1. Error code summary .................................................................................................................23

2. Function description .................................................................................................................24

Chapter 8 Description of MICOM circuit. .......................................................................................45

1. Under/Overcooling compensation circuit of refrigerator ............................................................45

2. Undercooling compensation circuit of freezer ..........................................................................46.

3. Sensor resistance characteristics table ....................................................................................48

Chapter 9 COMPRESSOR ...............................................................................................................49

1. How to judge A-inverter linear compressor error ......................................................................49

Chapter 10 How to replace doors ...................................................................................................74

1. Removing and Replacing Refrigerator Doors ...........................................................................74

Chapter 11 How to service the refrigerator home bar ..................................................................78

1. Family Home bar Model ...........................................................................................................78

How to replace Reed Switch......................................................................................................81

2. Wide Home bar Model...............................................................................................................82

3. Pillar disassembly and assembly...............................................................................................82

Chapter 12 How to replace refrigerator Cover TV Assembly .......................................................83

1. Cover TV service method .........................................................................................................83

Chapter 13 How to disassemble refrigerator Multi Duct Assembly ............................................84

1. Multi duct service method .........................................................................................................84

Chapter 14 How to adjust the refrigerator door level difference .................................................85

1. When the door height is different ..............................................................................................85

Chapter 15 How to adjust the door front and rear level difference .............................................86

1. When the bottom part of refrigerator door unleveled ................................................................86

2. When the bottom part of freezer door unleveled .....................................................................86

Chapter 16 How to Replace Water Valve & Fan .............................................................................87

Chapter 17 Heavy Repair Method of Refrigerator with R600a Refrigerant .................................89

1. Outline ......................................................................................................................................89

2. Heavy repair SVC method ........................................................................................................90

2

Table of Contents

Chapter 18 Exploded view ..........................................................................97