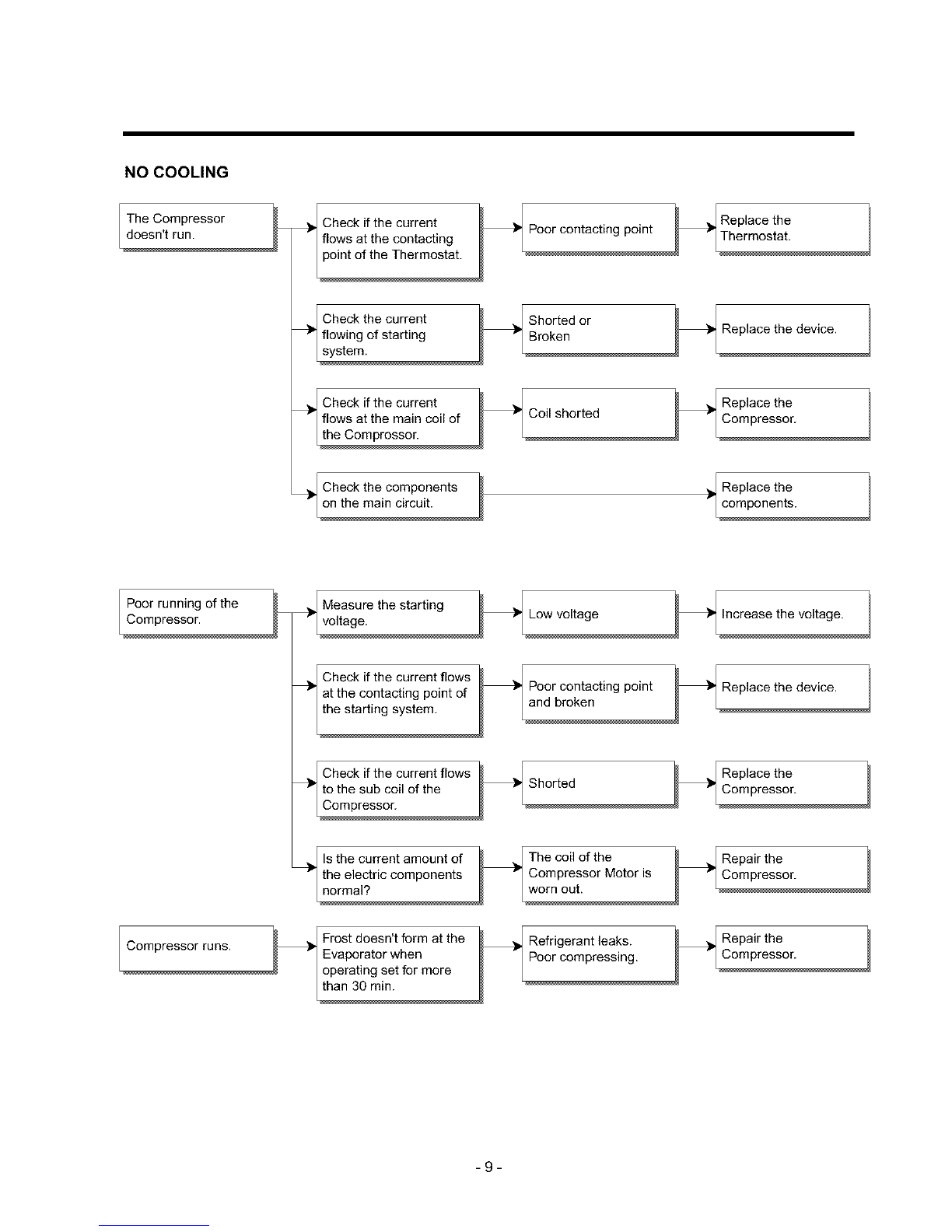

TROUBLESHOOTING

DEFECT CAUSE REMEDY

SYSTEM

PARTIALLY OR

COMPLETELY OUT

OF REFRIGERANT

CHARGE

EXCESSIVELY

FULL

HUMIDITY IN THE

SYSTEM

PRESENCE OF AIR

IN THE SYSTEM

BLOCKED

CAPILLARY

MOTOR-

COMPRESSOR

SHORT-CIRCUITED

OR BLOCKED

MOTOR-

COMPRESSOR

DOSE NOT

COMPRESS

NOISY MOTOR-

COMPRESSOR

EFFECT

Evaporatordoesnot frosteven

thoughmotor-compressorruns

continually.

This defectisindicatedbythe

presenceofwateroutsidethe

refrigeratornearthe motorcaused

byformationsof iceon the return

tube.

This defectisindicatedby the partial

frostingof the evaporatorandby

continua{defrostingcycles

determinedby the interruptionofthe

flow ofgas onthe evaporator.The

motorcompressorkeepsrunning.

Poorperformancedthe refrigerant

systemwhich isindicatedonthe

evaporatorwith a slightfrostwhich

does notfreeze and an excessive

overheatingofthe condenserand

motor-compressor.

Becausedthe lackdcirculation

Freon®in thesystem,there isno

frostingof the evaporator,whilea

slightoverheatingofthe first spiralof

the condenseris noted.

The systemdosenotwork and the

"OLP"intervenesinterrupting

deliveryto the motor-compressor.

Nofrostformson the evaporator,

evenif themotor-compressoris

apparentlyrunningregulary,

Incaseof mechanicalfailureinthe

motor-compressorthere in an

excessivenoisewhenthe systemis

functioning.Incasea suspension

springis unhooked,bangingwill be

heardandtherewill beespecially

strongvibrationswhen thesystem

starts upandstops.

An emptyrefrigerantsystem

indicatesaleakagedR134a.This

lossis generallyto belookedfor at

the solderingpointsconnectingthe

variouscomponentsor in an

eventualhole inthe evaporator

madeby the user.

If in the refrigerantsystema quantity

ofR134aisintroducedwhichis

greaterthanthat indicated,the

excessgas does notterminateits

expansionin the evaporatorbut

proceedsintothe returntube.

The refrigerantsystemis humid

when there isa smallpercentageof

waterpresent,which,not completely

retainedby the dehydratorfilter,

entersintocirculationwith the

Freon®and freezesatthe capillary

exitinthe evaporator.

There isair in the refrigerating

systemwhenduring thefilling phase

vacuumis not effectedor it isnot

adequatelydone.

Impuritiescontainedin the Freon@

or in thecomponentsofthe

refrigerationsystem before

assemblyand not retainedby the

filter can obstructthe capillary.

Incaseof shortcircuit,the

breakdownisdueto the electric

winding. Ifblocked,there is a

mechanicalfailurein the motor-

compressor.

Inthis casethere is a mechanical

failurein the diaphramvalveswhich

remainingcontinuallyopen, donot

permitthe compressortooperate.

Consequenteiy,Freon®doesnot

circulatein the system.

The causeof the excessivenoiseis

normallytobe soughtfor in a

mechanicalbreakdown,andonly

rarelyin the unhookingofone of the

suspensionsprings.

Leakagemustbe eliminatedby

resolderingthedefectivepointor

substitutingthe damaged

evaporator.

The system mustbe emptiedand

subsequentlyrefilledintroducingthe

correctquantityof R134a.

The system mustbe emptiedand

then refilledaftereliminatingthe

humidity.

Groupmustbedrainedand

subsequentlyrefilledaftercarefully

creatingvacuum.

Torestorethesystem it mustbe

emptied,substitutethe capillaryor

the evaporatorentirelyincase the

capillaryis coaxialwith respectto

the returntube,thenrefillit.

The motor,compressormustbe

replacedandthenproceedwith

refilling.

The motoFcomprossormustbe

replacedandthenproceedwith

refilling.

The motor,compressormustbe

replacedand thenproceedwith the

refilling.

-8-