1

Contents

Safety Precautions ----------------------------------------------- -------------------------------------- 1

Service Precautions ----------------------------------------------------------------------------------- 2-3

Specifications ------------------------------------------------------------------------------------------- 4

Feature Chart ------------------------------------------------------------------------------------------- 5

Circuit Diagram ------------------------------------------------------------------------------------------ 6-7

Cooling Systems ---------------------------------------------------------------------------------------- 8

Product Disassembly ---------------------------------------------------------------------------------- 9-11

Doors ------------------------------------------------------------- ----------------------------------------- 9

Door Switch ---------------------------------------------------------------------------------------------- 9

Electronic Control Display PCB ----------------------------------------------------------------- --- 9

Freezer Fan ---------------------------------------------------------------------------------------------- 10

Defrost Control ------------------------------------------------------------------------------------------ 10

Lamp ------------------------------------------------------------------------------------------------------- 10

Refrigerator Control Box ------------------------------------------------------------------------------ 11

Reversible Door --------------------------------------- --------------------------------------------------- 12-13

Adjustments ----------------------------------------------------------------------------------------------- 14-15

Compressor ---------------------------------------------------------------------- ------------------------ 14

PTC Starter----------------------------------------------------------------------------------------------- 14

Overload Protector (OLP) ---------------------------------------------------------------------------- 15

Troubleshooting ----------------------------------------------------------------------------------------- 16-21

Compressor & Electrical Components ------------------------------------------------------------ 16

PTC & OLP ------------------------------------ ---------------------------------------------------------- 17

Other Electrical Components ----------------------------------------------------------------------- 18

Service Diagnosis Chart ------------------------------------------------------------- ----------------- 19

Refrigerant Cycle --------------------------------------------------------------------------------------- 20-21

MICOM circuit & operation --------------------------------------------------------------------------- 22-39

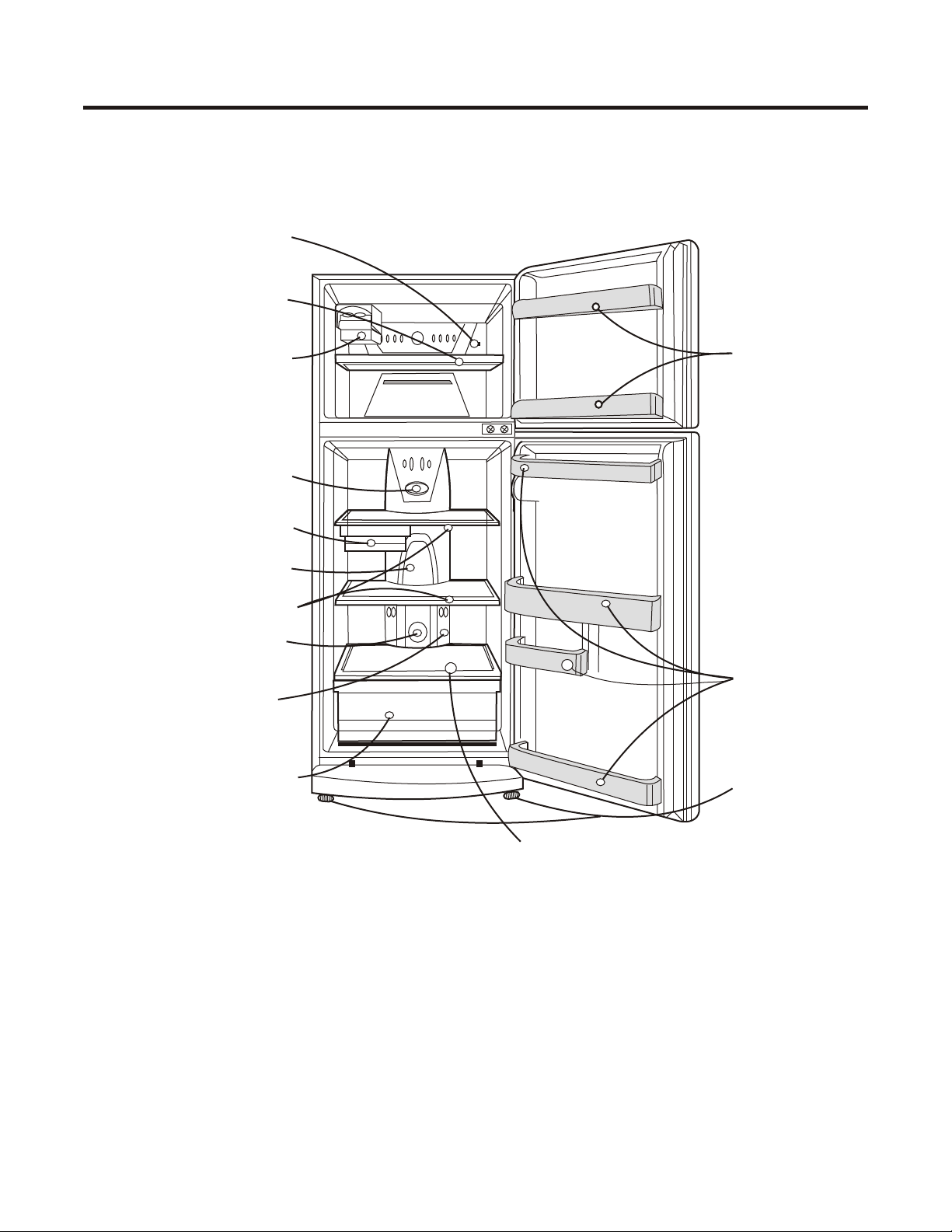

Refrigerator Exploded View-------------------------------------------------------------------------- 40-41

Service Parts list----------------------------------------------------------------------------------------- 42-43

Safety Precautions.

Read the following inst ructions before servicing your refrigerator.

1. Unplug the refrigerator before

servicing.

2. Visually inspect for gas leakage or

short circuit.

3. If testing with the refrigerator

plugged in, wear rubber gloves to

avoid electric shock.

4. Do not touch frozen metal parts;

your hands could freeze to the

surface. This may cause frostbite.

5. Be sure that no water is dripping

towards electrical or metal parts.

6. If you check the bottom part of the

refrigerator while the freezer

door is open, be careful standing

up. You could bump your head.

7. When you tilt your refrigerator be

sure to take out all metal, glass, or

other loose parts.

8. When servicing the evaporator,

wear cotton gloves to prevent cutting

by any of the evaporator fins.