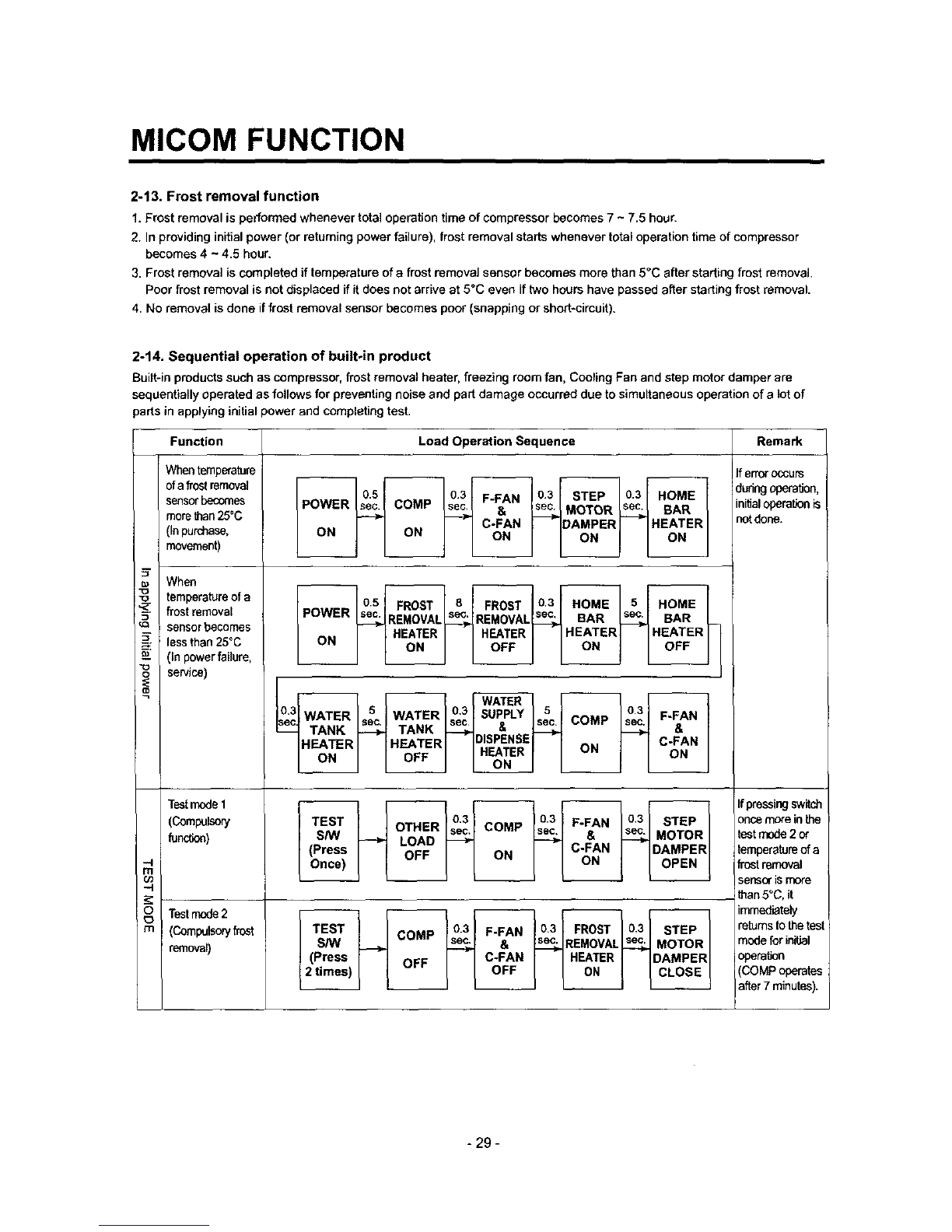

MICOM FUNCTION

2-1-2. LCD Back Light Control

1. in order to easily view display status on the LCD, LCD Back Light is turned on for a minute in application of initial power,

for a minute in button manipulation and for a minute after closing time from opening time of door.

2. If pressing any display button once with the backlight turned off, buzzer rings and button function is not performed but

only backlight is turned on (If pressing the first button with the back light turned off, only back light ON function is

performed).

3. If pressing the special freezing button and the freezing temperature adjustment button for more than asecond, the back

light is turned on and all the graphics of LCD are turned on. If releasing the button, the LCD graphic is displayed in the

previous status and the back light is turned off (check LCD graphic and back light ONIOFF status).

2-I-3. Outside temperature display function

1. Outside temperature sensor at the left U of refrigerator senses ambient temperature and displays the outside temperature

in the left side of"Outside temperature" text on the LCD of the display part.

2. Ambient temperature is displayed up to -9°C ~ 49°C and displayed as "Lo" for less than -10°C and as "HI" for more than

50°C. If the ambient temperature sensor fails, it is displayed as "Er".

3. Since display temperature of outside temperature istemperature sensed by the ambient sensor in the hinge U of the

freezing room, it may differ from the outside temperature display of other household electrical appliances.

2-t-4. Lock function (display button lock)

1. In power application of refrigerator, the only "Release" text is turned on at the right side of lock graphic of LCD with the

lock release status.

2. If desiring to lock the display status and pressing the lock/release button once, "Release" text isturned off at the right side

of lock graphic of LCD and "Lock" text isturned on with lock status.

3. The only buzzer sound rings and function is not performed even if pressing display button other than lock/release key in

the lock status.

4. If desiring to release the lock status and pressing the lock/release button once, %ock" text is turned off at the right side of

lock graphic of LCD and =Release" text isturned on with lock release status.

2-2. Dispenser use selection

You can select water or ice.

Please select water, slice ice and square ice by pressing

button as you desire.

Please press the push button lightly by catching and pushing in cup.

•The border line isindicated for the selected function.

• "Tak!" sounds if 5seconds pass after ice comes out.

It issound that the outlet of ice is closed.

REFERENCE : Please wait for 2-3 seconds in order to take final ice

slices or drops of water when taking out cup from the

pressing switches after taking ice or water.

2-3. Automatic ice maker

• The automatic ice maker can automatically make 8 pieces of i(;e cube at a time, 80 pieces e day. But these quantities may

be varied according to various conditions including how many times the refrigerator door opens and closes.

•ice making stops when the ice storage bin is full.

•If you don't want to use automatic ice-maker, change the ice-maker switch to ON-OFF.

If you want to use automatic ice-maker again, change the switch to OFF-ON.

NOTE : It isnormal that a noise is produced when ice made is dropped fete the ice storage bin.

- 26 -