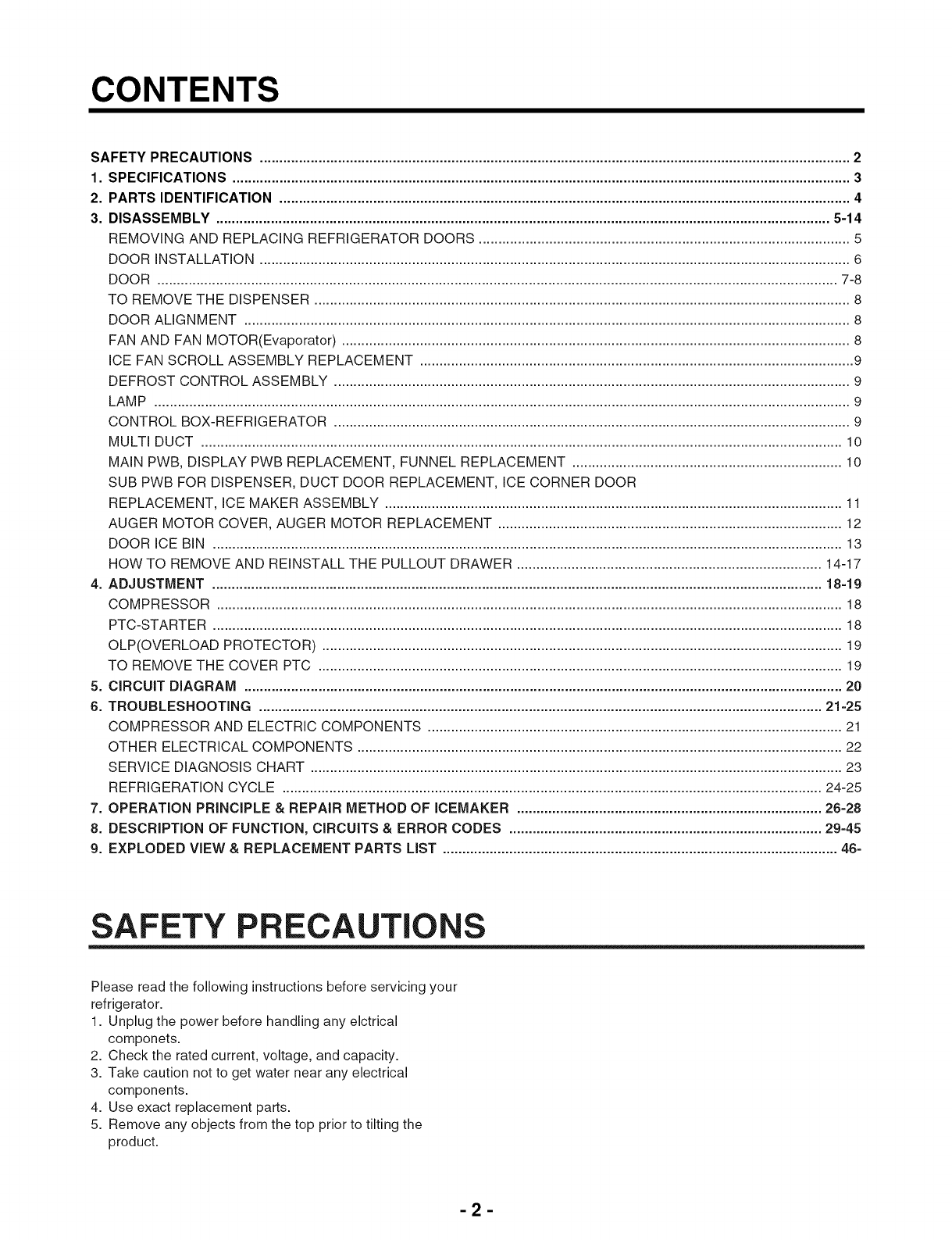

CONTENTS

SAFETY

PRECAUTIONS.

........ecescescceseeeeeeseeeeeeseeseeseeeseesceesaesenescessnesseesnenseeseeeaenenaeaenenanaeenensaesnessansseesaeeseesaeesesaeeneeeenteseneesenenes

2

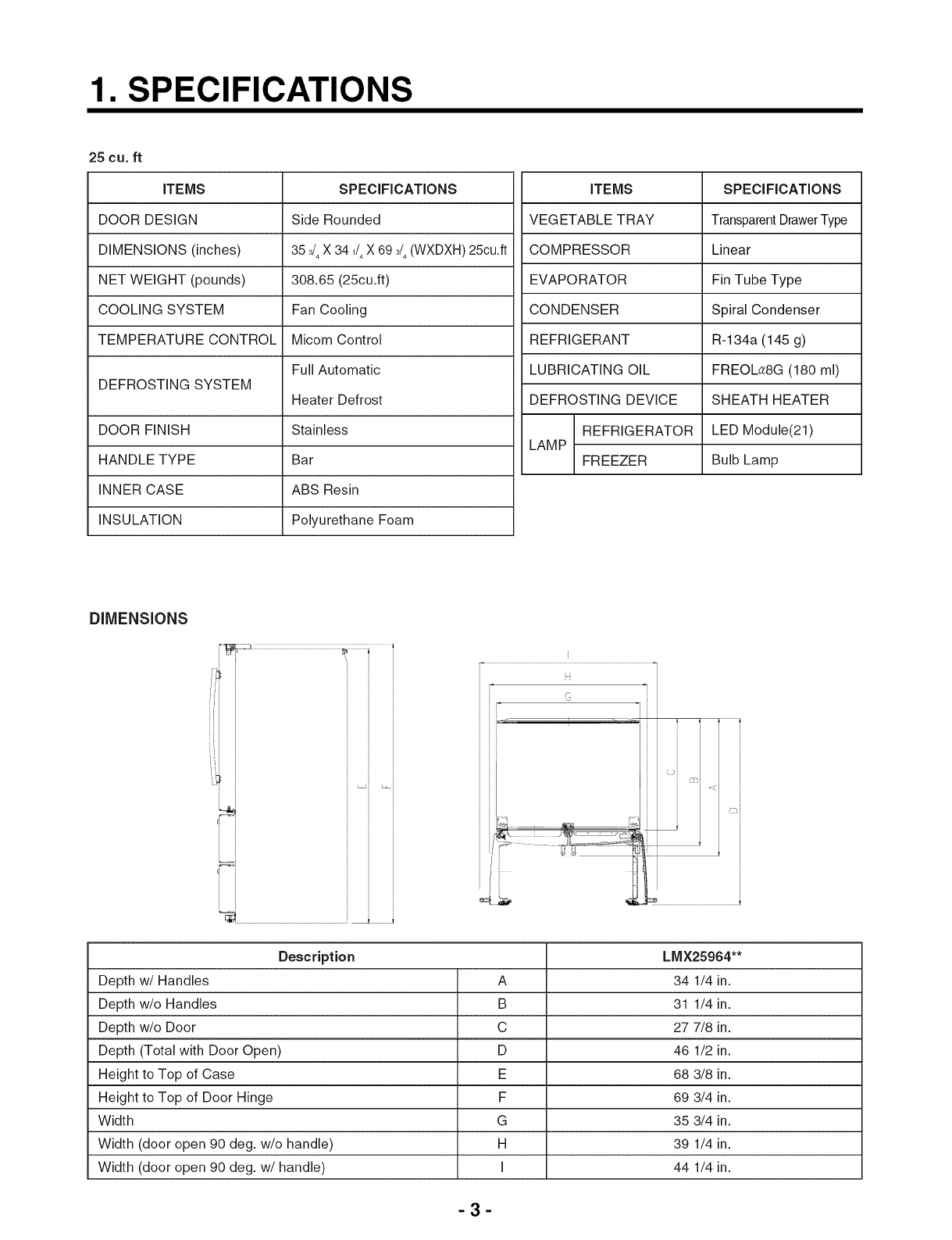

1.

SPECIFICATIONS.

ooo.

.s

cee

ceececeeecesceeeeeeceeeces

ce

enenseeenensensncenenenaesenenensaneneesaesaessanssensaeesessaessess

cesses

sesaeesaeeeaesaseneeeeseneneeneneneneeaes

3

2.

PARTS

IDENTIFICATION

..........ccceccesceecceeeeeeceeeeeeeeeee

cane

eee

nanenae nse

esnen

snes

neues

eens

eee

eens

ee

nee

nena

eae

nen

enna

enna

4

3.

DISASSEMBLY

00...

ceseecccecceeceeseeeeeeeeeeeceseeeecenenenenneeeaeesaecaeesaesaasaesaaesaeseeegaesaese

sess

ceases

seeeeeaeeeeesaeesaesaesaesnaeseenseneeeseaees

5-14

REMOVING

AND

REPLACING

REFRIGERATOR

DOORS

0000...

ceccceccceccecceeceeseeeeeceeeeeecaeeeeecaeecaecaaecaeeaaeaeeaesareneenseneeeneenes

5

DOOR

INSTALLATION

ooo...

ccccccccecceececseeececaceseeceeeeaecaeceaecaecsaecaecsaeceeseaeceneseesenesececaeeeaecacecaecaaecaeseaesaesaseaeesaesaresaeeeeseseseneeaeeenes

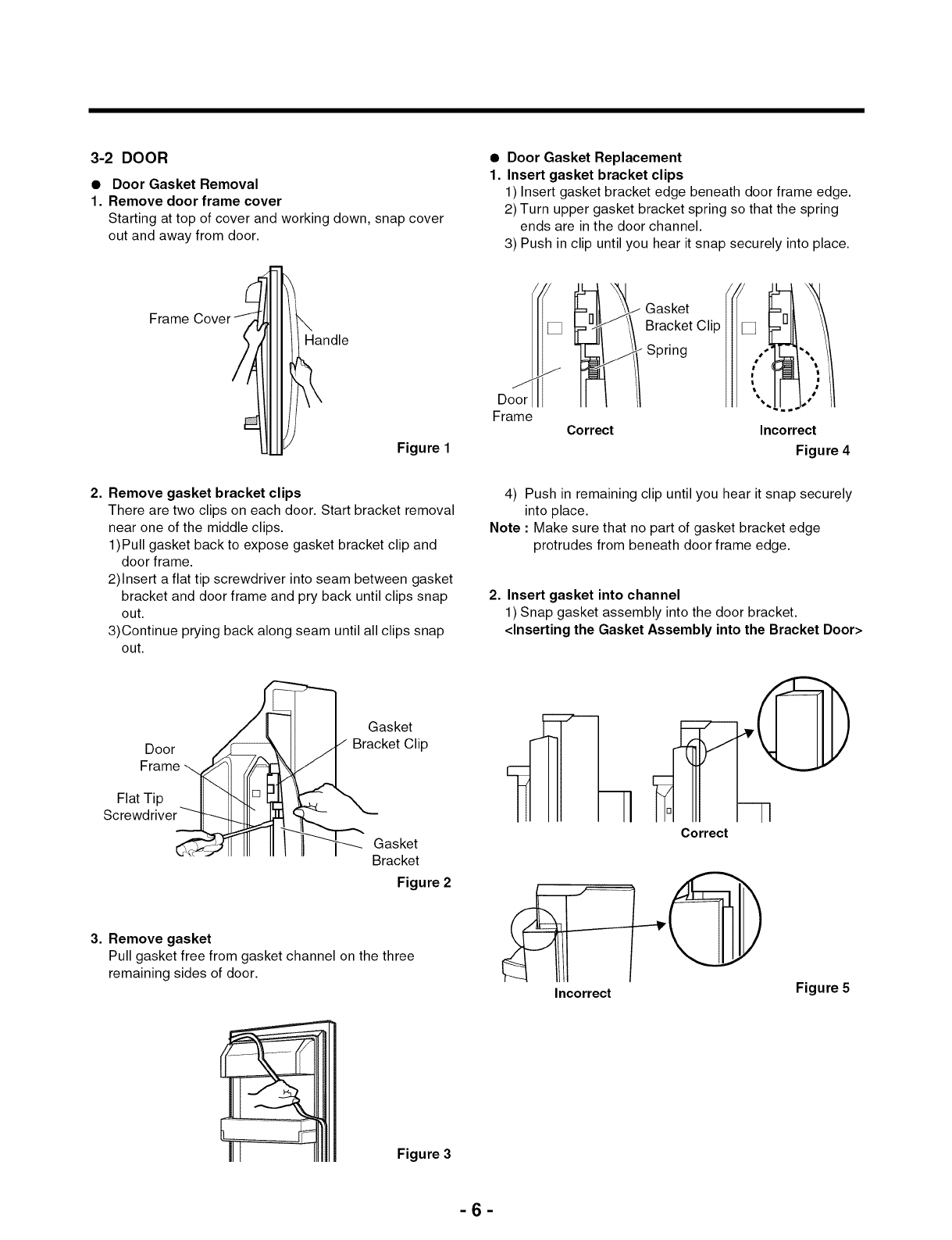

6

DOOR

oo

ceececcceccecccecceseceeceseceecesecenesessaecsnecaeeeaecacecaecaaecaecaaecaecsassaeceaeaessaeseeseaeseeseaeseneseeeaecaeecaeeececaeesaesaeeeeecaseeeseseetenseeteaes

7-8

TO

REMOVE

THE

DISPENSER

20.

.ecccceccceccecccececeeeeneeeeeceeeacecaceaaecacesaecaaeeaeceaesaeceaeaecaeseaesieeeaesecesneeaeseeesaeeeeesaeeeeeieeseeeeaees

8

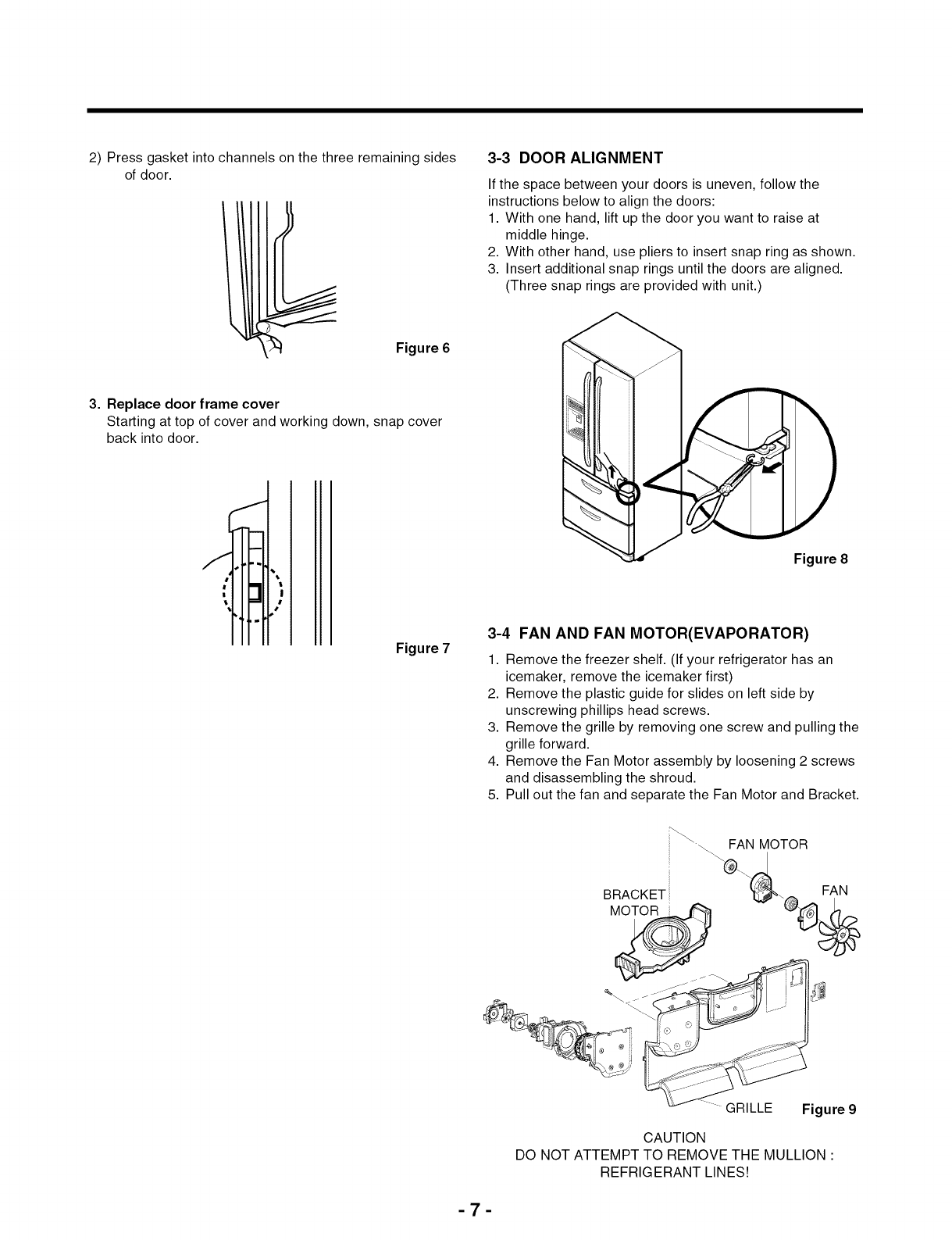

DOOR

ALIGNMENT

ooo..ececcceccecceescesceceeeececacesnecacesaecaeceaecaecsaecaecsaecaesaecenesaesecesenecaeeeaecacecaecaaecaeseaesaeceaeeaeenesareeaeseeeeenseneeaeeenes

8

FAN

AND

FAN

MOTOR(Evaporat0r)

........ccccsccccssccceesercesenseccsenceceaececsnaececeneeccaaececenaeceseneececassecsensesseasecscassecsenssessureescuteeesanes

8

ICE

FAN

SCROLL

ASSEMBLY

REPLACEMENT

ooo...

.eccceccccccescececeseeeeeeaeecaeeacecaecaaecaeeeaecaeeaecaeeeaeseeeaeseeeseeteneseeeeeeeeeieenaees

9

DEFROST

CONTROL

ASSEMBLY

o....eccccceceescceceecceeececeeeceseeseceaecsesesecneceeeeaecacecaecacecaeeaaecaaesaeseacsaeceaeeaeceeesaeseeeeeseseeeeeeaeeeees

9

LAMP

ooeeeececcecccecceeccesceseeeceseceeesesenecseecaeececacecaecacecaecaaesaecsaesaeseaesaessaesaesaeseeeaesenesaeecaecacecaeeacecaesaaecaesaecaecsaeseeesaeeneeeeseneeeeeenes

9

CONTROL

BOX-REFRIGERATOR

oo.

.cccceccceccesceececececeecececaecaaeceeceaecaecaaecaecaaesaesaesnesaeseneseesaeeececaeesaeseaeeaeseaeeeessuseareneeereaes

9

MULT

DUCT

oe

cececceccecceecceeceeceeceseeeeeeaeeaecace

caeeacecaceaaecacesaecaeceaeceecsaecaesaecaeseaeseeesaeseneseeseneseecaeeecesaeesaeceeesaeseaseeesseereeteas

10

MAIN

PWB,

DISPLAY

PWB

REPLACEMENT,

FUNNEL

REPLACEMENT.

...........:cccccececceeeeceeeceeceeeceeceeeeeseaeeereeareneeeneaes

10

SUB

PWB

FOR

DISPENSER,

DUCT

DOOR

REPLACEMENT,

ICE

CORNER

DOOR

REPLACEMENT,

ICE

MAKER

ASSEMBLY

o.uu....cccecccecceecceccecces

cesses

cesses

eeseceneeeeeeaeceecaeeeaesacecaecacecaeseaesaeeeaseeesiseereseneereeas

11

AUGER

MOTOR

COVER,

AUGER

MOTOR

REPLACEMENT

ou......ecccecccccecceeeceseececeeeeceeceeecaecaeceeseaecaeeeaeseseseeteneseneeaeeeees

12

DOOR

ICE

BIN

0

eeccecccecceeceecceseeecceneeeneeaeeeeecace

caeeacecaceaaecaecaaecaecsaecaecsaecaessaecaeseaeseeeaeseneeeeseneseecaesacecaeesaeceeeeaeseaseeeeuseereeteas

13

HOW

TO

REMOVE

AND

REINSTALL

THE

PULLOUT

DRAWER

...0.....ccccceccececececeececeeeececeeeeceaeeaeceeeaeeeeseeseneeareeseeees

14-17

A.

ADJUSTMENT

nnn.

.eceeececeeeccesesseeeeeeenencesececesncencesecensesecenaeenaeaaecaesaaecaesaaecaessaesaessaessessaessessseeseeseesesesaeenaeeesenaeeeseneseaeenes

18-19

COMPRESSOR

oooeececccecceceesececceeeeeceeeceeecaeceaeeseceaeceecenesenesaesenecaeeeaecace

caeeaaecaaesaecaeceaesaecaeseeseaeceeseaeseeeeeseeesereeaeseeesaeeeeeieeeaees

18

PTC-STARTER

.ecccceccceccesceecceseeeeceneeeneeaeeenecace

caecacecaeeaaecaecaaecaeceaeceecsaecaesaecaesaeseeeaeseneceseneseesaesacesaeesaececeaeseaseeeeeseeseeteas

18

OLP(OVERLOAD

PROTECTOR)

.0....cccccccecccceceeeececceecceeeaeceeceseceeeeseceneceneeaeeenecaeecaecacecaecaaecaeeaaecaeseaesaeseaseaeseaesenseeseneeneeenes

19

TO

REMOVE

THE

COVER

PTC

oui.

.eccccccccccescceceeseeecececescecacesaeceaesaeceaeseeceaeaessaeeaeseeecaeseceseneeaeeenecacesaeeaaecaesaaesiseseeeareeeeeeeeas

19

5.

CIRCUIT

DIAGRAM

oan...

ceececceccceccescneeceeecencesecseceseeenceseeeneeseecneeenecaaeene

seas

cae

eaansaesaansaessaesaessaessaseaseseseeseseseaseneseaaeeeaeaeeaeeaes

20

6.

TROUBLESHOOTING.

ooo...

ceeceecceccescceeceeecencesncenceseceneeseecnaeeaecaeecaesaaecaesaaecaesaaesaessaes

sess

aes

sess

seeseeesaeseseaseeeaeaaeeeaeeaseneseaeeaes

21-25

COMPRESSOR

AND

ELECTRIC

COMPONENTS.

0...

ceccecececeecececeeeececeeeeceeceaeceeceaecaeceaeseeeaeceneseseaesececaeeeaesaeesaesaeeeeenaees

21

OTHER

ELECTRICAL

COMPONENTS.

......ccececcecccecceecceecesecesceseceeeeseeeneceeeeneeecaeecaecacecaecaaecaeeaaesaeceaecaeeeaseaesesesenseseseneeaeenes

22

SERVICE

DIAGNOSIS

CHART

o.oo.

.ecceccecccecceecceeeeeeeeceeececeeeece

cae

caecacecaecaaecaecaaecaeceaesaecaaesaeseaesaeseaeseeeeseseeesaeesaeseeseeseeeieenaees

23

REFRIGERATION

CYCLE

oon.

cecceeccccccecececececeeceeececeeaecaeceaecaeceaecaecsaeceeseaesenesaeseneseecaesececaeeeaecacecaeseaeaeseaseseeeseeresunestees

24-25

7.

OPERATION

PRINCIPLE

&

REPAIR

METHOD

OF

ICEMAKER

............eecccsceecceeeeeecenceeeceneeeeceneeenenseeseeeeaesenseanenenaes

26-28

8.

DESCRIPTION

OF

FUNCTION,

CIRCUITS

&

ERROR

CODES

ooo.

..ececceccesceeeceeeeeeceseeeeceneeeneeneeeneesae

ceases

seaseanenaneaes

29-45

9.

EXPLODED

VIEW

&

REPLACEMENT

PARTS

LIST

oon...

see

ceeececceeececeeeeceneeeneneeseeenceseeseceseeseeeseeenaeseecnaeeaeseeesanseneeaeeans

46-

SAFETY

PRECAUTIONS

Please

read

the

following

instructions

before

servicing

your

refrigerator.

1.

2.

3.

Unplug

the

power

before

handling

any

electrical

componets.

Check

the

rated

current,

voltage,

and

capacity.

Take

caution

not

to

get

water

near

any

electrical

components.

.

Use

exact

replacement

parts.

.

Remove

any

objects

from

the

top

prior

to

tilting

the

product.