Please observe the following safety precautions to use the

refrigerator safely and correctly and to prevent accident or

injury when servicing.

1. Be careful of an electric shock. Disconnect power cord

from wall outlet and wait for more than three minutes

before replacing PWB parts. Shut off the power

whenever replacing and repairing electric components.

2. When connecting power cord, please wait for more than

five minutes after power cord was disconnected from the

wall outlet.

3. Please check if the power plug is pressed by the

refrigerator against the wall. If the power plug was

damaged, it could cause fire or electric shock.

4. If the wall outlet is overloaded, it may cause a fire.

Please use a dedicated circuit for the refrigerator.

5. Please make sure the outlet is properly grounded.

Particularly in a wet or damp area.

6. Use standard electrical components.

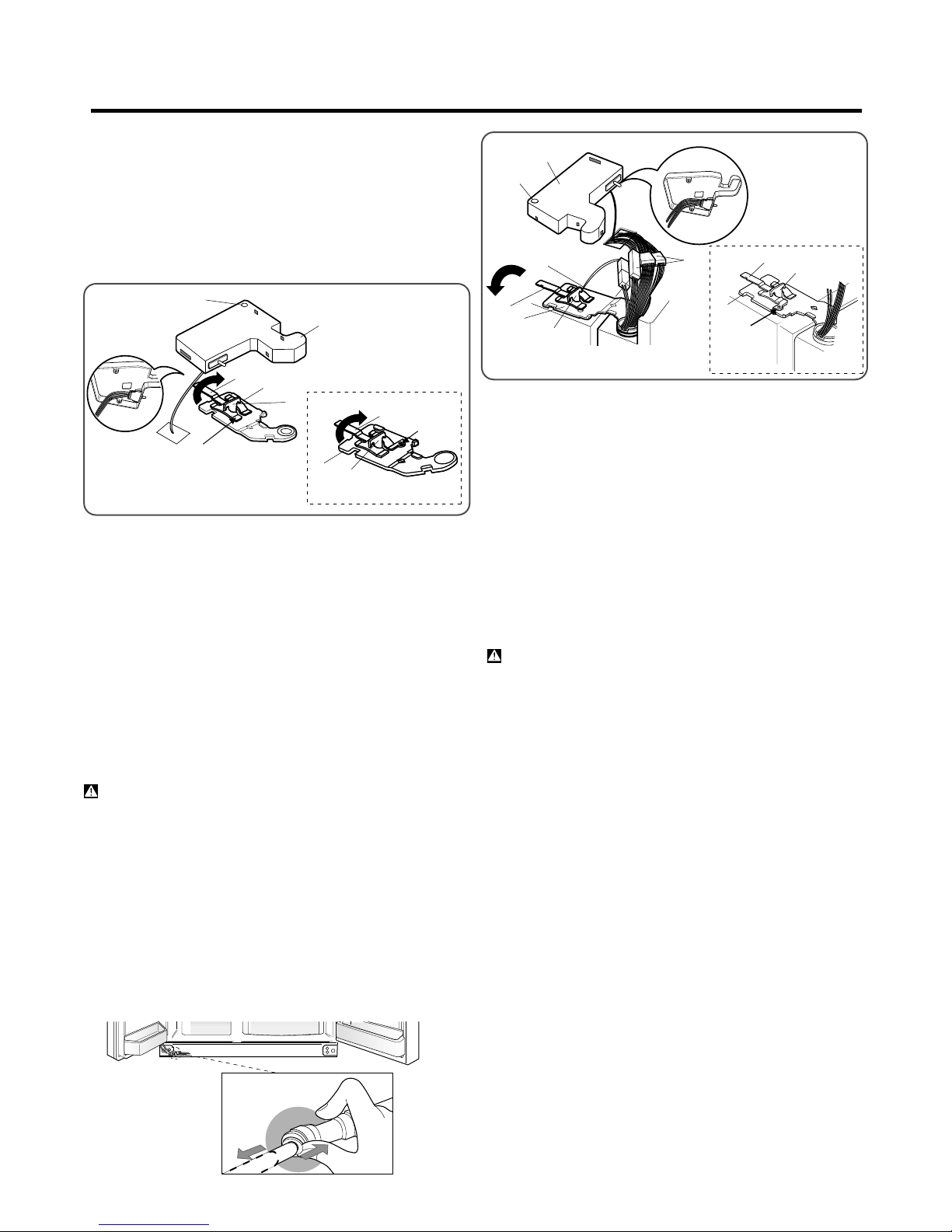

7. Make sure hooks are correctly engaged.

Remove dust and foreign materials from the housing

and connecting parts.

8. Do not fray, damage, run over, kink, bend, pull out, or

twist the power cord.

9. Please check for evidence of moisture intrusion in the

electrical components. Replace the parts or mask with

insulation tape if moisture intrusion was confirmed.

10. Do not touch the icemaker with hands or tools to

confirm the operation of geared motor.

11. Do not suggest that customers repair their refrigerator

themselves. This work requires special tools and

knowledge. Non-professionals could cause fire, injury,

or damage to the product.

12. Do not store flammable materials such as ether,

benzene, alcohol, chemicals, gas, or medicine in the

refrigerator.

13. Do not put anything on top of the refrigerator,

especially something containing water, like a vase.

14. Do not put glass bottles with full of water into the

freezer. The contents will freeze and break the glass

bottles.

15. When you scrap or discard the refrigerator, remove the

doors and dispose of it where children are not likely to

play in or around it.

WARNINGS AND PRECAUTIONS FOR SAFETY

- 3 -