2

CONTENTS

1. SPECIFICATION............................................................................................................................3

2. FEATURES & TECHNICAL EXPLANATION .................................................................................

3. PARTS IDENTIFICATION ............................................................................................................ 6

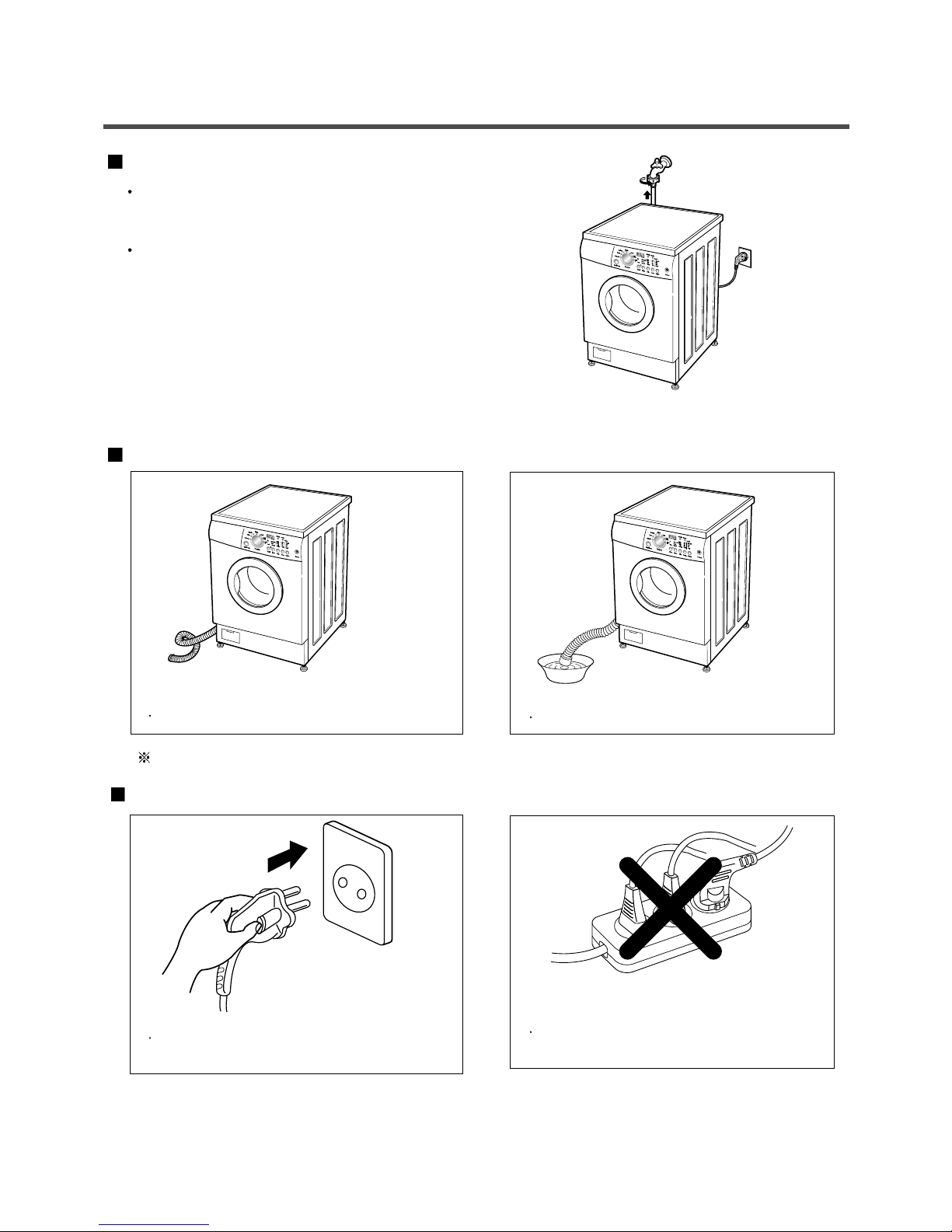

. INSTALLATION ............................................................................................................................. 7

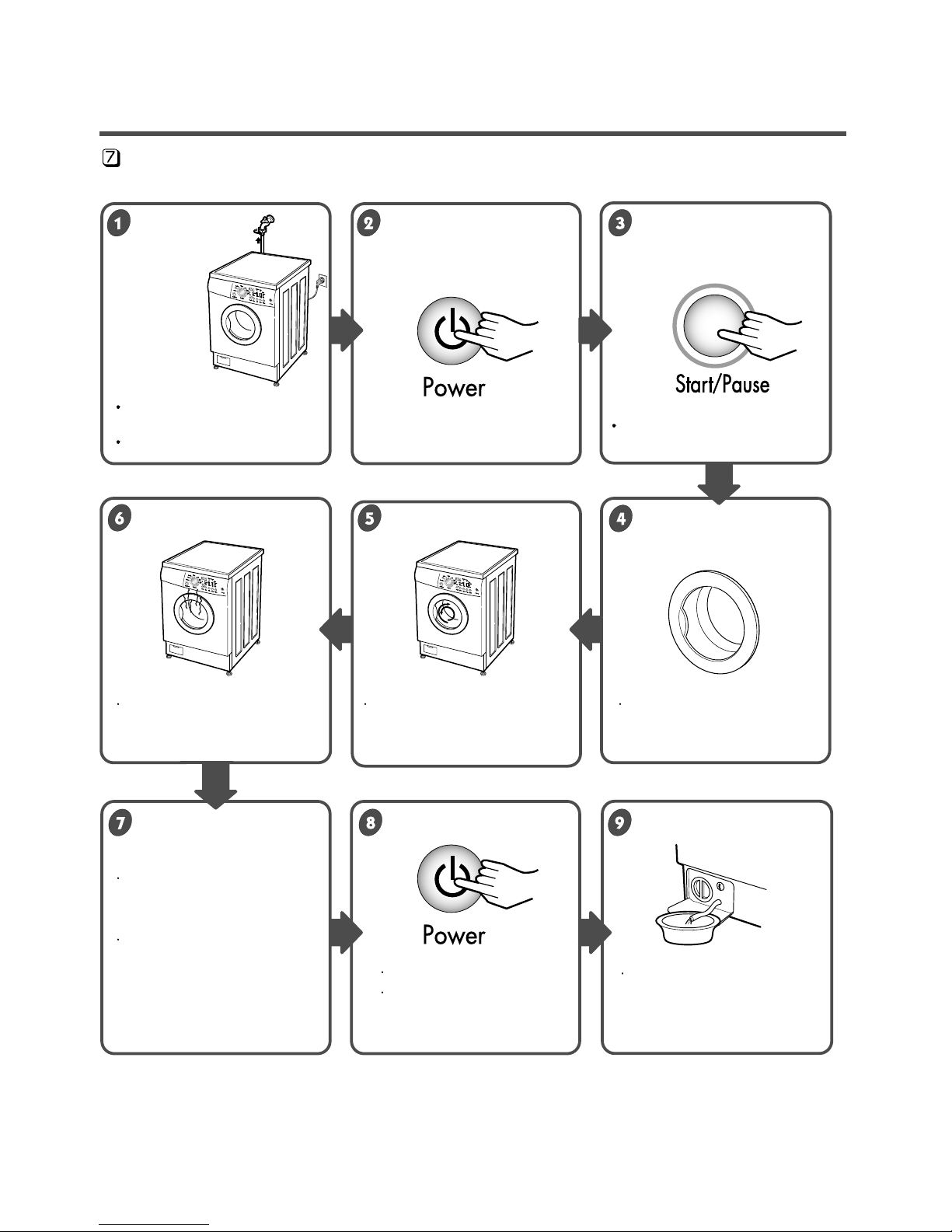

5. OPERATION ................................................................................................................................10

6. WIRING DIAGRAM / PROGRAM CHART...................................................................................12

7. TROUBLESHOOTING.................................................................................................................13

7-1.BEFORE PERFORMING SERVICE ....................................................................................13

7-2.QC TEST MODE..................................................................................................................13

7-3.HOW TO KNOW THE WATER LEVEL FREQUENCY.........................................................13

7- .ERROR DISPLAY ................................................................................................................1

8. ERROR DIAGNOSIS AND CHECK LIST ....................................................................................16

8-1. DIAGNOSIS AND ANSWER FOR ABNORMAL OPERATION ...........................................16

8-2. FAULT DIAGNOSIS AND TROUBLESHOOTING ..............................................................19

9. DISASSEMBLY INSTRUCTIONS ...............................................................................................25

10. EXPLODED VIEW AND PARTS LIST .......................................................................................32

10-1. THE EXPLODED VIEW OF CABINET ASSEMBLY .........................................................32

10-2. THE EXPLODED VIEW OF CONTROL PANEL AND DISPENSER ASSEMBLY ............33

10-3. THE EXPLODED VIEW OF DRUM AND TUB ASSEMBLY .............................................3

APPENDIX (Replacement parts list) ...........................................................................................35